using a tft lcd to move a servo arduino uno factory

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The 2.4 inch TFT LCD Touch Display Shield is a Bright, 4 white-LED backlight, on by default but you can connect the transistor to a digital pin for backlight control. So spice up your Arduino UNO project is a beautiful large touchscreen display shield with a built-in microSD card connection. This TFT display is big (2.4″ diagonal) bright (4 white-LED backlights) and colorful (18-bit 262,000 different shades)!

2.4 inch TFT LCD Touch Display Shield for ArduinoUno is fully assembled, tested and ready to go. Add the touch display without wiring, no soldering! Simply plug it in and load up a library – you ‘ll have it running in under 10 minutes! Works best with any classic Arduino ATMEGA328 Board.

The 2.4 inch TFT LCD Touch Display comes with 240×320 pixels with individual pixel control. It has way more resolution than a black and white 128×64 display. As a bonus, this display has a resistive touchscreen attached to it already, so you can detect finger presses anywhere on the screen.

Display worked perfect! No dead pixels, backlight was bright and touch screen had minimal lag and was very responsive. Recommended if you need a touchscreen.

This touch display works 100% right out of box . Touch screen and SD card reader functions works as designed. You just "plug and play" into the UNO module.

Arduino has a built-in function servo.write(degrees) that simplifies the control of servos. However, not all servos respect the same timings for all positions. Usually, 1 millisecond means 0 degrees, 1.5 milliseconds mean 90 degrees, and, of course, 2 milliseconds mean 180 degrees. Some servos have smaller or larger ranges.

For better control, we can use the servo.writeMicroseconds(us) function, which takes the exact number of microseconds as a parameter. Remember, 1 millisecond equals 1,000 microseconds.

In order to use more than one servo, we need to declare multiple servo objects, attach different pins to each one, and address each servo individually. First, we need to declare the servo objects—as many as we need:// Create servo objects

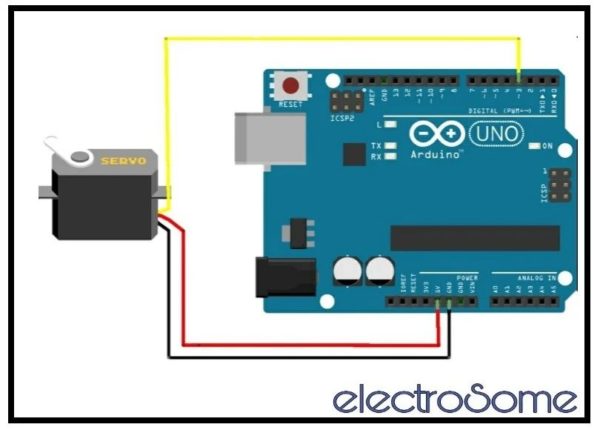

Connection-wise, the grounds from the servos go to GND on the Arduino, the servo power to 5V or VIN (depending on the power input), and in the end, each signal line has to be connected to a different digital pin. Contrary to popular belief, servos don"t need to be controlled by PWM pins—any digital pin will work.

There is a special breed of servos labelled as continuous rotation servos. While a normal servo goes to a specific position depending on the input signal, a continuous rotation servo either rotates clockwise or counter-clockwise at a speed proportional to the signal. For example, the Servo1.write(0) function will make the servomotor spin counter-clockwise at full speed. The Servo1.write(90) function will stop the motor and Servo1.write(180) will turn the motor clockwise at full speed.

There are multiple uses for such servos; however, they are really slow. If you are building a microwave and need a motor to turn the food, this is your choice. But be careful, microwaves are dangerous!

Thank you very much for this project, I am trying to build a multi sensor air quality meter, I used your example and now it is desplaying only 0, Other sensors SCD30 and BMP80 are working correctly

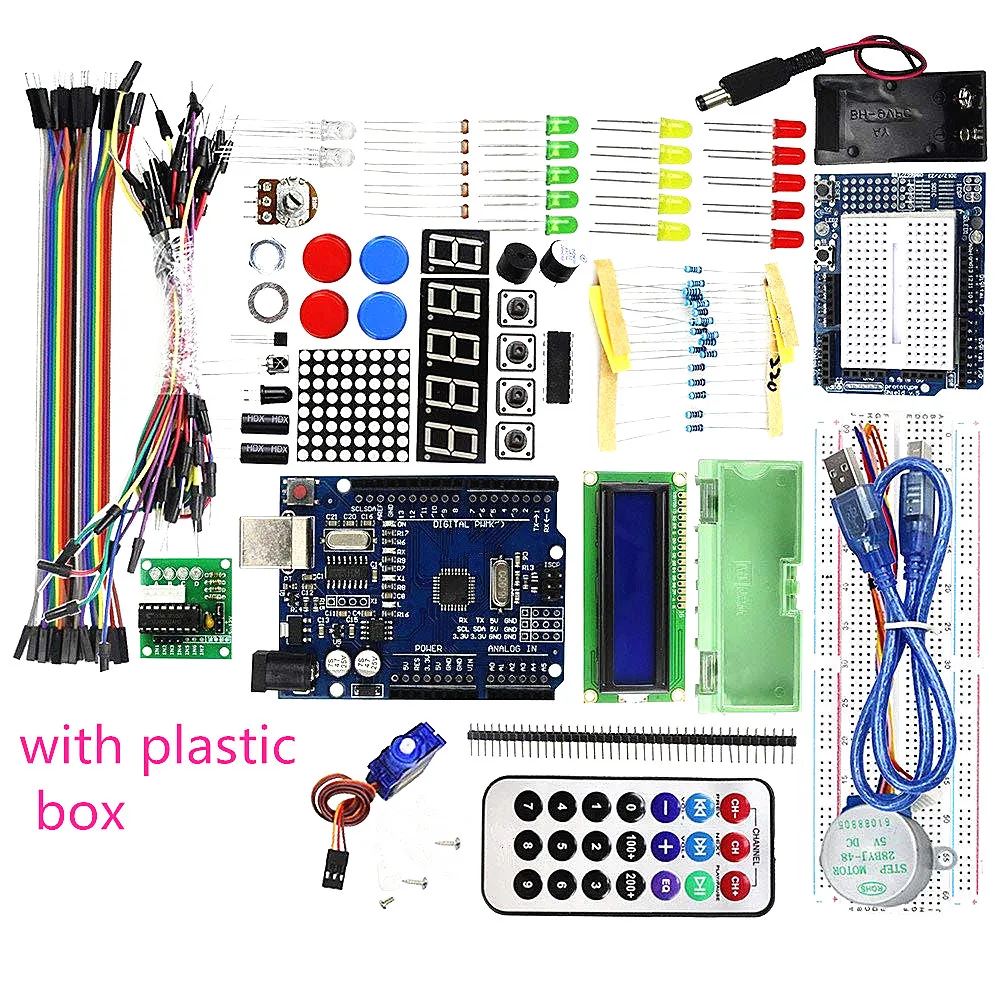

Welcome to the electronic interaction world! DFRobot proudly presents the Arduino beginner kit for those who are interested in learning about Arduino. Starting from basic LED control to more advanced IR remote control, this kit will guide you through the world of microcontrollers and physical computing.

A DFRduino UNO R3 (Compatible with Arduino Uno), the most stable and commonly used Arduino processor, together with DFRobot"s best selling prototype shield are included in this kit.

Beginner Kit for Arduino has strict guidelines on how it makes packaging design, hardware selection, and circuit production technology, meaning that DFRobot can always provide you with quality assurance.

There are 15 projects in the Arduino Getting Started tutorial to help you learn Adruino step by step from easy material to even the most difficult of concepts. The whole set of tutorials provides learning content for both the software and hardware systems. In the process of making interesting projects, you will not only learn programming knowledge such as variables and functions, but also understand the principles behind using electronic components such as light-emitting diodes, buzzers, and steering gears.

Each course will guide you through a quick implementation of the project, stimulate your interest in learning, and then delve into the knowledge of electronics and programming. So, the structure of this curriculum is broken down into the following: “materials list --> hardware connection --> code writing --> code review --> hardware review.”

Different from other tutorials, this tutorial systematically explains how to interpret Arduino code and how to understand the principles of electronic circuits in order to help you make creative Arduino programming projects.

The beginner kit for Arduino includes 15 project cards with detailed circuit diagrams. The students can choose any project they want to start creating what they are interested in. The kit effectively helps teachers launch workshops at school.

I have to say that I am loving the kit. I just wanted to let you know of an issue that I have encountered. In projects 11 and 12 of the kit, it requires the use of the 3 potentiometers. The problem is that the terminals of the potentiometers do not fit across into the sockets on the Prototyping Shield nor the provided breadboard. They are to wide.

Hello, your feedback is very precious to us. Just as you said, the potentiometer couldn"t be inserted to the hole easily, but with some strength to push it downward, it could be done. I"ve attached a picture about it. Btw, we will consider to upgrade it.

A rotary encoder is an electro-mechanical device that can convert the angular position of a shaft to either an analog or digital output signals that can be used to determine what direction the shaft is being rotated.

Rotary encoders come in various types but we are mainly looking at the incremental encoder which is also known as a quadrature rotary encoder due to how the device works.

The encoder has a knob attached to a disk with evenly spaced contact zones that are connected to the common pin C and two other separate contact pins A and B which are labelled CLK and DT respectively.

When the knob is turned, the disk will start rotating step by step and the pins A and B will start making contact with the common ground pin C. This generates two square wave signals that are interpreted to determine the direction of rotation. This is illustrated in the diagram below.

If the knob is turned clockwise, output A connects to the ground first followed by the B pin. For the counter clockwise direction the movement is in the opposite direction. In each case the generated square waves are read by the microcontroller.

The two output signals are at 90 degrees out of phase from each other. The direction of rotation can be determined by the state of the signals. For example in the above case when both signals are the same, the rotation is clockwise and if the signals are opposite, the rotation is counter clockwise.

Connecting the Rotary Encoder to Arduino is simple. Connect the + pin on the module to 5V on the Arduino and GND pin to ground. The CLK, DT and SW pins are connected to any of digital pins of the Arduino.

When the above code is uploaded to the Arduino, we can be able to rotate the knob of the encoder and observe the values on the serial monitor as shown below.

Before connecting the setup shown below you can make reference to my other tutorial on how to control the 28BYJ-48 stepper motor with the ULN2003 board and Arduino using the link:

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

MONCLER(モンクレール)の53 MONCLERネイビー ビッグロゴ クルーネック 半袖 TシャツS(Tシャツ/カットソー(半袖/袖なし))が通販できます。・・・MONCLERモンクレールビッグロゴ半袖Tシャツ・・・80368508390T・・・正規品/新品未使用・・・COTTON100%・・・col:773/ネイビー(黒に近いダークネイビー)・・・S肩幅:約42.0cm 身幅:約47.0cm着丈:約66.0cm 袖丈:約19.0cm※素人採寸の為、多少の誤差

One of the first uses of servo motors was to control the steering mechanisms of RC airplanes, cars, and boats. Today, you can find them in robots, industrial equipment, and many different Arduino projects.

Servo motors are capable of precise control of the rotation of a motor shaft. They allow you to set an exact angle of rotation with code, or with inputs like joysticks, push buttons, or potentiometers.

In this tutorial, we’ll take a look at how servo motors work and how to use an Arduino to control them. We’ll also look at two example programs you can run on the Arduino. The firstprogram will show you how to control the direction and position of a servo using two push buttons. Thesecondprogram will show you how to use a potentiometerto controlthe position of the servo.

BONUS: I made a quick start guide for this tutorial that you can download and go back to later if you can’t set this up right now. It covers all of the steps, diagrams, and code you need to get started.

Servos are DC motors that have been geared down to reduce the speed and increase the torque of the motor. They also have built in circuits that control the angle of rotation one degree at a time, and hold that position until another input is received. Servos will rotate a certain number of degrees depending on the width of the electrical pulses delivered by the Arduino:

The servo expects one pulse every 20 ms. For most servos, a 1 ms pulse results in a zerodegree rotation, a 1.5 ms pulse results in a 90 degree rotation, and a 2 ms pulse results in a 180 degree rotation.

Depending on the servo you use (larger ones especially), you should use a separate DC power supply to power it. Otherwise, the current drawn by the servo could damage your Arduino.

If you want to learn more about the Arduino, check out our Ultimate Guide to the Arduino video course. You’ll learn basic to advanced Arduino programming and circuit building techniques that will prepare you to build any project.

We’re going to use the Arduino’s built-in Servo library to program the servo. This library is included with the Arduino IDE, so there’s no need to install it.

The servo motorshould move to 0degrees, pause for one second, then move to 90degrees, pause for one second, then move to 180degrees, pause for one second, then start over.

On the first line we include the Servo library with #include

In the setup section, we initialize the servo with the attach() function. The attach() function takes one parameter – the pin that the servo is connected to. So we have servo1.attach(servoPin).

To move the servo, use the write() function with the angle of rotation as the argument. The angle is in degrees, from 0 degrees to 180 degrees. The angle changes the pulse width sent to the servo motor, which then determines the amount of rotation. We’re calling the function through the servo1 object, so we use servo1.write(angle), with 0 degrees, 90 degrees, and 180 degrees.

The write() function will work for most servos, but not all. Some servo motors have a range of 180 degrees, some have a range of 90 degrees, and some have anywhere in between. Using the write() function only allows for a maximum of 180 steps. However, there is a function that allows up to 1000steps, called writeMicroseconds(). If you want more precise control of your servo, you may want to use the writeMicroseconds() function instead of write().

In this sketch, we’ve replaced each write() function with a writeMicroseconds() function. Change the angular values from (0, 90, 180) degrees to (1000, 1500, 2000) microseconds. Upload and run the program using the same hardware setup. For a servo motor capable of a range up to 180, the values will be 1000 microseconds = 0 degrees, 1500 microseconds = 90 degrees, and 2000 microseconds = 180 degrees.

Depending on the servo motor you are using, you may notice a difference. Interestingly on my setup, while monitoring the pulses on an oscilloscope, I noticed that when using servo1.write(0);, the pulse width was only about 700microseconds, not 1000 which is the way the function should work when set at zero degrees. But when using servo1.writeMicroseconds(1000); the output was exactly 1000microseconds.

After uploading the compiled code, open the Serial Monitor on your Arduino. As you push on either button, the servo should increase or decrease as shown on the serial monitor. Initially, the code will set the servo at 90 degrees. Use the button connected to pin 3 to increase the angle. When you reach 180 degrees, the high end of the rotation, the LED connected to pin 5 will turn on. When you reach the low end of the range which is 0 degrees, the LED connected to pin 6 will turn on.

To determine the result of the button push, a whilestatement verifies the button and the angle of the shaft. while (digitalRead(pin3) == HIGH && pos < 180) determines that the button was pushed (HIGH) and the angle is less than 180, so the program adds one degree and loops on. The second button while (digitalRead(pin4) == HIGH && pos > 0) determines that the button was pushed (HIGH) and the angle is greater than 0. This causes the angle to decrease by one and loops on. The LedHi and LedLow level for LEDs are each controlled by anif statement that checks the angle to see if it’s 0 or 180. The LEDs are turned off as soon as the angle changes in each of the two while statements.

After uploading the code, open the serial monitor on your Arduino. As you adjust the potentiometer, the rotation of the servo will change accordingly. When you reach the lowerlimit of the range, the Low LED will turn on, and as you reach the upper limit, the High LED will turn on.

analogRead() takes in the voltage from the potentiometer as an analog signal. It accepts the values of the full range of input accepted in an Arduino (0-5V). It captures it as an integer in the range of (0-1023). So for example, a DC value of 0V would be captured as the integer 0; a full range value of 5V would be captured as the integer 1023, and half the input range of 2.5V would be captured as the integer 512, half of 1023.

The next line of code servo1.write(val); is the write() command that takes the integer stored in val as the argument and applies it to the servo. The servo receives a pulsefrom the servo1.write(val); and the pulse width is determined by the value of val. The servo uses the width of this pulse to determine its rotation.

Arduino is an open-source electronics platform. It consists ATmega328P 8-bit Microcontroller. It can be able to read inputs from different sensors & we can send instructions to the microcontroller in the Arduino. It provides Arduino IDE to write code & connect the hardware devices like Arduino boards & sensors.

It is an electric device that is used to control angular rotation. It is a rotary actuator or linear actuator. Servo motors have servomechanism. The servo mechanism helps the servo motor to control and monitor the motion of the motor. The user can control the rotation speed and position (angle) precisely.

Let’s take a look into a simple interfacing project this time. This is actuator interfacing with Arduino Uno and the actuator being servo motor, specifically SG90 servo motor. SG90 is a lightweight (just 9g) and tiny servo motor which has quite good output toque. We can use Arduino IDE to code this servo and control its movements precisely. We can rotate 180 with this servo motor.

This project uses SG90 servo motor interfaced with Arduino Uno which is programed to turn the servo motor from 0 degrees to 180 degrees and back to 0 degrees.

For demo purposes, with zero load on the servo motor, we are powering the servo motor using Arduino 5V pin. But it is important to keep in mind that the motor should be powered separately. This servo motor has input voltage of 4.8V to 6V DC. It is recommended that the servo motor should be powered externally (using a dedicated power supply) and the voltage should be within the accepted range. The maximum current draw from Arduino is 0.8A only. So when we use an external power supply, it will make sure that the Arduino board won’t be damaged due to excess current draw.

There is a common problem when dealing with SG90 (or even MG90S) that is the overshooting or undershooting. This is a problem has a bit to do with Control Systems. In general, we can say, the systems that are overdamped miss the target value, that causes the “undershoot”. This means, the servo would not really reach 0 to 180 degrees or other specified value. Whereas those systems that are underdamped go over the target. This causes the situation to “overshoot”. This is when the servo motor exceeds the specified degree and sweeps more area than it is supposed to do.

There are a couple of fixes available online for this overshoot/undershoot problem. You could use a better servo motor like “Tower pro MG 995” servos. This is not a micro servo like SG90 but it is more precise and it can also deliver more power. There are other servo motors that are used for model aircraft building; they are known to be more precise. They give very good results but are quite expensive. If you really want to use SG90 servo motor only and get precise degree turn, then, consider the following points to get better results:

The circuit connections for this project are very simple as the servo motor has only 3 pins. The red wire of the servo goes to 5V pin of Arduino Uno. The Black wire of the servo goes to Arduino Uno’s ground pin (GND). And the yellow wire (called the control pin of servo) goes to Arduino pin 8. This completes the circuit connections of the servo motor with Arduino Uno.

First, we need to include a library called “Servo.h” to be able to control various servo motors. If you don’t already have this library in your Arduino IDE, then you can go to “tools” à “Manage Libraries…” and type “Servo” in the Library Manager and install the one from “Michael Margolis, Arduino”.

Next, we declare a variable called “servo”. In void setup function, we use the servo.attach function to tell the Arduino board that the control pin of the servo motor is attached to pin 8 of Arduino (the function attaches the servo variable to the pin). The servo.write function is used to tell the servo the degree to which it should turn. At the beginning the default state of servo is considered as zero degree we keep this as origin position that is zero degrees. So we write servo.write(0). Then a delay function is used to create a delay of 2ms.

Next, in void loop, we use the servo.write function again to tell the servo to turn to 180 degrees and the delay function will hold this position for 1ms. Then the servo is instructed again to go back to 0 degrees, as we had initialized before. The delay function will hold this position for 1ms. This is repeated until the power is disconnected or servo is disconnected.

This is a beginner friendly project. It focuses on controlling an actuator, SG90 Servo motor, using Arduino Uno and Arduino IDE. It provides a strong basic foundation in dealing with actuators and helps beginners jump into more fun with actuators.

A joystick is an input device consisting of a stick that pivots on a base and reports its angle or direction to the device it is controlling. The Joystick Module is a tiny low cost option to add a game like control to your projects. Be it robotics or any other project that requires a precise human control. The module has two potentiometers for the X and Y axis measurements. Also a switch that can give an additional control option.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey