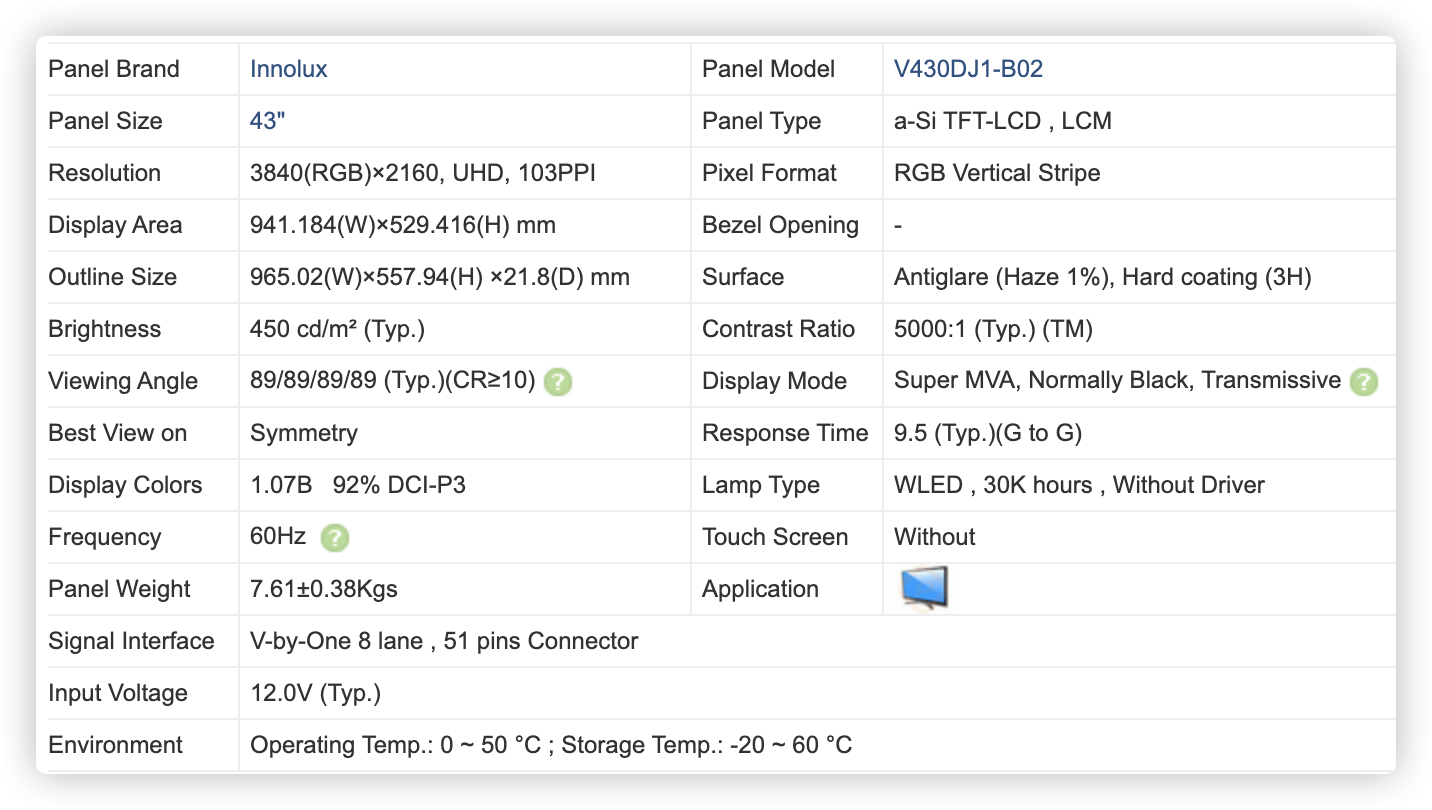

a si tft lcd cell supplier

A wide variety of a si tft options are available to you, such as original manufacturer, odm and agency.You can also choose from tft, ips and standard a si tft,

Panox Display provides free connectors for clients who purchase more than five products from us. Our product range includes connectors from Molex, Kyocera, AXE, AXG, JAE, Hiros, and more.

Panox Display provides a customized cover glass/touch panel service. We supply cover glass from Gorilla, AGC, and Panda, which all have excellent optical performance. We also supply driver ICs from Goodix and Focaltech.

If your applications are directly connected to a PC, a cellphone, or Raspberry Pi, and you have enough space to insert a board to input video, Panox Display can provide customized Controller/Driver boards with input connections for VGA, HDMI, DVI, DP, Type-C video input, MIPI, RGB, LVDS, and eDP.

The functions of our boards include, but are not limited to, adjustment of brightness, sound output, touch interface, extra data transmission, and gyroscope.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

According to LCD (Liquid Crystal Display) technology and LCD materials, mobile phone LCD assemblies can be classified into 2 types: TFT (Thin Flim Transistor) and OLED(Organic Light-Emitting Diode). TFT display needs with backlight, but OLED is light-emitting, each pixel is creating its own light.

For Original iPhone LCD, 5-8 plus and Xr, 11 is TFT, X-13 Pro Max is OLED (except XR and 11). But in mobile phone aftermarket, there are too many different types and different qualities, which makes customers confused.

What is in-cell? What is OGS or " with TP"? What is COF? What is COG? What is OEM? What is FOG? What is Original Change Glass? What is IPS? What is LTPS? What is a-Si?

HTPS with small size, high precision, and high contrast. Most used in magnified display products. Such as projectors, projection TVs, etc. And cannot be used as a mobile phone display, so we don"t talk about it here.

IGZO has 20–50 times the electron mobility than a-Sin. IGZO only has been licensed to Samsung Electronics and Sharp. However, it was Sharp who first implemented IGZO into their smartphones (Aquos Phone Zeta SH-02E), tablets, and 32-inch LCDs. IGZO for mobile phones is only Sharp. Almost all mobile phones on the market didn"t use IGZO.

Because the electrons deflect the liquid crystal molecules through the transistor. Electron mobility fundamentally determines the refresh rates of the TFT device. The smaller mobility, the slower transmission of holes and electrons, and the slower response rate. Can"t physically support high refresh rates.

In order to improve the response performance, can increase transistor size to enhance the migration, but this will lead to the extra TFT device that will occupy the display area pixel area. Therefore, the larger unit transistor area, the single-pixel occupy area is smaller(Pixel Aperture Ratio ), resulting in lower brightness.

Secondly, because the volume cannot be smaller, then the number of pixels per unit area is limited, which means the pixel density is small, which is what we call PPI is low, resulting in low resolution. The image needs to be zoomed, the original image data is lost, and resulting in the blurred image effect.

As we can see electron mobility of a-Si is very low (0.5-1cm2/Vs). But LTPS can deliver a hundred times the mobility than a-Si, and a much higher aperture ratio and PPI is much higher than a-Si resolution.

Compared with LTPS,a-si TFT have those "weakness":a-Si with so much low resolution and low definition. a-Si is 720*1280 with a very blurred display effect.

a-Si with so much bad display performance, but why are there still so many manufacturers producing phone LCDs with a-Si, or why do the customers willing to use a-Si LCD for their phone?

LCDs business has too much competition and wholesalers want to make more profit, they keep pushing suppliers to make LCDs at lower prices. So some of the suppliers start to produce aftermarket phone displays with a-Si to match customers" lower price requirements.

The customers with asymmetric information. End-Users don"t know how to distinguish LCDs qualities. Some of them just chase the price but not quality. That is another reason wholesalers want a lower price.

Now in the market a-Si LCDs for iPhone is TFT with TP but not in-cell. Our ZY a-Si will be in-cell not just TFT with TP. ZY a-Si incell for Xr and 11 ready now, please to get more details.

For more details or questions about in-cell and TFT with TP or about phone LCD display. Please click here to get more information, or Long press and scran the QR code to add me.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The most common semiconducting layer is made of amorphous silicon (a-Si). a-Si thin film transistor - liquid crystal display (TFT-LCD) has been the dominant technology for the manufacturing of active matrix TFT-LCD for over 20 years. a-Si is a low cost material in abundant supply.

a-Si is a low cost material in abundant supply. However, the electron mobility of a-Si is very low (around 1cm2/Vs) and can’t physically support high refresh rates such as the 240Hz needed for HDTV. Due to their high electron mobility, new materials such as metal oxide (MO) and low temperature polysilicon (LTPS) are now replacing a-Si to manufacture the industry’s two main types of screens: LCD and organic light-emitting diode (OLED) displays.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Used to describe a clocked parallel TFT connection that uses 18 data lines (6 for Red, 6 for Green, 6 for Blue) as well as Hsync, Vsync, data enable, and pixel clock to transfer data to the TFT. Theoretical color depth is 218 or 262,144 colors.

Used to describe a clocked parallel TFT connection that uses 24 data lines (8 for Red, 8 for Green, 8 for Blue) as well as Hsync, Vsync data enable, and pixel clock to transfer data to the TFT. Theoretical color depth is 224or 16,777,216 colors.

6800 is a parallel interface that uses Read/Write signal and an Enable signal to control the data bus. Communications with a display are only enabled when the enable signal is pulled high. The level of the Read/Write signal then determines whether data will be read from the display or written to the display. If the Read/Write signal is high, data will be read from the display whereas if the Read/Write signal is low, data will be written to the display. Sometimes the Write will be shown as a “notted” signal. For instance, there may be a bar over the name, a preceding exclamation mark, slash, or dash. While this looks like negation notation, in this context it simply means the signal is active low.

In theory, a material that perfectly reflects all light energy at every visible wavelength. In practice, a solid white (with known spectral data) that is used as the “reference white” for all measurements of absolute reflectance.

A liquid crystal display structure in which switching transistors or diodes are attached to each pixel to control the on/off voltage. It produces a brighter and sharper display with a broader viewing angle than a passive matrix display. Also known as AMLCD (active matrix liquid crystal display). See TFT (thin film transistor).

A/D or ADC converters must be used to process, store, or transport virtually any analog signal in digital form. TV tuner cards, for example, use fast video analog-to-digital converters. On-chip 8, 10, 12, or 16 bit analog-to-digital converters are common in microcontrollers. Digital storage oscilloscopes need very fast analog-to-digital converters. ADC converters are integral to current music reproduction technology. They are needed to create the pulse-code modulation (PCM) data streams that go onto CDs and digital music files.

AF (Anti-fingerprint) is a surface coating agent containing a fluorinated polyether. Excellent water and oil repellency, as well as anti-fouling properties, are achieved without altering the appearance, by forming a thin monomolecular layer on a surface such as glass. Normally using wet coating, spray coating, dip coating and spin coating process.

This is often described as a matte coating as it is non-reflective to the user since it diffuses rather than reflects ambient light. It provides a method for manufacturers to avoid glare on the viewing surface from other light sources and has been used in the LCD monitor market for many years since the first TFT displays started to emerge. The matte coating is included as an outer polarizing later which has been coarsened by mechanical or chemical processes. This achieves a surface coating which is not smooth and so can diffuse ambient light rather than reflect it.

An adhesive is applied between the display and touch panel using the inactive area around the perimeter of the module. This bonding method results in some inactive space ‘air gap’ between the touch panel substrate and the display. This is the most cost-effective and common solution.

A PI (polyimide) layer that is applied by spin coating. This thin film is then treated to impart a desired direction at which the liquid crystal molecules will attach and align.

AMOLED is Active Matrix OLED. An Active Matrix OLED uses a TFT (Thin Film Transistor) transistor-per-pixel architecture. Using a transistor-per-pixel allows higher resolution displays to be made and avoids the problems associated with high duty cycle passive displays.

The ratio between the transmissive portion of the pixel and its surrounding electronics, also known as fill factor. Generally, this is a limiting factor for luminance, the higher the aperture ratio; the brighter the luminance.

An anti-reflection (AR) coating is a type of optical coating applied to the surface touch panel to reduce reflection. Many coatings consist of transparent thin film structures with alternating layers of contrasting refractive index. Layer thicknesses are chosen to produce destructive interference in the beams reflected from the interfaces, and constructive interference in the corresponding transmitted beams.This makes the structure’s performance change with wavelength and incident angle, so that color effects often appear at oblique angles. Good performance can often be achieved for a relatively wide range of frequencies: usually a choice of IR, visible, or UV is offered.

A backlight is used behind the LCD glass to allow the LCM to be read in dark conditions. The vast majority of backlights are now LED. Historically there were also EL (electroluminescent) and CCFL (Cold Cathode Fluorescent Light) backlights, but as LED efficiency has increased and cost has decreased, EL and CCFL backlights have all but disappeared.

A frame of plastic or metal, fitting over the LCD glass, to protect the edges of the glass and actas a pressure device, compressing the elastomer connector between the PCB and LCD glass.

BGA stands for Ball Grid Array. A type of high-density electronic component package for integrated circuits. The BGA has solder balls on its backside, which line up with corresponding contacts on the front side of the PCB.The part and PCB are heated until the solder balls melt.

Normally an LCD’s backlight is set to the brightness that will make a white pixel fully illuminated. CABC automatically dims the backlight to the lowest level required for the brightest pixel on the display.

Simultaneously, the controller lightens the image by the same amount. Overall, there is no visible change in the image, but less power is used in the backlight for any image that does not contain a pure white pixel. In this way, CABC reduces the overall average power needed by the display and backlight.

An international unit of luminous intensity per projected area normal to the line of observation. Luminance may be described in units of Candelas per square meter, or nits.

Character LCDs include a fixed CGROM to define the bulk of the characters they display. However, since the CGROM cannot be changed the designers also included the CGRAM — a small number of characters (typically 8) that can be redefined at run-time. These eight characters are usually mapped to characters 0DEC (0x00HEX) to 7DEC (0x07HEX). The CGRAM definitions can be used to make small animations, bar graphs, and similar small graphic or sprite images. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780.

The CGROM stores the font that is displayed on a character LCD. When you tell a character LCD to display the letter ‘A’, it needs to know which dots to turn on so that we see an ‘A’. This information is stored in the CGROM. By definition, (since it is a ROM) the font that is stored in the CGROM cannot be changed. Be sure to check the datasheet of the character LCD module to make sure that it can display the characters you need. Typically, a CGROM for a character display module has 240 characters defined. The lower half of the CGROM maps to the normal ASCII characters. Since the early character display controllers were designed in Japan, many CGROM have Japanese characters in the upper 128 positions. There are also some CGROMs that have European or Cyrillic characters in these upper locations.

The WS0010 is a more modern character OLED controller, and the designers have included several CGROMs that can be chosen at run-time, so there is not the need to lock in a particular character set at design time. Since the CGROM is completely determined at the time of manufacture of the LCD controller, the designers also included a CGRAM, which allows the bitmaps of a few characters to be redefined at run-time. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780).

That part of color specification, which does not involve illuminance. Chromaticity is two-dimensional and specified by pairs of numbers such as dominant wavelength and purity.

A two-dimensional graph of the chromaticity coordinates, x as the abscissa and y as the ordinate, which shows the spectrum locus (chromaticity coordinates of monochromatic light, 380 nm-770 nm). It has many useful properties for comparing colors of both luminous and non-luminous materials.

A measurement of the color of light radiated by an object while it is being heated. This measurement is express in terms of absolute scale, or degrees Kelvin. Lower Kelvin temperatures such as 2400° K are red; higher temperatures such as 9300° K are blue. Neutral temperature is white, at 6504° K.

Small electronic circuits that provide voltages to the individual sub-pixel through the source lines. These are generally 8-bit driver circuits that provide 256 unique values per sub-pixel.

Cross – Talk is the defect produced by the interference of the adjacent pixels. The contrast of these crosstalk areas is different from other areas. Crosstalk can appear only with certain display patterns.

Fig.3 Top and bottom of a WL-CSP package sitting on the face of a U.S. penny. In the top-right, a SOT23 package is shown for comparison. Penny diameter: 19.05 mm (0.75 in).

Color STN Technology. Each pixel of a CSTN display is actually 3 separate colored pixels of Red / Green / Blue. Each of those colors are controlled individually by the graphic controller chip. In fact, a 320 by 240 pixel CSTN display actually contains 960 by 240 individually colored pixels

A capacitive touchscreen panel consists of an insulator such as glass, coated with a transparent conductor such as indium tin oxide (ITO). As the human body is also an electrical conductor, touching the surface of the screen results in a distortion of the screen’s electrostatic field,measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing.

A DC-to-DC converter is an electronic circuit which converts a source of direct current (DC) from one voltage level to another. It is a class of power converter. DC-to-DC converters are important in portable electronic devices such as cellular phones and laptop computers, which are supplied with power from batteries primarily. Such electronic devices often contain several sub-circuits, each with its own voltage level requirement different from that supplied by the battery or an external supply (sometimes higher or lower than the supply voltage). Additionally, the battery voltage declines as its stored energy is drained. Switched DC-to-DC converters offer a method to increase voltage from a partially lowered battery voltage thereby saving space instead of using multiple batteries to accomplish the same thing.

The Display Data RAM holds the letters that get shown on the LCD of a character LCD module. For instance, the letter ‘A’ is stored in its ASCII equivalent 65DEC (0x41HEX) in the DDRAM.

So a 20×2 character LCD would have enough DDRAM to store 40 letters. The value in the DDRAM is used to find the correct bitmap in the CGROM (Character Generator ROM) or CGRAM (Character Generator RAM), it is this small bitmap that gets displayed on the LCD. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780.

Translucent material used for light diffusion placed between backlight lighting sources and the back side of an LCD. This material will create a more uniform backlight for an LCD from several unique sources of light.

Apple has been granted a patent in 2011 that describes a method for fabricating thin DITO (Double-Sided Indium Tin Oxide) or SITO (Single-Sided Indium Tin Oxide) touch sensor panels with a thickness less than a minimum thickness tolerance of existing manufacturing equipment. In one embodiment, a sandwich of two thin glass sheets is formed such that the combined thickness of the glass sheets does not drop below the minimum thickness tolerance of existing manufacturing equipment when a thin film process is performed on the surfaces of the sandwich during fabrication. The sandwich may eventually be separated to form two thin SITO/DITO panels.

Another fabrication process involves laminating two patterned thick substrates, each having at least the minimum thickness tolerance of existing manufacturing equipment. One or both of the sides of the laminated substrates are then thinned so that when the substrates are separated, each is a thin DITO/SITO panel having a thickness less than the minimum thickness tolerance of existing manufacturing equipment.

EMI is disturbance that affects an electrical circuit due to either electromagnetic induction or electromagnetic radiation emitted from an external source. The disturbance may interrupt, obstruct, or otherwise degrade or limit the effective performance of the circuit. These effects can range from a simple degradation of data to a total loss of data. The source may be any object, artificial or natural, that carries rapidly changing electrical currents.

The sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. A buildup of static electricity can be caused by tribocharging or by electrostatic induction. The ESD occurs when differently-charged objects are brought close together or when the dielectric between them breaks down, often creating a visible spark.

ESD can create spectacular electric sparks (lightning, with the accompanying sound of thunder, is a large-scale ESD event), but also less dramatic forms which may be neither seen nor heard, yet still be large enough to cause damage to sensitive electronic devices. Electric sparks require a field strength above approximately 40 kV/cm in air, as notably occurs in lightning strikes. Other forms of ESD include corona discharge from sharp electrodes and brush discharge from blunt electrodes.

ESD can cause harmful effects of importance in industry, including explosions in gas, fuel vapor and coal dust, as well as failure of solid-state electronics components such as integrated circuits. These can suffer permanent damage when subjected to high voltages. Electronics manufacturers therefore establish electrostatic protective areas free of static, using measures to prevent charging, such as avoiding highly charging materials and measures to remove static such as grounding human workers, providing antistatic devices, and controlling humidity.

Refers to a graphic controller from Bridgetek/FTDI. EVE graphic controllers are easy to use and can control the display, touch, backlight, and audio features of an embedded system, with each appearing to the host MCU as a memory-mapped SPI device. The host MCU sends commands and data using SPI protocol. EVE modules accept high level commands, simplify writing images and fonts (included angled fonts) on TFTs. Fonts, buttons, and tables can each be easily sent to a TFT using a one-line command.

Electroluminescence (EL) is an optical phenomenon and electrical phenomenon in which a material emits light in response to the passage of an electric current or to a strong electric field.

A silicone rubber strip made up of sequentially spaced conductive and non-conductive material. A thin conductive material used to make connections between an LCD and a PC board.

A dead short is created when excess DC voltage is applied to an LCD. Conductive particles from one piece of glass are transferred through the liquid crystal fluid and deposited on the conductive surface of the opposite piece of glass.

Typical FETs are nearly perfect switches. Next to no current flows when they are off, and they drop only minuscule voltage when they are on. An N-FET (N-Type Field Effect Transistor) is typically used to switch a load to ground. The gate of a Logic Level N-FET can be driven by a 3.3v or 5v logic output (GPIO) of a microcontroller. A P-FET (P-Type Field Effect Transistor) is used to switch a load to a positive voltage, like 3.3v or 5v or more. Typically, you need to use a pull-up resistor and a small N-FET to create the gate drive for the P-FET.

Refers to any variety of electrical cable that is both flat and flexible, with flat solid conductors. A flexible flat cable is a type of flexible electronics. However, the term FFC usually refers to the extremely thin flat cable often found in high-density electronic applications like laptops and cell phones.

The space left between the epoxy seals on one end of the LCD glass after assembly. This space,used to fill the glass with the liquid crystal fluid, is noted by a mound of epoxy.

An LCD construction technique where the cell geometry is optimized for maximum contrast and viewing angle. The geometry is different for each LCD fluid.

Also known asflex circuits, is a technology for assembling electronic circuits by mounting electronic devices on flexible plastic substrates, such as polyimide, PEEK or transparent conductive polyester film. Additionally, flex circuits can be screen printed silver circuits on polyester. Flexible electronic assemblies may be manufactured using identical components used for rigid printed circuit boards, allowing the board to conform to a desired shape, or to flex during its use. An alternative approach to flexible electronics suggests various etching techniques to thin down the traditional silicon substrate to few tens of micrometers to gain reasonable flexibility.

Screen luminance as a function of video voltage approximately follows a mathematical power function of the input video signal, the exponent of which is called gamma.

Capacitive touch can be classified into glass- or film-substrate produced. Glass-substrate capacitive touchscreens are found in Apple’s iPhone and Samsung’s Galaxy S phone. The iPhone uses a glass-glass (GG) structure that forms the X-axis sensing electrode on the upper surface of a glass substrate and Y-axis sensing electrode on the bottom. While Apple’s GG method and other mobile phone makers’ glass/film (GF/GFF) designs are becoming mainstream, attempts to develop products such as G1F, and OGS (One Glass Solution) with better transmittance and thinness will continue. OGS is cover window integrated touch, which does not require separate touch sensor.

The advantages of GFF are low capital cost, suitable for small quantity batch production, and light structure. GG is suitable for mass production and has better appearance properties, but it has high investment costs and is heavier than film-based panels.

Grayscale is a range of shades of gray without apparent color. The darkest possible shade is black, which is the total absence of transmitted or reflected light. The lightest possible shade is white, the total transmission or reflection of light at all visible wavelengths. Intermediate shades of gray are represented by equal brightness levels of the three primary colors (red, green and blue) for transmitted light, or equal amounts of the three primary pigments (cyan, magenta and yellow) for reflected light.

HDMI means it is able to send a lot of data, very quickly. However, HDMI isn’t an analog communication like VGA, S-Video or parallel like 24-bit or 18-bit RGB TFTs. HDMI is actually a high-speed serial interface using a fancy TMDS (Transition Minimized Differential Signaling) protocol.

Unlike SPI where 1-bit is transferred per clock cycle, HDMI transfers 10-bits per clock cycle which further increases the bandwidth. The clock can be anywhere from 25 MHz all the way to 340 MHz. This intense bandwidth allows HDMI standard to support up to an amazing 48 bits of color depth (that’s dense!).

For embedded applications, the typical color depth and resolution are well within HDMI’s capabilities. The important thing about HDMI embedded displays is that they give you an easy way to connect an embedded display to the now small and low-cost embedded computers, such as a Raspberry Pi, or an Intel Compute Stick.

The main attribute of a color that distinguishes it from other colors. For example, a color may have a green, yellow, or purple hue. Colors defined as having hue are known as chromatic colors. White, black, and grays possess no hue.

In a typical I2C application, there will be one master, and one or more slaves. The specification allows for multiple masters, but this is not common in the field. I2C has two signals: SCL: Serial Clock; SDA: Serial Data. The I2C transfer includes an address, so multiple slaves can exist on the same I2C bus.

Typically, both the master and slave are implemented in hardware. The I2C master can be implemented in software quite easily, but it can be rather difficult to meet the timing requirements of I2C in a software slave implementation. As micro controllers continue to get faster, writing an I2C software slave will become easier. The I2C standard is pretty well defined, so there is not a huge amount of variation in I2C as it is implemented on LCD, capacitive touch and OLED controllers.

An in-cell display is a touch display in which the touch sensors are embedded within the screen. Traditional capacitive touchscreens have multiple layers of glass, including a capacitive touchscreen layer. In-cell displays eliminate the need for these external touch panel. This results in a thinner and lighter display than a comparative display with an external touch panel, enabling a sleeker final product for devices using an in-cell display.

The point where the fluid heats or cools to where it is no longer in the twisted nematic state. Since the molecules can no longer twist light, all incoming light is absorbed.

Indium tin oxide (ITO) is one of the most widely used transparent conducting oxides because of its two main properties: its electrical conductivity and optical transparency, as well as the ease with which it can be deposited as a thin film. As with all transparent conducting films, a compromise must be made between conductivity and transparency, since increasing the thickness and the concentration of charge carriers increases the material’s conductivity, but decreases its transparency. Thin films of indium tin oxide are most commonly deposited on surfaces by physical vapor deposition. Often used is electron beam evaporation, or a range of sputter deposition techniques.

An LCD is composed of two pieces of glass with a thin layer of liquid crystals between the glass layers. When a voltage is applied to the glass, the orientation of the crystals can be changed. This change in the crystal’s orientation (called polarization) will make either a dark or a light area, creating a character or image on the display.

A Light-Emitting Diode (LED) is a two-lead semiconductor light source which emits light when activated. When a suitable voltage is applied to the leads, electrons are able to recombine with electron holes within the device, releasing energy in the form of photons. This effect is called electroluminescence, and the color of the light (corresponding to the energy of the photon) is determined by the energy band gap of the semiconductor.

Many of today’s portable electronics require backlight LED-drivers with the following features: direct control of current, high efficiency, Pulse-Width-Modulation (PWM) dimming, over-voltage protection, load disconnect, small size, and ease of use.

By driving LED light sources with a regulated constant-current power supply the light output variation and lifetime issues resulting from voltage variation and voltage changes can be eliminated. Therefore, constant current drivers are generally recommended for powering LED light sources.

A measure of the brightness or luminous intensity of light, usually expressed in units of Candelas per square meter (cd/m2) or foot Lamberts. 1 fL = 3.426 cd/m2.

A twisted nematic LCD design where the backlight is blocked when pixels are in the unselected state. Therefore, when no voltage is applied, the screen is black.

A twisted nematic LCD design where light is transmitted when pixels are in the unselected state. Therefore, when no voltage is applied, the screen is white.

OCA is also called dry bonding. Optical bonding, including LOCA (Liquid Optically Clear Adhesive) and non-liquid OCA tape, are used in a wide range of electronic equipment – especially those with touch panels. The adhesive is used to bond the touch panel to the main liquid crystal display, and also to bond any protective cover, such as the lens, to the touch panel. The adhesive is then cured onto the device through UV, heat, moisture, or a combination of these three methods, depending on the manufacturer and specifications. Major applications include capacitive touch panels, 3D televisions (3D TV), and glass retarders.

Optical bonding improves the optical performance of the display. It eliminates the air gap between the cover glass and the LCD, and usually includes an anti-reflective (A/R) coating (as well as anti-smudge and anti-glare treatments on the cover glass). Optical bonding improves the contrast ratio by reducing the amount of reflected light, thus improving the viewability of the LCD screen. This is especially important in outdoor.

Besides the optical advantages, bonding a sheet of glass to the LCD also improves the durability of the display. It can resist scratches, condensation, and has an improved range of operating temperatures. As touchscreen devices become ubiquitous in consumer markets, this increased ruggedness becomes even more important. Also, by reducing the light loss due to reflection, the battery life of the device can be extended as the device does not need as much backlight to power the display.

One Glass Solution is a touchscreen technology which reduces the thickness of a display by removing one of the layers of glass from the traditional capacitive touchscreen stack. The touch sensor is made directly on the cover lens.

On-Cell Touch (OCT) technology permits the Projected Capacitive (PCAP) touch sensor layer to be built into the LCD structure. With this integrated structure, the touch functionality is embedded within the display itself rather than a separate touch screen component on top of the display. The reduction in the number of layers also reduces parallax errors providing a superior touch interface. Fewer layers also means backlight intensity can be reduced while providing the same brightness level. The usual multitouch display has an 88% transparency while an OCT display is 93%. This helps reduce lighting power requirements and extends battery life.

For optical bonding optically clear adhesive is applied over the entire surface between the display assembly and touch panel. This bonding method removes all air and air bubbles from the viewing area providing a more rugged and optically attractive solution. Removal of ‘air gap’ between the module and touch panel eliminates surface-to-surface reflections which degrade contrast and ultimately viewing angles, especially significant in sunlight conditions.

A printed circuit board (PCB) mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.

Printed circuit boards are used in all but the simplest electronic products. They are also used in some electrical products, such as passive switch boxes.

A circuit board prior to assembly of electronic components is known as PCB. Once electronic components are soldered, the board is called Printed Circuit Assembly (PCA) or Printed Circuit Board Assembly (PCBA) or PCB Assembly. Different Manual and Automatic PCB Assembly Tools are used in this process.

PCN stands for Product Change Notification. A product change notification (PCN) is a document issued by a manufacturer to inform customers about a change to a mass-produced product or its manufacturing process.

Passive Matrix refers to the arrangement of the driving electrodes in the OLED display. In PMOLED displays, there is an array of horizontal conductors and an array of vertical conductors, with the OLED material between them. A pixel is formed where the vertical and horizontal conductors intersect.

A method of storing a full-color pixel in a single 16-bit word of memory. For each pixel, the red and blue channels can take on 32 levels, encoded as 5 bits each. The green channel can take on any of 64 levels, encoded as 6 bits. Theoretical color depth is 216 or 65,536 colors.

This is memory that may be written to some value, then later read. RAM is the normal memory in a computer system. RAM only holds data when the RAM is powered. If power is interrupted, the data stored in the RAM is lost.

The number of times per second the screen is refreshed or redrawn. This number is usually stated in Hz (Hertz) or cycles per second. A rate of 60 Hz is equal to 60 times per second.

A resistive touch screen is made of two transparent layers of glass or plastic, each coated with a conducting layer of Indium Tin Oxide (ITO). The conducting sides face one another and are separated by an air gap. When pressure is applied by the user, the top layer bends and touches the bottom layer. This causes a small amount of current to flow at the point where they connect. The location of the touch event can then be measured by the sensors.

In this variant, if the top sheet has electrodes for the vertical direction (Y), the bottom sheet will have electrodes for the horizontal direction (X). The top and bottom sheets measure each others’ voltages and based on that sensors can determine the location of the touch point.

In this variant, the voltage of the bottom sheet is measured by the top sheet, with electrodes placed at four corners of the bottom sheet. The top sheet does not have any electrodes.

These screens are similar to Analog 4 wire screens. The only difference is an extra set of electrodes, which automatically take care of alignment and recalibration issues that crop up in the 4 wire screens over long term use.

A technique where the alignment layer (Polyimide) on the LCD substrate is rubbed in one or more directions. This process aligns the liquid crystal molecules parallel to the buffing direction.

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of PCBs. An electronic device so made is called a surface-mount device (SMD). In the industry it has largely replaced the through-hole technology construction method of fitting components with wire leads into holes in the circuit board. Both technologies can be used on the same board for components not suited to surface mounting such as large transformers and heat-sink power semiconductors.

An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

SPI is a simple serial bus that is often used by LCD or OLED controllers. SPI as implemented for OLED and LCD controllers typically uses a “3-wire SPI” or “4-wire SPI” scheme. SPI was originally championed by Motorola (now Freescale). In its original “pure” form SPI uses four signals:

Each pixel is made up of three independently controlled sub-pixels. In a color display these sub-pixels have red, green, or blue color filters. Or, in the case of a grayscale display, each sub-pixel will have a clear transparent filter, allowing the full grayscale range to be displayed. Each sub-pixel is capable of generating different intensities, creating a range of colors or grayscale values, which is perceived as a mixture of each sub-pixel value.

Tape-automated bonding (TAB) is a process that places bare integrated circuits onto a flexible printed circuit board (FPC) by attaching them to fine conductors in a polyamide or polyimide film, thus providing a means to directly connect to external circuits.

TFTs are also known as “Active Matrix TFT LCD modules” and have an array of these thin film transistors fabricated on the glass that makes the LCD. By using this active transistor-per-pixel architecture, the contrast of each pixel is good, allowing bright full-color, full motion images to be displayed.

USB is an industry standard developed in the mid-1990s that defines the cables, connectors and communications protocols used in a bus for connection, communication, and power supply between computers and electronic devices.

VA is also called VTN, PMVA, GDV, etc. it is a type of LCD in which the liquid crystals naturally align vertically to the glass substrates. When no voltage is applied, the liquid crystals remain perpendicular to the substrate, creating a black display between crossed polarizers. When voltage is applied, the liquid crystals shift to a tilted position, allowing light to pass through and create a gray-scale display depending on the amount of tilt generated by the electric field. VA displays have a deeper-black background, a higher contrast ratio, a wider viewing angle, and better image quality at extreme temperatures over traditional twisted-nematic displays.

Short for Zero Insertion Force connector. This kind of connector is intended to be used with FPC (Flexible Printed Circuit) or FFC (Flat Flexible Cable). Typically, a ZIF connector has a movable element that can be opened or closed. In the open position FPC/FFC can be easily slid in, then the connector is closed to make firm contact.

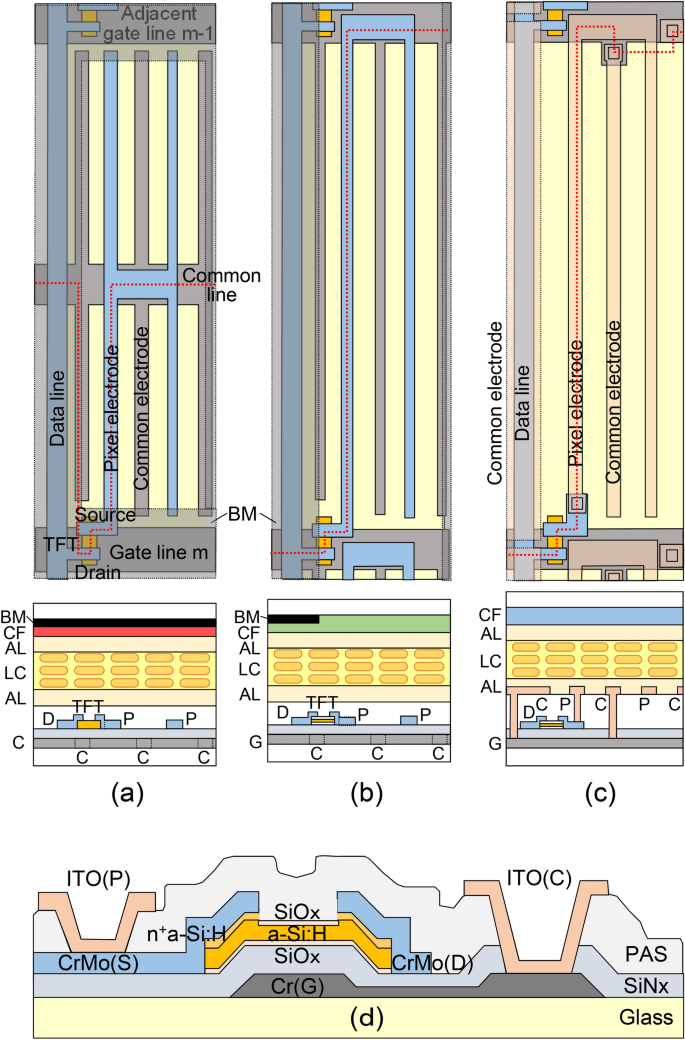

Thin-Film Transistor Liquid Crystal Displays use thin-film transistors to control the voltage applied to the liquid crystal layer at a sub-pixel level. The structure of TFT LCDs consists of a TFT “sandwich” and a BLU (Backlight Unit). A typical configuration is shown in the schematic diagram below.

Firstly, between the back and front polarizers, TFT LCD cells are made with two glass substrates – one for color filters, the other for a TFT array – and a liquid crystal layer sandwiched in between.

Secondly, BLU (Backlight Unit) usually consists of three components: BEF (Brightness Enhancement Film), DBEF (Dual Brightness Enhancement Film), and LGP (Light Guide Plate).

For normally black TFT LCDs, if we follow along a piece of light setting off from its backlight source, it will bea)guided uniformly by LGP;b)reflected and enhanced by BEF and DBEF;c)polarized by the back polarizer;d)polarization changed by twisted LC under the voltage applied by TFT arrays;e)“tinted” red/green/blue by corresponding color filter of the subpixel;f)let through the front polarizer by matched polarization; andg)finally, it will reach the surface and appears in viewer’s eyes.

For normally white panels, processd)will be the opposite – known as the polarization rotation effect, light is twisted in a voltage-off stage and can pass through the front polarizer by default, thus displaying white normally. However, when the voltage applied increases, this polarization rotation effect would be gradually diminished. And the light would not be able to pass through the front polarizer anymore without changing its polarization. In this way, certain pixels will appear in different colors.

Normally black LCDs have higher contrast and wider viewing angles without grayscale inversion phenomenon compared to their normally white relatives. And whether TFT LCDs are normally black or white depends on their LC switching mode:

2Chen, HW., Lee, JH., Lin, BY.et al.Liquid crystal display and organic light-emitting diode display: present status and future perspectives.Light Sci Appl7,17168 (2018).https://doi.org/10.1038/lsa.2017.168

Schematic diagram of the (a) TN mode, (b) VA mode, (c) FFS mode, and (d) IPS mode. *LC orientations shown are under applied voltages. C/F stands for the color filter.

As previously mentioned, TN mode functions with the polarization rotation effect. Under traditional TN/VA display mode, the liquid crystal molecules are vertically arranged, with a relatively narrow visual angle. When an external force is exerted on the screen, the liquid crystal molecular structure will sink in a herringbone pattern to slowly recover – a pattern called vertical alignment. Therefore, an evident “water ripple” usually appears when the display surface is touched and impacts the user experience. In comparison, the VA mode provides higher contrast. And MVA (multi-domain vertical alignment) is an upgraded version of VA with improved viewing angles.

Under IPS mode, the LC directors are horizontally (homogeneously) aligned, which makes them free from ripple effects when made into touch panels. The drawback is lower transmittance, especially for LCs in a “dead zone”close to electrodes.

In an FFS cell, LC molecules rotate in both vertical and horizontal dimensions, enabling excellent viewing angles, high transmittance, low driving voltage/power consumptions, and high contrast ratio.

3 Yang DK, Wu ST.Fundamentals of Liquid Crystal Devices. 2nd edition. New York, USA: John Wiley & Sons. 2014.4 BOE ADSDS Ultra Hard screen Technology, Restoring Real and Beautiful Life. 2020 BOE Technology Group Co., Ltd. Retrieved December 01, 2020, fromhttps://www.boe.com/en/cxkj/boecx/boecxxqy/dynamic/pecbbd751.html

LG Display"s oxide TFT technology can be applied to various display products. Since its performance is more than 50 times higher than that of the existing a-Si TFT, it can be applied to the entire product lines from mobiles to laptops and large TVs.

By reducing the size of the TFTs that make up individual pixels and increasing their performance, a display with high resolution and rich colors can be achieved.

By applying oxide TFT, the size of the circuit part of the panel outside the screen can be drastically reduced, making it possible to create a slim design display.

Oxide TFT is highly energy-efficient because the leakage current is very small when the screen is not working, so it can extend the battery life of notebooks or tablets.

LG Display is a pioneer in the industry"s first successful mass-production by researching and developing oxide TFT technology for the longest period of time. LG Display guarantees product reliability that customers can trust and use for a long time.

in-TOUCH products with built-in touch function can maintain slim design and superior image quality compared to add-on (out-cell) touch products with added touch electrodes. It is a technology unique to LG Display that can be applied not only in IT but also in various fields such as home application, health, industrial, and medical products. in-Touch has a built-in touch electrode in the LCD, optimized for slim & light products that can perform touch operation without additional touch electrodes or cover glass.

LG Display"s IT Mini LED technology is combined with IPS technology to realize high contrast ratio, color gamut, wide viewing angle, and image quality of HDR 1000 or higher.

Sony Corporation and Chi Mei Optoelectronics have agreed on the basic terms of a transaction whereby Sony will acquire CMO" s wholly-owned Japanese subsidiary, International Display Technology.

Sony and CMO have agreed that Sony will purchase all the shares of a new company spun-off from IDTech. Sony plans to produce low-temperature polysilicon thin film transistor liquid crystal (LTPS-TFT-LCD) display panels in the new company. The acquisition price has been set at approximately 18.5 Billion Japanese Yen for all the shares of the new company and includes purchase of all of the production equipment, facilities, and personnel at IDTech"s plant in Yasu-shi, Shiga prefecture, Japan.

IDTech is a world leader in the design, development, and production of amorphous silicon thin film transistor liquid crystal (a-Si TFT LCD) displays. Among IDTech"s leading edge products are the world"s highest resolution TFT LCDs for medical displays, wide-angle view in-plane switching (IPS) display monitors, twisted nematic LCD notebook displays, and specialized TFT substrates.

The IDTech facility will complement Sony"s present LTPS-TFT-LCD manufacturing base, which was established in 1997 as the STLCD Corporation, a joint venture between Sony and Toyota Industries Corporation, for the production of LTPS TFT LCD display panels for mobile products, such as cell phones and cameras. A second production line at STLCD was completed in 2002 in which production was expanded to 40,000 (600x720mm) base plates per month; Sony expects to continue the expansion of production and its acquisition of IDTech is part of those plans.

Sony will make an investment for equipment and facility modification of approx. 27 Billion Yen level, leading to building a manufacturing facility with production capability of 25,000?i550x650mm?j base plates /month. This will lead to further enhance the business in the field of LTPS-TFT-LCD display panel for use in mobile products, such as mobile phones. The name of the new company is due to be decided by the end of Mar.2005, when the necessary procedures for the acquisition and new company formation is planned to be completed. The commercial base mass production for LTPS-TFT-LCD display panel is scheduled to start from Apr. 2006.

CMO acquired IBM"s Third Generation TFT LCD plant in 2001, and formed IDTech in a precedent-setting Taiwan-Japan joint venture. From this acquisition, CMO has successfully leveraged IDTech"s leading technology, its skilled workforce, advanced management system, global logistics system and profitable customer base, which provided a strong starting base for CMO"s LCD production in a very competitive industry. Since that time, CMO has been aggressively building its next generation fabs. in Taiwan, including a 5.5 Generation fab., which will begin mass production this year. Because of the fact that the new fabs. will operate with new state-of-the-art equipment and greater efficiency, to better manage its total production capacity, CMO ultimately agreed to sell IDTech"s Yasu fab. to Sony.

“The sale of IDTech will in no way lessen our commitment to our customers, rather it will improve our customer relations because of improved efficiency. The sale to Sony was based on CMO and Sony"s strong business relationship, particularly in the area of LCD business. We are glad we can help Sony to strengthen its production capacity in the mobile devices business. We firmly believe that IDTech"s production capabilities together with Sony"s world-class management and technology will fulfill Sony"s plans.”

”LTPS-TFT-LCD display panels are used in various mobile products such as video cameras, digital still cameras and mobile telephones and we expect the market to dramatically grow from now onwards as well. The basic agreement with CMO and IDTech this time leading to the acquisition of Yasu Business Facility, IDTech will further expand Sony"s mobile display production and will strengthen the business. Through the succession of the personnel asset of Yasu Business Facility, we target to promptly launch Sony"s 2nd manufacturing base following STLCD Corporation, leading to the supply of excellent products to customers in the world.”

This agreement has been well-accepted by Toyota Industries Corporation as well, and initial capital participation by approximately 20% is being considered. From the cooperation by Toyota Industries Corporation, Sony will target the technology convergence of the new company and STLCD Corporation, leading to the build-up of an enhanced quality and production efficiency in the LTPS-TFT-LCD display panels production line to better satisfy the customers" needs.

We supply optimum quality 12 INCH TFT with A/D Card facility which is procured from established vendors across the world. Our auto display cards find its applications in medical instruments, for variousread more...

2711P PanelView™ Plus 7 Graphic Terminals are available in standard and performance versions. Our performance versions are available in conformal coat, stainless steel and on-machine (ArmorView™ Plus 7) options, offering flexibility to meet your specific needs.

Sahakar nagar, Bengaluru Building Number 216/2, 2nd Floor, 10th Cross, F Block, 14th Main Cantt Sahakar Nagar, Sahakar nagar, Bengaluru - 560092, Dist. Bengaluru, Karnataka

Urban, Bengaluru No. 19, Mobas Towers Opp Ramakrishna Ashram Above Pizza Hut Bull Tem, V V Puram, Urban, Bengaluru - 560019, Dist. Bengaluru, Karnataka

Bengaluru No. 4 AM 402, I Floor, 4th A Main, Kasturi Nagar East Of NGEF, Kasturi Nagar, Ramamurthy Nagar Main Road, Bengaluru - 560016, Dist. Bengaluru, Karnataka

Mitsubishi Electric"s thin-film-transistor liquid-crystal display (TFT-LCD) modules are built for a wide variety of industrial uses, such as for measuring instruments, automatic teller machines (ATM), point of sale terminals (POS), factory automation equipment (FA) and more. Designed for high reliability, optimal visibility,read more...

Bommanahalli, Bengaluru 172/800/788, Ground Floor, Mahalaxmi Complex, 12th E Main, Kaveri Nagar, DC Halli Main Road, Bommanahalli, Bengaluru - 560068, Dist. Bengaluru, Karnataka

2.4 Inch Touch Screen TFT Display Shield adds a touch up to your Arduino project with a beautiful large touchscreen display shield with built-in micro SD card connection. This TFT display is big (2.4 diagonal) bright and colorful! 240320 pixels with individual pixel control. It has way more resolution than a black and whiteread more...

YELAHANKA NEW TOWN, Bengaluru 3rd Floor, LIG 3 stage No. 2232 16th B Cross, Yelahanka new town OPP. HDFC ATM, YELAHANKA NEW TOWN, Bengaluru - 560064, Dist. Bengaluru, Karnataka

Malleshwaram, Bengaluru No. 83, 4th Main, Between 8th & 9th Cross No. 83, 4th Main, Between 8th & 9th Cross, , Malleshwaram, Bengaluru-560003, Karnataka,India, Malleshwaram, Bengaluru - 560003, Dist. Bengaluru, Karnataka

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey