lcd display color change manufacturer

FCS LCDs are a uniquely different color technology. They are not a replacement for OLEDs or TFTs, because they do not display video or high-resolution photos.

When Henry Ford built his first car, he told his customers they could have any color car they wanted, as long as it was black. Car manufacturers now offer multiple options to their consumers. The customer can choose paint color, interior color, automatic or manual transmission, and even heated seats.

In the past, OEM designers were restricted to standard size color displays set by the OLED or TFT manufacturer. FSC technology removes this constraint at a surprisingly low cost.

FSC color displays take the single color offered by static/segmented display, and add seven additional colors. The following YouTube video shows the display as it changes colors.

FSC LCD Displays implement an RGB backlight to display brilliant bright colors. The colors are brighter than other displays because there is no filter.

The lack of filter allows a darker black positive mode (dark letters on a light background) and a brighter white negative mode (light colored letters on a dark background).

Create a drawing that includes the size of the glass, the icons, and segments you want. The icons and segments can be placed on the drawing to show an approximate location. Click here for an online design form to help you quickly design the display.

After you submit your drawing, you will receive a counter drawing (CAD drawing showing the exact dimensions of the display) within three-to-five business days.

If you must have color, and need video or very high resolution, then choose TFT or OLED; if you need a custom color display and you do not need thousands of different colors then FSC is your best choice. If you can do without color and need very lost cost and low power usage, stay tuned for the next article on monochrome (non-color) displays.

FSC LCD’sare a uniquely different color technology. They are not a replacement for OLED’s or TFT’s because they do not display video or high resolution photos.

Henry Ford meets Burger King -When Henry Ford built his first car, he told his customers they could have any color car they wanted as long as it was black. Car manufacturers now offer multiple options to their consumers. The customer can choose their paint color, interior color, automatic or manual transmission, even heated seats.

In the past, OEM designers were restricted to standard size color displays set by the OLED or TFT manufacturer. FSC technology removes this constraint and at a surprisingly low cost.

FSC color displays take the single color offered by static/segmented display and add seven additional colors. The attached Youtube link shows a video of the display as it changes colors. (

How does this new technology work? FSC LCD Displays implement an RGB backlight to display brilliant bright colors. The colors are brighter then other displays because there is no filter.

The lack of filter allows a darker black positive mode (dark letters on a light background) and a brighter white negative mode (light colored letters on a dark background)..

Five steps to your own custom color LCD display moduleCreate a drawing that includes the size of the glass,the icons and segments you want. The icons and segments can be placed on the drawing to show an approximate location. Here is a link to our engineering support page. Call us if you need support with your designs.

After you submit your drawing, you will recevie a counter drawing (A cad drawing showing the exact dimensions of the display) within three to five business days.

What is the difference between a FSC color display and a segmet/static display?The FSC display provides seven colors plus the background color. The static display only offers one color.

E Ink Gallery™, based on the Advanced Color ePaper (ACeP™) is a high quality, full color reflective display. In the ACeP™ system, the ink can produce full color at every pixel, without the use of a color filter array (CFA).

ACeP™ achieves a full color gamut, including all eight primary colors, using only colored pigments. The display utilizes a single layer of electrophoretic fluid which is controlled using voltages compatible with commercial TFT backplanes. The fluid can be incorporated into either microcapsule or Microcup® structures. The richness of the colors is achieved by having all the colored pigments in every picture element (pixel) rather than the side-by-side pixel colors achieved with a CFA. This eliminates the light attenuation, which can be quite significant. ACeP™ maintains the ultra-low-power and paper-like readability under all lighting conditions of regular E Ink ePaper.

This next generation, full color ePaper module, has a color gamut ideally reaching 60,000, an improvement over the earlier generations. The contrast ratio is improved by 40%, from 10 to 14, providing a more impactful visual experience. The look and feel of the new generation is similar to color prints, with the benefit of digital changes that allow for instant updates to match with promotion and communication needs. E Ink Gallery Plus will be available in various sizes for customers, including 13.3-inch, 25.3-inch, and 28-inch and is targeted for indoor commercial signage for retail, restaurants, transportation and public information displays.

In Gallery 3, the black and white update time has been improved to 350 milliseconds (ms), the fast color mode is 500 ms, standard color mode is 750-1000 ms and best color is achieved at 1500 ms. This is a substantial improvement over the first generation of E Ink Gallery, which had a black and white update time of two seconds and color updates of ten seconds. In addition, Gallery 3 will have an improved resolution of 300 pixels per inch (ppi) versus the earlier 150ppi and an operating temperature of 0-50 degrees Celsius, on par with black and white eReaders. E Ink Gallery 3 will also support pen input in black and white, with an addition of several other colors and an update time of 30 ms. E Ink Gallery 3 will be featuring E Ink’s new ComfortGaze™ front light, which offers a blue-light safe viewing experience.

E Ink Gallery Palette uses the same full-color ePaper film as our ACeP product but is driven by simpler electronics to support cost sensitive applications that do not require the full-color performance of ACeP. Gallery Palette supports the seven most frequently used colors in advertising and signage, namely: Black, White, Red, Yellow, Blue, Green and Orange. Gallery Palette is geared toward applications where power autonomy is an essential requirement but only need a limited color range. Our customers are using Gallery Palette in areas such as smart digital badges, movable advertisement, indoor signage and lots more.

E Ink Kaleido™ displays offer 16 levels of grayscale and are capable of displaying 4096 colors, enable ultra low power and high mobility devices with a paper-like experience, ideal for image-rich information applications such as charts, graphs, maps, photos, comics and advertising. And just like E Ink"s monochrome ePaper products, Kaleido’s crisp text and detailed color graphics are fully viewable in direct sunlight, and have the same low power attributes.

E Ink Kaleido™ utilizes a new printed Color Filter Array (CFA) technology in conjunction with E Ink’s second generation Carta ink, which is faster and brighter than previous generations. The new printing process alleviates the need for a glass-based CFA, making the displays thinner and lighter than previous generations, while simultaneously having higher optical quality. This allows eReader companies to combine the power of traditional black and white displays with color for a more fully realized eBook shopping experience. In addition, E Ink’s faster ink enables quicker updates for animations and page turns. With this new color technology, E Ink’s eNote product lines are now able to introduce writing tablets with color highlighters, pens and markers, giving new options for education and professional devices.

In early 2021 E Ink released a new generation in the Kaleido family, named E Ink Kaleido™ Plus. In this new version, we’ve made adjustments to the printed CFA, to allow for a better color balance, and printing texture, and we’ve brought the CFA closer to the ink, to reduce light scattering. New image rendering algorithms allow for crisper text. In addition, we have made adjustments to the light guides, allowing for better optimization of the LED color spectrum to minimize color blending.

This new generation of E Ink Kaleido offers richer colors, along with 16 levels of grayscale and 4096 colors, perfect for displaying colorful images and information on eReaders and eNote devices. By optimizing the design of the ePaper module structure, E Ink Kaleido 3 has increased its color saturation by 30 percent compared to the previous generation, E Ink Kaleido Plus. In addition to improved color performance, Kaleido 3 uses E Ink ComfortGaze™, a front light that has been engineered to reduce the amount of blue light reflected off the surface of the display, providing further comfort while reading. The E Ink Kaleido 3 module is available in various panel sizes, including 7.8-inch, 10.3-inch, and 13.3-inch. Kaleido 3 features a black and white resolution of 300ppi, and a color resolution of 150ppi, which is an improvement over Kaleido Plus"s color resolution of 100ppi. The responsiveness of the ink enables the module to play animations and videos, providing new options for digital reading and writing in educational and professional applications.

Color ePaper displays enabled by E Ink Triton deliver high-contrast, sunlight readable, low-power performance that further closes the digital divide between paper and electronic displays.

E Ink Spectra is a multi-pigment electronic ink offered in mass production for retail and electronic shelf tag labels. EPDs using Spectra offer the same high-contrast, sunlight readable, low-power performance attributes of our other display types - now with a pop of color. The first generation of Spectra, E Ink Spectra™ 3000, features black, white and red or yellow pigments.

The new four-particle electronic ink, E Ink SpectraTM 3100, is a major step forward in the technology, and incorporates retailer’s requests for additional color functionality, by utilizing black, white, red and yellow particles to offer vibrant color rich content. Unlike earlier generations, Spectra 3100 has an improved update time, and an expanded temperature range for red and yellow states, to satisfy retailers’ needs to operate ESL tags in various environments within their stores. In addition, Spectra 3100 will be offered in panels with an updated all-in-one driver IC that supports premium ESLs with higher resolution across various sizes.

Spectra 3100 Plus adds bright orange to the existing four colors (black, white, red, and yellow) of the previous generation. The combination of five vivid and saturated colors creates a more eye-catching display, which will help retailers improve their marketing and advertising performance. E Ink Spectra 3100 Plus adopts a new waveform to display the fifth color, orange. In addition to offering a wide range of solid and saturated colors, E Ink Spectra 3100 Plus can create a partial image flashing effect, E Ink Sparkle, when E Ink Spectra 3100 Plus is equipped with the relevant All-in-One Driver IC.

E Ink Spectra 3100 Plus offers a variety of display sizes, including 1.64-inch, 2.36-inch, 3-inch, 4.37-inch, 7.3-inch, and 8.14-inch, allowing retailers to choose a suitable size of five-color ePaper for different application scenarios.

E Ink Prism™ will transform the way spaces and surroundings are experienced. Manufacturers and designers will now have the ability to integrate innovative films with architectural and design to dynamically change colors, patterns, and habitats.

It doesn’t stop at color. Programmable patterns and shapes can be integrated to create designs or function. Doors can indicate if a conference room is occupied, wall designs can respond to noise, temperature, or motion in the room. Whatever the idea, the opportunities are endless and only limited by a designer’s imagination.

Electronic display screens have changed considerably over the past century. The emergence of LCDs and OLEDs ushered in a new age of screen technology. It led to significant improvements in image sharpness, color, contrast, and space utilization; yet, screens are still far from ideal color rendering and brightness.

However, groundbreaking advancements in quantum dots are enabling LCDs and OLEDs to break new barriers in image quality and screen efficiency. Quantum dots are nanocrystals that are about 60 million times smaller than a tennis ball. Their tiny size makes it possible for them to create almost every color in the spectrum. Introduced in 2013, quantum dot technology enhances the brightness and color fidelity of screens with minimal change to the manufacturing process. But recent innovations in quantum dots have made these enhancements very substantial. As a result, quantum dot technology is expected to be a standard feature of upcoming displays.

LCD and OLED displays were major improvements from the traditional CRT television sets that were sold throughout the 20th century. There are numerous reasons the market shifted to LCD and LED electronics since the early 2000s. These screens are far more efficient and much more compact than their predecessor, allowing for new design freedom. They have better sharpness because the pixel density is much higher. The screens are also a fraction of the thickness of the old CRT sets, which allows consumers to utilize their space more efficiently.

While developments in LCD and OLED display technology solved some problems, not all frustrations for consumers were addressed. Those screens aren’t the most efficient, and their RGB color gamut and brightness also leave a lot to be desired.

In some aspects, OLED displays offer advantages over LCD televisions (e.g. they are thinner and have better black levels). However, they are much more expensive (most standard 55- to 65-inch OLED television units cost at least $2,000); and suffer from poor brightness (OLED displays have a brightness of only 500 nits, which is about half that of a standard LCD screen). As a result, OLED screens have poor visibility in brightly lit rooms.

The color gamut and brightness issues plaguing standard LCDs and OLEDs stem from a lack of efficient color-converting phosphors that emit photons with a narrow spectrum, particularly in the green. The narrower the emission spectrum, the purer is the color (and the wider is the color gamut of the display); the more efficient the converter, the brighter is the screen.

With this concept in mind, developers such as Nanosys and Samsung introduced quantum dot enhancement films (QDEFs) as an augmenting component in niche segments of LCDs. The first generation of QDEFs were based on green-emitting cadmium selenide and indium phosphide quantum dots, with emission widths of about 25-30 nm and 35-40 nm, respectively. As a result, QD screens had a BT2020 color gamut coverage 40-50% larger than LCDs — adding millions of new colors.

However, innovations in quantum dot technology are making way for a new generation of green quantum dots, based on materials called perovskites that are poised to broadly reshape the landscape of LCD and OLED displays. Perovskite quantum dots are superior to the previous generations of dots: they have much narrower emission widths, emit photons at nearly 100% efficiency, and are easier to scale up (without compromising on quality). Perovskite-based QDEFs, like the QDot™ Sharp Green Film developed by Quantum Solutions, one of the leading innovators in the field of quantum dot technology, emit green photons with remarkably narrow spectral line widths (< 20-23 nm). Such pure green QDEFs translate into bright screens covering >90% of the BT2020 color gamut; and displays with the most accurate, true-to-life colors.

The close-to-perfect photon emission efficiency of perovskite quantum dots enables displays that sustain high brightness levels (1000-2000 nits) while operating more efficiently. This leads to comfortable viewing even in the most illuminated environments. QDEFs appreciably upgrade the user experience of screens at affordable price points. Consumers have taken notice. Soon, they will be a prominent feature in most LCDs and OLEDs.

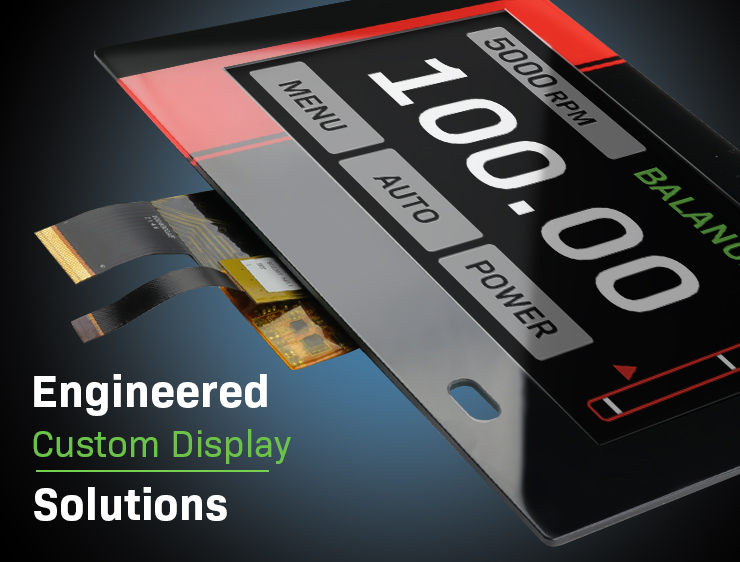

Manufacturer of standard and custom LCD monitors including TFT color LCD monitors and touch screen displays for industrial, commercial, law enforcement, medical and surgical applications. Specifications include LCD panels with resolutions up to 1920 x 1080 full HD; 250 nits to 1,300 nits brightness, 12 vdc, 24 vdc or 90-240 vac power; 4:3 and 16:9 aspect ratio; standard, rack mount, panel mount and open frame configurations; VGA, BNC, composite, S-Video, HDMI, DVI, DisplayPort, and component video inputs. Displays are available with various accessories including tabletop stands, DVI to VGA adapters, VGA and DVI cables, power cords and Medical grade power supplies with green dot power cords. UL, cUL, FCC, CE & RoHS approved. Three year warranty.

Microtips Technology is a leading custom lcd module manufacturer and we offer a full array of products and services. We have the most advances display technologies available to use in your design and if there is anything you want to change about one of our displays, we can make it happen. All of our displays are fully customizable to your specification and can include extra features like a capacitive touchscreen, an anti-reflective or anti-glare coating, or custom cover glass. Our sales and engineering staff will be with you through the entire process and will ensure our custom lcd display and your end product look their very best.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

As a full service provider of LCD modules, PDI specializes in small format (typically 15” and less) character display, graphic display, color display, and custom display formats. Our Customers leverage PDI’s decades of LCD display experience, technical expertise, and manufacturing capabilities to obtain the most competitively priced, highest quality LCD module solution. These solutions span the spectrum from off the shelf standard products to completely custom display based solutions. PDI’s mission is to actively engage our customers early in the design phase. We will utilize our years of LCD experience and our understanding of the compete LCD module system to provide a smooth transition from design concept to prototypes, through pilot run and into high volume production.

Alternatively, if a 100% identical cross match design of an existing display is needed, our team will evaluate your current solution, offer any recommendations for design improvement and then quote accordingly, typically saving up to 20%. Once PDI develops a 100% compatible drop-in replacement display, this LCD module is then fully tested and qualified in the product application prior to shipping. This process insures a plug and play solution.

PDI produces its LCD displays utilizing the latest or most practical technology trends including Chip on Glass (COG), Chip on Board (COB), Tape Automated Bonding (TAB) and Chip on Flex (COF). PDI can integrate touch panels into any of our display systems. In addition to a full portfolio of standard and custom LCD modules, PDI offers manufacturing services to build your display into the next higher sub-assembly or final assembly to give customers the competitive cost advantages afforded to those utilizing off-shore based manufacturing. Often this practice includes integrating the display design and existing peripheral components such as PCB’s, switches, overlays and custom cables which eliminates interconnects, improves the overall system reliability and most importantly, reduces cost.

Customers that need a new supplier for an existing production display. This occurs for a variety of reasons including cost pressures, lead time concerns, quality issues, stocking needs, or lack of responsiveness from current LCD supplier.

Customers that have a new program and require a display solution.This can either be a standard or custom display, and may require engineering support to determine the best display solution.

Customers that need a display, but may also be looking for a more integrated solution. Sometimes this includes a display, touch panel, keypad, I/O connector and custom PCB solution.

Since 2001 we’ve provided product development, engineering design services, and turn-key solutions for all industries. Work with our engineers to develop the ideal display for your unique application.

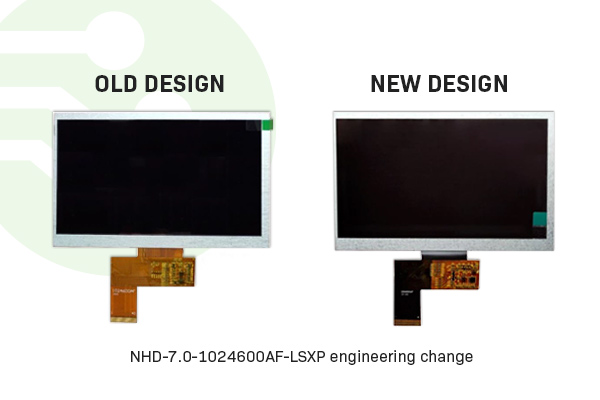

For more than 20 years, Newhaven Display International has provided custom display solutions worldwide across various industries including medical, agriculture, industrial, handheld, audio/video, automotive, consumer, appliance, security, casino, military, energy, POS, test & measurement, and telecom.

Our US-based engineering staff works together to help you prototype, design, test, build, and manufacture your custom display solution to perfectly fit your application and make your product a success. Keep in mind that minimum order quantities (MOQ) and NRE may apply depending on your custom solution request.

Easily modify any connectors on your display to meet your application’s requirements. Soldering for pin headers, boxed headers, right angles headers, and any other connectors which your display may require.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

Custom backlight configurations can be made with voltage/input current, brightness or colors/NVIS. Perhaps it is just changing the assembly type from array to side LEDs.

We have complete control over our display products" design, manufacturing, and quality control processes. Our USA based Engineers will work with you on a prototype to validate and test your design.

Elo takes great pride in controlling many aspects of an LCD display, including brightness, contrast, color and other parameters. For more information about some of the parameters and tolerance expected from one monitor to the next, even when comparing identical monitors, please read the information below.

Analog video signal:Scalar needs to convert the analog to a digital signal and it’s unavoidable that there will be distortion of color performance in this process.

Color format:Different color formats can cause different color performance. RGB uses additive color mixing because it describes what kind of light needs to be emitted to produce a given color. RGB stores individual values for red, green and blue. RGBA is RGB with an additional channel, alpha, to indicate transparency.

Elo includes some basic settings in the On-Screen Display (OSD) to control the appearance of the display. The available adjustments vary with the type of monitor. Please reference the “User Guides” located under the “Resource” section on the product’s webpage. Check the following settings and any other options that can affect the picture:

Furthermore, the age and use of a monitor will affect its LCD screen. It is important to keep in mind that monitor manufacturers can use multiple part suppliers for the same products—two “identical” monitors might have LCD panels that are not from the same supplier.

You don"t necessarily want to set the monitors to the same settings. Even though they are usually close, two of the same exact monitors can show colors slightly different. You may need to adjust the RGB settings on one monitor to match the other. The best way to adjust them is to bring up a perfectly red screen on both monitors (use MS Paint because you can set the color just the way you want) and then adjust them till they look the same. Repeat for blue and green. Once you get it the way you want, write down the RGB settings just in case your monitor resets and you lose your settings.

Each monitor is tested at the factory, and the color is manually calibrated to ensure it is within an allowable range. Please note, the Elo warranty does not cover color uniformity differences between two monitors. In fact, both are in the manufacturer specification for uniformity.

Elo does “White Balance” to make sure all color temperatures (5500K, 6500K, 7500K and 9300K) are within the spec and records all of the data for each Elo monitor on the production line

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

What is Micro OLED? Why Micro OLED is good choice for AR/VR devices. Apple"s first VR/MR headset will be launched next year. This headset will be equipped with three screens, two of them are micro OLED displays.

Now LCD is the most common VR device screen on the market, and a few VR products use OLED screens and Mirco-OLED screens. Micro OLED is unfamiliar for VR players. Arpara 5K PC VR, the world"s first VR device, is using the micro-OLED display.

This enhanced IPS LCD Screen is 2.9 inch 480*720, Panox Display`s convertor board on FPC make higher resolution compatible with GBA circuit board. This makes 3*3 pixels display one pixel as the original display.

BOE responded to investors about the development of AR/VR display panels, saying that BOE has provided VR/AR/MR smart applications display solutions, including high PPI, high refresh rate of Fast LCD and ultra-high resolution, ultra-high contrast of Micro OLED (silicon-based OLED) and other representative display technology.

As the new energy vehicle market continues to develop in ways that exceed initial expectations, the automotive industry continues to promote the trend towards "electrification, intelligence, Internet connection" and other technological innovations that, when combined, are driving the continuous demand for on-board displays.

SID Display brought together the industry’s biggest players – including BOE, Samsung Display, Tianma, TCL Huaxin, LG Display, Visionox, AUO and Innolux, among others.

According to India"s latest report, Samsung"s Image Display Division purchased about 48 million panels in 2021 and shipped 42 million units. In 2022, meanwhile, it plans to purchase 56 million panels and ship 48 million units in 2022. The panels it purchases will be made up of 53 million OPEN Cell LCD TVs, 1 million QD OLED panels, and 2 million WOLED TV panels.

With the explosive growth of new energy vehicles and vehicle intelligence in 2021, in-vehicle display technology has also undergone a period of rapid development. First, end-users and OEMs have begun to pursue multi-screen, high-resolution, and large-size displays. And, secondly, major panel manufacturers have actively adopted diversification strategies based on their own particular strengths and adjusted their own layouts accordingly.

AM-OLED shows the current is still in the technology leading period, folding, screen camera, narrow frame, high refresh rate, low power consumption, ultra-thin display technology popular with the market, terminal application penetration accelerated, and gradually from smartphones, smart wear small main penetration areas to the car, laptop size expansion, industry in rapid expansion period, no previous display industry facing cyclical fluctuations, the overall industry pattern initially formed.

Yanshun Chen, BOE’s chairman, recently revealed at the performance exchange meeting that BOE"s flexible AMOLED product shipments totaled nearly 60 million pieces in 2021. According to consulting agency data, the company enjoys a global market share of 17%, meaning it ranks second in the world. The company’s goal in 2022 is to ship more than 100 million pieces, a figure which constitutes full production capacity. Production capacity will then be boosted further in 2023, when the company’s Chongqing"s flexible OLED production line starts mass production.

LCD Monitor Course II, which kicks off this session, will address certain points one must know to choose the LCD monitor best-suited to one"s needs from the various models available. Part 1 will focus on color gamut. While wide color gamuts are the latest trend in LCD monitors, color gamut is a term that lends itself to misunderstanding. Our hope is that this session will help users better understand the color gamut of LCD monitors and better select, use, and adjust the products.

Note: Below is the translation from the Japanese of the ITmedia article "IT Media LCD Monitor Course II, Part 1" published on November 11, 2008. Copyright 2011 ITmedia Inc. All Rights Reserved.

A color gamut defines a more specific range of colors from the range of colors identifiable by the human eye (i.e., the visible spectrum). While color imaging devices include a wide range of devices, such as digital cameras, scanners, monitors, and printers, since the range of colors they can reproduce varies, the color gamut is established to make these differences clear and to reconcile the colors that can be used in common between devices.

Various methods are used to express (diagram) the color gamut, but the common method used for display products is the xy chromaticity diagram of the XYZ color system established by the International Commission on Illumination (CIE). In an xy chromaticity diagram, the colors of the visible range are represented using numerical figures and graphed as color coordinates. In the following xy chromaticity diagram, the area shaped like an upside-down "U" surrounded by dotted lines indicates the range of colors visible to human beings with the naked eye.

Various standards govern color gamuts. The three standards frequently cited in relation to personal computers are sRGB, Adobe RGB, and NTSC. The color gamut defined by each standard is depicted as a triangle on the xy chromaticity diagram. These triangles show the peak RGB coordinates connected by straight lines. A larger area inside a triangle is regarded to represent a standard capable of displaying more colors. For LCD monitors, this means that a product compatible with a color gamut associated with a larger triangle can reproduce a wider range of colors on screen.

This is a CIE XYZ color system xy chromaticity diagram. The areas enclosed in dotted lines represent the range of colors human beings can see with the naked eye. The ranges corresponding to the sRGB, Adobe RGB, and NTSC standards defining color gamuts appear as triangles connecting their RGB peak coordinates. The color gamut of an LCD monitor"s hardware can be indicated using similar triangles. An LCD monitor is not capable of reproduction (display) of colors outside its color gamut.

The standard color gamut for personal computers is the international sRGB standard prepared in 1998 by the International Electrotechnical Commission (IEC). sRGB has established a firm position as the standard in Windows environments. In most cases, products like LCD monitors, printers, digital cameras, and various applications are configured to reproduce the sRGB color gamut as accurately as possible. By ensuring that the devices and applications used in the input and output of image data are sRGB compatible, we can reduce discrepancies in color between input and output.

However, a look at the xy chromaticity diagram shows that the range of colors that can be expressed using sRGB is narrow. In particular, sRGB excludes the range of highly saturated colors. For this reason, as well as the fact that advances in devices such as digital cameras and printers have led to widespread use of devices capable of reproducing colors more vivid than those allowed under the sRGB standard, the Adobe RGB standard and its wider color gamut have recently drawn interest. Adobe RGB is characterized by a broader range than sRGB, particularly in the G domain—that is, by its ability to express more vivid greens.

Adobe RGB was defined in 1998 by Adobe Systems, maker of the well-known Photoshop series of photo-retouching software products. While not an international standard like sRGB, it has become— backed by the high market share of Adobe"s graphics applications—the de facto standard in professional color imaging environments and in the print and publishing industries. Growing numbers of LCD monitors can reproduce most of the Adobe RGB color gamut.

NTSC, the color-gamut standard for analog television, is a color gamut developed by the National Television Standards Committee of the United States. While the range of colors that can be depicted under the NTSC standard is close to that of Adobe RGB, its R and B values differ slightly. The sRGB color gamut covers about 72% of the NTSC gamut. While monitors capable of reproducing the NTSC color gamut are required in places like video production sites, this is less important for individual users or for applications involving still images. sRGB compatibility and the capacity to reproduce the Adobe RGB color gamut are key points of LCD monitors that handle still images.

The visual differences between Adobe RGB (photo at left) and sRGB (photo at right). Converting a photograph in the Adobe RGB color gamut to the sRGB domain results in the loss of highly saturated color data and loss of tonal subtleties (i.e., a susceptibility to color saturation and tone jumping). The Adobe RGB color gamut can reproduce more highly saturated colors than sRGB color. (Note that the actual colors displayed will vary with factors such as the monitor used to view them and the software environment. The sample photographs should be used for reference only.)

In general, the LCD monitors currently available for use with PCs have color gamuts capable of displaying nearly the entire sRGB gamut, thanks to the specifications for their LCD panels (and panel controls). However, given the rising demand mentioned above for reproducing color gamuts broader than sRGB, recent models have expanded the color gamuts of LCD monitors, with Adobe RGB serving as one target. But how is such expansion of LCD monitor color gamuts taking place?

Improvements in backlights account for a significant proportion of the technologies expanding the color gamuts of LCD monitors. There are two major approaches to doing this: one involves expanding the color gamut of cold cathodes, the mainstream backlight technology; the other involves RGB LED backlights.

On the subject of color-gamut expansion using cold cathodes, while strengthening the LCD panel"s color filter is a quick fix, this also lowers screen luminance by decreasing light transmissivity. Increasing the luminance of the cold cathode to counter this effect tends to shorten the life of the device and often results in lighting irregularities. Efforts to date have overcome these drawbacks to a large extent; many LCD monitors feature cold cathodes with wide color gamuts resulting from modification of their phosphors. This generates cost benefits as well, since it makes it possible to expand the color gamut without major changes in the existing structure.

Use of RGB LED backlights has increased relatively recently. These backlights make it possible to achieve higher levels of luminance and purity of color than cold cathodes. Despite certain disadvantages, including lower color stability (i.e., radiant-heat problems) than a cold cathode and difficulty in attaining a uniform white color across the entire screen, since it involves a mixture of RGB LEDs, these weaknesses have been resolved for the most part. RGB LED backlights cost more than cold-cathode backlights and are currently used in a fairly small proportion of LCD monitors. However, based on their efficacy in expanding color gamuts, the number of LCD monitors incorporating the technology will likely increase. This is also true for LCD televisions.

In passing, many LCD monitors that extol wide color gamuts promote the area ratios of specific color gamuts (i.e., triangles on the xy chromaticity diagram). Many of us have probably have seen indications of attributes such as Adobe RGB rates and NTSC rates in product catalogs.

However, these are only area ratios. Very few products include the entire Adobe RGB and NTSC color gamuts. Even if a monitor featured a 120% Adobe RGB ratio, it would remain impossible to determine the extent of the difference in RGB values between the LCD monitor"s color gamut and the Adobe RGB color gamut. Since such statements lend themselves to misinterpretation, it is important to avoid being confused by product specifications.

To eliminate problems involving labeled specifications, some manufacturers use the expression "coverage" in place of "area." Clearly, for example, an LCD monitor labeled as having Adobe RGB coverage of 95% can reproduce 95% of the Adobe RGB color gamut.

From the user"s perspective, coverage is a more user-friendly, easier-to-understand type of labeling than surface ratio. While switching all labeling to coverage presents difficulties, showing in xy chromaticity diagrams the color gamuts of LCD monitors to be used in color management will certainly make it easier for users to form their own judgments.

With regard to the difference between area labeling and coverage labeling as gauges of an LCD monitor"s color gamut, to use Adobe RGB as an example, in many cases, even a monitor with an Adobe RGB ratio of 100% in terms of area will feature coverage of less than 100 percent. Since coverage impacts practical use, one must avoid the mistake of seeing a higher figure as automatically better.

When we check the color gamut of an LCD monitor, it"s also important to remember that a wide color gamut is not necessarily equivalent to high image quality. This point may generate misunderstanding among many people.

Color gamut is one spec used to measure the image quality of an LCD monitor, but color gamut alone does not determine image quality. The quality of the controls used to realize the full capabilities of an LCD panel having a wide color gamut is crucial. In essence, the capacity to generate accurate colors suited to one"s own purposes outweighs a wide color gamut.

When considering an LCD monitor with a wide color gamut, we need to determine if it has a color-gamut conversion function. Such functions control the LCD monitor"s color gamut based on the target color gamut, such as Adobe RGB or sRGB. For example, by selecting sRGB mode from a menu option, we can adjust even an LCD monitor with a wide color gamut and high Adobe RGB coverage so that the colors displayed on screen fall within the sRGB color gamut.

Few current LCD monitors offer color-gamut conversion functions (i.e., feature compatibility with both Adobe RGB and sRGB color gamuts). However, a color-gamut conversion function is essential for applications demanding accurate color generation in the Adobe RGB and sRGB color gamuts, such as photo retouching and Web production.

For purposes requiring accurate color generation, an LCD color monitor lacking any color-gamut conversion function but having a wide color gamut can actually be a disadvantage in some cases. These LCD monitors display each RGB color mapped to the color gamut inherent to the LCD panel in eight bits at full color. As a result, the colors generated are often too vivid for displaying images in the sRGB color gamut (i.e., the sRGB color gamut cannot be reproduced accurately).

Shown here are examples of an sRGB color gamut photograph displayed on an sRGB-compatible LCD monitor (photo at left) and on an LCD monitor with a wide color gamut but incompatible with sRGB and with no color-gamut conversion function (photo at right). While the photograph at right appears vivid, saturation is unnaturally high in parts of the photo. We also see a significant departure from the colors envisioned by the photographer, as well as so-called memory colors.

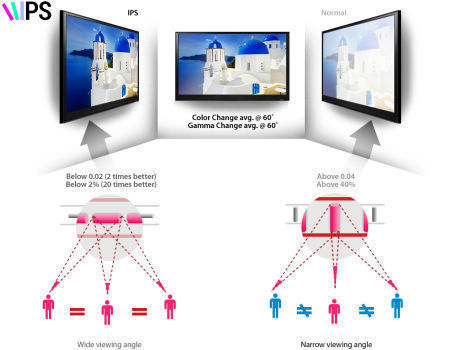

In more than a few cases, as expanding LCD monitor color gamuts result in the capacity to reproduce a wider range of colors and more opportunities to check colors or adjusting images on monitor screens, problems such as breakdowns in tonal gradations, variations in chromaticity caused by narrow viewing angles, and screen display irregularities, less conspicuous at color gamuts in the sRGB range, have become more pronounced. As mentioned earlier, the mere fact of incorporating an LCD panel with a wide color gamut does not ensure that an LCD monitor offers high image quality. On this subject, let"s take a close look at various technologies for putting a wide color gamut to use.

First we look at technologies to increase gradation. Key here is the internal gamma-correction function for multi-level gradation. This function displays eight-bit input signals on screen in each RGB color from the PC side after first subjecting them to multi-level gradation to 10 or more bits in each RGB color inside the LCD monitor, then assigning these to each RGB eight-bit color deemed optimal. This improves tonal gradations and gaps in hue by improving the gamma curve.

On the subject of the viewing angle of an LCD panel, while larger screen sizes generally make it easier to see differences, particularly with products with wide color gamuts, variations in chromaticity can be an issue. For the most part, chromaticity variation due to viewing angle is determined by the technology of the LCD panel, with superior ones showing no variation in color even when viewed from a moderate angle. Setting aside the various particulars of LCD panel technologies, these generally include in-plane switching (IPS), vertical alignment (VA), and twisted nematic (TN) panels, listed from smaller to larger chromaticity variation. While TN technology has advanced to the point at which viewing angle characteristics are much improved from several years back, a significant gap remains between this technology and VA and IPS technologies. If color performance and chromaticity variation are important, VA or IPS technology remains the better choice.

A uniformity-correction function is a technology for reducing display irregularities. The uniformity referred to here refers to colors and brightness (luminance) on screen. An LCD monitor with superior uniformity has low levels of screen luminance irregularities or color irregularities. High-performance LCD monitors feature systems that measure luminance and chromaticity at each position on screen and correct them internally.

This is a comparison of monitors with and without uniformity correction. An LCD monitor with uniformity correction (photo at left) has more uniform luminance and color on screen than one lacking uniformity correction (photo at right). The two photographs above have been adjusted to equalize levels to emphasize display irregularities. Actual irregularities would be less conspicuous.

To make full use of an LCD monitor with a wide color gamut and to display colors as the user intended, one needs to consider adopting a calibration environment. LCD monitor calibration is a system for measuring colors on screen using a special-purpose calibrator and reflecting the characteristics of the colors in the ICC profile (a file defining device color characteristics) used by the operating system. Going through an ICC profile ensures uniformity between the color information handled by graphics software or other software and the colors generated by the LCD monitor to a high degree of precision.

Software calibration refers to following the instructions of specialized calibration software to adjust parameters such as luminance, contrast, and color temperature (RGB balance) using the LCD monitor"s adjustment menu, approaching the intended color through manual adjustments. Graphics driver colors are manipulated in some cases in place of the LCD monitor"s adjustment menu. Software calibration features low cost and can be used to calibrate any LCD monitor.

However, variations in precision can arise since software calibration involves manual adjustment. Internally, RGB gradation can suffer because display balance is matched by thinning RGB output levels using software processing. Even so, use of software calibration will likely make it easier to reproduce colors as intended than using no calibration at all.

In contrast, hardware calibration is clearly more precise than software calibration. It also requires less effort, although it can be used only with compatible LCD monitors and entails certain setup costs. In general, it involves the following steps: calibration software controls the calibrator; matching color characteristics on screen with target color characteristics and directly adjusting the LCD monitor"s luminance, contrast, and gamma-correction table (look-up table) at the hardware level. Another aspect of hardware calibration that cannot be overlooked is its ease of use. All tasks through the preparation of an ICC profile for the results of adjustment and registering this to the OS are done automatically.

The EIZO LCD monitors currently compatible with hardware calibration include models in the ColorEdge series. The FlexScan series uses software calibration. (Note: As of January 2011, FlexScan monitors compatible with EasyPIX ver. 2 offer hardware calibration functionality.)

By combining a ColorEdge-series monitor with a calibrator and ColorNavigator special-purpose color-calibration software, one can achieve easy, precise hardware calibration.

In the next session, we will examine LCD monitor interfaces and a number of video interfaces for LCD monitors, including the latest generation of interfaces such as HDMI and DisplayPort.

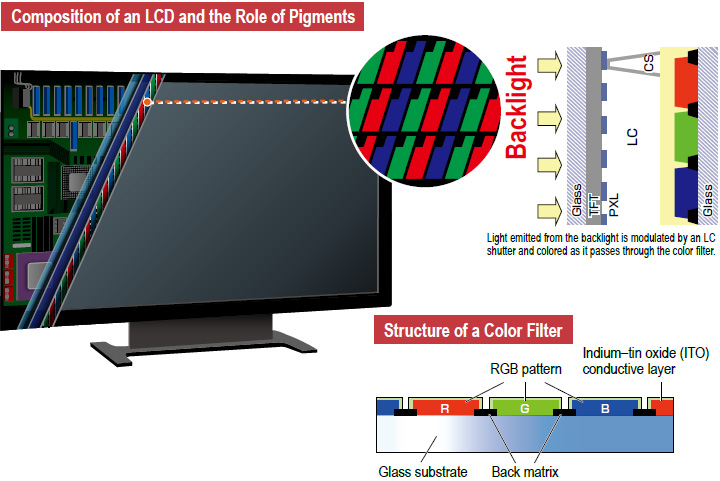

Color images on liquid crystal displays (LCDs) used in LCD televisions, computers and smartphones are produced using the three primary colors of light—red (R), green (G) and blue (B). These colors are created using pigments. LCDs produce images by transmitting light emitted from a backlight lamp through a color filter to which an RGB pattern has been applied. As a consequence, the pigments used in the color filter are crucial to picture quality.

With Japan’s shift to digital terrestrial television driving up demand for flatpanel LCD televisions and the popularity of smartphones increasing, in 2007 DIC launched the G58 series of green pigments, which achieved a remarkable increase in brightness. The series includes FASTOGEN GREEN A350, a green pigment characterized by outstanding brightness and contrast that ensures excellent picture quality even with little light from the backlight. In fiscal year 2014, DIC developed the G59 series of green pigments for wide color gamut color filters, which deliver superior brightness and color reproduction, making them suitable for use in filters for next-generation high-definition displays, including those for ultra-high-definition (UHD) televisions. DIC currently enjoys an 85%- plus share of the global market for green pigments for color filters, making its products the de facto standard. DIC also manufactures blue pigments for color filters. In 2012, the Company developed the A series, which boasts a superb balance between brightness and contrast. The optical properties of pigments in this series have earned high marks from smartphone manufacturers and boosted DIC’s share of the global market for blue pigments to approximately 50%.

DIC’s pigments for color filters, which satisfy the diverse performance requirements of displays used in LCD televisions, smartphones, tablets and notebook computers while at the same time adding value, have been adopted for use by many color filter manufacturers. In addition to improving picture quality, these pigments reduce energy consumption and, by extension, lower emissions of CO₂. Having positioned pigments for color filters as a business that it expects to drive growth, DIC continues working to reinforce its development and product supply capabilities.

DIC first succeeded in developing offset printing inks in-house in 1915 and 10 years later began production of organic pigments for its own use. Over subsequent years, the Company amassed development and design capabilities, as well as production technologies, crucial to the manufacture of fine chemicals and in 1973 commercialized revolutionary high-performance, long-lasting nematic LCs, which were adopted by Sharp Corporation for use in the world’s first pocket calculator incorporating an LCD. DIC’s passion and development prowess are also evident in its pigments for color filters.

Large-screen LCD televisions are expected to deliver superbly realistic and accurate color reproduction. The small LCDs used in smartphones and other devices must be clear, easy to read and bright enough to ensure legibility even with less light. This is because reduced light requirements results in longer battery life. Increasing brightness requires making color filters thinner and more transparent, but this alone will not deliver vivid colors and resolution. With the question of how best to realize both high brightness and vivid colors on ongoing challenge for display manufacturers, DIC has responded by developing innovative pigments for this application.

Copper has traditionally been the central material used in green pigments. In developing its green pigments for color filters, DIC defied conventional wisdom by exploring the use of a different central material with the goal of further enhancing performance characteristics. Through a process of trial and error, the Company narrowed down the list of suitable materials from a wide range of candidates, eventually choosing zinc. DIC also significantly improved transparency by reducing the size of pigment particles, thereby achieving a dramatic increase in contrast, which ensures a bright, clear picture quality even with less light. The outcome of these efforts was the groundbreaking G58 series.

Picture quality is influenced significantly by the brightness and contrast of the pigment used in the color filter. (Left: High brightness and high contrast; Right: Low brightness and low contrast)

In the area of blue pigments for color filters, DIC also leveraged its superior molecular design capabilities to achieve outstanding tinting strength and precise particle size control. To develop the A series of blue pigments for color filters, the Company also employed specialty particle surface processing to ensure highly stable dispersion, realizing an excellent balance between brightness and contrast. Products in the A series currently dominate the market for blue pigments for color filters, delivering excellent optical properties that continue to earn solid marks from smartphone manufacturers.

DIC’s success in developing a steady stream of pioneering functional pigments is supported by the seamless integration of basic technologies amassed in various fields as a manufacturer of color materials, the crossbusiness R&D configuration of its Central Research Laboratories and production technologies that facilitate the mass production of products with performance characteristics realized in the laboratory.

The value chain extending from functional pigments through to color filters for LCDs encompasses manufacturers of pigments, pigment dispersions, resist inks, color filters and LCDs. In developing pigments for color filters, we gather information on the latest trends from LCD manufacturers, which we apply to the formulation of nextgeneration product strategies.

Production of pigment dispersions, color filters and LCDs is concentrated primarily in East Asia. Recent years have seen a particularly sharp increase in the People’s Republic of China (PRC), which is on the verge of overtaking the Republic of Korea (ROK) as No. 1 in terms of volume produced. We are making full use of the DIC Group’s global network by working closely with local Group companies to bolster the adoption of DIC pigments for color filters for use in LCDs.

The evolution of display backlight technology from light-emitting diodes (LEDs) to organic light-emitting diodes (OLEDs) to quantum dots (light-emitting semiconductor nanoparticles) is also a key factor underscoring changes in the performance requirements of pigment customers. At the Central Research Laboratories, dedicated molecular design, analysis, simulation and other technical groups promote cross-collaboration with the goal of accelerating all stages of the development of products with new optical properties, from planning through to commercialization.

In June 2017, DIC announced that plans to expand the production capacity for blue pigments for color filters of its Kashima Plant, in Ibaraki Prefecture, to 1.5 times the current level by fiscal year 2021. In light of growing demand—underpinned by growth in emerging economies— and an increase in the volume of pigments used attributable to the trend toward larger displays, DIC estimates that the global display market will continue to expand at a rate of approximately 3.5% annually between now and fiscal year 2025. Demand for A series blue pigments for color filters has risen sharply since launch, reflecting a steady increase in the number of customers adopting these pigments for use. DIC will capitalize on the expansion of its production capacity to boost sales of these pigments to 1.5 times the fiscal year 2016 level by fiscal year 2021, to solidify its top share of the global market for blue pigments for color filters, as it has done for its green pigments for this application, which are currently recognized as the de facto standard worldwide.

Securing the top share of the global market for pigments for color filters by offering products with unrivaled optical properties with unrivaled optical properties

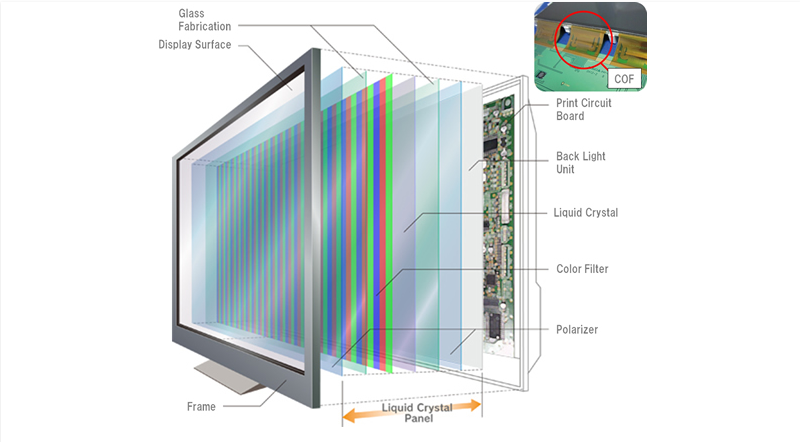

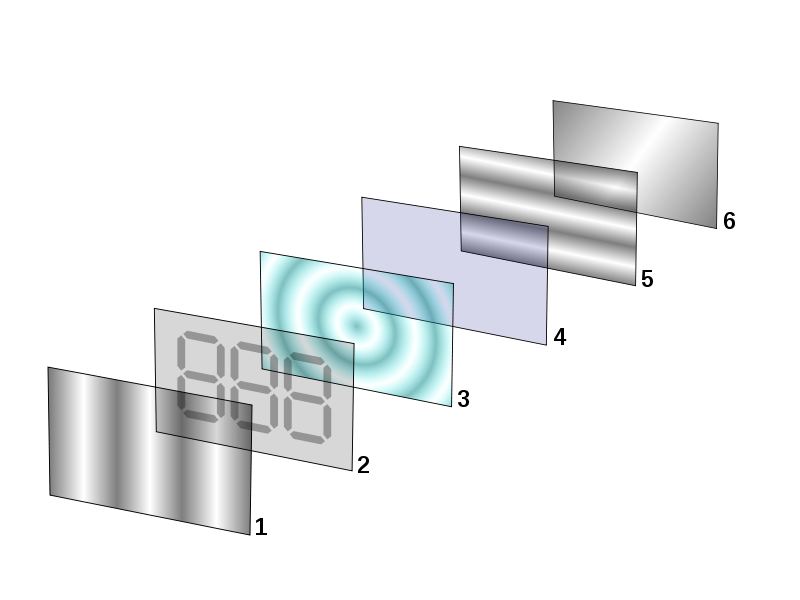

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey