a-si active matrix tft lcd h-ips in stock

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

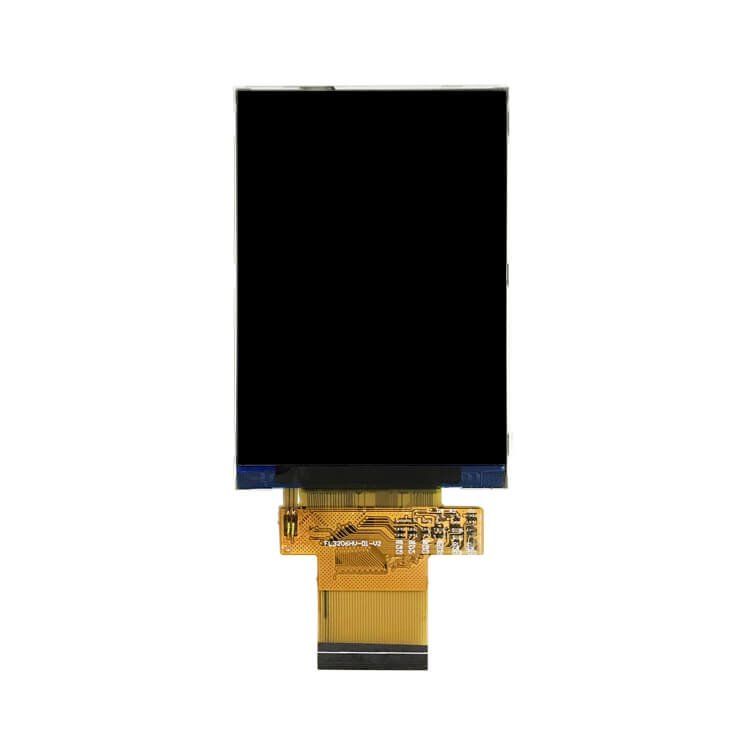

4DLCD-24320240-IPS is a color active matrix LCD module incorporating amorphous silicon TFT (Thin Film Transistor). It is composed of a color TFT-LCD panel, driver IC, FPC and a backlight unit. The module display area contains 240X320 pixels and can display up to 262K colors. This product accords with RoHS environmental criterion.

This is a Raw TFT Display, it features no processor and cannot be programmed directly. It needs to be coupled with a Processor and circuitry capable of driving this type of display. For complete modules ready to go, please refer to our Intelligent Display Module products.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

The transistor switches used in Active Matrix Displays must not protrude significantly above the surface of the display substrates lest they might interfere with a uniform liquid crystal layer thickness. They must be implemented in thin films of suitable materials. Hence, the name Thin Film Transistors (TFT). While AM and TFT have a different meaning, they are often used interchangeably to indicate a higher performance display.

TFTs can be formed by amorphous silicon (denoted α-Si TFT), by poly-crystalline silicon (LTPS for Low Temperature Poly Silicon), or by semiconducting metal oxides (Ox-TFT or IGZO-TFT for Indium Gallium Zinc Oxide).

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The birefringence of an STN display can be approximated with a stretched transparent plastic film. Adding such a film to an STN display instead of the 2nd STN display is a lot more attractive and has almost the same performance. This is referred to as a Film Compensated STN display (FSTN, or sometimes if two films are used as FFSTN).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Throughout the development of these technologies, there were the initial type, super, advanced, pro, etc. versions, which led to a lot of acronyms like (S-IPS, AS-IPS, H-IPS, FFS-Pro)

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

Microtech Technology Company Limitedestablished in 2001,offers professional design and manufacturing services for hundreds types of Liquid Crytal Display modules and Touch Panels-TN,FSTN,TFT,RTP,CTP.With the advantages of high contrast,fast response time,wide viewable angle and low power consumption,Microtech"s products are widely used in Industrial Equipment,Medical devices,Home Intelligent Devices,Digital cameras,Video Game Devices,Instruments etc.Since its establishment,the management has been following human-oriented strategy and developing reliance among customers.To comply with these beliefs and ISO 9001:2015 standards,Microtech keeps on recruiting capable professionals,adopting advanced technology,developing new products,improving process and enhancing quality.Based on its strong R&D capacity, outstanding product quality and professional service,Microtech has won the high reputation from both mainland and oversea customers,and established long-term strategic partner relationship with them.

In order to obtain an excellent quality management team and offer our customers professional & efficient service and satisfied products,We comprehensively carry out Zero Defect quality management,implement ISO9001:2008 standards training and organize the examination /enrollment of quality management personnel national professional qualification.Our Mission "Efficient and timely service is the key to our success.Our success is tied with our client"s success. We are dedicated to provide excellent service to our customer at the most competitive prices." To provide customer a value added LCD product by stringent quality control,comprehensive technical support,and utilization of latest technology.

With our motto "Quality and Services are vital to enterpriess",Microtech aims to produce high quality LCD module to meet the customers" specific needs in all-round way.Meanwhile we seek for continuous service improvement,increase our market share,strengthen our competitiveness,and ultimately,expand our market worldwide!

Used to describe a clocked parallel TFT connection that uses 18 data lines (6 for Red, 6 for Green, 6 for Blue) as well as Hsync, Vsync, data enable, and pixel clock to transfer data to the TFT. Theoretical color depth is 218 or 262,144 colors.

Used to describe a clocked parallel TFT connection that uses 24 data lines (8 for Red, 8 for Green, 8 for Blue) as well as Hsync, Vsync data enable, and pixel clock to transfer data to the TFT. Theoretical color depth is 224or 16,777,216 colors.

6800 is a parallel interface that uses Read/Write signal and an Enable signal to control the data bus. Communications with a display are only enabled when the enable signal is pulled high. The level of the Read/Write signal then determines whether data will be read from the display or written to the display. If the Read/Write signal is high, data will be read from the display whereas if the Read/Write signal is low, data will be written to the display. Sometimes the Write will be shown as a “notted” signal. For instance, there may be a bar over the name, a preceding exclamation mark, slash, or dash. While this looks like negation notation, in this context it simply means the signal is active low.

A liquid crystal display structure in which switching transistors or diodes are attached to each pixel to control the on/off voltage. It produces a brighter and sharper display with a broader viewing angle than a passive matrix display. Also known as AMLCD (active matrix liquid crystal display). See TFT (thin film transistor).

This is often described as a matte coating as it is non-reflective to the user since it diffuses rather than reflects ambient light. It provides a method for manufacturers to avoid glare on the viewing surface from other light sources and has been used in the LCD monitor market for many years since the first TFT displays started to emerge. The matte coating is included as an outer polarizing later which has been coarsened by mechanical or chemical processes. This achieves a surface coating which is not smooth and so can diffuse ambient light rather than reflect it.

An adhesive is applied between the display and touch panel using the inactive area around the perimeter of the module. This bonding method results in some inactive space ‘air gap’ between the touch panel substrate and the display. This is the most cost-effective and common solution.

AMOLED is Active Matrix OLED. An Active Matrix OLED uses a TFT (Thin Film Transistor) transistor-per-pixel architecture. Using a transistor-per-pixel allows higher resolution displays to be made and avoids the problems associated with high duty cycle passive displays.

An anti-reflection (AR) coating is a type of optical coating applied to the surface touch panel to reduce reflection. Many coatings consist of transparent thin film structures with alternating layers of contrasting refractive index. Layer thicknesses are chosen to produce destructive interference in the beams reflected from the interfaces, and constructive interference in the corresponding transmitted beams.This makes the structure’s performance change with wavelength and incident angle, so that color effects often appear at oblique angles. Good performance can often be achieved for a relatively wide range of frequencies: usually a choice of IR, visible, or UV is offered.

A backlight is used behind the LCD glass to allow the LCM to be read in dark conditions. The vast majority of backlights are now LED. Historically there were also EL (electroluminescent) and CCFL (Cold Cathode Fluorescent Light) backlights, but as LED efficiency has increased and cost has decreased, EL and CCFL backlights have all but disappeared.

A frame of plastic or metal, fitting over the LCD glass, to protect the edges of the glass and actas a pressure device, compressing the elastomer connector between the PCB and LCD glass.

Normally an LCD’s backlight is set to the brightness that will make a white pixel fully illuminated. CABC automatically dims the backlight to the lowest level required for the brightest pixel on the display.

Character LCDs include a fixed CGROM to define the bulk of the characters they display. However, since the CGROM cannot be changed the designers also included the CGRAM — a small number of characters (typically 8) that can be redefined at run-time. These eight characters are usually mapped to characters 0DEC (0x00HEX) to 7DEC (0x07HEX). The CGRAM definitions can be used to make small animations, bar graphs, and similar small graphic or sprite images. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780.

The CGROM stores the font that is displayed on a character LCD. When you tell a character LCD to display the letter ‘A’, it needs to know which dots to turn on so that we see an ‘A’. This information is stored in the CGROM. By definition, (since it is a ROM) the font that is stored in the CGROM cannot be changed. Be sure to check the datasheet of the character LCD module to make sure that it can display the characters you need. Typically, a CGROM for a character display module has 240 characters defined. The lower half of the CGROM maps to the normal ASCII characters. Since the early character display controllers were designed in Japan, many CGROM have Japanese characters in the upper 128 positions. There are also some CGROMs that have European or Cyrillic characters in these upper locations.

The WS0010 is a more modern character OLED controller, and the designers have included several CGROMs that can be chosen at run-time, so there is not the need to lock in a particular character set at design time. Since the CGROM is completely determined at the time of manufacture of the LCD controller, the designers also included a CGRAM, which allows the bitmaps of a few characters to be redefined at run-time. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780).

The Display Data RAM holds the letters that get shown on the LCD of a character LCD module. For instance, the letter ‘A’ is stored in its ASCII equivalent 65DEC (0x41HEX) in the DDRAM.

So a 20×2 character LCD would have enough DDRAM to store 40 letters. The value in the DDRAM is used to find the correct bitmap in the CGROM (Character Generator ROM) or CGRAM (Character Generator RAM), it is this small bitmap that gets displayed on the LCD. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780.

Translucent material used for light diffusion placed between backlight lighting sources and the back side of an LCD. This material will create a more uniform backlight for an LCD from several unique sources of light.

Refers to a graphic controller from Bridgetek/FTDI. EVE graphic controllers are easy to use and can control the display, touch, backlight, and audio features of an embedded system, with each appearing to the host MCU as a memory-mapped SPI device. The host MCU sends commands and data using SPI protocol. EVE modules accept high level commands, simplify writing images and fonts (included angled fonts) on TFTs. Fonts, buttons, and tables can each be easily sent to a TFT using a one-line command.

A silicone rubber strip made up of sequentially spaced conductive and non-conductive material. A thin conductive material used to make connections between an LCD and a PC board.

A dead short is created when excess DC voltage is applied to an LCD. Conductive particles from one piece of glass are transferred through the liquid crystal fluid and deposited on the conductive surface of the opposite piece of glass.

The space left between the epoxy seals on one end of the LCD glass after assembly. This space,used to fill the glass with the liquid crystal fluid, is noted by a mound of epoxy.

An LCD construction technique where the cell geometry is optimized for maximum contrast and viewing angle. The geometry is different for each LCD fluid.

HDMI means it is able to send a lot of data, very quickly. However, HDMI isn’t an analog communication like VGA, S-Video or parallel like 24-bit or 18-bit RGB TFTs. HDMI is actually a high-speed serial interface using a fancy TMDS (Transition Minimized Differential Signaling) protocol.

Typically, both the master and slave are implemented in hardware. The I2C master can be implemented in software quite easily, but it can be rather difficult to meet the timing requirements of I2C in a software slave implementation. As micro controllers continue to get faster, writing an I2C software slave will become easier. The I2C standard is pretty well defined, so there is not a huge amount of variation in I2C as it is implemented on LCD, capacitive touch and OLED controllers.

An LCD is composed of two pieces of glass with a thin layer of liquid crystals between the glass layers. When a voltage is applied to the glass, the orientation of the crystals can be changed. This change in the crystal’s orientation (called polarization) will make either a dark or a light area, creating a character or image on the display.

A twisted nematic LCD design where the backlight is blocked when pixels are in the unselected state. Therefore, when no voltage is applied, the screen is black.

A twisted nematic LCD design where light is transmitted when pixels are in the unselected state. Therefore, when no voltage is applied, the screen is white.

Optical bonding improves the optical performance of the display. It eliminates the air gap between the cover glass and the LCD, and usually includes an anti-reflective (A/R) coating (as well as anti-smudge and anti-glare treatments on the cover glass). Optical bonding improves the contrast ratio by reducing the amount of reflected light, thus improving the viewability of the LCD screen. This is especially important in outdoor.

Besides the optical advantages, bonding a sheet of glass to the LCD also improves the durability of the display. It can resist scratches, condensation, and has an improved range of operating temperatures. As touchscreen devices become ubiquitous in consumer markets, this increased ruggedness becomes even more important. Also, by reducing the light loss due to reflection, the battery life of the device can be extended as the device does not need as much backlight to power the display.

On-Cell Touch (OCT) technology permits the Projected Capacitive (PCAP) touch sensor layer to be built into the LCD structure. With this integrated structure, the touch functionality is embedded within the display itself rather than a separate touch screen component on top of the display. The reduction in the number of layers also reduces parallax errors providing a superior touch interface. Fewer layers also means backlight intensity can be reduced while providing the same brightness level. The usual multitouch display has an 88% transparency while an OCT display is 93%. This helps reduce lighting power requirements and extends battery life.

For optical bonding optically clear adhesive is applied over the entire surface between the display assembly and touch panel. This bonding method removes all air and air bubbles from the viewing area providing a more rugged and optically attractive solution. Removal of ‘air gap’ between the module and touch panel eliminates surface-to-surface reflections which degrade contrast and ultimately viewing angles, especially significant in sunlight conditions.

Passive Matrix refers to the arrangement of the driving electrodes in the OLED display. In PMOLED displays, there is an array of horizontal conductors and an array of vertical conductors, with the OLED material between them. A pixel is formed where the vertical and horizontal conductors intersect.

A technique where the alignment layer (Polyimide) on the LCD substrate is rubbed in one or more directions. This process aligns the liquid crystal molecules parallel to the buffing direction.

An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

SPI is a simple serial bus that is often used by LCD or OLED controllers. SPI as implemented for OLED and LCD controllers typically uses a “3-wire SPI” or “4-wire SPI” scheme. SPI was originally championed by Motorola (now Freescale). In its original “pure” form SPI uses four signals:

TFTs are also known as “Active Matrix TFT LCD modules” and have an array of these thin film transistors fabricated on the glass that makes the LCD. By using this active transistor-per-pixel architecture, the contrast of each pixel is good, allowing bright full-color, full motion images to be displayed.

VA is also called VTN, PMVA, GDV, etc. it is a type of LCD in which the liquid crystals naturally align vertically to the glass substrates. When no voltage is applied, the liquid crystals remain perpendicular to the substrate, creating a black display between crossed polarizers. When voltage is applied, the liquid crystals shift to a tilted position, allowing light to pass through and create a gray-scale display depending on the amount of tilt generated by the electric field. VA displays have a deeper-black background, a higher contrast ratio, a wider viewing angle, and better image quality at extreme temperatures over traditional twisted-nematic displays.

4DLCD-35480320-IPS is a color active matrix LCD module incorporating amorphous silicon TFT (Thin Film Transistor). It is composed of a color IPS TFT-LCD panel, driver IC, FPC and a backlight unit.

This is a Raw TFT Display, it features no processor and cannot be programmed directly. It needs to be coupled with a Processor and circuitry capable of driving this type of display. For complete modules ready to go, please refer to our Intelligent Display Module products.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Figures 3a–d show optical and SEM (scanning electron microscopy) images of the fabricated CL and CLSE pixel structures. Each structure has the same pixel size (80 μm × 240 μm) and minimum pattern size (5 μm). As shown in Fig. 3d, the white line patterns are the ITO interdigitated pixel and common electrodes. They are well connected to the source electrode and gate line via through holes, and the common electrodes at both ends cover the underlying data lines to prevent electrical noise from being applied to the LC layer. As will be shown later, this noise shield electrode (SE) is what makes the black matrix above the data line unnecessary

Optical and SEM (scanning electron microscopy) images of fabricated (a, b) CL and (c, d) CLSE pixel structures. The five white line patterns in (d) are the ITO interdigitated pixel and common electrodes. (e) Images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel. (f) The three-black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM) and (g) optical images of pixels without BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines).

Figure 3e shows images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel fabricated in our laboratory, (f) the three black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM), and (g) optical images of panel areas without the BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines). As can be seen in the image from the normal direction, the brightness and contrast of the display area with the top BM and middle BM patterns are almost the same, but the contrast of the display area without the BM is relatively lower because of the lower darkness level of the LC off pixels indicating “HITACHI”. As shown in Fig. 3g, this is due to light leaking through the aperture between the data line and adjacent common lines. Therefore, in the CL structure, the BM on the drain line is necessary to obtain a high contrast ratio by shielding light leakage. This is the same as in the conventional structure. On the contrary, there is no light leakage along the gate line through the gaps between the gate line and edges of the pixel/common electrodes, as is clearly shown in Fig. 3g. This is a unique advantage of the CL structure because the conventional structure must shield these gaps with the BM to prevent light leakage. The suppression of light leakage along the gate line in the CL structure is due to the driving scheme (see Fig. 2b,a for a comparison with the conventional structure). During the holding period (tOFF) in the conventional structure, regardless of the pixel voltage, Vp (including Vp = 0), nonzero Vgp and Vgc are always applied to keep the TFT off, and these voltages are applied to the LC layer, inducing light leakage as reported in

Figure 4a shows the gate voltage (Vg) dependence of the panel brightness, while the inset shows that of the TFT current (transfer characteristics). The gray curves are for the conventional IPS TFT-LCD with the TFT before enhancement, the common line, and the matrix BM (MBM) shown at the top of Fig. 3f. The blue curves are for the proposed CL structure with the enhanced TFT and the stripe BM (SBM) shown in the middle of Fig. 3f. In this case, enhanced TFT characteristics were obtained by using an MNOS TFT without back-channel oxidation that was enhanced by the BTS process. In both structures, the threshold voltages for panel brightness, defined by extrapolating the straight part of the brightness curves, reflect those of the TFT transfer curves defined as Vg at a drain current of 10−12 A, and they are well matched to be 4 V and 9 V, respectively. The maximum brightness for the CL structure is 137% higher than that for the conventional structure, which is due to the increase in the aperture ratio from 38 to 52% that results from the elimination of the common line and the BM covering the gate line.

(a) Dependence of panel brightness and TFT current on gate voltage for the conventional pixel structure of 38% aperture ratio (AR) with matrix black matrix (MBM) over both drain and gate lines and proposed CL pixel structure of 52% AR with strip black matrix (SBM) over only the drain lines. Transfer characteristics before and after bias temperature stress (BTS) treatment are shown in the inset. (b) Charging and (c) holding characteristics of enhanced TFT of the CL structure with gate as a common line. Vg and Vd in the TFT ON state are 30 V and +/−7 V, respectively.

To estimate the charging and holding characteristics of the MNOS-enhanced TFT in the panel, the gate TFT ON and OFF time dependences of the panel brightness were measured (Fig. 4b,c). The charging characteristics in Fig. 4b are plotted as a function of tON at tOFF = 16.6 ms, Vg = 30 V, and Vd = ± 7 V. The holding characteristics in Fig. 4c are plotted as a function of tOFF at tON = 34 μs. 95.1% charging at tON = 34 μs and 95.3% holding at tOFF = 16.6 ms indicate that the enhanced TFT has sufficient charging and holding performance to drive a standard VGA (640 × 480 pixels) panel (the number of scanning lines is estimated as tOFF/tON = 16.6/0.034 = 488).

To confirm the driving conditions for the CL structure without the BM along the gate line (with the SBM), the tOFF dependence of the contrast ratio (CR) in the CL panel was further investigated as shown in Fig. 5a, where CR is plotted as a function of tOFF for the CL panels with the matrix BM (MBM) and the strip BM (SBM). The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. The SBM and MBM panels keep CR higher than 240 with tOFF > 16.6 ms, the frame period of a display panel without flicker being noticeable to the human eye. both panels decrease CR when tOFF is less than 16.6 ms; the CR of the SBM panel decreases faster than the CR of the MBM panel. As shown in the inset, the decrease in CR was due to the increase in dark-state brightness with decreasing tOFF as light leakage increases along the gate line. This light leakage is induced by the voltage Vgp = Vgc = VgON = 30 V applied only for 34 μs during the TFT ON (charging) state, which is 1/488th the duration, tOFF = 16.6 ms, of the TFT OFF (holding) state with Vgp = Vgc = VgOFF = 0 V, but the ratio increases with decreasing tOFF and becomes effective enough to switch on LC layer and induce light leakage. However, it should be stressed again that the CL panel with the normal holding (TFT OFF) time of 16.6 ms does not suffer from the light leakage along the gate line, so the aperture ratio can be increased by removing the BM along the gate line.

(a) Contrast ratio (CR) for CL panels with matrix BM (MBM) and stripe BM (SBM) plotted as a function of tOFF. The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. Vd (= VLC) dependence of (b) brightness and (c) contrast ratio of the CLSE panel. Insets of (b): optical images indicating the elimination of the BM from the CLSE structure (upper left) and the MBM in the conventional structure (lower right). Insets of (c): CLSE panel composed of different areas with three different pixel structures and aperture ratios (ARs), i.e., CLSE structure without BM (60%), CL structure with SBM (52%), and conventional structure with MBM (38%).

Figure 6 indicates the effect of bias temperature stress (BTS) on the TFT characteristics. As the stressing time, tS, of the positive gate stress voltage, Vst = + 77 V, increases from 0 to 3600 s, the transfer (Id-Vg) curve shifts in the positive direction (Fig. 6a). Vth is defined as Vg at which Id = 10−12 A and ΔVth is defined as the Vth shift from the initial value via BTS. As shown in Fig. 6b, ΔVth increases logarithmically with increasing tS: ΔVth = 2.17 + 4.93 × log (tS). The mechanism behind the gate-stress-induced Vth shift is electron tunnel injection from the a-Si:H semiconductor into the SiOx gate insulator. For confirmation, ΔVth of MNOS TFTs with different SiOx thicknesses is plotted as a function of the electric field applied to the SiOx layer in Fig. 6c. Here, the thickness of the SiOx was varied (5, 10, 20, 50 nm), while the SiN thickness was fixed at 200 nm. The electric field applied to SiOx, Eox, was calculated using the following equation,

Effect of bias temperature stress (BTS) on TFT characteristics. (a) The transfer (Id–Vg) curve shifts in the positive direction with positive gate bias stress of Vst = + 77 V over the duration of 0–3600 s. (b) ΔVth, defined as the Vth shift from the initial value via BTS, increases logarithmically with increasing tS, following ΔVth = 2.17 + 4.93 × log (tS). (c) ΔVth of MNOS TFTs with different SiOx thicknesses from 5 to 50 nm as a function of the electric field applied to the SiOx layer.

Figure 7a shows the effect of back-channel oxidation (BCO) and passivation (PAS) on the Id-Vg characteristics of the MNOS TFT. The Id-Vg curve with Vth = 5.1 V is further enhanced to Vth = 10.9 V after BCO, although there is a slight degradation of the slope of the current increase in the sub-threshold region. The slope recovers after PAS without any change to the enhanced characteristics

(a) Effect of back-channel oxidation (BCO) and passivation (PAS) on Id–Vg characteristics of MNOS TFT. (b) Vth and Vth standard deviation, σVth, after BTS and after BCO without BTS treatments and (c) SiOX thickness as a function of position along gate-line, x.

The advantage of BCO over BTS is the uniformity of the enhanced characteristics; Fig. 7b shows the distribution of the enhanced Vth as a function of position along gate-line, x, for the MNOS TFTs connected with a 90-mm-long gate line in the TFT substrate after BTS and BCO treatments. The average value of Vth and the standard deviation, σVth, for pristine TFTs before BTS or BCO, are 5.1 V and 0.35 V, respectively. After BCO, Vth is uniformly enhanced, with an average Vth = 11 V and σVth = 0.4 V without increasing σVth. On the other hand, after BTS, Vth is nonuniformly enhanced with an average Vth = 9.3 V and σVth of 1.4 V. In particular, Vth increases linearly as a function of position along gate-line, x. As the gate SiOx thickness linearly decreases, from (54 nm) to (47 nm) with increasing x as shown in Fig. 7c, the increase in ΔVth after BTS with x is due to increase in the electric field applied to SiOx as shown in Fig. 6c and Eq. 1.

It has been shown that the Vth of the MNOS TFT is independent of the gate SiOx thickness when the thickness is more than 5 nm8a, Vth of the MNOS TFT with the BCO treatment becomes almost independent of the BCO SiOx thickness. As shown in the inset, the thickness of BCO SiOx composed of oxidized a-Si:H linearly increases with BCO processing time, and the Vth increase almost saturates at a BCO SiOx thickness greater than 5 nm. Therefore, the enhanced MNOS TFT after BCO has a uniformly high Vth that is robust to thickness fluctuations of the gate and BCO SiOx layers. BCO also has an advantage over BTS in terms of the stability of Vth as shown in Fig. 8b, which plots the annealing time dependence of Vth for BCO and BTS. In this experiment, the stoichiometry (x) of the gate SiOx was 1.78 for BTS and 1.78 and 1.9 for BCO. The annealing temperature in the N2 atmosphere was 200 °C. In the case of BTS, Vth decreased to the pristine value after approximately 5 h of annealing, while Vth decreased more slowly in the case of BCO. In particular, the annealing time required for Vth to fall to 7 V was 7.5 times longer than that of BTS. Increasing the stoichiometry (x) of the gate SiOx dramatically improved the BCO-enhanced Vth to as much as 11 V, which was stably maintained after 24 h of annealing at 200 °C.

(a) Dependence of Vth on thickness of back-channel oxidized (BCO) SiOX. The inset shows the SiOx thickness dependence on the BCO process time for RF powers of 200 W and 500 W. (b) Stability of Vth as a function of annealing time for three different TFTs with gate SiOx stoichiometry, x = 1.78 and bias temperature stress (BTS), x = 1.78 and BCO, and x = 1.9 and BCO. The temperature of annealing in the N2 atmosphere was 200 °C. (c) Band diagram of back-channel oxidized MNOS TFT. The red arrows show the electric dipoles at the SiOX/a-Si:H and a-Si:H/BCO SiOX interfaces.

A schematic band model for the MNOS TFT with the BCO treatment and the sectional structure of the interface between the a-Si:H and gate and BCO SiOx are shown in Fig. 8c. The uniformly high Vth that is independent of SiOx thickness is due to the dipoles generated at the channel and back-channel interfaces between a-Si:H and SiOx8 of reference

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey