lcd monitors brighter than lcd quotation

Unlike CRT monitors, LCD monitors display information well at only the resolution they are designed for, which is known as the native resolution. Digital displays address each individual pixel using a fixed matrix of horizontal and vertical dots. If you change the resolution settings, the LCD scales the image and the quality suffers. Native resolutions are typically:

When you look at an LCD monitor from an angle, the image can look dimmer or even disappear. Colors can also be misrepresented. To compensate for this problem, LCD monitor makers have designed wider viewing angles. (Do not confuse this with a widescreen display, which means the display is physically wider.) Manufacturers give a measure of viewing angle in degrees (a greater number of degrees is better). In general, look for between 120 and 170 degrees. Because manufacturers measure viewing angles differently, the best way to evaluate it is to test the display yourself. Check the angle from the top and bottom as well as the sides, bearing in mind how you will typically use the display.

This is a measurement of the amount of light the LCD monitor produces. It is given in nits or one candelas per square meter (cd/m2). One nit is equal to one cd/m2. Typical brightness ratings range from 250 to 350 cd/m2 for monitors that perform general-purpose tasks. For displaying movies, a brighter luminance rating such as 500 cd/m2 is desirable.

The contrast ratio rates the degree of difference of an LCD monitor"s ability to produce bright whites and the dark blacks. The figure is usually expressed as a ratio, for example, 500:1. Typically, contrast ratios range from 450:1 to 600:1, and they can be rated as high as 1000:1. Ratios more than 600:1, however, provide little improvement over lower ratios.

Unlike CRT monitors, LCD monitors have much more flexibility for positioning the screen the way you want it. LCD monitors can swivel, tilt up and down, and even rotate from landscape (with the horizontal plane longer than the vertical plane) to portrait mode (with the vertical plane longer than the horizontal plane). In addition, because they are lightweight and thin, most LCD monitors have built-in brackets for wall or arm mounting.

Besides the basic features, some LCD monitors have other conveniences such as integrated speakers, built-in Universal Serial Bus (USB) ports and anti-theft locks.

Contrast ratio - The difference in light intensity between white and black on an LCD display is called contrast ratio. The higher the contrast ratio, the easier it is to see details.

Ghosting - An effect of slower response times that cause blurring of images on an LCD monitor, it"s also known as latency. The effect is caused by voltage temporarily leaking from energized elements to neighboring, non-energized elements on the display.

Luminance - Also known as brightness, it is the level of light emitted by an LCD display. Luminance is measured in nits or candelas per square meter (cd/m2). One nit is equal to one cd/m2.

Stuck pixels - A pixel that is stuck either "on" or "off", meaning that it is always illuminated, unlit, or stuck on one color regardless of the image the LCD monitor displays can also be called a dead pixel.

TRU-Vu High Bright Sunlight Readable Monitors enable users to see clear, sharp video images even in direct sunlight with a bright screen. Our high brightness screens produce at least 1,000 nits brightness. Some go up to 2,500 nits of brightness. This makes them far brighter than standard LCD monitors. Specifically, consumer or commercial-grade monitors typically offer only 150 to 300 nits brightness. High brightness displays and sunlight readable touch screens will ensure crystal-clear video images even in bright sunlight. The result is better performance and bold colors in other high ambient light conditions as well. They are also available with optical bonding as monitors or touch screen displays.

In outdoor or bright conditions, it is imperative to increase the brightness of a display to ensure crisp images. The number of nits an LCD display emits is the main factor in determining the monitor’s perceived brightness. A monitor luminance of around 200-350 nits will work well indoors. Most LCD displays and monitors fall in this range. However, 400-700 nits would be required for use in daylight conditions. Most importantly, a Sunlight readable display requires at least 1,000 nits or more for viewing in direct, bright sunlight . These high brightness displays are available with 16:9 aspect ratio or 4:3 aspect ratio screens. All TRU-Vu Sunlight Readable monitors and high-brightness touch screens are TAA Compliant.

Some monitors feature a sheet of glass over the LCD panel to protect it from accidental or intentional damage. However, the glass also produces unwanted glare and reflections. Internal reflections in the air gap between the glass and the LCD panel diminish image quality even further. In order to combat this, monitors are optically bonded.

Optical bondingis the process of laminating protective glass or a touch screen panel to the LCD panel with an optical-grade resin. This completely fills the air gap between the glass and LCD panel. It not only eliminates the internal reflections, but also increases the contrast ratio. This makes the screen appear much brighter and more viewable in bright light conditions. Optical bonding also eliminates internal moisture and condensation. Moreover, it will make the monitor more rugged and durable. Lastly, an Anti-Reflective coating is applied to the outside of the glass. Consequently, this will drastically reduce glare and surface reflections.

For installations in indirect sunlight, or reflected bright light, our Daylight Viewable displays will most likely suffice. These are also more cost-effective than Sunlight Readable monitors with 1,000 nits brightness. Daylight viewable monitors feature LCD screens with 400 nits to 700 nits brightness. The LCD panels also include optical bonding.

Daylight-viewable touchscreens with optical bonding are also significantly brighter than standard touch screens. Consequently, they produce far better image quality in bright conditions. Although they are not as bright as Sunlight Readable touch screens, daylight readable touch screens do offer the benefit of lower power consumption. This may be useful in portable or mobile applications. We currently offer over 60 monitors with optical bonding; all are TAA-Compliant.

Our outdoor high brightness Sunlight Readable LCD monitors feature waterproof stainless steel enclosures. These are ideal for factory wash-down environments. Additionally, they are perfect for outside use in challenging weather. Our panel mount enclosures are made from steel, stainless steel, or aluminum. This enables them to be flush-mounted. Outdoor LCD monitors with high brightness work in a wider range of temperatures. Consequently, this broadens the environments in which they may be used. Additionally, temperature ranges are very important to consider when using outdoors. When we combine extreme operating temperatures with outdoor waterproof enclosures, we ensure your high brightness monitors will be able to function in even the harshest wet and hot environments. We will also modify or customize any model to meet your exact requirements.

In conclusion, we deploy TRU-Vu outdoor waterproof sunlight readable monitors and high brightness touch screens in a wide range of industries. For example, military, law enforcement, manufacturing plants benefit from high bright LCD displays. Amusement parks, sports stadiums, mass transit, and construction & heavy equipment also rely on high bright sunlight readable displays. In addition, outdoor high brightness LCD monitors are demanded in pipeline inspection, kiosks, marine, oil & gas, drones, security applications. When it counts, you can rely on TRU-Vu Monitors to deliver the optimal weather resistant high bright LCD monitor solution for your specific needs.

Yaham LED displays are an excellent option for businesses who want a high-quality display that is flexible, durable, and energy-efficient. In addition, our LED displays use less power than LCDs, making them an eco-friendly choice for your business.

On the other hand, LCD screens are preferred for displays that are needed up close because of their high resolution—for example, handheld gadgets such as smartphones or TV screens. In addition, LCD screens can produce 4K displays which are perfect for watching vivid displays or videos from a closer perspective.

That is why you will not see an LCD screen used on round edges. LCDs are sleek and lightweight which is perfect for mobile devices making them look more attractive and feel handier.

The LCD screens commonly found in outdoor uses can be problematic because they struggle to withstand the elements. On the other hand, LEDs have been improving steadily with higher quality and lower costs, making them a better option for long-term use.

Energy-efficient backlighting indeed allows LED televisions to have an almost 40% lower power consumption than LCD screens and significantly less than a plasma television.

For all the new technologies that have come our way in recent times, it’s worth taking a minute to consider an old battle going on between two display types. Two display types that can be found across monitors, TVs, mobile phones, cameras and pretty much any other device that has a screen.

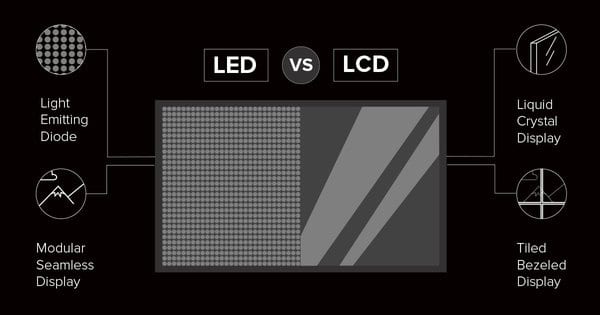

In one corner is LED (light-emitting diode). It’s the most common type of display on the market, however, it might be unfamiliar because there’s slight labelling confusion with LCD (liquid crystal display).

For display purposes the two are the same, and if you see a TV or smartphone that states it has an ‘LED’ screen, it’s an LCD. The LED part just refers to the lighting source, not the display itself.

In a nutshell, LED LCD screens use a backlight to illuminate their pixels, while OLED’s pixels produce their own light. You might hear OLED’s pixels called ‘self-emissive’, while LCD tech is ‘transmissive’.

The light of an OLED display can be controlled on a pixel-by-pixel basis. This sort of dexterity isn’t possible with an LED LCD – but there are drawbacks to this approach, which we’ll come to later.

In cheaper TVs and LCD-screen phones, LED LCD displays tend to use ‘edge lighting’, where LEDs sit to the side of the display, not behind it. The light from these LEDs is fired through a matrix that feeds it through the red, green and blue pixels and into our eyes.

LED LCD screens can go brighter than OLED. That’s a big deal in the TV world, but even more so for smartphones, which are often used outdoors and in bright sunlight.

Take an LCD screen into a darkened room and you may notice that parts of a purely black image aren’t black, because you can still see the backlighting (or edge lighting) showing through.

You’ll often see a contrast ratio quoted in a product’s specification, particularly when it comes to TVs and monitors. This tells you how much brighter a display’s whites are compared to its blacks. A decent LCD screen might have a contrast ratio of 1,000:1, which means the whites are a thousand times brighter than the blacks.

Viewing angles are generally worse in LCDs, but this varies hugely depending on the display technology used. And there are lots of different kinds of LCD panel.

Perhaps the most basic is twisted nematic (TN). This is the type used in budget computer monitors, cheaper laptops, and very low-cost phones, and it offers poor angled viewing. If you’ve ever noticed that your computer screen looks all shadowy from a certain angle, it’s more than likely it uses a twisted nematic panel.

Thankfully, a lot of LCD devices use IPS panels these days. This stands for ‘in-plane switching’ and it generally provides better colour performance and dramatically improved viewing angles.

IPS is used in most smartphones and tablets, plenty of computer monitors and lots of TVs. It’s important to note that IPS and LED LCD aren’t mutually exclusive; it’s just another bit of jargon to tack on. Beware of the marketing blurb and head straight to the spec sheet.

The latest LCD screens can produce fantastic natural-looking colours. However, as is the case with viewing angles, it depends on the specific technology used.

Where OLED struggles is in colour volume. That is, bright scenes may challenge an OLED panel’s ability to maintain levels of colour saturation. It’s a weakness that LCD-favouring manufacturers enjoy pointing out.

Both have been the subject of further advancements in recent years. For LCD there’s Quantum Dot and Mini LED. The former uses a quantum-dot screen with blue LEDs rather than white LEDs and ‘nanocrystals’ of various sizes to convert light into different colours by altering its wavelength. Several TV manufacturers have jumped onboard Quantum Dot technology, but the most popular has been Samsung’s QLED branded TVs.

Mini LED is another derivation of LED LCD panels, employing smaller-sized LEDs that can emit more light than standard versions, increasing brightness output of the TV. And as they are smaller, more can be fitted into a screen, leading to greater control over brightness and contrast. This type of TV is becoming more popular, though in the UK and Europe it’s still relatively expensive. You can read more about Mini LED and its advantages in our explainer.

OLED, meanwhile, hasn’t stood still either. LG is the biggest manufacturer of large-sized OLED panels and has produced panels branded as evo OLED that are brighter than older versions. It uses a different material for its blue OLED material layer within the panel (deuterium), which can last for longer and can have more electrical current passed through it, increasing the brightness of the screen, and elevating the colour volume (range of colours it can display).

While LED LCD has been around for much longer and is cheaper to make, manufacturers are beginning to move away from it, at least in the sense of the ‘standard’ LCD LED displays, opting to explore the likes of Mini LED and Quantum Dot variations.

OLED has gained momentum and become cheaper, with prices dipping well below the £1000 price point. OLED is much better than LED LCD at handling darkness and lighting precision, and offers much wider viewing angles, which is great for when large groups of people are watching TV. Refresh rates and motion processing are also better with OLED though there is the spectre of image retention.

If you’re dealing with a limited budget, whether you’re buying a phone, a monitor, a laptop or a TV, you’ll almost certainly end up with an LCD-based screen. OLED, meanwhile, incurs more of a premium but is getting cheaper, appearing in handheld gaming devices, laptops, some of the best smartphones as well as TVs

Which is better? Even if you eliminate money from the equation, it really comes down to personal taste. Neither OLED nor LCD LED is perfect. Some extol OLED’s skill in handling darkness, and its lighting precision. Others prefer LCD’s ability to go brighter and maintain colours at bright levels.

How do you decide? Stop reading this and go to a shop to check it out for yourself. While a shop floor isn’t the best environment in which to evaluate ultimate picture quality, it will at least provide an opportunity for you to realise your priorities. Whether you choose to side with LCD or OLED, you can take comfort in the fact that both technologies have matured considerably, making this is a safe time to invest.

Cathode-ray-tube (CRT) displays have been used extensively in vision research because of their superior response times and reduced motion smear, relative to the liquid crystal displays (LCDs) commonly used in homes and offices. To produce an image on a CRT screen, a stream of electrons is shot at a phosphor-coated screen from an electron gun that can be rapidly turned on or off and repositioned. When hit by the electron stream, the phosphor luminesces for a period that varies with the phosphor’s characteristics. Some phosphors (e.g., P15) have virtually no persistence; others (e.g., P31) have persistence that can remain visible for several seconds (Di Lollo, Seiffert, Burchett, Rabeeh, & Ruman, 1997). LCD screens are based on a totally different technology: A steady light source positioned behind the screen is blocked by a layer of liquid crystals arranged in a matrix of pixels. The liquid crystals act as switches that allow the passage of light when a voltage is applied to them. The amount of light transmitted varies with the input voltage. Until recently, LCD screens reacted sluggishly to changes in input voltage. Recent advances in LCD technology, however, have improved their temporal characteristics, making them potential candidates for the laboratory.

Kihara, Kawahara, and Takeda (2010) have shown that observers exhibit comparable performance with CRT and LCD monitors on two well-known attentional and perceptual tasks: the attentional blink and metacontrast masking. As the authors noted, however, these results do not necessarily demonstrate that LCDs are suitable for all experimental paradigms. For instance, because of phosphor persistence, CRT images are known to remain visible for some time after the initial image has been turned off (Di Lollo et al., 1997; Groner, Groner, Müller, Bischof, & Di Lollo, 1993). It is possible that LCD monitors will produce similar residual images as a result of a delay in shifting from one liquid crystal orientation to another. These residual images, which we refer to as display persistence, were not of critical importance in the paradigms investigated by Kihara et al. because the target stimuli were invariably followed by masks that overwrote any lingering persistence on the display screen. On the other hand, residual images are potentially harmful in paradigms that require precise timing of stimulus offset. One of the objectives of the present study was to investigate the duration of display persistence on both CRT and LCD monitors.

In the present work, we examined the time course of the visibility of display persistence on both CRT and LCD monitors under light-adapted and dark-adapted viewing. A vertical or horizontal bar was displayed on the monitor behind a closed mechanical shutter. The shutter opened rapidly at varying intervals following the offset of the bar. Therefore, any image still visible on the screen was the result of display persistence. The observers’ task was to identify the bar’s orientation.

A second, and just as important, objective of the present work was to examine the timing of LCD screens. Previous estimates had revealed LCD displays to be sluggish, requiring as long as 150 ms to reach maximum luminance (Liang & Badano, 2007). This slow rise time rendered LCD screens unsuitable for experiments or applications that require brief displays. A recent advance in LCD technology, known as overdrive technology, however, has resulted in substantial reductions in their response times, bringing LCD screens within the range of useful devices.

The principal objective of overdrive technology is to speed the transition from one level of luminance to another, as when a light stimulus is presented on a dark background. Figure 1 illustrates how this is done. Panels a and b show the course of events without overdrive. The two functions in each panel illustrate a shift from a lower level (Level 1) to higher levels (Levels 2 and 3) of intensity. Panel a illustrates changes in the voltages applied to the liquid crystals to achieve and maintain the desired level of luminance. Panel b illustrates the temporal course of the changes in luminance in response to the changes in voltage. Clearly, the sudden increments in voltage (panel a) result in sluggish changes in luminance (panel b). The important thing to note is that the rate of change in luminance is faster for the higher voltage (panel b, segmented line). For example, luminance reaches Level 2 sooner when the voltage is switched to Level 3 than when it is switched to Level 2. This phenomenon is used in overdrive technology to achieve a faster transition between different levels of luminance.

Stimuli were presented on one of two computer monitors: a 21-in CRT (AccuSync 120 equipped with B22 phosphor, denoted as having “medium-short” persistence, manufactured by NEC: www.necdisplay.com) and a 23-in. LCD (BenQ XL2410T, www.benq.com). B22 phosphor is also known as P22 phosphor. The CRT was set at a resolution of 800 × 600 pixels and the LCD at 1,920 × 1,080 pixels. Both monitors operated at a refresh rate of 120 Hz and were switched on at least 30 min before the beginning of the experiment. The brightness and contrast settings of both display monitors were set to maximum, so as to examine the worst-case scenario for both monitors. The luminance of the stimuli under different viewing conditions is specified below.

The display consisted of a vertical or horizontal light bar presented in the center of a darker background. At the viewing distance of 42 cm, the bar subtended 3.4º × 13.6º (210 × 57 pixels in the CRT monitor, 340 × 90 pixels in the LCD monitor). The orientation of the bar was chosen randomly on each trial, with the constraint that each orientation was chosen an equal number of times.

Each trial began with a 200-ms display of the bar behind a closed shutter. The shutter opened at varying delays following the offset of the bar. In calculating the shutter delays, we took into account the time required for the raster to travel from the top of the screen to the screen location beyond that occupied by the vertical bar. This was done to ensure that the bar had been removed from the screen before the shutter began to open. Given a refresh rate of 120 Hz, the signal to open the shutter was issued 6 ms after the beginning of the raster scan. This was designated as the 0-ms delay. Longer delays were obtained by adding the appropriate temporal intervals. Because of the shutter-opening time, the actual shutter delays were 2–4 ms longer than those shown in the figures. When the shutter opened, the observer attempted to identify the orientation of the bar on the basis of the display persistence remaining on the screen. A total of 48 responses were collected at each combination of lighting condition, monitor, and shutter-opening delay. Stimulus presentation and shutter control were governed by programs written in E-Prime (Version 2.0; Psychological Software Tools, Pittsburgh, PA).

The experiment was conducted in a dark room, and each observer was dark-adapted for at least 30 min prior to the session. The luminance of the white bar on the CRT monitor was 120.0 cd/m2, and the luminance of the black background was 0.2 cd/m2, as measured by a Minolta LS-110 luminance meter. The corresponding luminance values for the LCD screen were 242.1 cd/m2 and 0.2 cd/m2. The range of shutter-opening delays from stimulus offset was set to encompass identification accuracies from near-perfect to near-chance.

The results for the CRT screen, illustrated in Fig. 2, show that the phosphorescence of the CRT screen remained visible (accuracy above 50%) for over 3 s for all observers. Di Lollo et al. (1997) reported similar estimates for P4 and P31 phosphors. In contrast, the display persistence of the LCD screen was negligible, with accuracy hovering around chance even at a nominal shutter delay of 0 (averaged across the three observers, the percentage of correct responses was 49%). We conclude that under dark-adapted conditions, the LCD screen was superior in producing essentially no display persistence, as compared to substantial persistence for the CRT screen.

The above measurements were performed with the brightness and contrast settings of both the CRT and the LCD screens set to maximum. Because these settings resulted in higher luminance for the LCD screen (see above), we replicated the measurements with the luminance of the LCD screen set to match that of the CRT screen. As specified above, the luminance of the CRT was 120.0 cd/m2 for the white bar and 0.2 cd/m2 for the black background. The matching values for the LCD screen were 123.1 cd/m2 and 0.1 cd/m2, respectively. Averaged across the three observers, the percentage of correct responses obtained at the lower luminance setting for the LCD screen was 52%, which was very similar to that obtained at the higher setting. Phenomenologically, the stimuli were never visible on any trial.

The procedures here were the same as in dark-adapted viewing, except that the session was conducted under normal room-lighting conditions. The monitor was not covered with a shield, and participants were not dark-adapted prior to the session. The luminance of the CRT monitor was 123.5 cd/m2 for the white bar and 3.5 cd/m2 for the black background. The corresponding estimates for the LCD monitor were 242.6 cd/m2 for the white bar and 0.8 cd/m2 for the black background. The results for the CRT screen are illustrated in Fig. 3. As expected, the visibility of display persistence was shorter than in dark-adapted viewing (Fig. 2), reaching chance level approximately 125 ms after stimulus offset. Even such relatively short persistence, however, can be harmful when brief exposures are required as in studies of iconic memory and temporal integration. A notable finding was that when the polarity of the displays was reversed (i.e., a black bar on a white background), no persistence was visible even at the shortest shutter delay (averaged across the three observers, the percentage of correct responses at a nominal shutter delay of 0 was 49%).

The results for the LCD screen revealed no display persistence even at the shortest shutter delay for either white-on-black or black-on-white displays (averaged across the three observers, the percentages of correct responses at a nominal shutter delay of 0 were 47% and 49%, respectively). As was done in the dark-adapted viewing condition, a separate set of estimates were obtained for the LCD screen with the luminance set to match that of the CRT. As specified above, the luminance of the CRT was 123.5 cd/m2 for the white bar and 3.5 cd/m2 for the black background. The matching values for the LCD screen were 124.0 cd/m2 and 0.9 cd/m2, respectively. Averaged across the three observers, the percentages of correct responses obtained at the lower luminance setting for the LCD screen were 47% for white-on-black displays and 49% for black-on-white displays. These results were very similar to those obtained at the higher setting. Phenomenologically, the stimuli were never visible on any trial.Part II: Photometric estimates of luminance

Earlier estimates of the time to reach maximum luminance in LCD screens have ranged up to 47 ms for black-to-white transitions (Wiens et al., 2004) and up to 150 ms for gray-to-gray transitions (Liang & Badano, 2007). Those estimates, however, were obtained before the advent of overdrive technology, which boosts the voltage applied to the liquid crystals, thereby markedly improving the temporal response characteristics of LCD screens. The present photometric measurements were performed to assess the extent to which the response times were improved by overdrive technology.

The monitors and the stimuli were the same as those used for the psychophysical estimates. The luminance of the stimuli was measured with a photo diode (S7686, Hamamatsu Photonics) calibrated for the human spectral sensitivity function (spectral response range 480–660 nm, peak sensitivity 550 nm), with an active area of 2.8 × 2.4 mm. The photodiode was placed on the center of the screen, and its output was amplified by a Thorlabs PDA200C photo diode amplifier. The signal was sampled at a rate of 25 kHz by a quickDAQ (Version 1.6.0.8) data acquisition system on a laptop computer via a Data Translation DT9804-EC-I USB Data Acquisition Function Module. In preliminary trials, we found that the LCD display reached maximum luminance within a single 8.33-ms refresh frame. To add a margin of safety, each display consisted of two consecutive frames, for a total display duration of 16.7 ms. A total of 100 such trials, separated by 100-ms gaps, were recorded in the data acquisition system. The average of those 100 trials was then smoothed by means of a central-moving-average procedure using 11 data points, 5 on either side of the point whose mean was to be calculated. The measurements were performed in a dimly lit room.

The results for the LCD screen are illustrated in Fig. 5. Estimates were obtained for a black-to-white transition (RGB 0 to 255) and for two gray-to-gray transitions (RGB 10 to 65 and 25 to 165). As was the case for the CRT functions (Fig. 4), the LCD functions in Fig. 5 are delayed by approximately 4.2 ms from the zero point. This was to be expected, on the grounds that, just like CRT monitors, LCD monitors operate on a raster-scan system.

Luminance changes produced by a light bar displayed for two refresh cycles on an LCD screen running at 120 Hz. Three luminance transitions were tested: one black-to-white transition (RGB 0, 0, 0 to 255, 255, 255, labeled as 0–255), and two gray-to-gray transitions (RGB 25, 25, 25 to 165, 165, 165, labeled as 25–165, and RGB 10, 10, 10 to 65, 65, 65, labeled as 10–65). Represented on the ordinate is the strength of the illumination signal (in microvolts) recorded by the photo diode

The functions in Figs. 4 (CRT) and 5 (LCD) differ substantially from one another in maximum intensity (approximately 200 and 14 μV, respectively). As noted in the Method section, the two screens were set to maximum luminance. This resulted in photometric readings of 120.0 and 242.1 cd/m2 for the CRT and LCD screens, respectively. The photometric measures illustrated in Figs. 4 and 5, however, exhibit the opposite relationship, with the CRT having the greater intensity. This discrepancy can be understood in terms of the different sampling rates used in the measurements. The luminance values of 120.0 and 242.1 cd/m2 were obtained with a photometer that averaged the screen output over a period of about 1.5 s (~0.67 Hz), whereas the intensity values in Figs. 4 and 5 were obtained with a light sensor that sampled the output every 0.00004 s (25 kHz). The important consideration is that any given pixel in the CRT screen was activated only once per refresh cycle (see Fig. 4), whereas the corresponding pixels in the LCD screen emitted light continuously. To yield similar time-averaged luminances, therefore, the electron beam in the CRT needed to have a higher intensity relative to the backlight of the LCD screen. This difference in intensity is reflected in the functions in Figs. 4 and 5.

A taxonomic survey of commercially available LCD monitors was obviously beyond the scope of the present work. To gain some indication of the generality of the findings reported in the foregoing analysis, however, we tested two additional LCD monitors: a Dell 1907FPc (not equipped with overdrive, released February 2006) and a ViewSonic VS12841 (equipped with overdrive, released December 2009). A further reason for testing additional monitors was to ascertain whether the superior temporal characteristics exhibited by the BenQ XL2410T could be ascribed to the implementation of overdrive technology. The three monitors (Dell, ViewSonic, and BenQ) are compared in Fig. 7. The data were collected as described above, with the following exceptions. The stimuli were displayed for 66.7 ms because preliminary results indicated that all of the monitors reached asymptotic level within this time window. The BenQ monitor was refreshed at a rate of 120 Hz (i.e., the stimuli were displayed for eight frames). Because the Dell and the ViewSonic monitors could not reach a frame rate of 120 Hz, they were run at 60 Hz (i.e., the stimuli were displayed for four frames). In addition, the ViewSonic and the BenQ monitors were run with the overdrive feature either ON or OFF. This could not be done with the Dell monitor, which was not equipped with overdrive.

Luminance changes produced by a light bar displayed for 66.7 ms on three LCD screens. (a) Dell 1907FPc, run at 60 Hz; (b) ViewSonic VS12841, run at 60 Hz; (c) BenQ XL2410T, run at 120 Hz. Three luminance transitions, fully described in the Fig. 5 caption, were tested in each monitor: one black-to-white transition (RGB 0–255) and two gray-to-gray transitions (RGB 25–165 and RGB 10–65). The ViewSonic and the BenQ monitors were tested with the overdrive feature turned ON (bold functions) and OFF (thin functions). Represented on each ordinate is the strength of the illumination signal (in microvolts) recorded by the photo diode

The photometric measurements are illustrated in Fig. 7 and Table 1. Clearly, the response characteristics of both the ViewSonic and BenQ monitors were markedly improved with overdrive turned on. It is also clear that the performance of older models, exemplified by the Dell monitor, is inferior to that of more recent models, even with overdrive in the newer models turned off. All functions in Fig. 7 exhibited some 60-Hz fluctuations, most noticeable in Fig. 7a. Similar fluctuations have been reported by Kihara et al. (2010, Fig. 4c) and by Wiens et al. (2004, Fig. 1b). This 60-Hz component is inherent in the LCD power supply and can be much reduced or eliminated by a 60-Hz notch filter on the power cable, by placing the power supply away from the monitor, or by shielding the main LCD circuit board with a sheet of mu-metal.

Table 1 Rise times, fall times, and durations (in milliseconds) for the BenQ XL2410T, ViewSonic VS12841, and Dell 1907FPc LCD monitors, for three RGB transitions and with overdrive turned OFF or ONGeneral discussion and conclusions

The psychophysical estimates are unambiguous: For white images on a black background, the BenQ LCD screen never produced any display persistence, even in dark-adapted viewing, whereas the CRT produced substantial persistence in both light- and dark-adapted viewing. On the other hand, neither monitor produced any measurable visible persistence for black images on a white background. Clearly, when display persistence is a concern, LCD screens are preferable to CRT screens unless the displays consist of black-on-white stimuli.

As compared to photometric estimates obtained with LCD monitors without overdrive or with overdrive turned off (Fig. 7; see also Liang & Badano, 2007; Wiens et al., 2004), the present estimates highlight the substantial improvement in temporal response characteristics brought about by overdrive technology. For example, our estimated rise time of 1–6 ms is considerably shorter than estimates obtained without overdrive (2–25 ms in our estimates, 20–150 ms in past research; Liang & Badano, 2007; Wiens et al., 2004) and approaches that of CRTs (<1 ms). Clearly, recent advances in LCD technology have resulted in a substantial reduction in response times, making LCD screens suitable for presenting brief displays.

Of the many display monitors available commercially, only one CRT and three LCD monitors were selected for testing in the present work. A complete taxonomy of all available monitors would obviously be unfeasible. Alternatively, one might set out to formulate some general rule relating the photometric characteristics of any given monitor to the manufacturer specifications. However, this calculation would be complicated by the fact that manufacturers use different methods and criteria for assessing the temporal characteristics of their displays.

Liquid Crystal Display (LCD) screens are a staple in the digital display marketplace and are used in display applications across every industry. With every display application presenting a unique set of requirements, the selection of specialized LCDs has grown to meet these demands.

LCD screens can be grouped into three categories: TN (twisted nematic), IPS (in-plane switching), and VA (Vertical Alignment). Each of these screen types has its own unique qualities, almost all of them having to do with how images appear across the various screen types.

This technology consists of nematic liquid crystal sandwiched between two plates of glass. When power is applied to the electrodes, the liquid crystals twist 90°. TN (Twisted Nematic) LCDs are the most common LCD screen type. They offer full-color images, and moderate viewing angles.

TN LCDs maintain a dedicated user base despite other screen types growing in popularity due to some unique key features that TN display offer. For one,

Displays with VA screens deliver wide viewing angles, high contrast, and good color reproduction. They maintain high response rates similar to TN TFTs but may not reach the same sunlight readable brightness levels as comparable TN or IPS LCDs. VA displays are generally best for applications that need to be viewed from multiple angles, like digital signage in a commercial setting.

IPS (In-Plane Switching) technology improves image quality by acting on the liquid crystal inside the display screen. When voltage is applied, the crystals rotate parallel (or “in-plane”) rather than upright to allow light to pass through. This behavior results in several significant improvements to the image quality of these screens.

IPS is superior in contrast, brightness, viewing angles, and color representation compared to TN screens. Images on screen retain their quality without becoming washed out or distorted, no matter what angle they’re viewed from. Because of this, viewers have the flexibility to view content on the screen from almost anywhere rather than having to look at the display from a front-center position.

IPS displays offer a slightly lower refresh rate than TN displays. Remember that the time for pixels to go from inactive to active is measured in milliseconds. So for most users, the difference in refresh rates will go unnoticed.

Based on current trends, IPS and TN screen types will be expected to remain the dominant formats for some time. As human interface display technology advances and new product designs are developed, customers will likely choose IPS LCDs to replace the similarly priced TN LCDs for their new projects.

Before answering the questions below, it would be helpful to provide a simple overview of how a TFT LCD works. Every monitor or touchscreen computer includes an LCD panel. The LCD panel is the component that you are viewing at this very moment. This panel includes a thin layer of TFT LCD pixels, where each pixel includes a red, blue, and green rectangle. You can actually see the individual pixels on a display if you place a drop of water on it. The drop will magnify the pixel area and reveal a pixel with a red, blue, and green rectangle. Each red, blue, and green rectangle is a small lens that can be adjusted to allow varying amounts of light to pass through. The colors you see on your screen are determined by how much light is passing through each adjustable red, green, and blue element of each pixel.

The light that you see does not come from the pixels themselves, but from the backlight behind the pixels, which is a series of carefully placed LEDs that emit white light that projects through the LCD pixels. You cannot see the individual backlight LEDs when you look at your monitor, because there is layer of light diffusing material between the LED backlight and the LCD pixel layer. The light diffusing material scatters the light from each individual backlight LED, so they do not show up as bright spots on your monitor.

To summarize, the three layers of an LCD panel are the TFT LCD pixel layer, the diffuser layer, and the LED backlight layer. Note that some LCDs have edge-lit backlighting, but there is no need to go into detail about this, as the same principles apply. That completes LCD panel course 101. Now, what makes a display sunlight readable?

There are two general ways to make an LCD brighter and therefore readable in sunlight. The first and simplest way is to increase the brightness of the backlight. LCD brightness is measured in Nits. Typical LCD panels have a screen brightness between 250 Nits to 450 Nits. LCD brightness of 800 Nits or higher is generally considered sunlight readable, but most sunlight readable displays are 1000 nits. Increasing the brightness of the LCD panel backlight is the most common method of making an LCD panel sunlight readable. Most of Teguar’s industrial panel PCs and touchscreen monitors are available with this type of high brightness LCD.

Another way to make an LCD sunlight readable is to change the diffuser material between the LED backlight and the LCD pixels to a “transflective” material. The transflective material is similar to reflective sunglasses or a one way window, where the shiny side is facing the LCD surface. When transflective material is used, the sunlight entering the LCD panel travels through the pixels, bounces off the transflective material, and is reflected back through the pixels to your eyes. In this case, the sunlight has much less of an impact on viewability than a traditional LCD panel, as the sunlight is reflecting back through the LCD pixels and contributing to the LCD brightness. One drawback of transflective diffuser LCDs is that they don’t allow for as much of the backlight to pass through the diffuser material, so in low light conditions the LCD does not appear as bright. Transflective diffuser LCDs are not as common as high brightness backlight LCDs.

Optical bonding improves viewability of touchscreen PCs in sunlight or other high-bright environments. In a touchscreen computer, the touchscreen sensor and the LCD panel are separate components. The touchscreen is mounted in front of the LCD surface and there is a small air gap between these two components. When sunlight passes through the touchscreen layer, some amount of the light is reflected between the LCD surface and the touchscreen; this reflection reduces LCD viewability.

Optical bonding is a process where a clear adhesive gel is placed between the LCD to the touchscreen. The gel hardens and bonds the touchscreen to the LCD to eliminate the air gap, improving contrast and clarity. Optical bonding is available on many of Teguar’s touchscreen computers and industrial monitors.

The brightness of a sunlight readable display may be overwhelming at night, when there is little or no ambient light. Most industrial computers with sunlight readable LCDs are available with an optional auto-dimming feature. With this feature, an ambient light sensor on the front bezel measures incoming light and adjusts the backlight brightness to match the current light conditions. This is typically a requirement for industrial touchscreen computers that are used in both sunlight and moonlight.

Sunlight also comes with a high amount of UV radiation that can damage the components used in touch screens. PCAP touch screens resist UV damage better than Resistive, but even a PCAP screen must be protected from too much UV exposure. Teguar computers are best suited for environments that provide some level of shade, such as a roof or overhang above the computer, or a structure that blocks the screen from direct exposure to the sun. Most outdoor computer manufactures, Teguar included, will offer a specialized shroud/hood that mounts directly to the unit to provide some level of shade.

Touchscreen computers in vehicles commonly require high brightness LCDs, because of the ambient sunlight coming through the windows. Sunlight readable LCDs are also used in many indoor applications surrounded by windows, such as air traffic control centers, railroad cars, marine vessels, agriculture machinery, and public kiosks.

Before you invest in a new digital display, you need to know what you are shopping for. A lot of technology out there sounds impressive, with names like LED, LCD, cloud-based, IoT, and so on. At Neoti, we believe in educating the customer so they can find the screen solution that fits their needs best. Educated customers have the information they need and are happier and more satisfied with their decisions. When looking for new digital display solutions, you will have to decide between LCD displays and LED display panels, but what does that mean, and what are they? We will explain why LED screens are better than LCD displays.

An LCD screen uses the same basic technology that has been around for many years in cell phones, camcorder viewfinders, and monitors. The screens are made of two layers of glass-like material that are polarized and affixed together. One of the layers has a special polymer coating that holds the individual liquid crystals. An electronic current then passes through the individual crystals and allows the crystal to either pass or block light to create an image. The crystals don’t produce any light, so an external source like a light bulb is needed. The light makes the image visible on the screen.

Overall, when talking about picture quality, design flexibility, product lifespan, and maintenance, LED displays are the superior product. As mentioned, LED screens are an improvement over the LCD technology. They provide a seamless display, unlike the LCDs with its tiled bezels. Initially, the LED is more expensive, but it will save money in the long run by using less energy. They are more efficient and will save money on electrical bills. They deliver a crisper, brighter image than LCDs, especially when ambient light is present.

No native resolution. Currently, the only display technology capable of multi-syncing (displaying different resolutions and refresh rates without the need for scaling).Display lag is extremely low due to its nature, which does not have the ability to store image data before output, unlike LCDs, plasma displays and OLED displays.

Colored sub-pixels may age at different rates, leading to a color shift. Sensitive to UV light from direct sunlight. Is considered the highest quality but also the most expensive display technology currently produced, with products rarely being available for less than $1200.

:max_bytes(150000):strip_icc()/CRT-vs-LCD-monitor-cfe0b6f375b542928baf22a0478a57a3.jpg)

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, digital clocks, calculators, and mobile telephones, including smartphones. LCD screens are also used on consumer electronics products such as DVD players, video game devices and clocks. LCD screens have replaced heavy, bulky cathode-ray tube (CRT) displays in nearly all applications. LCD screens are available in a wider range of screen sizes than CRT and plasma displays, with LCD screens available in sizes ranging from tiny digital watches to very large television receivers. LCDs are slowly being replaced by OLEDs, which can be easily made into different shapes, and have a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile (because OLEDs use a single glass or plastic panel whereas LCDs use two glass panels; the thickness of the panels increases with size but the increase is more noticeable on LCDs) and potentially lower power consumption (as the display is only "on" where needed and there is no backlight). OLEDs, however, are more expensive for a given display size due to the very expensive electroluminescent materials or phosphors that they use. Also due to the use of phosphors, OLEDs suffer from screen burn-in and there is currently no way to recycle OLED displays, whereas LCD panels can be recycled, although the technology required to recycle LCDs is not yet widespread. Attempts to maintain the competitiveness of LCDs are quantum dot displays, marketed as SUHD, QLED or Triluminos, which are displays with blue LED backlighting and a Quantum-dot enhancement film (QDEF) that converts part of the blue light into red and green, offering similar performance to an OLED display at a lower price, but the quantum dot layer that gives these displays their characteristics can not yet be recycled.

Since LCD screens do not use phosphors, they rarely suffer image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs are, however, susceptible to image persistence.battery-powered electronic equipment more efficiently than a CRT can be. By 2008, annual sales of televisions with LCD screens exceeded sales of CRT units worldwide, and the CRT became obsolete for most purposes.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs, along with OLED displays, are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,transparent and flexible, but they cannot emit light without a backlight like OLED and microLED, which are other technologies that can also be made flexible and transparent.

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey