seiko epson lcd panel manufacturer

Under the agreement, Universal Display will supply its proprietary phosphorescent OLED materials and technology to Epson for AR/VR display applications.“We are pleased to continue our partnership with Japanese panel maker Seiko Epson,” said Steven V. Abramson, President and Chief Executive Officer of Universal Display Corporation, in a press release. “Our mission is to enable our customers and the OLED industry with our highly-efficient, high-performing proprietary OLED technologies and UniversalPHOLED materials. We look forward to further collaborating with Epson as the proliferation of OLEDs is expected to broaden and grow in the consumer electronics landscape.”

TOKYO, March 12 (Reuters) - Sony Corpsaid it would start talks with Seiko Epson Corpon an alliance in small-sized LCDs, including a possible purchase of some of Seiko Epson"s display assets, in a move to strengthen its LCD operations.

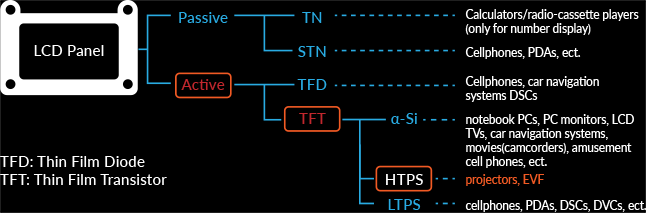

Details of the pact, including the value of the deal, have not been decided, but Sony said it was interested in Seiko Epson’s technology and output capacity of amorphous silicon thin-film transistor (TFT) LCDs, known as low-cost displays.

Sony focuses on low-temperature polysilicon TFT LCDs, which offer better picture quality, in the small- and medium-sized category. The addition of amorphous silicon TFT LCDs could boost its competitiveness as a panel supplier and maker of mobile devices with displays, such as cellphones and digital cameras.

“I don’t think this is bad if the deal boosts Sony’s competitiveness in panels, including patents and technologies, and if that leads to an improvement in Sony’s competitiveness in products like digital cameras, camcorders and games,” he said.

Unlike Seiko Epson, Sony offers a wide range of consumer electronics products that come with small displays, such as Cyber-shot digital cameras, Sony Ericssonphones, Handycam camcorders and PlayStation Portable game players.

The company, which competes with Canon Incin printers and with Sharp in display panels, is projecting a record net loss of 100 billion yen ($1 billion) for the year ending this month, hit by costs of restructuring its ailing LCD and microchip businesses.

“It is our understanding that it is difficult to turn around earnings in the small- and medium-sized LCD display business on our own,” Seiko EpsonPresident Minoru Usui told a news conference.

Seiko Epson was the sixth-largest maker of small- and mid-sized LCDs in 2008 and Sony ranked eighth, preliminary estimates by research firm DisplaySearch showed.

Usui said Seiko Epson is targeting a recurring profit, which is pretax and excludes special items, of about 20 billion yen for the year starting in April 2010.

Prior to the announcement, Seiko Epson shares closed up 2.7 percent at 1,117 yen, while those of Sony fell 3.7 percent to 1,735 yen. The benchmark Nikkei averagedropped 2.4 percent. (Editing by Chris Gallagher)

Epson"s Simple LCDC series offers LCD Controllers with basic functionality. These products offer a low cost while retaining the advantage of a low power single chip solution. The Simple LCDC series supports TFT LCD panels from QVGA up to WVGA resolution, and is suitable for factory automation (FA) controller, medical instrument, measuring equipment, and office automation (OA) applications. The following Simple LCDCs are available.

1024K Byte embedded SRAM. The CPU interface supports an indirect 16-bit bus. The embedded display buffer supports WVGA up to 800x480 at 16bpp for single layer display. The S1D13L02 features a pixel doubling function which allows easy migration to larger panel sizes using existing image data -- such as QVGA to VGA. It also provides features such as: up to 3 display layers overlay, independent resizing of PIP window image data using the bi-cubic scaler (from x1/8 up to x8), transparency, alpha blending, gammma correction by LUT, and window rotation.

In 1988, Seiko Epson became the first in the world to adopt LCD technology in a projector, and in 1989 launched the VPJ-700, a compact full-color LCD video projector.

However, selling the world"s first projector was not easy. The engineering team was expanded to more than 20 members to launch the improved VPJ-2000, but sales did not increase, making the situation worse. At the time, video cameras and other products were becoming increasingly popular, but the need for LCD projectors as a device for projecting images in daily life and in business was limited.

Five engineers and two sales representatives were chosen to reinvent the LCD projector business. Considering that the original team had around 20 people, the team was trimmed considerably.

While the development team worked to increase product competitiveness and reduce cost, the production team and sales team continued to expand their operations. They repeatedly visited distributors and carried the prototype around the world. Once distributors could see the actual difference in brightness and resolution, they knew they could sell Epson"s products.

Seiko Epson is developing OLED technologies for many years. In May 2004 the company unveiled a prototype 40-inch OLED display in May 2004 and in 2009 Epson unveiled new inkjet-printing technology that will enable HDTV OLEDs. Seiko Epson aimed to produce 37" or larger TVs by 2012, but that never materialized.

Today Seiko Epson is mostly focused on inkjet technologies, and has an active collaboration with Merck. In 2016 the company unveiled augmented reality glasses that use OLED microdisplays (the company claims it is producing those microdisplays in-house).

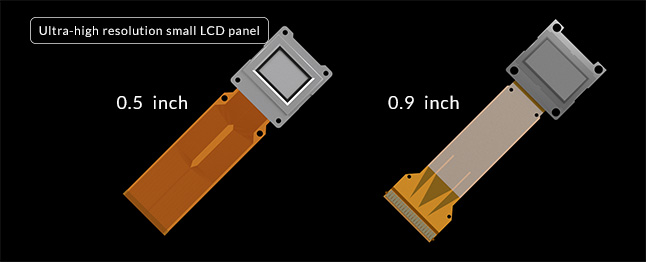

(PhysOrg.com) -- Seiko Epson Corporation has announced the world"s first 4K panel for 3LCD (liquid crystal display) projectors. The panel will enable the projectors to produce a bright image of 4096 x 2160 pixels resolution (2160p), which is four times the resolution of a top range high definition television or Blu-Ray Disc.

Epson"s panel is a 4K compatible HTPS (high temperature polysilicon) TFT (thin film transistor) liquid crystal panel for 3LCD projectors. The panel measures only 1.64 inches (4.2 cm) along the diagonal. The images have outstanding contrast and brightness, and rich vibrant colors.

The panel uses a C2 Fine LCD, which is a technology invented by Epson that combines an inorganic liquid crystal alignment layer with a vertical alignment layer.

3LCD projectors have three separate LCD panels: one each for red, green and blue light. The single color light passes through the LCD panel that creates shades of the color. The single color images are then combined by a prism to create a full color image that is projected onto the screen via the projector lens. Because the 3LCD technology has no moving parts in the light control system the projected image is smooth, sharply detailed, and there is no break-up in the motion or color.

The new panels may mean 3LCD projectors will find application in replacing the large, expensive projectors used for digitally projecting film in cinemas, for industrial and corporate presentations, and in schools and at big events. They will also be ideal for applications such as industrial and architectural design and simulations requiring high resolutions. The 4K panels can also be used to project four full HD images simultaneously.

A prototype of a projector using the 4K panel will be exhibited at the International Broadcast Equipment Exhibition at Makuhari Messe, Chiba, in Japan from 18 to 20 November, 2009. It is not known when the panel will be released to the market.

Seiko Epson Corp. engages in the development, manufacture, and sale of information equipment. It operates through the following segments: Information Equipment, Device and Precision Products, and Others. The Information Equipment segment offers inkjet printers, page printers, serial impact dot matrix printers, large-format inkjet printers, color image scanners, mini printers, point-of-sale systems printers, projectors, projector panels, label writers, and personal computers. The Device and Precision Products segment offers crystal units, crystal oscillators, quartz sensors, complementary metal-oxide semiconductor large scale integration products, watches, watch movements, plastic corrective lenses, precision industrial robots, integrated circuit handlers, and industrial inkjet equipment. The Others segment engages in the intra-group services and small-and medium-sized liquid crystal display. The company was founded on May 18, 1942 and is headquartered in Suwa, Japan.

Seiko Epson develops, manufactures, marketing, and servicing of information equipment (inkjet printers, scanners, POS system products, LCD projectors, etc.), electronic devices (small- and medium-size LCD displays, semiconductors, crystal devices, etc.), precision instruments (watches, plastic eyeglass lenses, FA equipment, etc.), and other products

Wed Sep 23, 2009: Sony to acquire the loss-making small and medium-sized LCD operations of Seiko Epson. The panel assets that will be transferred to Sony include output facilities for amorphous silicon thin-film transistor (TFT) LCDs, known as low-cost displays, and intellectual property rights for low-temperature polysilicon TFT LCDs, which offer better picture quality. Sony focuses on low-temperature polysilicon TFT LCDs in the small and medium-sized category, and the addition of amorphous silicon TFT LCDs is expected to strengthen its operations as a panel supplier as well as a maker of mobile devices with displays, such as cellphones and digital cameras.

October 25, 2006: OMRON Corporation (TSE: 6645; ADR: OMRNY; "OMRON"), a global leader in automation, sensing and control technology, announced that it has reached a preliminary agreement to acquire the semiconductor business assets of Seiko Epson"s consolidated subsidiary, Yasu Semiconductor Corporation. OMRON develops, manufactures, and markets custom ICs that offer functionality and cost-performance not found in general-purpose semiconductors, as well as MEMS (Micro Electro Mechanical Systems) products such as flow sensors and pressure sensors that utilize semiconductor processes in their manufacture. OMRON"s semiconductor-related sales for fiscal 2005 were 6.6 billion yen. The acquisition of the business assets resulting from this preliminary agreement is aimed at further reinforcing these semiconductor operations, while strengthening the OMRON Group"s line of semiconductor-equipped products.

In 1973 Seiko-Epson introduced the 06LC watch, the first LCD watch to reach the market. The 06LC digital watch was received even more favorably by the market than had been expected. And despite initial concerns about the display"s reliability, not one watch was returned due to a faulty display panel. Since then, LCD watches became a great success. After a few years prices became lower and lots of different functions were developed transforming them into a 80s icon.

Seiko Epson Corporation (“Epson”) has begun shipping samples of the S1D13709, a new display controller IC with built-in memory that is capable of easily controlling the display of both text and graphics on color TFT[1] and STN[2] LCD panels. This display controller is ideal for control panels used on factory automation equipment and office equipment such as printers and multifunction units.

STN panels are often used as control panels on factory automation systems and office equipment, but demand for color TFT panels in these applications has been growing in recent years because of their good visibility and greater powers of expression. The new S1D13709, with built-in CGROM[3], can enable such popular features as mixed text and graphics, overlays, and smooth scrolling (vertical and horizontal) on both STN and TFT LCD panels. In addition, since memory for the display is built-in, no external memory is needed. This saves space and design work for users. The software of the new S1D13709 is compatible with that of the S1D13700, Epson’s previous display controller IC for monochrome STN LCD panels. This makes it easy for S1D13700 users to migrate to color TFT LCD panels.

Going forward, Epson intends to leverage its unique set of compact, energy-saving, and high-precision technologies to help enrich society by providing products and services that solve real issues for customers.

Users of the S1D13700, Epson’s previous display controller IC for monochrome STN display panels, can use the new S1D13709 with their existing software to control color TFT LCDs (some restrictions apply).

TOKYO, Nov 15 Asia Pulse - Sanyo Epson Imaging Devices Corp., a joint venture between Sanyo Electric Co. (TSE:6764) and Seiko Epson Corp. (TSE:6724), will move part of its production of color LCD panels from Nagano Prefecture to Suzhou, China , company sources said.

Most of the displays made in Suzhou will be STN (super twist nematic) panels for use in cell phones sold overseas. Integrated production will be carried out in China to enhance efficiency.

diagonal) HTPS panels which utilize Epson"s C2 Fine technology. The Epson Pro Cinema 1080 UB is the first projector we experienced with this new technology and it looked fantastic.

broadcasting, technology seems determined to keep pace. This is largely the result of a lot of market competition - particularly in the DLP vs 3LCD arena. Epson began producing full high definition C2 Fine panels for home projectors last year and things seem to be getting better and better. The new D7 model is an improved version of these HTPS panels.

luminance while using the same lamp as previous models. That means the same lamp will result in brighter images. Conversely, manufacturers can insert lower-watt lamps to achieve the same levels of luminance experienced with a D6 panel.

The D7 panels are a definite improvement, but an incremental one. The main thing you"ll see with these panels are an increased contrast ratio and a clear support for Deep Color options within the moving-target HDMI 13 specification. We haven"t sen a practical demonstration of the benefits of the Mini-LVDS interface, but anything that serves to reduce noise is a welcome advancement. And of course LCD is a 3-chip solution - and for those of you susceptible to color wheel rainbow artifacts - 3LCD is looking better and better with every update.

HTPS is an abbreviation of High Temperature Poly-Silicon, an active matrix transmissive LCD. It"s superior in that it is smaller, has higher resolution and higher contrast, and can embed drivers. The main function of HTPS is as a light valve for projectors.

The liquid crystal research of the 1960s was characterized by the discovery of and experiments on the properties of the liquid crystals. George H. Heilmeier of the RCA based his research on that of Williams, diving into the electro-optical nature of the crystals. After many attempts to use the liquid crystals to display different colors, he created the first working LCD using something called a dynamic scattering mode (DSM) that, when voltage is applied, turns the clear liquid crystal layer into a more translucent state. Heilmeier was thus deemed the inventor of the LCD.

In the late 1960s, the United Kingdom Royal Radar Establishment (RRE) discovered the cyanobiphenyl liquid crystal, a type that was fitting for LCD usage in terms of stability and temperature. In 1968, Bernard Lechner of RCA created the idea of a TFT-based LCD, and in that same year, he and several others brought that idea into reality using Heilmeier’s DSM LCD.

After the LCD’s entrance into the field of display technology, the 1970s were full of expansive research into improving the LCD and making it appropriate for a greater variety of applications. In 1970, the twisted nematic field effect was patented in Switzerland with credited inventors being Wolfgang Helfrich and Martin Schadt. This twisted nematic (TN) effect soon conjoined with products that entered the international markets like Japan’s electronic industry. In the US, the same patent was filed by James Fergason in 1971. His company, ILIXCO, known today as LXD Incorporated, manufactured TN-effect LCDs which grew to overshadow the DSM models. TN LCDs offered better features like lower operating voltages and power consumption.

From this, the first digital clock, or more specifically an electronic quartz wristwatch, using a TN-LCD and consisting of four digits was patented in the US and released to consumers in 1972. Japan’s Sharp Corporation, in 1975, began mass production of digital watch and pocket calculator TN LCDs, and eventually, other Japanese corporations began to rise in the market for wristwatch displays. Seiko, as an example, developed the first six-digit TN-based LCD quartz watch, an upgrade from the original four-digit watch.

Nevertheless, the DSM LCD was not rendered completely useless. A 1972 development by the North American Rockwell Microelectronics Corp integrated the DSM LCD into calculators marketed by Lloyds Electronics. These required a form of internal light to show the display, and so backlightswere also incorporated into these calculators. Shortly after, in 1973, Sharp Corporation brought DSM LCD pocket-sized calculators into the picture. A polymer called polyimide was used as the orientation layer of liquid crystal molecules.

In the 1980s, there was rapid progress made in creating usable products with this new LCD research. Color LCD television screens were first developed in Japan during this decade. Because of the limit in response times due to large display size (correlated with a large number of pixels), the first TVs were handheld/pocket TVs. Seiko Epson, or Epson, created the first LCD TV, releasing it to the public in 1982, which was soon followed by their first fully colored display pocket LCD TV in 1984. Also in 1984 was the first commercial TFT LCD display: Citizen Watch’s 2.7 inch color LCD TV. Shortly after, in 1988, Sharp Corporation created a 14 inch full-color TFT LCD that used an active matrix and had full-motion properties. Large-size LCDs now made LCD integration into large flat-panel displays like LCD screens and LCD monitors possible. LCD projection technology, first created by Epson, became readily available to consumers in compact and fully colored modes in 1989.

The LCD growth in the 1990s focused more on the optical properties of these new displays in attempts to advance their quality and abilities. Hitachi engineers were integral to the analysis of the LCD industry, previously centered in Japan, began expanding and moving towards South Korea, Taiwan, and later China as well.

As we entered the new century, the prominence of LCDs boomed. They surpassed the previously popular cathode-ray tube (CRT) displays in both image quality and sales across the world in 2007. Other developments continued to be made, such as the manufacturing of even larger displays, adoption of transparent and flexible materials for LCD hardware, and creation of more methods to

As of today, as LCD displays have developed quite a bit, but have remained consistent in structure. Illuminated by a backlight, the display consists of, from outermost to innermost two polarizers, two substrates (typically glass), electrodes, and the liquid crystal layer. Closer to the surface is sometimes a color filter as well, using an RGB scheme. As light passes through the polarizer closest to the backlight, it enters the liquid crystal layer. Now, depending on whether an electric field directed by the electrodes is present, the liquid crystal will behave differently. Whether using a TN, IPS, or MVS LCD, the electrode electric field will alter the orientation of the liquid crystal molecules to then affect the polarization of the passing light. If the light is polarized properly, it will pass completely through the color filter and surface polarizer, displaying a certain color. If partially polarized correctly, it will display a medium level of light, or a less bright color. If not polarized properly, the light will not pass the surface, and no color will be displayed.

1927: Vsevolod Frederiks in Russian devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology.

1967: Bernard Lechner, Frank Marlowe, Edward Nester and Juri Tults built the first LCD to operate at television rates using discrete MOS transistors wired to the device.

1968: A research group at RCA laboratories in the US, headed by George Heilmeier, developed the first LCDs based on DSM (dynamic scattering mode) and the first bistable LCD using a mixture of cholesteric and nematic liquid crystals. The result sparked a worldwide effort to further develop LCDs. George H. Heilmeier was inducted in the National Inventors Hall of Fame and credited with the invention of LCDs. Heilmeier’s work is an IEEE Milestone.

1979, Peter Le Comber and Walter Spear at University of Dundee discovered that hydrogenated amorphous silicon (Alpha-Si:H) thin film transistors were suitable to drive LCDs. This is the major breakthrough that led to LCD television and computer displays.

1972: Tadashi Sasaki and Tomio Wada at Sharp Corporation built a prototype desktop calculator with a dynamic scattering LCD and started a program to build the first truly portable handheld calculator.

Universal Display announced an OLED evaluation agreement with Seiko Epson Corporation. Under the agreement, Universal Display will supply its proprietary phosphorescent OLED materials and technology to Epson for AR/VR (augmented reality/virtual reality) display applications. Details and financial terms of the agreement have not been disclosed.

“We are pleased to continue our partnership with Japanese panel maker Seiko Epson,” said Steven V. Abramson, president and CEO of Universal Display Corporation. “Our mission is to enable our customers and the OLED industry with our highly-efficient, high-performing proprietary OLED technologies and UniversalPHOLED materials. We look forward to further collaborating with Epson as the proliferation of OLEDs is expected to broaden and grow in the consumer electronics landscape.”

After visiting the Seiko Epson Shiojiri factory in the Nagano region I was able to arrange a visit to the Monozukuri Museum at the Seiko Epson headquarters located in Kami-suwa.

I headed to the Epson HQ after leaving the Gishodo Museum I had visited earlier that day. It was just a short train ride from Shimo-suwa to Kami-suwa. This train driver had a Seiko pocket watch like seen on many Japan Rail trains.

I checked into the security reception and met my contact Yoshiko Kotani who works with the Monozukuri Museum. In the same facility there is a school where students study in a range of different areas related to the production segments that Epson is involved with. The term Monozukuri literally translates to production but is more accurately translated as craftsmanship.

We headed across the campus to a building with some of the school facilities and also the museum. We started with a brief summary of Seiko Epson Corporation and the different parts of the company. Epson has an annual revenue of approximately $9 billion, this is broken down into $1.5 billion for watches, $1.5 billion for projectors and $6 billion for printers.

The history of Epson can be traced back to 1942 with the founding of Daiwa-kogyo a third-party supplier. In 1943 the Daini-seikosha Suwa factory was evacuated and relocated to the Daiwa-kogyo location. In 1959 the companies were merged and renamed as Suwa-seikosha. In 1961 Sinshu-seiki was founded and it was made up of six different divisions.

The printing section of the business had originally started with Seiko’s involvement in the 1964 Olympics. To record the times Seiko developed a small printer that could be connected to the timing devices. The electronic printer proved to be incredibly successful and in 1975 Sinshu-seiki created the Epson brand. Epson stands for “Electronic Printer SON” referencing its origins and in 1982 Sinshu-seiki renamed the company Epson.

The first watch product was a ladies type 5 movement that also utilised parts from Daini-seikosha. There was also a movement that was used in the men"s Super models.

Following the Crystal Chronometer was the Astron. This was obviously a significant milestone in not only Seiko’s history but for the whole industry. There is an Astron movement also on display.

As part of the creation of stepper motors for the Astron, the SAM-D samarium-cobalt rare-earth bonded magnets were developed. These became the basis for the Suwa Seikosha Co., Ltd. magnet business.

In 1978 Epson released the Melody IC the world’s first electronic sound generating device. This development was based on the company"s research into CMOS technologies and the IC was able to produce three sounds, a melody, buzzer and chime. This technology was rapidly introduced into a Seiko watch providing an alarm function in the same year.

Following these watch focused displays was a stand showing the first printer developed for the 1964 Olympics. This was designed specifically to print times from the Seiko timing system. There was also an image of the world’s first digital stopwatch that was also developed for the games.

In 1979 Epson released the terminal printer TP-80 a serial dot matrix printer. This proved to be very successful and the range was quickly expanded keeping pace with the rapid developments in the computer industry. By the mid-80’s Epson had grown to be the world’s largest printer manufacturer.

In 1982 Epson released the world’s first handheld computer the HC-20. This had built-in screen and printer as well as a CP-20 acoustic coupler accessory.

In the early 1990’s Epson began releasing inkjet printers and in 1994 introduced the MJ-700V2C the first full color product that could achieve 720 dpi printing.

The next exhibit was a display about the production of quartz crystals. Seiko Epson produce their own crystals and over the years have been able to increase their size and quality.

Next was a display showing the Epson Metal Injection Moulding (MIM) process. This process allows for the creation of complex shapes and minimises waste while increasing strength. This process has been used for the production of specialised nozzles, dental implants, locks and gundam feet. The process has also been used to produce the Landmaster single piece case and bezel as well as Grand Seiko case backs.

The next area on display was the optical products that were produced by Seiko. These optical products include lenses for projectors, lenses for small cameras and eyewear. In 2013 the eyewear portion of the company was completely moved to the optical company Hoya and they also agreed to purchase 50% of Seiko Optical Products Co., LTD., ("SOP") that was previously SEIKO"s wholly owned subsidiary.

Epson released a watch, the Chrono-bit, with PDA functionality in 2000. This was a competitor to the SII Ruputer that had been released a couple of years earlier.

Epson is also a large producer of projectors. The projector division of Epson has approximately the same amount of revenue as the watch division. In 1989 Epson released their first 3LCD projector the VPJ-700. Examples of the early Epson projectors were also on display.

There was also a display with an Epson Stylus 800 inkjet printer that was selected by NASA for use on the STS-95 Discovery space shuttle mission in 1998. This unit has serial number 1001 and is displayed with official mission patches, cap and a signed crew poster. The crew included John H. Glenn Jr. who at age 77 became the oldest person in space.

There were really too many nice watches to examine each closely but I did like the example of the 6347 that was surprisingly the only vintage mechanical moon-phase model made by Seiko.

A small display of the Seiko e-ink watches were then shown including the first bracelet model from 2006. There was an accompanying sign explaining how the e-ink technology works.

There was also an explanation of the new Epson PaperLab that is the world’s first complete paper recycling system. You can input used paper into the unit and three minutes later a new sheet of A4 paper is produced. This self-contained system allows users completely secure document destruction and is environmentally friendly.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey