msk tft display manufacturer

Dr Pan: Hello, Greg. TFT LCD module is one of the best LCD technology. We can simply consider it as TFT+LCD+LED backlight, and monochrome LCD module consists of LCD+LED backlight. An image on an LCD we can see is composed of pixels. TFT is the abbreviation for thin film transistor and it controls the R, G, B colors of each pixel respectively on the surface of LCD.

TFT LCD is a high standard product and it is not well customized as monochrome LCD. But still, it has a variety of options to meet the customers’ requirements.The sizes range from 1.44 inch to 130.0 inch;

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

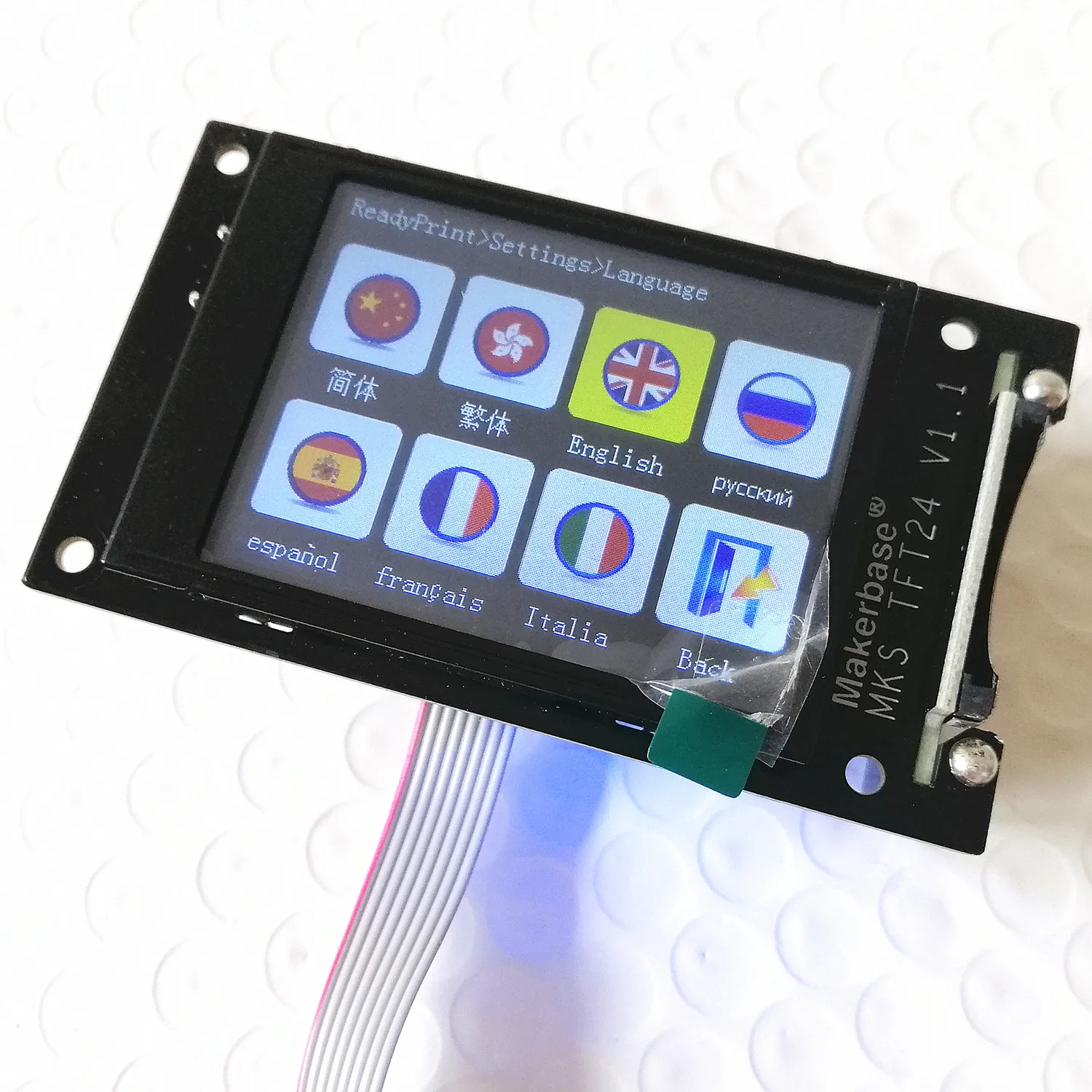

If you want to change some function or add new function and so on, you can refer to MKS TFT source code and build it, update it to MKS TFT, Link as below:

MKS TFT 2.4 inch touch screen to control a 3D printer or CNC machine. This high quality touch screen is a controller on its own, because it has own processor onboard and does not rely on the processor of the 3D printer or CNC machine. Due to this the screen features a 2.4 inch full colour touch screen, can be integrated with WIFI upgrade, can read a SD card, can detect power failure with power detection module and filament runout with runout module.

The thin film transistor-liquid crystal display (TFT-LCD) has been used all over the world. Although the manufacture process of TFT-LCD was highly automated, employees are hired to do manual job in module assembly process. The operators may have high risk of musculoskeletal disorders because of the long work hours and the repetitive activities in an unfitted work station. The tools of this study were questionnaire, checklist and to evaluate the work place design. The result shows that the participants reported high musculoskeletal disorder symptoms in shoulder (59.8%), neck (49.5%), wrist (39.5%), and upper back (30.6%). And, to reduce the ergonomic risk factors, revising the height of the work benches, chairs and redesigning the truck to decrease the chance of unsuitable positions were recommended and to reduce other ergonomics hazards and seta good human machine interface and appropriate job design.

The present invention relates to a display device, and more particularly, to a liquid crystal display (LCD) device and a method for manufacturing the same.

Ultra-thin sized flat panel displays having a display screen with a thickness of several centimeters or less, and in particular, flat panel LCD devices, are widely used in monitors for notebook computers, spacecraft, and aircraft.

Such LCD devices have low power consumption and are easy to carry. In this respect, the LCD device is receiving much attention as an advanced display device that can substitute for a cathode ray tube (CRT).

An LCD device includes a thin film transistor (TFT) substrate, a color filter substrate, and a liquid crystal layer sealed between the TFT substrate and the color filter substrate. The LCD is a non-light-emitting device that can obtain an image effect based on electro-optical characteristics of the liquid crystal layer.

In other words, a TFT array and pixel electrodes are formed on the TFT substrate, while a black matrix pattern, a color filter layer, and a common electrode are formed on the color filter substrate. The TFT substrate and the color filter substrate are bonded to each other by a sealant such as epoxy resin.

A driving circuit is connected with the TFT substrate using a tape carrier package as a medium. The driving circuit generates various control signals and signal voltages to display images.

The development and application of TFT-LCD industries have been accelerated in accordance with an increase of the dimensions and increase of the resolution of LCD devices. To increase the productivity and ensure the low cost, many efforts have been continued in view of simplified process steps and an improvement of yield.

Another object of the present invention is to provide an LCD device and a method for manufacturing the same in which a color filter layer is formed on a pixel electrode in a state where a TFT is not driven.

To achieve these and other advantages and in accordance with the purpose of the present invention, as embodied and broadly described, an LCD device according to the present invention includes first and second substrates, a TFT formed in a predetermined region on the first substrate, a pixel electrode formed in a pixel region on the first substrate, a color filter layer formed on the pixel electrode, a black matrix pattern formed in a region other than the pixel electrode, and a liquid crystal layer formed between the first and second substrates.

To further achieve these and other advantages and in accordance with the purpose of the present invention, a method for manufacturing an LCD device having a pixel region defined by gate and data lines, includes forming a TFT on a first substrate, forming a black matrix pattern in a region other than the pixel region, forming a pixel electrode in the pixel region, and forming a color filter layer on the pixel electrode. In forming the TFT, when forming source and drain electrodes, an n+ layer between them is removed. When removing the n+ layer, a gate insulating film in a pad region is also removed by an etching process to remove a gate pad.

In another aspect of the present invention, in forming a TFT, a metal layer for the source and drain, an n+ layer for an ohmic contact, and a semiconductor layer of a-Si are patterned, and the patterned metal layer is selectively removed to form source and drain electrodes and at the same time remove an n+ layer between the source and drain electrodes. When removing the n+ layer, a gate insulating film in a pad region may also be removed to expose a gate pad.

Consequently, the number of masks required when forming a plurality of patterns on the substrate is minimized to reduce the manufacturing cost, and a color filter material can be electrodeposited by applying a voltage to the data line only in a state such that the TFT is not driven.

As shown in FIG. 3, the LCD device according to the first embodiment of the present invention includes first and second substrates 31 and 31 a, a TFT and a pixel electrode 45 formed on the first substrate 31, a color filter layer 47 formed on the pixel electrode 45, a black matrix pattern 43 formed in a region other than the pixel electrode 45, a common electrode 32 formed on the second substrate 31 a, and a liquid crystal layer (not shown) formed between the first and second substrates 31 and 31 a.

The TFT includes: a gate electrode 33 apatterned on the first substrate 31; a gate insulating film 35 formed on an entire surface of the first substrate 31, including the gate electrode 33 a; a semiconductor layer 37 of amorphous silicon (a-Si) patterned on the gate insulating film 35; source and drain electrodes 41 band 41 cformed on the a-Si layer 37; and an n+ layer 39 for ohmic contact formed between the source and drain electrodes 41 band 41 cand the a-Si layer 37.

As described above, in the second embodiment of the present invention, the black matrix pattern 43 and the color filter layer 47 are formed on the substrate in which a TFT and the pixel electrode 45 are arranged. When etching the metal layer to form the source and drain electrodes 41 band 41 c, the n+ layer of a channel portion and the gate insulating film on the gate pad are simultaneously removed to minimize the number of masks and simplify the process steps.

Meanwhile, the connecting pattern 91 connects the data line 41 awith the drain electrode 41 cthrough an upper portion above the gate line 33. When a color filter material is electrodeposited to form a color filter layer in a later process, the connecting pattern 91 serves to electrodeposit the color filter material by a voltage only applied to the data line in a state such that the TFT is not driven. The connecting pattern 91 forms a single body with the data line 41 aand the drain electrode 41 c. Alternatively, the connecting pattern 91 may be formed by a separate process.

As shown in FIG. 8d, a light-shielding material is formed on the entire surface including the pixel electrode 45 and then patterned to remain on a region other then the pixel electrode 45, so that a black matrix pattern 43 is formed. At this time, the light-shielding material is patterned to expose the connecting pattern 91. This connecting pattern 91 allows the color filter material to be electrodeposited on the pixel electrode 45 with only the voltage applied to the data line, without driving the TFT, by connecting the data line 41 awith the drain electrode 41 cthrough the upper portion above the gate line 33. Once the color filter material is electrodeposited, the connecting pattern is removed to electrically open the data line 41 aand the drain electrode 41 c.

Subsequently, as shown in FIG. 8e, the color filter material is electrodeposited on the pixel electrode 45 to form the color filter layer 47. At this time, if a voltage is applied to the data line 41 ain a state that the TFT is not driven, the voltage is transferred to the pixel electrode 47 through the connecting pattern 91 so that the color filter material can be electrodeposited.

As described above, in the third embodiment of the present invention, the number of masks can remarkably be reduced. Also, since the color filter material can be deposited in a state that the TFT is not driven, it is possible to prevent characteristics of the TFT from being changed.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey