a si tft lcd cell manufacturer

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

These products are all widely used in various industries such as in medicine, home security, automotive, energy field solar charging, and domestic equipment use.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

The company started in 1983 as a corporate spin-off from the American oscilloscope company Tektronix. In 2015, Planar Systems became a subsidiary of the Chinese manufacturer Leyard Optoelectronics.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

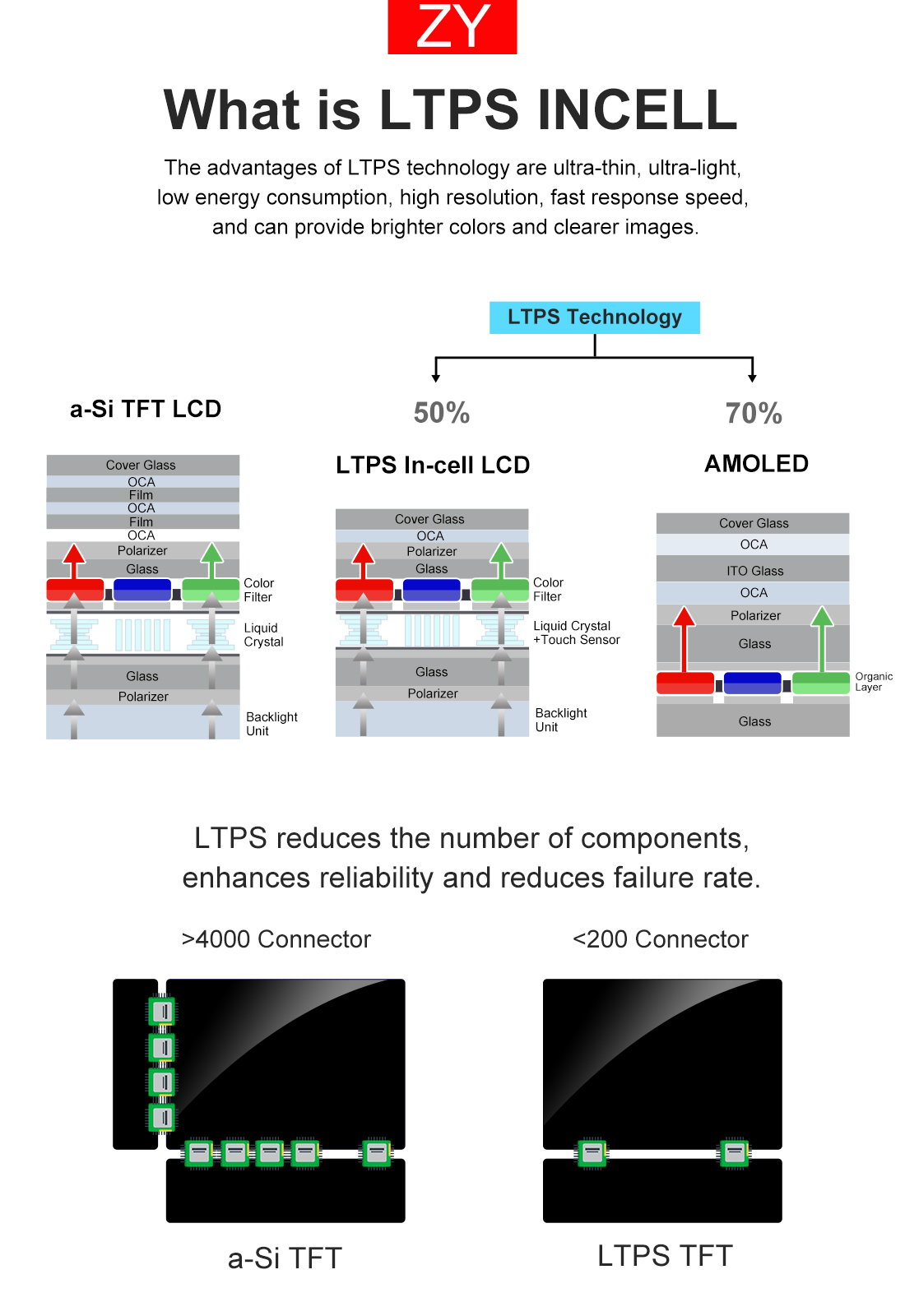

According to LCD (Liquid Crystal Display) technology and LCD materials, mobile phone LCD assemblies can be classified into 2 types: TFT (Thin Flim Transistor) and OLED(Organic Light-Emitting Diode). TFT display needs with backlight, but OLED is light-emitting, each pixel is creating its own light.

For Original iPhone LCD, 5-8 plus and Xr, 11 is TFT, X-13 Pro Max is OLED (except XR and 11). But in mobile phone aftermarket, there are too many different types and different qualities, which makes customers confused.

What is in-cell? What is OGS or " with TP"? What is COF? What is COG? What is OEM? What is FOG? What is Original Change Glass? What is IPS? What is LTPS? What is a-Si?

HTPS with small size, high precision, and high contrast. Most used in magnified display products. Such as projectors, projection TVs, etc. And cannot be used as a mobile phone display, so we don"t talk about it here.

IGZO has 20–50 times the electron mobility than a-Sin. IGZO only has been licensed to Samsung Electronics and Sharp. However, it was Sharp who first implemented IGZO into their smartphones (Aquos Phone Zeta SH-02E), tablets, and 32-inch LCDs. IGZO for mobile phones is only Sharp. Almost all mobile phones on the market didn"t use IGZO.

Because the electrons deflect the liquid crystal molecules through the transistor. Electron mobility fundamentally determines the refresh rates of the TFT device. The smaller mobility, the slower transmission of holes and electrons, and the slower response rate. Can"t physically support high refresh rates.

In order to improve the response performance, can increase transistor size to enhance the migration, but this will lead to the extra TFT device that will occupy the display area pixel area. Therefore, the larger unit transistor area, the single-pixel occupy area is smaller(Pixel Aperture Ratio ), resulting in lower brightness.

Secondly, because the volume cannot be smaller, then the number of pixels per unit area is limited, which means the pixel density is small, which is what we call PPI is low, resulting in low resolution. The image needs to be zoomed, the original image data is lost, and resulting in the blurred image effect.

As we can see electron mobility of a-Si is very low (0.5-1cm2/Vs). But LTPS can deliver a hundred times the mobility than a-Si, and a much higher aperture ratio and PPI is much higher than a-Si resolution.

Compared with LTPS,a-si TFT have those "weakness":a-Si with so much low resolution and low definition. a-Si is 720*1280 with a very blurred display effect.

a-Si with so much bad display performance, but why are there still so many manufacturers producing phone LCDs with a-Si, or why do the customers willing to use a-Si LCD for their phone?

LCDs business has too much competition and wholesalers want to make more profit, they keep pushing suppliers to make LCDs at lower prices. So some of the suppliers start to produce aftermarket phone displays with a-Si to match customers" lower price requirements.

The customers with asymmetric information. End-Users don"t know how to distinguish LCDs qualities. Some of them just chase the price but not quality. That is another reason wholesalers want a lower price.

Now in the market a-Si LCDs for iPhone is TFT with TP but not in-cell. Our ZY a-Si will be in-cell not just TFT with TP. ZY a-Si incell for Xr and 11 ready now, please to get more details.

For more details or questions about in-cell and TFT with TP or about phone LCD display. Please click here to get more information, or Long press and scran the QR code to add me.

The most common semiconducting layer is made of amorphous silicon (a-Si). a-Si thin film transistor - liquid crystal display (TFT-LCD) has been the dominant technology for the manufacturing of active matrix TFT-LCD for over 20 years. a-Si is a low cost material in abundant supply.

a-Si is a low cost material in abundant supply. However, the electron mobility of a-Si is very low (around 1cm2/Vs) and can’t physically support high refresh rates such as the 240Hz needed for HDTV. Due to their high electron mobility, new materials such as metal oxide (MO) and low temperature polysilicon (LTPS) are now replacing a-Si to manufacture the industry’s two main types of screens: LCD and organic light-emitting diode (OLED) displays.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Panox Display provides free connectors for clients who purchase more than five products from us. Our product range includes connectors from Molex, Kyocera, AXE, AXG, JAE, Hiros, and more.

Panox Display provides a customized cover glass/touch panel service. We supply cover glass from Gorilla, AGC, and Panda, which all have excellent optical performance. We also supply driver ICs from Goodix and Focaltech.

If your applications are directly connected to a PC, a cellphone, or Raspberry Pi, and you have enough space to insert a board to input video, Panox Display can provide customized Controller/Driver boards with input connections for VGA, HDMI, DVI, DP, Type-C video input, MIPI, RGB, LVDS, and eDP.

The functions of our boards include, but are not limited to, adjustment of brightness, sound output, touch interface, extra data transmission, and gyroscope.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

2015, sold to giantplus and tce photomasks, gen 3 still operated by giantplus, gen 4 line sold to giantplus, equipment sold and line demolished, remainder operated by tce

Cantwell, John; Hayashi, Takabumi (January 4, 2019). Paradigm Shift in Technologies and Innovation Systems. Springer Nature. ISBN 9789813293502 – via Google Books.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

www.wisechip.com.tw. "WiseChip History – WiseChip Semiconductor Inc". www.wisechip.com.tw. Archived from the original on 2018-02-17. Retrieved 2018-02-17.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Pooler, Michael (29 September 2015). "Subscribe to read". Financial Times. Archived from the original on 2019-10-25. Retrieved 2019-10-25. Cite uses generic title (help)

TFT-LCD Panel manufacturer lines from ICS Components are Samsung (SEC), Samsung Mobile Display (SMD), LG Display (LGD), AUO, Chimei-Innolux (CMI), Mitsubishi and Tianma. Our keen knowledge of TFT-LCD industry has helped us develop solutions that answer the needs of our world-wide clients. These solutions allow you to Increase productivity, reduce operating costs, and increase customer satisfaction. ICS offers;

A leading innovator of TFT-LCD technology, LG Display will show a full line-up of Advanced High Performance In-Plane Switching (AH-IPS) products. The AH-IPS panels deliver ultra-high resolution, notable for their superiority in use for smartbooks(tablet PCs) and smartphones.

AH-IPS technology, an advanced form of IPS, has realizes 1.5 to 2 times the resolution of typical LCD panels. This ultra-high resolution becomes particularly valuable when the emphasis is on displaying highly detailed images. The technology also improves display"s color accuracy, which in turn leads to reproduce the original color precisely without color distortion. In addition, it provides greater light transmission which translates into lower power consumption while delivering exceptional picture quality, making it ideal for use in outdoor settings.

Chi Mei originally established in 2003 and publicly listed in 2006, Innolux Display Corp., following its merger with Chi Mei Optoelectronics and TPO Displays Corp., began operating under the name Chimei Innolux Corporation (CMI) in March 2010. With products spanning the full range of TFT-LCD panel modules and LCD display products, including TV panels, desktop monitors and notebook computer panels, AV & mobile panels, desktop monitors and televisions, Chimei Innolux is a world-leading TFT-LCD supplier to cutting-edge information and consumer electronics product makers worldwide.

AU Optronics Corp. (AUO) is a global leader of thin film transistor liquid crystal display panels (TFT-LCD). AUO is able to provide customers with a full range of panel sizes and comprehensive applications, offering TFT-LCD panels in sizes ranging from 1.2 inches to greater than 71 inches. AUO generated NT$467.2 billion in sales revenue in 2010 (US$16 billion) with global operations in Taiwan, Mainland China, Japan, Singapore, South Korea, the U.S., and Europe. Additionally, AUO is the first pure TFT-LCD manufacturer to be successfully listed at the New York Stock Exchange (NYSE). AUO extended its market to the green energy industry in late 2008. The Display and Solar businesses were established respectively as the Company"s two core businesses in October, 2010.

Tianma Micro-electronics Co. was founded in 1983 and in publicly traded on the Shenzhen Stock Exchange (SZ.000050) since 1995. They specialize in the design, manufacturing, and supply of high quality LCD and LCM products. The front to backend operations are completely in-house spanning from Research & Development, Design to Manufacturing, and Production to Sales with 27+ years of experience and strong growth. Affiliated companies within our Tianma Group, include Shenzhen Tianma, Shanghai Tianma, Shanghai AVIC, Chengdu Tianma, and Wuhan Tianma; combined to make up our state-of-the-art STN-LCD, CSTN-LCD, TFT-LCD, AMOLED, and CF production lines. Our branch offices include Tianma USA, Tianma Europe, and Tianma Korea to offer world-class global support.

Tianma supports a wide range of applications in Mobile Phone, MP3/MP4, Automotive, Industrial, Medical, Home Automation, and others. They are fully capable of custom design display to meet customers’ need around the world. They are the leader of small-to-medium size displays in Technology, Quality, Competitive Pricing, and long-term Support.

A not-for-profit organization, IEEE is the world"s largest technical professional organization dedicated to advancing technology for the benefit of humanity.

A not-for-profit organization, IEEE is the world"s largest technical professional organization dedicated to advancing technology for the benefit of humanity.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Wider viewing angles are not always welcome or needed. Image you work on the airplane. The person sitting next to you always looking at your screen, it can be very uncomfortable. There are more expensive technologies to narrow the viewing angle on purpose to protect the privacy.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

What you need to choose is AMOLED for your TV and mobile phones instead of PMOLED. If you have budget leftover, you can also add touch screen functionality as most of the touch nowadays uses PCAP (Projective Capacitive) touch panel.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

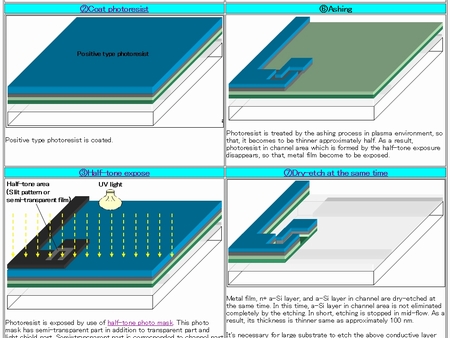

TFT LCD screen has always been the mainstream in the display industry, and its longevity is by no means accidental. It has achieved brilliant results in terms of luminous efficiency, full color, and life, and it is still being deepened. . What are the specific parts of its manufacturing process? Below, Youyi Vision will briefly introduce you:

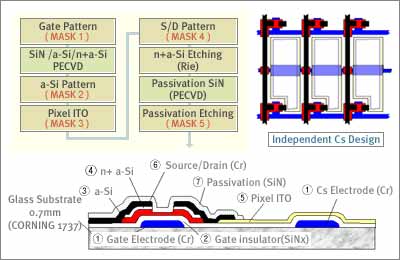

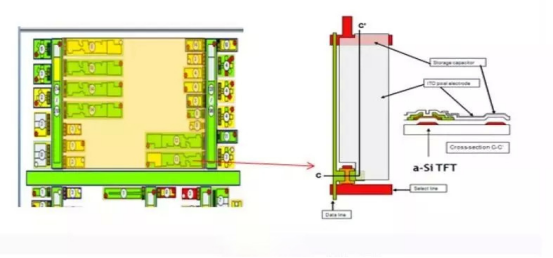

The manufacturing process of TFT LCD screen has the following parts: forming a tft array on a tft substrate; forming a color filter pattern and an ito conductive layer on a color filter substrate; forming a liquid crystal cell with two substrates; installing peripheral circuits and assembling a backlight And other module assembly.

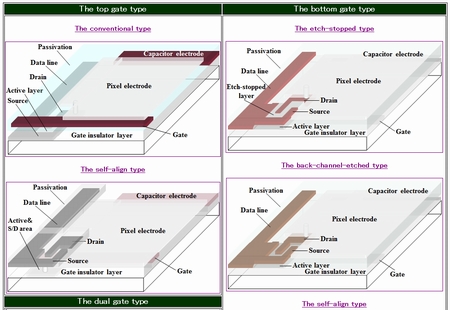

The process of forming a tft array on a tft substrate has realized industrialization of tft types including: amorphous silicon tft (a-si tft), polysilicon tft (p-si tft), monocrystalline silicon tft (c-si tft) ) Several kinds. Currently the most used is still a-si tft. The manufacturing process of a-si tft is to sputter the gate material film on the borosilicate glass substrate, and form the gate wiring pattern after mask exposure, development, and dry etching.

Stepper exposure machine is generally used for mask exposure. The second step is to use the pecvd method for continuous film formation to form a sinx film, an undoped a-si film, and a phosphorus-doped n+a-si film. Then mask exposure and dry etching are performed to form the a-si pattern of the tft part. The third step is to form a transparent electrode (ito film) by a sputtering film forming method, and then form a display electrode pattern through mask exposure and wet etching. The fourth step is to form the contact hole pattern of the insulating film at the gate end using mask exposure and dry etching. The fifth step is to sputter Al, etc. into a film, expose and etch with a mask to form the source, drain and signal line patterns of tft. Finally, a protective insulating film is formed by the pecvd method, and then the insulating film is etched and formed by mask exposure and dry etching (the protective film is used to protect the gate, the end of the signal line electrode and the display electrode). At this point, the entire process is completed.

Sony Corporation and Chi Mei Optoelectronics have agreed on the basic terms of a transaction whereby Sony will acquire CMO" s wholly-owned Japanese subsidiary, International Display Technology.

Sony and CMO have agreed that Sony will purchase all the shares of a new company spun-off from IDTech. Sony plans to produce low-temperature polysilicon thin film transistor liquid crystal (LTPS-TFT-LCD) display panels in the new company. The acquisition price has been set at approximately 18.5 Billion Japanese Yen for all the shares of the new company and includes purchase of all of the production equipment, facilities, and personnel at IDTech"s plant in Yasu-shi, Shiga prefecture, Japan.

IDTech is a world leader in the design, development, and production of amorphous silicon thin film transistor liquid crystal (a-Si TFT LCD) displays. Among IDTech"s leading edge products are the world"s highest resolution TFT LCDs for medical displays, wide-angle view in-plane switching (IPS) display monitors, twisted nematic LCD notebook displays, and specialized TFT substrates.

The IDTech facility will complement Sony"s present LTPS-TFT-LCD manufacturing base, which was established in 1997 as the STLCD Corporation, a joint venture between Sony and Toyota Industries Corporation, for the production of LTPS TFT LCD display panels for mobile products, such as cell phones and cameras. A second production line at STLCD was completed in 2002 in which production was expanded to 40,000 (600x720mm) base plates per month; Sony expects to continue the expansion of production and its acquisition of IDTech is part of those plans.

Sony will make an investment for equipment and facility modification of approx. 27 Billion Yen level, leading to building a manufacturing facility with production capability of 25,000?i550x650mm?j base plates /month. This will lead to further enhance the business in the field of LTPS-TFT-LCD display panel for use in mobile products, such as mobile phones. The name of the new company is due to be decided by the end of Mar.2005, when the necessary procedures for the acquisition and new company formation is planned to be completed. The commercial base mass production for LTPS-TFT-LCD display panel is scheduled to start from Apr. 2006.

CMO acquired IBM"s Third Generation TFT LCD plant in 2001, and formed IDTech in a precedent-setting Taiwan-Japan joint venture. From this acquisition, CMO has successfully leveraged IDTech"s leading technology, its skilled workforce, advanced management system, global logistics system and profitable customer base, which provided a strong starting base for CMO"s LCD production in a very competitive industry. Since that time, CMO has been aggressively building its next generation fabs. in Taiwan, including a 5.5 Generation fab., which will begin mass production this year. Because of the fact that the new fabs. will operate with new state-of-the-art equipment and greater efficiency, to better manage its total production capacity, CMO ultimately agreed to sell IDTech"s Yasu fab. to Sony.

“The sale of IDTech will in no way lessen our commitment to our customers, rather it will improve our customer relations because of improved efficiency. The sale to Sony was based on CMO and Sony"s strong business relationship, particularly in the area of LCD business. We are glad we can help Sony to strengthen its production capacity in the mobile devices business. We firmly believe that IDTech"s production capabilities together with Sony"s world-class management and technology will fulfill Sony"s plans.”

”LTPS-TFT-LCD display panels are used in various mobile products such as video cameras, digital still cameras and mobile telephones and we expect the market to dramatically grow from now onwards as well. The basic agreement with CMO and IDTech this time leading to the acquisition of Yasu Business Facility, IDTech will further expand Sony"s mobile display production and will strengthen the business. Through the succession of the personnel asset of Yasu Business Facility, we target to promptly launch Sony"s 2nd manufacturing base following STLCD Corporation, leading to the supply of excellent products to customers in the world.”

This agreement has been well-accepted by Toyota Industries Corporation as well, and initial capital participation by approximately 20% is being considered. From the cooperation by Toyota Industries Corporation, Sony will target the technology convergence of the new company and STLCD Corporation, leading to the build-up of an enhanced quality and production efficiency in the LTPS-TFT-LCD display panels production line to better satisfy the customers" needs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey