are lcd touch screen controls better than glass touch controls brands

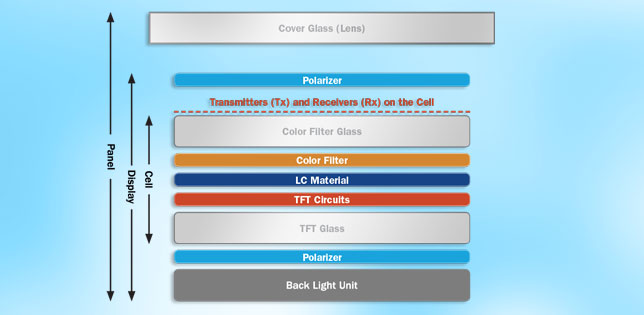

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The liquid crystals are made up of a part solid, part liquid substance that can be "twisted" by applying an electrical voltage to them. They block the polarized light when they are off, but reflect red, green, or blue light when activated.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

![]()

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Touch screens give the user control of a device through simple or multi-touch gestures. They enable the user to interact directly with what is displayed rather than using a mouse, trackpad, or other separate components.

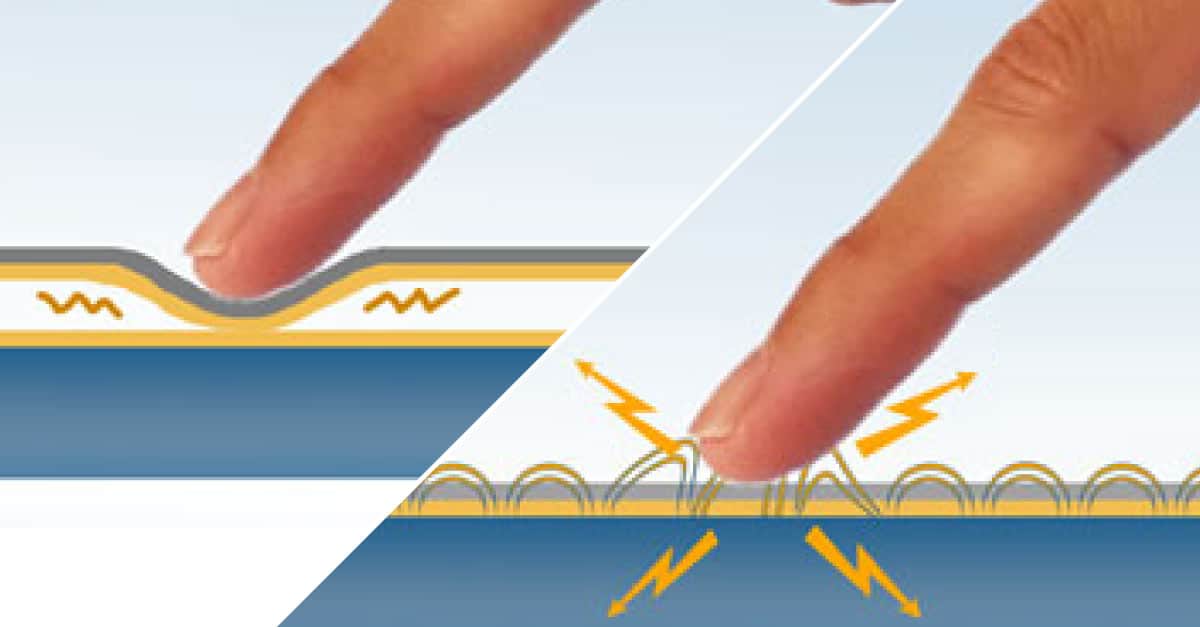

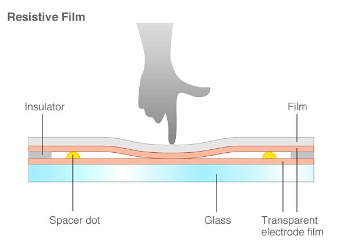

Resistive touch screens have a flexible top layer and a rigid bottom layer separated by insulating dots, with the inside surface of each layer coated with a transparent conductive coating.

Projected capacitive technologies detect touch by measuring the capacitance at each addressable electrode. When a finger or a conductive stylus approaches an electrode, it disturbs the electromagnetic field and alters the capacitance. This change in capacitance can be measured by the electronics and then converted into X,Y locations that the system can use to detect touch.

3M Project Capacitive Technology (3M PCT) is based on mutual capacitance to create multi-touch interactive. Mutual capacitance is the intentional or unintentional capacitance between two "charge holding objects” (see illustration). Projected capacitance touchscreens intentionally create mutual capacitance between elements of columns and rows in the vicinity where each intersect the other. This allows the system electronics to measure each node (intersection) individually to detect multiple touches on the screen during one screen scan.

When a finger touches near an intersection, some of the mutual capacitance between the row and column is coupled to the finger which reduce the capacitance at the intersection as measured by the system electronics. This reduced capacitance crosses the "touch threshold" set by the electronics indicating a touch has occurred.

Dispersive Signal Technology (DST) consists of a chemically-strengthened glass substrate with piezos mounted on each corner, mated to a sophisticated, dedicated controller.

The DST Touch System determines the touch position by pinpointing the source of "bending waves" created by finger or stylus contact within the glass substrate. This process of interpreting bending waves within the glass substrate helps eliminate traditional performance issues related to on-screen contaminants and surface damage, and provides fast, accurate touch attributes.

Acoustic wave touch screens use transducers mounted at the edge of a glass overlay to emit ultrasonic sound waves along two sides. These waves are reflected across the surface of the glass and received by sensors. A finger or other soft tipped stylus absorbs some of the acoustic energy and the controller measures the amplitude change of the wave to determine touch location.

Infrared touch screens are based on light-beam interruption technology. Instead of an overlay on the surface, a frame surrounds the display. The frame has light sources, or light emitting diodes (LEDs) on one side and light detectors on the opposite side, creating an optical grid across the screen.

Optical touch screen technology uses two line scanning cameras located at the corners of the screen. The cameras track the movement of any object close to the surface by detecting the interruption of an infra-red light source. The light is emitted in a plane across the surface of the screen and can be either active (infra-red LED) or passive (special reflective surfaces).

The term "multi-touch" is now in common use to describe any touch screen that can recognise more than one point of contact, in effect the use of two or more fingers simultaneously.

However, there are now several different types of multi-touch, depending on the touch technology employed. Below is an explanation of the different types of touch available which also acts as a guide for the terms we use for describing the touch screens we supply.

Single Touch occurs when a finger or stylus creates a touch event on the surface of a touch sensor or within a touch field so it is detected by the touch controller and the application can determine the X,Y coordinates of the touch event.

Single Touch occurs when a finger or stylus creates a touch event on the surface of a touch sensor or within a touch field so it is detected by the touch controller and the application can determine the X,Y coordinates of the touch event.

These technologies have been integrated into millions of devices and typically do not have the ability to detect or resolve more than a single touch point at a time as part of their standard configuration.

Inactive pens enable the same input characteristics as a finger, but with greater pointing accuracy, while sophisticated, active pens can provide more control and uses for the touch system with drawing and palm rejection capabilities, and mouse event capabilities.

Enhancements to firmware, software and hardware by many single touch technologies have increased their touch functionality. Some touch technologies can use advanced processing capabilities to "detect" or recognize that a second touch event is occurring, which is called a "gesture event".

Since single touch systems can´t resolve the exact location of the second touch event, they rely on algorithms to interpret or anticipate the intended gesture event input. Common industry terms for this functionality are two-finger gestures, dual touch, dual control, and gesture touch.

The best demonstration of Two Touch capability is to draw two parallel lines on the screen at the same time. Two Touch systems can also support gesturing.

Multi-touch refers to a touch system´s ability to simultaneously detect and resolve a minimum of 3+ touch points. All 3 or more touches are detected and fully resolved resulting in a dramatically improved touch experience.

To take full advantage of the multi-touch capabilities of this device, you can download multi-touch development applications from the following software companies:

Touchtech Lima is a premium multi-touch software solution. It is designed for multi-touch table and wall displays to create interactive presentations using your existing files (pictures, videos, and documents etc).

NUITEQ´s multi-touch software product Snowflake Suite is a premium multi-touch software solution. It is designed for multi-touch table and wall displays to create interactive presentations using your existing files (pictures, videos, and documents etc).

MultiTouch pack from Aduma is all about engaging touch presentations. It is used across a variety of markets whenever there is a need to captivate and engage an audience.

Omnitapps Multi Touch Suite is the fully customizable (multi) touch application suite. It offers a collection of applications that offers you a unique way to present your products or services.

Specifications are subject to change without notice. Touch Screen Middle East makes no additional warranties, expressed or implied, including but not limited to any implied warranties of merchantability or fitness for a particular purpose. User is responsible for determining whether the Products and Software are fit for the User´s particular purpose and suitable for its method of production, including intellectual property liability for User´s application.

A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

One of the main reasons why resistive touch panels still exist is its simple manufacturing process and low production cost. The MOQ (Minimum Order Quantity) and NRE (Non-Recurring Expense) are low. The driving is simple and low cost. The power consumption is low too. Resistive touch panel also immune to EMI well. Although it can’t use cover lens at the surface, the overlay can make it flexible for designs.

Resistive touchscreens offer an unparalleled level of durability. Manufacturing companies, restaurants and retailers often prefer them over other types of touchscreens for this very reason. With their durable construction, resistive touchscreens can withstand moisture and stress without succumbing to damage.

You can control a resistive touchscreen using a stylus or while wearing gloves. Most capacitive touchscreens only register commands performed with a bare finger (or a special capacitive stylus). If you use a stylus or a gloved finger to tap the interface, the capacitive touchscreen won’t respond to your command. Resistive touchscreens register and respond to all forms of input, though. You can control them with a bare finger, a gloved finger, a stylus or pretty much any other object.

The biggest advantages for resistive touch panel are its touch experience and clarity. It can only be used for single touch, no gestures or multi-touch. False touches can be generated if using two or more fingers to touch it.

Resistive touch panel’s transparency is relatively low. In order to prevent Newton rings or fingerprint mark, sometimes AG(anti-glare) film has to be used to make it look more smoky. Optical bonding can’t be used for RTP. The surface of resistive touch panel is soft and easily get scratched.

There are still a few potential cons associated with resistive touchscreens. When compared to capacitive touchscreens, resistive touchscreens aren’t as sensitive. They are still responsive, but you’ll have to tap or press the interface with greater force for a resistive touchscreen to recognize your input.

Resistive touchscreens usually offer lower display resolutions than capacitive touchscreens. Granted, not all applications require a high-resolution display. If a touchscreen is used as a point-of-sale (POS) system in a retail environment, for example, resolution shouldn’t be a concern.

If you have any questions about Orient Display capacitive touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

Selecting the most suitable type of touch screen for your project can improve device functionality and durability, which can mean a significant increase in customer adoption.

This article highlights the unique advantages and drawbacks of common touch screen technology, to help product design engineers make an informed decision.

Resistive touch is a legacy form of touch screen technology that was broadly popular for many years, but has been replaced by capacitive touch for many applications. Currently, resistive touch has a smaller range of common uses, but can still capably address certain needs.

The core elements of a resistive touch screen are two substrate layers, separated by a gap filled with either air or an inert gas. A flexible film-based substrate is always used for the top layer, while the bottom layers substrate can be either film or glass. A conductive material is applied to the inner-facing sides of the substrate layers, across from the air gap.

When a user applies pressure to the top surface, the film indents and causes the conductive material on the top layer to make an electrical contact with the conductive surface of the bottom layer. This activity creates a difference in voltage that the system registers as a touch. The location of this contact is pinpointed on the X and Y axes, and the touch controller then interprets the action. Because physical force is needed for a resistive touch screen to function, it is similar to a mechanical switch.

Resistive touch screens must be calibrated before they are used to ensure accurate and reliable operation. A user must apply pressure to the four corners of the screen, and sometimes on its center, to calibrate the screen with the rest of the system via a lookup database.

Because resistive touch screens interpret physical pressure as a touch, they are effective in a variety of environments using single touch. Any object capable of applying force to the screen can be used with the same result. For example, in applications where end users wear gloves, resistive touch screens offer reliable single-touch functionality.

Since resistive touch screens area actuated via mechanical force, they continue to function as intended even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens. For example, on single-touch applications within agricultural equipment, boats and underwater machinery.

Besides the functional advantages of resistive touch screens, price is a common reason why OEMs select this option. In projects where cost is a top concern, companies can use this option to realize savings that may not be possible with alternatives.

The configuration of a resistive touch screen removes the possibility of gestures, such as pinching and zooming, or any actions requiring multi-touch functionality. These screens cannot determine the location of a touch if more than one input is present.

In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens were invented before resistive touch screens. However, early iterations of this technology were prone to sensing false touches and creating noise that interfered with other nearby electronics. Due to these limitations, resistive touch screens and other options, like infrared touch screens, dominated the industry.

With more development and refinement of controller ICs, projected capacitive (PCAP) touch screens became the preferred touch technology for a majority of applications. For example, this technology is now commonly used on tablets, laptops and smartphones. Though PCAP stands for “projected capacitive (PCAP) touch”, it’s more commonly referred to as “capacitive touch”.

The foundation of PCAP touch screens is an array of conductors that create an electromagnetic field. As a user touches a PCAP screen, the conductive finger or object pulls or adds charge to that field, changing its strength. A touch controller measures the location of this change and then instructs the system to take a certain action, depending on the type of input received.

For a device with PCAP touch technology to acknowledge an input, users simply need to touch the screen. No physical pressure is required, unlike resistive touch screens.

Another key difference from resistive touch technology is that PCAP screens can accommodate a variety of inputs, with different gestures and more contact points instructing the system to take a variety of actions. PCAP touch can support multi-touch functionality, swipes, pinches, and zoom gestures which aren’t possible with resistive touch screens.

A PCAP touch screen is very similar to a solid state switch, as its mechanism of action requires a change in the electrical field over a control point.

The value that comes with recognizing multiple inputs is a clear and positive differentiator for PCAP touch screens. Users can initiate a variety of commands, providing more functionality in devices where this technology is used. Consider how consumers now expect smartphones, tablets, and interactive laptop screens to support actions requiring two fingers, like pinching and zooming. In more specialized settings, such as multi-player gaming applications, PCAP touch screens can support more than 10 inputs at a single time.

PCAP touch screens do not require initial calibration, offering a simpler experience than resistive touch screens. Additionally, PCAP touch screens are highly accurate even as they support a variety of gestures and subsequent actions by the system.

Since their top layer is usually made of glass, PCAP touch screens offer a high degree of optical transmission and avoid the appearance of haze to users. Additionally, the glass top layerprovides improved durability compared to the film top layer of resistive touch screens – even for the largest sizes of up to 80 inches (and growing).

Operation in environments where a PCAP screen may be exposed to liquids or moisture — including conductive liquids like salt water — is possible through specialized controller algorithms and tuning. PCAP technology has evolved to support medical glove and thick industrial glove operation, as well as passive stylus operation.

PCAP touch screens can be customized with different cover lens materials (soda lime, super glasses, PMMA) based on application specific needs. Cover lenses can be ruggedized with chemical strengthening and substrates that improve impact resistance. This can be especially valuable for public-facing applications, like ATMs, gas pump displays, and industrial applications. Specialized films or coatings – such as AG (anti-glare), AR (anti-reflective), AF (anti-fingerprint) – can be added to the cover lens substrate to improve optical performance.

Unlike resistive touch screens, PCAP touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can’t.

If cost is a top concern for a project, PCAP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

The below table compares the advantages and disadvantages of projected capacitive touch vs resistive touch screens.CharacteristicsPCAP TouchResistive TouchRequires calibrationNoYes

As a leading manufacturer of touch and display products, New Vision Display can help you determine the specific needs of your project and tune your PCAP touchscreen controllers to meet them. Our PRECI-Touch® products are based primarily on PCAP touch technology and can be customized for a variety of applications using a wide range of materials, stacks, and controllers.

Whether your product will be used in a life-saving medical device, the center console of an automobile, or the navigation controls on a yacht – we can deliver an effective solution for your application. To get started on your project, contact our specialists today.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

Interactive touch screens have become such an integral part of everyday life that they’re almost as likely to be found in the playroom of a preschool-age child as on the factory floor or in the field. And as touch screens become increasingly integrated with consumer and industrial IoT, their demand continues to grow across every market sector.

At Pivot International, we are the global one-source partner helping companies worldwide successfully design, engineer, manufacture, distribute, and deploy the latest in consumer and industrial touch screen technologies and IoT innovations. With more than 50 years of experience, in-house DFM expertise that spans fourteen industries, and 320,000 square feet of tricontinental manufacturing capability (including domestic options), we deliver a smooth, seamless, highly collaborative approach to NPD and successful product launch.

There are five types of touch screen technologies: resistive, capacitative, near-field imaging, infrared, and ultrasound. Each is differentially suited for various consumer and industrial applications. Let’s take a look at each.

Resistive touch screens are the most common industrial touch screen technology. They are constructed of two interfacing glass sheets or specialized films that respond to direct pressure. Traditionally, the glass sheets or films used in this type of touch screen are coated with indium tin oxide (ITO), a transparent conductive material. But this material is increasingly being replaced with more advanced materials, including copper microwires, silver metal mesh, silver nanowires, and graphene.

The switch from ITO to these other materials results from the need to integrate touch functions into the LCD panel rather than manufacturing a transparent touch screen overlay. This makes for a thinner, lighter device with enhanced optical benefits. Because resistive touch screens respond to pressure, they are more reliably responsive to touch than the capacitative versions we’ll discuss below. However, resistive touch screens offer lower resolution image quality than their capacitative counterparts. They are also slower to respond to touch and can register only one pressure point at a time, therefore precluding multi-touch functionality.

Capacitive touch screens were first invented in the 1960s but didn’t appear in the consumer market until the advent of the iPhone. The strength of capacitative technology lies in its instant responsiveness and superior image quality. Capacitive touch screens function on electrical conductivity that alters the screen’s electrical field. Multi-touch functions (think “pinch-to-zoom”) are made possible by triangulating electrical alterations to calculate paired coordinates that “read” the touch location. Unlike resistive touch screens, capacitive touch screens are unresponsive to touch that does not emit an electrical charge. (Which is why it’s almost impossible to use an iPhone while wearing a glove.)

Some capacitive touch screens include a protective layer that protects the display from moisture, extreme temperature, impacts, and solvents, making it suitable for industrial and outdoor applications. For example, our teams at Pivot created a control system for dairy farms with IoT data reporting and touch screen technology that controls milk tank temperatures and wash cycles.

Like capacitative touch screens, near-field imaging touch screens read touch commands by measuring an electrostatic field. The difference is that NFI touch screens feature a corner-configured electrostatic charge, making them more responsive to touch from almost any source. (Even if you’re wearing a glove, NFI devices will instantly register and respond.) A primary advantage of NFI touch screens is that they can withstand extreme field conditions. This makes them a perfect fit for the industrial and security and defense applications that Pivot brings specialized experience in.

Infrared touch screens rely on a grid of LEDs and light-detector photocells placed at opposing positions. The LEDs beam an infrared matrix across the screen that, when “broken” by touch, provides the basis for the device to detect the input location. Infrared touch screens require dozens of components and precision manufacturing. Despite being more expensive to produce, they are often the ideal product solution for applications that include ticketing kiosks, ATMs, office automation, medtech, and even beverage dispensers like the one Pivot created with an integrated processor and customizable I/O system.

Ultrasound technology has enjoyed cross-industry applications for more than a century. But today’s surface acoustic wave touch screens are light years beyond their earlier incarnations and make it possible to make almost any surface responsive to touch. SAW touch screens work by projecting ultrasound waves across the surface of a screen. As the soundwaves are absorbed by whatever comes in contact with the surface, the screen’s controller chip can instantly identify, read, and accurately respond to commands.

Touch screens are found everywhere from our smartphones to self-serve kiosks at the airport. Given their many uses, it should come as no surprise that there are several touch monitor types. Each has its advantages and disadvantages and is suited to specific tasks.

That’s right. Long before your precious smartphone entered the market in the late 00s, touch panels had already been an established technology for nearly 4 decades.

It’s quite possible that you’re not clear on exactly what a touch panel is, what the touch panel types are, or how they’re applied in your daily life, beyond that of your smartphone. For that and more, we’re here to help.

Quite simply, touch panels, which are also known as touchscreens or touch monitors, are tools that allow people to operate computers through direct touch. More specifically, via the use of internal sensors, a user’s touch is detected, then translated, into an instructional command that parlays into visible function.

Delving deeper into the technical side of things, touch panels are not as cut-and-dry as they may seem. In fact, the way they sense and react to touch can widely differ based on their inherent designs. As such, there are 4 touch panel types in regular use – Resistive, Optical Imaging, Projected Capacitive, and Infrared. Below, we’ll dig into their specifics, which include their advantages, disadvantages, and real-life product applications.

Resistive touch panels are cost-effective variants that detect commands by way of pressure placed on the screen. This pressure sensitivity is generally limited to single-point touch, with a 20-inch maximum screen, which is fine for many usage cases. These range from styluses to fingertips. As a result, if used correctly, resistive touch panels will remain functional even if a water drop has landed on the screen.

As a result of this versatility, however, many will find that resistive touch panels are less durable than their competitors. Moreover, with its reliance on single-point touch, this touch panel type is not actually capable of multi-touch functionality. Regardless, resistive touch panels are often found in grocery stores, where stylus-based signatures are typically required after credit card purchases.

Some like it hot and some don’t. Infrared touch panels definitely fall into the latter category. By setting up a grid of infrared beams across the panel, which may be up to 150-inches, touch is detected by way of this panel’s disruption.

Although infrared touch panels are durable and support multi-touch functionality, it does possess one potential drawback. Depending on where you sit, literally.

Despite infrared implying heat, infrared touch panels actually perform rather poorly in it, particularly in direct sunlight. In those circumstances, the infrared light beams can be disrupted by the sun’s rays, as opposed to your fingers. As such, be sure to place your infrared touch panel device in an appropriately dark location.

Light, and the disruption thereof, is not just a great way to produce a shadow, but also to design a touch panel type. To take advantage of this principle, optical imaging touch panels are designed to sense touch through infrared cameras and the disruption of light strips. This can be achieved through any input you want, across its 100-inch maximum size, from gloves to bare hands, and beyond.

All in all, optical imaging touch panels are just about the most versatile option the touch-based world can offer. From durability to multi-touch, and universal input prospects, the possibilities may truly be endless. Although its only disadvantage may be its non-compact design, common applications of optical imaging touch panels include certain varieties of interactive whiteboards.

If you identify with the phrase, “go with what you know”, then projected capacitive touch panels are the touch panel type for you. For now, you can guess where you know it from.

By way of their electrical-based touch detection, Projected Capacitive touch panels are known for their high precision and high-speed response times. What’s more is that they possess multi-touch functionality and can be used within small, compact, yet expensive, devices. Due to their underlying technology, it has proven challenging to scale up to larger sizes. Figured it out yet?

Assuming you haven’t, or would like to enjoy the gratified feeling associated with being right, allow us to reveal where you interact with projected capacitive touch panels on a daily basis – Smart Phones! What’s more is that they’re not alone, with tablet computers and GPS devices also utilizing projected capacitive touch screens.

It would be a mistake to assume that the applications of all these touch panel types are limited to that of consumer-level devices, or even those that have been previously mentioned. Really, these touch panel types can be found throughout everyday life and in a variety of industries.

What’s more is that in many of these industries, these touch panel types are used less to market products to consumers, and more to sell solutions to businesses. Whether it be in regards to finance, manufacturing, retail, medicine, or education, there is always a need for touch-based solutions. In conjunction with the so-called ‘Internet-of-things’, these touch-based solutions play a key role in practices related to industry 4.0.

In practice, these solutions largely offer a form of personnel management. In hospitals, stores, or banks, for instance, these touch panel types can be used to answer basic questions, provide product information, or offer directions, based on the user’s needs. When it comes to manufacturing, on the other hand, these solutions enable employee management in the possible form of workplace allocation or attendance tracking.

At the end of the day, touch panels are here to stay. In the four decades since their inception, the level of adoption this technology has experienced is remarkable. They transform how we teach in classrooms and collaborate with colleagues.

Although you may not have been clear on the specific details of each touch panel type, we hope that you are now. This knowledge will absolutely serve you well, particularly if you’re interested in ViewSonic’s selection of touch-based solutions.

Since the smartphone first burst onto the scene over a decade ago, our collective familiarity with touch screen technology has become ubiquitous. Practically everybody in society—from the young to the elderly—can intuitively use touch screens across a variety of product mediums. Whether it’s smart devices or self-checkout kiosks, touch screen technology touches many parts of our lives.

However, most people are unaware that there are different types of touch screen technology, varying significantly in their design, construction, and purpose. This article will explore the principal types of touch screen technology, their potential market applications, and their respective pros and cons.

PCAP technology is a newer variation of the commonly used capacitive touch sensors. Combining the same grid-patterned electrode style of traditional capacitive sensors results in a high-resolution, fast, and intuitively responsive touch screen that can be used with even laminated glass. Pro Display offers a range of PCAP touch technologies including ourInteractive Touch Foil, which transforms any glass or acrylic surface into a touch screen (and can even be used with gloves), great for use in store window displays these foils are a great example of how projected capacitive touch screen technology can be used. PCAP solutions are available in single, dual and multi touch options up to 40 touch points.

Some of our most popular PCAP technologies include ourInteractive Touch Table, ideal for meeting rooms and collaborative workspaces and ourInteractive Projection Foils, which incorporate our range of high gain / high contrast rear projection films.

Infrared touch screens operate in a completely different manner than any variation of capacitive touch screens. An array of LED and infrared photosensors are located in a grid axis around the bezels of an infrared screen, detecting even the slightest disruption in the light beams they produce to register a point of contact. Given that these beams are projected in such a dense grid pattern, infrared screens offer users a rapid response time and excellent tracking capabilities.

We can provide a range of infrared display technologies including ourintouch Interactive Touch Screen Overlay kits, that transform any screen or surface into an interactive display. These overlay kits, which are compatible with LCD, LED or Projection displays, allow you to create brand new touch display installations or retrofit touch to an existing screen, table, or video wall with little to no disruption. Our Infrared solutions are suited to a wide range of applications, available in single, dual and multi touch functionalities up to 32 touch points.

Some of our most popular Infrared technologies include ourDigital Glass Touch screens, supporting UST projection and available in sizes up to 8000mm x 3000mm and ourInteractive Transparent Screens, ideal for museum and immersive experience displays.

As an established visual displays manufacturer, we like to keep on top of trends in order to understand the full potential of our technologies. One interactive trend we’ve seen recently, is the pairing of our displays with theMicrosoft Azure Kinectto create a gesture based interactive display. The Azure Kinect contains a depth sensor, spatial microphone array with video camera as well as an orientation sensor, using body tracking to register movement and therefore interact with the content on screen. This opens up a world of opportunity for interactive content as the screen can be operated using movements from all over the body, rather than just being limited to your hands.

This Kinect sensor can be used alongside many of our display technologies including rear projection displays and newer, more lucrative displays like ourTransparent OLED Screensproviding users with the closest existing experience to that of the hit movie ‘Minority Report’!

Now that you know a bit more about PCAP, infrared andgesture touch technologies, you might be wondering which one is best suited to your application and why. Let’s look into the pros and cons of each technology, as well as outlining which are best for different use-cases.

PCAP screens share many of the same advantages and disadvantages of capacitive touch screens, with a few key additional benefits and drawbacks. PCAP screens possess greater scratch resistance than infrared touch screens, usually featuring a glass or acrylic overlay to protect the display underneath.

PCAP screens allow for multi-touch use, allowing users to manipulate their screen applications using up to 40 touch points instead of the single touch point offered by standard capacitive touch screens, while better maintaining functionality in the presence of dirt, dust, grease and water.

If you do use a PCAP screen, however, you’ll be unable to operate the screen with solid objects like a plastic card or pen—only tapping with thin cotton/latex gloves or an exposed finger will create the desired response from the device. The screens are also highly sensitive to electro-magnetic interference and radio frequency interference. Therefore, if you use a PCAP screen around these waves then this will likely affect the usability and performance of the screen.

Infrared, the most standout technology when compared to PCAP and capacitive touch screens, comes with its own unique advantages. IR touch relies on the sensors located around the inside of the screen’s bezels to register a touch and effectively have an unlimited “touch life” since wear and tear from physically using the device will not degrade the screen’s responsiveness. However, due to touch frames sitting on top of the display itself, the screen surface is still susceptible to wear and tear. This can be solved by one of two ways, one option is to set the touch frame away from the screen itself, to allow the sensors to register the touch before the user makes contact with the screen. Alternatively, our touch frames can be manufactured with a glass or acrylic overlay to protect the display, ideal for softer screens like LCD’s and monitors.

That’s not to say there are no cons to infrared screens. Since the screen’s response is triggered by registering an optical event, accidental triggering can occur easily by movement close to the screen. These screens are also sensitive to dirt and grime accumulation, which could impede the light beams and cause malfunction, and they’re more sensitive to water, snow and rain than the aforementioned screen types.

In theory the Kinect gesture technology is the ideal interactive solution for a post-COVID world, allowing users to interact with content without making a physical connection to your display. This technology has great potential for use in immersive environments and exhibitions to recreate the kind of futuristic technologies seen on the silver screen. The nature of this technology also means that it can be controlled with more than just your hands, with the ability to track 32 joints including the eyes.

Whilst the body tracking foundations of this technology could potentially change the way we use touch screens entirely, it still has its drawbacks. Whilst technologies like Infrared and PCAP offer solutions with up to 40 touch points, the Azure Kinect is limited to the amount of bodies it can track based on the field of view, making it unsuitable for use in high traffic areas.

A touch screen is an electronic visual display that allows the user to control an electronic device simply by touching the icons on the display. The touch screen technology in industries makes navigating simple and quick for operators.

In the industries, hardware input devices such as mice and keyboards are being replaced by touchscreen technology. The use of a touch screen for HMI ensures efficient functioning, improved user performance, and enhanced productivity. While selecting a touch screen technology for your application, you need to consider a lot of factors. In this article, we will discuss the resistive and capacitive touch screens that are commonly used in industrial automation.

Resistive touch screens have two layers that are either made of PET film or glass/ polycarbonate plastic. Glass usually makes up the bottom layer, and glass or film makes up the upper layer. Depending on the application, alternative pairings such as glass/glass and film/film are also used. Each pairing offers its own specific features. However, both layers have a uniform resistance value over their whole surface.

Indium Tin Oxide (ITO), a transparent metal oxide, is deposited on the inner surface of each of the two layers. When voltage is applied, ITO allows for a gradient across each layer for touch point detection. The bottom and top layers in touch screens are separated by an air gap and the spacer dots that are generally present on the bottom layer. The spacer dots prevent the top and bottom layers from touching each other when no pressure is applied.

The resistive touch screen technology works in a simplified manner. The two layers in them act as the voltage divider. When the pressure is applied to the touch screen, the top layer bends to make touch with the bottom layer. This results in a change in resistance between the two layers and, as a result, a change in current. The controller interprets this change, and the software determines the actual contact point.

The electrodes in resistive touchscreens develop a uniform voltage throughout the whole conductive surface. This delivers a precise voltage reading corresponding to the area of layers that contact each other when pressed. In this section, we will discuss three common types of resistive touch screen technologies. Each type offers different durability and sensitivity.

In a 4-wire analog resistive touch screen technology, both the top and bottom layers have two electrodes (busbars) perpendicular to each other. The top layers’ electrodes are oriented along the positive and negative Y-axis, while the bottom layer’s electrodes are oriented along the positive and negative X-axis. Using this type of electrical-coordinate configuration in this type, the controller senses the coordinates when the two layers touch each other.

In 5-wire analog resistive touch technology, the bottom layer has four electrodes on four corners. These electrodes are linked via four wires. The fifth wire is a sensing wire embedded in the top layer. When touch is registered on any layer, this sensing wire transmits the specific voltage corresponding to the coordinates to the controller or processor. This type is more robust since it has fewer components and a simple design.

The 8-wire sensing circuit is the most sensitive resistive touch screen technology. It differs slightly from 4-wire analog touchscreens. Each electrode in this touch technology has two wires instead of one. This adds a layer of redundancy to the circuit. If one of the wire pairs loses resistance over time, the second wire continues to deliver a secondary signal to the CPU. That implies a more costly resistive touchscreen with an 8-wire analog circuit will be more durable. It also eliminates the drift issues present in other types of resistive touchscreens.

Easy Input Detection: Because resistive touchscreens are pressure-sensitive, they may be used with any input device, such as a gloved hand or a pen/stylus. These screens do not require a conductive item like capacitive touchscreens.

Higher Sensor Resolution: Resistive touchscreens have more sensors than capacitive touchscreens. That’s why a finer tip functions better in resistive touch technology. Users can choose a fine-tipped stylus whenever the icons on an app are tiny.

Fewer Accidental Touches: Light touches are not detectable by a resistive touchscreen. That’s why resistive touch screens are preferred in an environment when there is the anticipation of accidental touches on the screen. These touches can be from rainfall or liquid fall etc.

Usage under Harsh Environments: The standard resistive touch screens are sensitive to harsh temperature and humidity fluctuations, which can damage the precision of the touch screen.

But they handle the harsh environmental conditions better than capacitive touchscreens. That’s why resistive touch screens are still preferred over capacitive touchscreens in outdoor environments.

Display Clarity:Resistive touchscreens come with only 75% clarity. They display low-quality images as multiple films are layered in the structuring of these screens. People with limited eyesight may face additional challenges as a result of this. In these touchscreens, the ITO coating of the top flexible layer cracks because of the continuous stretching and retraction of this layer. Which also contributes to the deterioration of the air gap between the ITO layers. The spacing among the conducting layers permits dirt and dust to gather, reducing the display clarity even more over time.

Inability to Self-Calibrate: The performance of resistive touch screens is affected by the continuous distortion and warping of the ITO layer. This modification necessitates recalibrating the screen again and again.

Easy to Damage: The top hard-coated layer must be thin enough to sustain the touchscreen panel’s flexibility. As a result, sharp items, scratching, and poking can easily damage this layer.

Low Optical Transmissivity: Resistive touchscreens offer low optical transmissivity (less than 80%). The presence of two layers of PET/ glass, an air gap, and spacer dots in the manufacturing of resistive touchscreens can result in a loss of refractive and reflecting light, resulting in a more blurry and shaded display.

Aging:Another disadvantage is that resistive touchscreens suffer the process of aging, which begins to happen when PET film degrades at high temperatures. The indicator of aging is touchscreen discoloration, in which the touchscreen display begins to turn white.

No Support to Multitouch: Resistive touch technology does not support multitouch since it only responds to one location input. It does not support the use of two-finger gestures.

Size Limitation: Resistive touch technology is hard to build in sizes larger than 27 – 28 inches due to the difficulties of making a uniform ITO coating for large size layers.

A capacitive touch screen has an insulator such as glass with a transparent conductor coating. This coating material is usually Indium Tin Oxide (ITO).When there is a touch on the screen, a little amount of charge is attracted to the point of contact. Circuits in each corner of the screen measure the charge and transmit it to the controller for processing.

In surface capacitive technology, the conductive coating is present only on one side of the insulator, and four electrodes are present on four corners of the touchscreen. When a small modest voltage is applied to the conductive layer, it results in an electrostatic field. This field is uniform over the surface area of the conductive layer. A capacitor is developed when a conductive surface (e.g., a human finger) comes into contact with an uncoated surface. The controller attached to the sensor infers the touch’s position from the capacitance change recorded from the four corners of the screen.

In this technology, a single layer of conductive material is etched to make an X-Y grid pattern of electrodes, or two separate and perpendicular layers of conductive material with parallel lines or tracks etched to form the X-Y grid. The capacitance of the closest conductive traces is changed when a conductive object(e.g., a finger) is placed on a grid of conductive traces. The change in trace capacitance is monitored, and the touch position is calculated. An X-Y grid allows for better resolution than resistive technology.

Multi-Touch Technology: Capacitive touch screens can identify and measure multi-touch locations simultaneously. This Multi-touch technology is used to serve a purpose similar to the function keys (Control, Alt, Option, Command, and so on) on a regular keyboard. However, advancements in hardware can enable multi-touch to allow several users to simultaneously use the same device, such as the Microsoft Surface 300+ touch capability.

Durability: The strength and durability of capacitive touchscreen technology are other significant advantages. These touchscreens are more durable than resistive touchscreens, especially when subjected to heavy use.

Requires Less Pressure: Capacitive touchscreens detect touch using the electrical current of the human body and need less pressure to function than resistive touchscreens. To operate a capacitive touchscreen, you just need to drag your finger across the surface.

Cracked Screens Continue to Function: Minor cracks do not affect the operation of a capacitive touchscreen. It continues to measure the electrical charge generated by the operator and uses this information to establish where the contact happened.

Optical Clarity and Readability: A capacitive touch screen offers more clarity than resistive touch screens. It offers amazing image quality because of the usage of a glass layer.

Liquid, contaminant, and scratch-resist: The double-glass layout in the capacitive touch technology efficiently prevents the adverse effects of external environmental elements on the touch screen. The capacitive touch technology still computes the touch position accurately even when the screen is covered with dirt, dust, oil stains, etc.

Cost Inefficient: Capacitive touchscreens are more expensive than resistive touch screens. The price tends to rise exponentially with an increase in display size.

Limited to capacitive objects as input: Proper static charge interference is required to register a touch on capacitive screens. Hence only selective input objects such as bare fingers can interact with these screens. Which restricts the usage of these screens in hazardous environments where gloves use is a must.

When you use your cell phone or POS device, have you ever wondered why you could control them by touch LCD screen? Yes, capacitive touch screen technology can achieve these functions.

In capacitive touchscreen, glass panel of LCD is covered with a capacitive layer with a static charge. When we touch the screen with finger or conductive stylus, some of the charge shifts from the device to the finger/stylus. This decreased charge is noticed by the controller. And the system will be able to figure out the exact location of touch.

Sharp image with better contrast - devices using capacitive touch screen have extraordinary picture quality thanks to their use of a glass layer. It can transmit 90~98% LCD"s light.

Sensitive to touch - unlike resistive touch screens, which need pressure to pinpoint a touch, capacitive touch screens can sense a slight conductive object"s touch. And it can detect multiple touch points.

Incredible durability - the top glass layer makes the capacitive touch panel extremely durable and reliable, especially when comparing with resistive touchscreen. Cracked capacitive touch screen continues to function.

Easy to clean - TFT LCD capacitive touch screens come with a sturdy glass top layer. It is easier to clean and is not impacted by dirt, rain, grease or dust. It makes capacitive touch screens very well suited for long term use.

The best touch screen monitors allow you to interact with your desktop computer via tap, swipe and pinch-to-zoom. Alternatively, you can install it as a secondary monitor to use with an office-based laptop.

In this article, we"ve gathered together the best touch screen monitors available today – in a range of sizes from 21 inches to a special ultrawide monitor(opens in new tab) that"s 49 inches. If you"re after a smaller secondary monitor that can be carried with your laptop for use on the go, see our list of the best portable monitors(opens in new tab). (Portable monitors can also be had with touch sensitivity, but they"re smaller and are powered by your laptop"s battery, so they don"t need their own power supply.)

If you"ve already researched the best monitors for photo editing(opens in new tab) or the best video editing monitors(opens in new tab), you may have realized that none of them are touch screen monitors. But why not? Why would you consider choosing a new monitor without touch sensitivity?

After all, the best touch screen monitor will add an extra, more ergonomic form of user input, so must be better, right? Well, it"s not quite that simple. At the bottom of this page, you"ll find tips on what to look for when buying a touch screen monitor, including connectivity, size, and that all-important image quality.

Dell"s P2418HT has fairly typical touch screen display credentials: a 23.8-inch screen size and Full HD (1920 x 1080) resolution. But it stands out from the crowd in other areas.

Its special articulating stand transitions the display from a standard desktop monitor to a downward 60-degree angle touch orientation. It also supports extended tilt and swivel capabilities, so you can adjust the screen to your task or a more comfortable position. Plus, a protective cushion at the base of the screen offers a buffer against bumps when the stand is fully compressed.

Marketed at commercial and educational settings as well as home use, the TD2230 boasts a 7H hardness-rated protective glass for extra scratch protection and durability. Super-thin screen bezels give the panel a modern, sleek look, plus there are integrated stereo speakers for added versatility.

The ViewSonic TD2230 boasts upmarket image quality thanks to its IPS LCD display that provides better color and contrast consistency, regardless of your viewing position, while the 1920 x 1080 screen res is high enough for crisp image clarity when spread across the 21.5-inch panel size. 250 cd/m2 max brightness and a 1000:1 contrast ratio are pretty typical, while HDMI, DisplayPort and analog VGA connectors ensure you"ll be able to hook this monitor to pretty much any computer running Windows 10, Android or Linux.

Want a larger than average touch screen monitor? This 27-inch offering is our pick, as it"s based around an IPS LED-backlit display. That translates more dependable color accuracy and contrast that won"t shift depending on whether you"re viewing the centre of the screen or the corners.

The Full HD resolution is spread a little thin across a 27-inch display, so images will look slightly pixelated, but this is an unavoidable compromise you have to make if you want a touch screen monitor larger than 24 inches. The PCT2785 does score well in terms of versatility though, as you get a built-in HD webcam and microphone, making it great for homeworking(opens in new tab) and video conferencing.

If you can get past the uninspiring black plastic design of the Philips 242B9T, this touch screen monitor has a lot to offer. It should be easy to connect to pretty much any computer, thanks to its full array of HDMI, DVI, VGA and DisplayPort connectivity and included cables for all but DVI. It"s even got its own built-in 2W stereo speakers, while the clever Z-hinge stand allows a huge -5 to 90 degrees of tilt adjustment, making it extra-ergonomic when using the 10-point capacitive multi-touch display.

The T272HL boasts a slightly above-average 300cd/m2 brightness, along with 10-point capacitive multi-touch. There are also a pair of 2w internal speakers, and the stand allows a large 10-60 degrees of tilt to enhance touch ergonomics.

If you"re after a larger-than-average touch screen monitor, the T272HL is a reasonable choice, but there are compromises to be made. For starters, this is still a 1920 x 1080 Full HD monitor, so while it may be physically larger than a 23/24-inch Full HD display, images will simply look larger, not more detailed.

At 21.5 inches, the Asus VT229H is one of the smaller touch screen monitors on this list, but it still sports the same Full HD (1920 x 1080) resolution as larger 24 and even 27-inch touch screen displays, meaning you get more pixels per inch and slightly crisper image quality. This is also an IPS LCD, with wide 178 x 178-degree viewing angles and reliably consistent color and contrast, regardless of your viewing angle.

Most touch screen monitors are just that: a monitor, with a touch interface. But this 21.5-inch display also adds a pair of 2W stereo speakers for sound output, along with dual-array microphones and a built-in webcam for video conferencing. The IPS LCD display panel ensures decent color and contrast uniformity, while the Full HD 1920 x 1080 resolution is easily enough to for crisp image quality on a screen this size.

The square black exterior is typical of Lenovo"s business-orientated products and may not be to everyone"s taste. Plus you"ll need to connect via DisplayPort only, as there"s no HDMI input. But otherwise this touch screen monitor offers a lot for a very reasonable price.

The obvious drawback with a touch screen monitor is the aforementioned size restrictions because if you want one larger than 27 inches, you"re out of luck. The next step up in size for touch screen monitors are 50+ inch displays designed for corporate presentations rather than home computing.

Even most 27-inch touch screen monitors have the same Full HD 1920 x 1020 resolution as their smaller 21-24-inch stablemates. So you"re not actually getting more pixels, only bigger ones. This can make your images just look more blocky unless you sit further away from the screen.

It"s not just outright screen resolution where touch screen monitors can fall short of their non-touch alternatives. Top-end screens designed for image and video editing are often factory color calibrated: they use LCD displays that can display a huge range of colors, or feature fast refresh rates for smoother video playback and gaming. However, touch screen monitors aren"t intended for color-critical image or video work: they tend to be all-purpose displays designed for more general applications like web browsing and basic image viewing.

Connectivity also tends to be compromised on touch screen monitors. You can forget about USB-C hubs(opens in new tab) with Power Delivery, and even DisplayPort connections can be a rarity.

These are the two primary forms of touch input. Resistive touch requires you to physically press the screen (which itself is slightly spongy) for it to register an input. It"s a cheaper form of touch input, and a resistive touch screen is also tougher than a capacitive equivalent, so they"re popular for use in ATMs and retail checkouts.

However, resistive technology doesn"t support multi-touch and won"t give the same fluid sensitivity as the touch screens we"re now accustomed to on phones and tablets. Consequently, most modern touch screen monitors use capacitive touch screens supporting 10-point multi-touch. These operate exactly like a phone or tablet"s touch screen, requiring only a light tap, swipe, or pinch to register inputs. All the mon

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey