lcd screen heat damage manufacturer

LCDs used in outdoor situations have many concerns to deal with in addition to any that they might normally encounter during indoor use. Initially some concerns are weather related such as moisture in the air or extreme temperatures. Another concern that is often not understood or just not known about at all is sunlight damage.

Liquid crystal displays use organic components that are susceptible to UV (<400 nm) and IR (>750 nm). These bandwidths of radiation have an observable impact on the organic components in LCDs. Extended exposure has been known to cause a color shift and a washed out look to images displayed with the LCD.

In any case it is important to protect your display from the elements, especially if it is going to be exposed to harsh environments not intended by the manufacturer. One way to do this would be to utilize a Hot Mirror with a UV blocker. This will significantly reduce the amount of IR radiation between 750 nm and 1200 nm, as well as the UV radiation below 400 nm. If the LCD is going to be used outdoors for extended periods then an extended hot mirror may be necessary, which extends the bandwidth protection out to 1600 nm and will help reduce some of the longer wavelength IR damage.

Another concern with liquid crystal displays are their susceptibility to overheating due to excess IR radiation. The LCD is intended to operate within a certain range of temperatures according to the manufacturer’s instructions and outdoor use can lead to higher than normal temperatures. The display being exposed to excessive heat can cause the crystal to become isotropic and fail to perform properly. A hot mirror can help alleviate these concerns as well by reducing the amount of infrared radiation that heats the display.

(1)LCD displays are usually packaged with silicone. If the working temperature exceeds the solid phase transition temperature (typically 125 °C), the packaging material will become a rubber state and rapidly heat and expand, resulting in an open circuit and failure of the LCD bar screen.

(2)If the operating temperature of the LCD screen exceeds the maximum load-bearing temperature of the chip, its luminous rate will drop rapidly, resulting in light attenuation. The life of an LCD screen is reflected by the attenuation of light, that is to say, the brightness of the LCD screen will decrease over time.

(4)The shape of silicone products is greatly affected by temperature. As the temperature increases, the internal heat of the silica gel increases and the refractive index decreases, resulting in an increase in the light efficiency of the liquid crystal display.

In summary, it can be concluded that a reasonable temperature is a key to the LCD panel, and users need to follow the instructions to ensure the normal use of the LCD strip screen.

Liquid crystal displays (LCD) have become an essential component to the industry of display technology. Involved in a variety of contexts beyond the indoors like LCD TVs and home/office automation devices, the LCD has expanded its usage to many environments, such as cars and digital signage, and, thus, many temperature variations as well.

As with any substance that requires a specific molecular characteristic or behavior, LCDs have an operating temperature range in which the device, if within, can continue to function properly and well. In addition to that, there is also an ideal storage temperature range to preserve the device until used.

This operating temperature range affects the electronic portion within the device, seen as falling outside the range can cause LCD technology to overheat in hot temperatures or slow down in the cold. As for the liquid crystal layer, it can deteriorate if put in high heat, rendering it and the display itself defective.

In order for the LCD panel to avoid defects, a standard commercial LCD’s operation range and storage range should be kept in mind. Without adaptive features, a typical LCD TV has an operating range from its cold limit of 0°C (32°F) to its heat limit of 50°C (122°F) (other LCD devices’ ranges may vary a bit from these numbers).

The storage range is a bit wider, from -20°C (-4°F) to 60°C (140°F). Though these ranges are quite reasonable for many indoor and even outdoor areas, there are also quite a few regions where temperatures can drop below 0°C or rise above 32°C, and in these conditions, LCDs must be adapted to ensure functionality.

Heat, can greatly affect the electronics and liquid crystals under an LCD screen. In consideration of heat, both external heat and internally generated heat must be taken into consideration.

Seen as the liquid crystals are manipulated in a device by altering their orientations and alignments, heat can disrupt this by randomizing what is meant to be controlled. If this happens, the LCD electronics cannot command a certain formation of the liquid crystal layer under a pixel, and the LED backlighting will not pass through as expected, which can often lead to dark spots, if not an entirely dark image. This inevitably disrupts the display’s readability.

Depending on the upper limit of the operation temperature range, LCD device can be permanently damaged by extreme heat. With long exposure to extreme heat, besides the destruction of the liquid crystals, battery life can shorten, hardware can crack or even melt, response time may slow to prevent even more heat generation from the device.

The LED backlight and the internal circuitry, typically TFT-based in the common TFT LCDs, are components that can generate heat that damages the device and its display. To address this concern with overheating, many devices use cooling fans paired with vents.

Some devices that are used in extremely high ambient temperatures may even require air conditioning. With air vents to carry the heat out, the device can expel it into the surroundings.

But this leads to another problem: how can moisture be prevented from entering through the vent? If moisture enters the device and high heat is present, condensation can occur, fogging the display from inside, and in some cases, short-circuiting may cause the device to turn off. In order to circumvent this issue, the shapes of the air vents are specific in a way that allows only for air movement, not forms of moisture.

In the opposite direction is extreme cold. What typically occurs in the cold is “ghosting” (the burning of an image in the screen through discoloration) and the gradual slowing and lagging of response times. Like heat-affected LCD modules, the extreme temperature can affect the liquid crystals. This layer is a medium between the liquid and solid state, so it is still susceptible to freezing.

An LCD device can be left in freezing temperatures because it will likely not be permanently damaged like in the heat, but it is important to understand the device’s limits and how to take precautions when storing the device. The standard and most common lower-bound storage range limit is -20°C, below freezing, but if possible, it would be best to keep it above that limit, or else there is still a risk of permanent damage.

If the device is not adapted for the cold, it would be good to keep it bundled up, trapping the heat within layers. However, this is only a temporary solution. Adapted, rugged devices have advantages such as screen enclosure insulation for heat level preservation and, in more extreme cases, heaters to generate extra heat to raise the internal temperature to a level above the minimum.

Display types have a lot of variation. Choices like alphanumeric or graphic LCD, human-machine interactive LCD modules and touchscreen panels capabilities, the width of the viewing angle, level of contrast ratios, types of backlighting, and liquid crystal alignment methods are often considered. For example, the twisted nematic LCD provides for the fastest response time at the lowest cost, but cannot offer the highest contrast ratio or widest viewing angle.

Environment-based factors must consider things besides the obvious temperature like UV exposure and humidity/moisture, as they all are necessary in finding the perfect fit extreme temperature LCD module.

Besides the LCD modules, recent new products have opened doors in wide temperature range displays, such as OLED displays. OLED displays offer better displays in regard to contrast, brightness, response times, viewing angles, and even power consumption in comparison to traditional LCD displays.

The Macbook Pro 13" LCD display is hard to dismantle. With the iBooks and PowerBooks and even plastic macbooks models it was easy to swap the panel case, only 2 or 4 screws to unscrew and the job was done but with the unibody MBP 13"/15"/17" Apple made it more difficult. You need to heat the glued front glass to take it out and have access to the screws that retain the LCD screen. Doing this would probably void the warranty if you still have one and you could also damage the LCD if too much heat is applied to the screen. A complete LCD display swap would be more secure but would also cost much more.

LC displays (LCD) have a well-defined isotropic or operating temperature limit, above which the actual liquid crystal molecules will lose their orientation and will assume a random orientation instead of ‘twisting’ through the light valve.

The site goes on to note that temperatures above 100°C (212°F) can permanently damage the coating on LCD displays, though Samsung claims that storing your display at temperatures above 45°C (113°F) can damage it, so it"s possible that Vartech"s 100°C threshold is specifically a property of their ruggedized displays.

Vartech also mentions that as temperatures drop the viscosity of the LC increases, resulting in slower response times (which will first manifest as "ghosting", and further as very slow image updates/transitions, like a bad PowerPoint slideshow in slow-mo). The site doesn"t make mention of whether excessively low temperatures can permanently damage a display, but the line

LCD displays, especially older, mature display technologies such as segment and character LCDs have a very low fallout rate; so when we receive a request to return a large number of failures, we are concerned and want to solve the problem right away.

One percent failure is cause for alarm; after some investigation we found that the delaminating of LCD polarizers (or polarizers peeling away from the glass) was a result of excessive heat being applied to the display.

LCD displays, like microprocessors, are very sensitive to excessive heat and must be protected from exposure to high temperatures for long periods of time. In order to avoid the delaminating of LCD polarizers, the only time to expose the display to high heat is when it is being attached to the PCB (Printed Circuit Board).

When soldering a LCD, try to use hand soldering. If you do wave-solder, we recommend the display not be exposed to heat in excess of 300C (572 F) and then only for a few seconds.

There are two times when a display will face this extreme environment: manufacturing of the LCD and when being soldered to a PCB. Great care must be taken to avoid damage.

The entire LCD assembly is then "baked" to cure the adhesive with the temperature of the oven and the amount of time in the oven being critical. If the temperature is excessive, or the LCDs are left in too long, the polarizer will peel away from the glass.

All completed LCDs should be 100% visually inspected to identify the delaminating of LCD polarizer issue. If there is a problem, it should be pulled from the lot as defective. It should not reach the customers manufacturing location.

LCD Displays, like most electronic components are soldered to a PCB, either by wave or hand solder. When the temperature of the solder is excessive, or the heat source is kept in contact for an extended period of time, the polarizer will begin to peel away.

If you find that during your manufacturing process the LCD will be exposed to excessive heat, it is recommended to incorporate a heat shunt and divert the excessive heat away from the adhesive and polarizer.

LCD’s are manufactured with ROHS (Restriction of Certain Hazardous Substances) or non-RoHS (Lead based) solder with each type of solder having its own unique melting point.

Lead-based solder is mainly used in aviation, military and some medical industries with a melting temperature of 180C (356F). If requested, we are able to manufacture the LCD with non-RoHS solder.

Have you ever left your TV or monitor on for days, stuck on the same image? You return to your screen, only to find an image burned into the display. No matter what you do, it won"t go away. It is a permanent image burn.

Why do monitors and TVs get image burn? Why can"t manufacturers prevent LCDs and plasma screens from a burnt image imprint? Moreover, what can you do to fix an image burn?

Before flat-screens and crystal displays, most TVs and monitors featured CRT (Cathode Ray Tube) technology. In CRTs, individual pixels comprise a red, blue, and green phosphor component. Depending on the intensity of each phosphor component, the pixel appears to the human eye as a unique color.

When a particular still image remains for too long, the intensity of each phosphor component diminishes at an uneven rate. The result is a ghost image on the screen, which is known as image burning.

This is a very simplified version of how a plasma screen works. However, the main thing to understand is that plasma screens use phosphor material (like CRTs) to turn those photons into images.

LCD and LED do not work in the same way as CRTs, either. LCD and LED screens use backlit liquid crystals to display colors. Although manufacturers market screens using LED and LCD, an LED screen is still a type of LCD. The white backlight filters through the liquid crystals, which extract particular colors per pixel.

LCD and LED displays don"t suffer from the same type of image burn as CRTs and plasma screens. They"re not completely clear, though. LCD and LED screens suffer from image persistence. Read on to find out more about image persistence.

Before you can fix screen burn-in, take a second to understand why these images burn in the first place. LCDs and LEDs don"t suffer from burn-in as seriously as plasma screens. But static images can leave an imprint on both display types if left alone for too long. So, why does image burn happen?

First, let"s tackle plasma screen burn-in. Remember why CRTs experience image burn? When a still image remains on the screen for too long, the phosphor components in each pixel wear out at different rates. The uneven burn rates leave behind a ghost image, forever etched into the screen.

Plasma screens also suffer from phosphor deterioration. Plasma burning occurs when pixels on the screen are damaged through long exposure. The phosphor loses its intensity and only shows the light it was fed repeatedly. In this case, the still image, which causes the burn.

LCD and LED screens can also experience image burn, though the image burn process can take longer to develop into a permanent issue. In addition, LCD and LED screens suffer from another issue, known as image retention (also known as image persistence or an LCD shadow).

Image retention is a temporary issue that you are more likely to notice before it becomes a permanent issue. However, proper image burn can still affect LCD, LED, and OLED screens.

Image retention is a different issue from image burn (although it is a precursor to image burn). For example, you"re using an image of a steam train as a reference point for a drawing. You have the steam train image on your screen for a few hours before you decide to play a video game instead.

When you load up the video game on the screen, you can still see the faint outline of the steam train on the screen. The steam train image will remain for a short while, but the movement and color changes of the video game (or film, TV show, or other media type) should erase the retained image.

The other thing to consider is that LED and OLED image burn-in, when it happens, is irreversible. That"s because of how LED and OLED screens work. Individual pixels within an LED display decay when they emit light.

Under normal use, an LED, OLED, or QLED screen won"t suffer image burn. However, if you leave your screen on a single channel for hours every day, then burn-in can become an issue, as it would with almost any screen.

Issues arise when a screen shows a single news channel 24 hours a day, every day, causing channel logos to burn-in, along with the outline of the scrolling news ticker and so on. News channels are a well-known source of television burn-in, no matter the screen type.

Image burn-in fixes exist for LCD and plasma screens. How effective an image burn-in fix is depends on the screen damage. Depending on the length and severity of the image burn, some displays may have permanent damage.

The best fix for screen burn is to prevent it in the first place. Okay, that isn"t super useful if your screen is already experiencing image burn. However, you should always try not to leave your screen on a still image for too long. The time it takes for an image to burn-in varies from screen to screen, between manufacturers, sizes, and panel type.

Another prevention method is to reduce screen contrast as much as you can. Unfortunately, most screens aren"t calibrated correctly, often pushing the contrast and brightness settings too high.

Lower contrast means the lighting across your screen is more even. This means less strain on specific areas of the screen, which helps protect against image burning.

If your plasma or LCD screen already has image burn-in, you can try turning on white static for 12 to 24 hours. The constant moving of white-and-black across your screen in random patterns can help remove the ghost image from your screen.

Unfortunately, this won"t work for extreme cases. Some TVs will have a built-in pattern swiping option that basically accomplishes the same thing (filling your screen with random patterns).

Pixel-shift constantly slightly adjusts the image on your screen, which varies the pixel usage to counteract image burn. You might have to enable a pixel or screen shift option in your screen settings. Pixel-shift is a handy feature for LED and OLED screens that cannot recover from image burn and should help counteract an LCD shadow.

Other modern screens feature built-in screen refresh functions that the manufacturer will advise using to remove image retention and image burn issues.

The best tool for fixing ghost images is JScreenFix. The original program helps fix monitors with dead pixels, but the same company also released an "advanced" version of the tool, known as JScreenFix Deluxe.

While the Deluxe version uses advanced algorithms to repair burned screens and prolong plasma and LCD longevity, the official site is no longer up and running, and there is no way to download the full version officially.

If you have television burn-in, you can attach a laptop to your TV using an HDMI cable, extend your desktop to the television, and share the white screensaver. Hopefully, that will shift your television burn-in.

The team over at ScreenBurnFixer offers a few different ways you can attempt to fix screen burn on your TV or monitor. As with any other screen burn-in fixes, their chance of working depends on the scale of the issue.

You can head to the ScreenBurnFixer Video page and find a video that matches your screen type, then let the video play for as long as possible (we"re talking multiple hours, not a quick half an hour blast). Alternatively, head to the Chart page and find your device or a device that matches your specifications.

There are several ways you can attempt to fix screen burn-in. The results will vary between the screen type and the level of burn-in. A screen with extensive image burn may not clear entirely, although you might see an improvement.

Some screen degradation over time is understandable. However, if you follow the steps in this guide, you"ll protect your screen from image burn before it becomes a permanent issue.

Many cities around the world, especially Paris and other European cities, are seeing heat waves like they’ve never known this summer. Record-breaking temperatures swept across the continent, impacting Europeans, many of whom don’t have air conditioning in their homes.

These extreme temperatures can also harm digital displays, which are typically designed to operate between 32 and 90 degrees Fahrenheit. However, as the temperature increases for long periods, like the intense European heat, which reached 108.7 degrees Fahrenheit in Paris, digital signage may experience issues or even stop functioning.

Because heat damage has been so prevalent this year, it’s essential to take a moment and think about how to protect your displays. Even if you haven’t been affected by the recent heat waves, consider your area’s climate and whether or not your devices are protected.

If you’re worried about heat damage or live in an area where extreme temperatures are prevalent, consider exploring a custom solution. Manufacturers can often create screen enclosures complete with fans or an internal heating unit. Each of these elements helps air circulate within the displays, thus stabilizing the internal temperature. Some custom work can protect devices from temperatures ranging anywhere from -22 degrees to 131 degrees Fahrenheit. Thermal management technology is an ideal safeguard for when temperatures fall outside of the optimal operating zone.

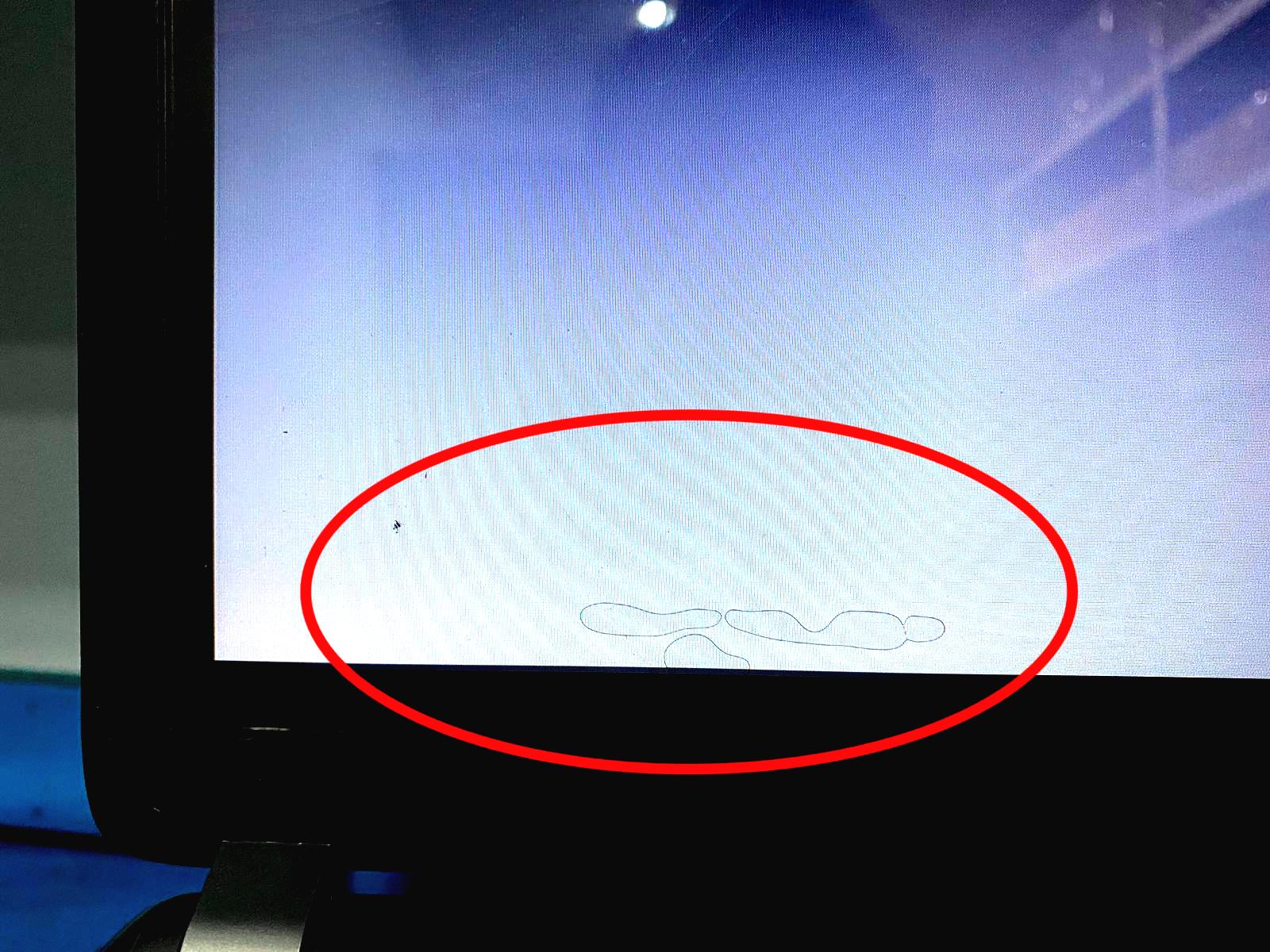

Whether outside or indoors, protecting your displays from direct sunlight is crucial. Direct sunlight will not only increase a device’s overall temperature, but it can also create specific hotspots. Hotspots refer to areas of high heat that can lead to permanent scarring of the LCD, LED or plasma screen. In LCD screens specifically, direct sunlight can cause the Liquid Crystal cells inside the display to boil, leaving behind a black spot. This phenomenon is known as solar clearing. If the LCD screen overheats, it can also lead to isotropic failure, and you may need to replace the device. Position digital signage out of direct sunlight, whenever possible. Whether inside a custom screen enclosure or under a tent or awning, this tactic will extend the life of your device. At least very least, provide proper airflow to keep the displays cool and functioning properly.

Sunlight also creates a problem from a user experience perspective. Direct sunlight can obstruct the display, making it hard to view what is on the screen—whether it’s a food and drink menu or advertisement. By installing anti-glare glass, you’ll improve your customers’ experiences and ensure they see what you want to show them.

Anti-glare glass protects your screens, as well. They deflect the light, improving readability as well as keeping your digital displays cool. Do your research first, though, as some anti-glare displays will reduce visibility for people wearing polarized lenses.

Temperature regulation should be a key player from the beginning of your digital signage deployment. Installation should begin with a site assessment to determine where to place your displays to avoid hotspots and solar clearing as well as optimize the user experience. Installers should also understand how sunlight and heat affect digital displays, not to mention how the devices themselves can generate heat after being powered on for long periods.

Unfortunately some water got into my LCD screen creating weird dim patches against the bright back light. only the screen seems to be affected, not anything else.

I am thinking of keeping it in the sun so that water could evaporate, or maybe using a hair dryer. What adverse effects may this have on my LCD screen?

EDIT2 : I tried other options to make the water go away, none of them worked. Seems like heat is the only solution, but I"d still like to know of any adverse effects so that I don"t damage it further.

The 100,000-hour figure assumes that every diode will be running at full brightness, consistently — which, on an LED screen, is virtually never the case. The lifespan figure can also be misleading because it indicates when a diode degrades to half-brightness, not completely dark. Many other variables affect an LED display’s lifespan; you can’t rely solely on the number on the diode spec sheet.

“The reality is, your screen can often last significantly longer than 100,000 hours,” says Kevin Izatt, a senior product manager in Samsung’s Display division. “We’ve had displays that have been up for 15-plus years with more than adequate brightness. Because the diode is actually only one factor in the lifespan of your LED display.”

The biggest contributor to diode degradation is heat. As you increase a diode’s brightness, it produces more heat. Your display’s physical environment also contributes to the temperature of the diodes, especially for outdoor displays.

The quality of your display’s power supply — and how hard it drives the diodes — can have a significant impact on your screen’s lifespan. The other components being powered, such as fans and electrical components, have their own lifespans as well, which are also impacted by the power supply.

“Something like airflow is very important,” says Izatt. “You need a screen that has good cooling, and a design that allows heat to flow out of the back through vents.”

It’s easy to see why: The circuit boards powering the display release heat, and that heat needs to go somewhere. Without a strong design, thermal stress will degrade the life of the display, except for the highest-quality parts — optimal conditions notwithstanding.

To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program. Samsung will come on site to remove your existing display and provide a discount on a new LED bundle kit.

Traded-in LCD displays that are still operating will be refurbished and resold, and your business will receive a cash rebate. Nonworking displays will be recycled and their parts reused.

As you plan your LED signage rollout — or an upgrade — learn how to configure and tailor your screens’ real-time messaging with an integrated CMS in thisfree guide. And if you haven’t decided what kind of display is best suited to your current project, compare all ofSamsung’s LED displays.

If the picture responds to input but displays a messy image, such as jumbled multicolored squares, the AV (audio visual) board may be damaged. This is usually a rectangular circuit board located near the audio and visual cables. Replace obviously damaged parts using a soldering iron, or order a replacement board and carefully install it to the same screws and ribbon cables.

Check input cables for damage, or try other cables of the same type. If necessary, inspect the circuit board they are attached to and re-solder damaged connections.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey