lcd panel sits manufacturer

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

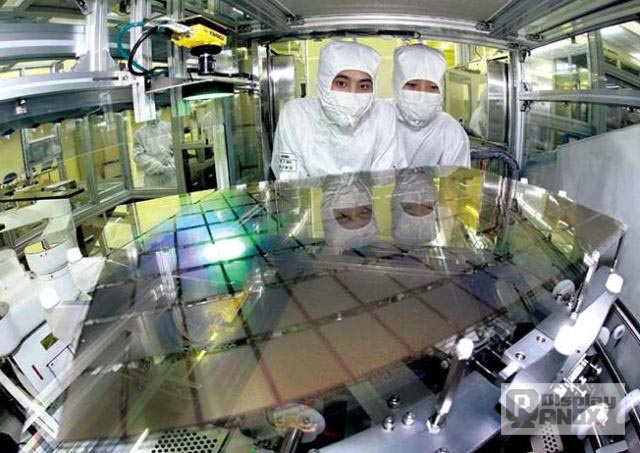

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Since 1995 Digital View has been providing LCD controller boards, related accessories and engineering services for video display systems, commercial video monitors and other non-consumer displays systems using LCD panels. Offices in USA, UK and Hong Kong with distribution globally.

Backlit LCDs provide excellent visibility indoors, but require high-brightness backlights to produce enough brightness for for direct sunlight readability - 1000 nits or more, to be exact. All that brightness requires a lot of power to operate, making traditional high-brightness LCD signage costly in multiple ways.

Sun Vision Display panels actually turn sunlight into an asset through their reflective LCD technology.They"re the perfect solution for sunny locations. In fact, as sunlight or ambient light shining on the display increases, so does the brightness of the Sun Vision Display panel"s image - all while consuming almost no power (less than 6 watts). No need to shield the display from the sun!

At iTech Company, we combine engineering and manufacturing experience to deliver the highest quality of industrial monitor displays. Our LCD Plastic Case Monitors features an optional touch screen functionality for interactive usage. For some outdoor applications, it may require a much higher brightness level. Our products offer from 200nits to 1000nits, which ensure readability even when used in direct sunlight. Its spill proof and anti-dust protection will give a longer product life time.Best suited for space limited retail and hospitality settings, these products deliver high resolution and clear images. Check out the specifications of each of our products for more info.

Samsung’s display-making subsidiary, Samsung Display initially decided to shut down its LCD business by the end of 2020. The company was reportedly forced to reconsider after the demand for LCD panels increased in the post-pandemic (Covid-19) period. In 2021, more reports suggested that the company again decided to stop producing LCD panels, but Samsung didn’t stop making them. However, according to a report by Sammobile, Samsung Display is now finally ready to shut down its LCD production. The report also suggests that Samsung is now buying LCD panels from China.

As per the report, Samsung might be planning to shut down LCD panel production in June as it doesn’t align with Samsung Display’s long-term vision for the business. The company plans to substitute LCD panels with Quantum Dot (QD-OLED) displays as Samsung recently repurposed an obsolete LCD plant to produce OLED panels.

The company is not willing to compete in a market that’s dominated by affordable panels from Chinese and Taiwanese counterparts. The falling prices of LCD are also preventing Samsung from continuing production, the report claims.

Samsung Display’s largest buyer was the consumer electronics arm of the conglomerate, Samsung Electronics. However, the company itself is opting for affordable LCD panels from Chinese and Taiwanese suppliers. Samsung Display is expected to primarily focus on the manufacturing of Quantum Dot and OLED displays after its LCD business shuts down. The employees appointed for the LCD production are also likely to be transferred to the QD division.

Today’s vivid, immersive displays rely on layers of Corning glass to provide a stunning viewing experience. Wherever you look for news and entertainment, chances are Corning glass is there, too. We are the science and engineering powerhouse behind revolutionary display inventions, including glass cathode-ray bulbs for the first televisions and the LCD glass that made smartphones and laptop computers commonplace. We set the standard for the industry with Corning® EAGLE XG® Slim Glass substrates, manufacturing over 25 billion square feet — enough to pave the Great Wall of China 25 times, or cover nearly 390,000 football fields — while eliminating the equivalent of 6,000 truckloads of heavy metals from entering the environment. Today, we continue to enable the display industry and emerging technologies with our three-glass portfolio.

New design freedoms are taking shape with Corning LotusTMNXT Glass. Thanks to Corning Lotus NXT Glass, devices with OLED displays that curve, flex, or extend edge-to-edge across a device are all within reach. Flexible OLED devices use a plastic backplane substrate, which calls for Corning’s high-tech display glass to enable the manufacturing process —to date, it"s enabled more than 2 billion OLED devices. Corning Lotus NXT Glass continues to emerge as the leader most-advantaged glass for rigid and flexible OLED panels – outperforming competitors and enabling the designs and performance that consumers love.

Looking beyond incumbent LCD and OLED display technology, Corning"s display portfolio is finding new opportunities in emerging technology applications, including Quantum Dot, Micro LED and Mini LED. With our proven track record of successfully navigating the display technology roadmap, our proprietary fusion manufacturing platform and reliable supply network, our commitment to our customers and innovation, and our innovative portfolio, we are excited to support the next generation of displays.

When you stop and think about what goes into displaying one of these amazing images, you might recognize most are protected by a glass cover. You might even be familiar with display types like LCD or OLED. Yet for many, the recognition stops there. You may see the image on the surface, but rarely think about what creates that image, how it achieves life-like, vibrant color, and the journey it makes to reach our eyes.

Though each layer of the glass stack is formed with the same fusion manufacturing process, the compositions of the glass are different – allowing for different properties and benefits. LCD and OLED displays, whether on mobile devices with glass cover and back or otherwise, utilize different super-thin layers of glass specific to their applications:

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved January 18, 2023, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed January 18, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: January 18, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited January 18, 2023)

LCD panel production capacity share from 2016 to 2025, by country [Graph], DSCC, June 8, 2020. [Online]. Available: https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

(Reuters) - Foxconn Technology Group is reconsidering plans to make advanced liquid crystal display panels at a $10 billion Wisconsin campus, and said it intends to hire mostly engineers and researchers rather than the manufacturing workforce the project originally promised.

Foxconn, which received controversial state and local incentives for the project, initially planned to manufacture advanced large screen displays for TVs and other consumer and professional products at the facility, which is under construction. It later said it would build smaller LCD screens instead.

Rather than a focus on LCD manufacturing, Foxconn wants to create a “technology hub” in Wisconsin that would largely consist of research facilities along with packaging and assembly operations, Woo said. It would also produce specialized tech products for industrial, healthcare, and professional applications, he added.

Rather than manufacturing LCD panels in the United States, Woo said it would be more profitable to make them in greater China and Japan, ship them to Mexico for final assembly, and import the finished product to the United States.

He said that would represent a supply chain that fits with Foxconn’s current “fluid, good business model.”FILE PHOTO: A shovel and FoxConn logo are seen before the arrival of U.S. President Donald Trump as he participates in the Foxconn Technology Group groundbreaking ceremony for its LCD manufacturing campus, in Mount Pleasant, Wisconsin, U.S., June 28, 2018. REUTERS/Darren Hauck

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey