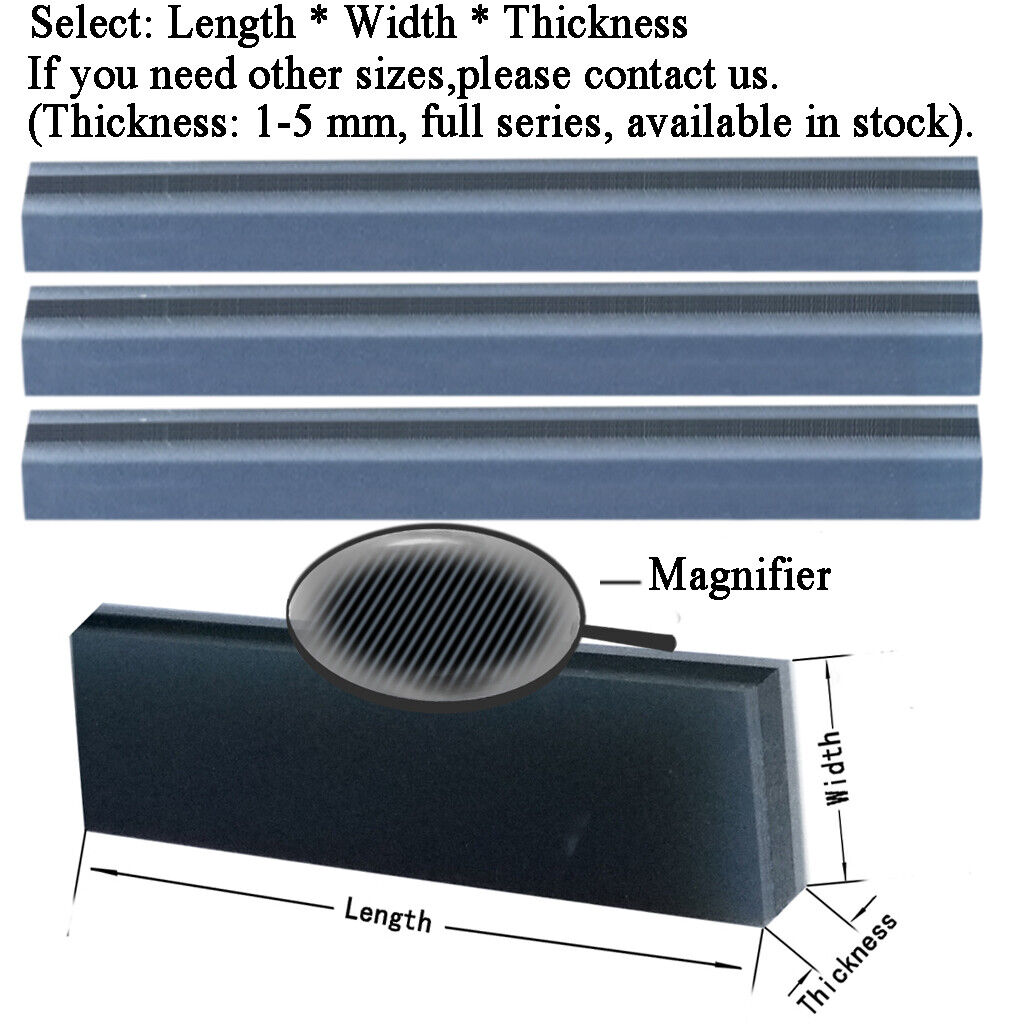

lcd display rubber contact in stock

As others note it"s a "zebra connector" which conducts through the plane of the rubber but not across it (ie in the directions you"d expect for it to work).

The "pitch" of the band s of conduction/non conduction are finer than the pitch of the contacts concerned so that short circuits are not formed between the contacts when the strip is moved "sideways".

This method allows ease of assembly, self alignment of the "connecter" - as long as the LCD contacts and PCB contacts are aligned the rubber strip alignment is non-crucial.

PIN is the most commonly used connection for LCD. I am often asked to answer one question. Can we make the pitch between two PINs 1.0 mm? Of course, we can as long as you pay for the extra cost. There are 4 common used types of pitches: 1.27 mm, 1.5 mm, 2.0 mm and 2.54 mm. The widths of PIN are 0.635 mm, 0.75 m,1.0 mm and 1.27 mm. If you can order 50 thousand each buy, we can make the custom PIN (even bent PIN) and the custom pitch for you and there is no extra cost.

A printed circuit board and an LCD are connected by flexible zebra paper, which adopts heat sealing processing or soldering processing and can be used in all kinds of harsh environments.

Our Levy electric scooters come with the option of standard tires that contain inner tubes, tubeless tires, and solid rubber tires. There are tradeoffs to each of them, and we don"t recommend one over the other, but rather leave it up to your personal preference.

Stockwell Elastomerics is a leading provider of gaskets for touch screens, displays and integrated touch panel assemblies that serve several functions: sealing, load distributing, gap filling, mechanical shock protection and over-press cushioning.

Often a touch screen gasket or display gasket will help spread the compression load of the housing or bezel on the display. Without a gasket, the enclosure that holds the display in place can create pressure points on the display. In some cases, these pressures can cause distortions, false contacts or short circuits.

Similar to load distributing, touch panel gaskets are used to fill gaps between the screen and the display and/or the screen and bezel. The display gasket will take up gaps generated by tolerance stack-ups in the device.

Display gaskets offer some degree of cushioning to protect the display from damage due to mechanical shock. In the event that a device is dropped or banged, the gasket will act as a touchscreen cushion, offering a limited amount of protection.

Touchscreen gaskets also serve as display cushions when a user presses on the display too hard. The gasket deflects, takes up and spreads the load offering some protection from over-press or overloading in a small area.

LCD dust seals and touch screen dust seals are the most basic requirement of display gasketing. These are often static (not portable), indoor applications where the device is not to be exposed to water. Sealing can be achieved by closed cell sponge materials or fine pore open cell materials such as PORON urethane foam.

Outdoor displays such as outdoor information kiosks, ATMs and remote monitoring equipment require more design consideration. To contend with environments such as direct or wind-driven rain, sealing an enclosure, case or housing from ingress requires the proper material as well as proper compression on the gasket. Silicone foam or silicone sponge materials are preferred. Silicone gaskets remain flexible at low temperatures allowing for continued sealing against melting ice and snow as well as protecting against mechanical shock where many other materials will firm up in the cold and transfer energy. Other key features are: closed cell structure, low-stress relaxation, UV and ozone resistance, and general long life.

Light leaking is sometimes a concern with certain LCD or LED display applications. This can be addressed with black gasketing with either a very thin adhesive or a black supported adhesive. A common material configuration for this is soft PORON urethane foam with 3M 9795B adhesive. The 3M 9795B is a film supported double coat adhesive with a black PET support layer that does not pipe light.

Touchscreen gaskets and display gaskets tend to have narrow walls that don’t always lend themselves to easy installation. This can be addressed in a few ways such as fixturing or utilizing the centers as temporary supports. The preferred adhesives for touchscreen gaskets and display gaskets are repositionable adhesives such as Adchem 8311M or 3M 9415 depending on the bond strength required. Stockwell Elastomerics also offers medium and high bond strength adhesives for permanent bonding. View the current listing of pressure sensitive adhesive options.

It is important to keep in mind the clamping loads. While wider gasket walls generally seal better, the overall surface area is directly related to the loads applied to the LCD and touchscreen. Compression Force Deflection curves of various materials are available to aid designers.

The gasket thickness will depend on the designed gap in the enclosure, the fastening scheme, rigidity of the housing and the level of sealing required. Many touch screen gaskets are thin and soft but as the display gets larger the tolerance stacks typically get larger as well. This may require a thicker gasket depending on the fastener locations.

Some OEMs and contract manufacturers prefer to have the center of the gasket remain in place, held in place with small, breakaway tabs. Leaving the centers intact allows for easier positioning on the display when a fixture is not being used. Low tack, clean peeling adhesive is needed.

If the Holts stuff is kind to plastics it may be o.k. It says that it leaves no residue so probably evaporates away with any oil or grease. Perhaps some Isopropanol (SHL Manufacturing Ltd.) which pretty much evaporates away totally, or electro-mechanical contact cleaner as available from R.S. It might just need the multicore ribbon cable/plug physically pushing towards contacts a bit. The contacts are very unlikely to be dirty.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey