igzo tft display in stock

U.S would have smartphones, accounting for around 81% of the region"s population. Multiple industrial manufacturers are seeking to release cutting-edge smartphones with cutting-edge features like 5G connectivity and IGZO screens in response to the spike in adoption of smartphones and the appearance of impending 5G technology. This is anticipated to help the IGZO display market in U.S flourish.

China consumer electronics company announce the launch of its initial 85-inch 8K 120Hz screen world showcase industry conferencing. The TV offers a contrast of much more over 5000:1 on its 1G1D elevated Display screen, which would be IGZO technology, and consumes 30% less electricity than TVs of a similar size. It is projected that many new product introductions would boost IGZO display sales in the following years.

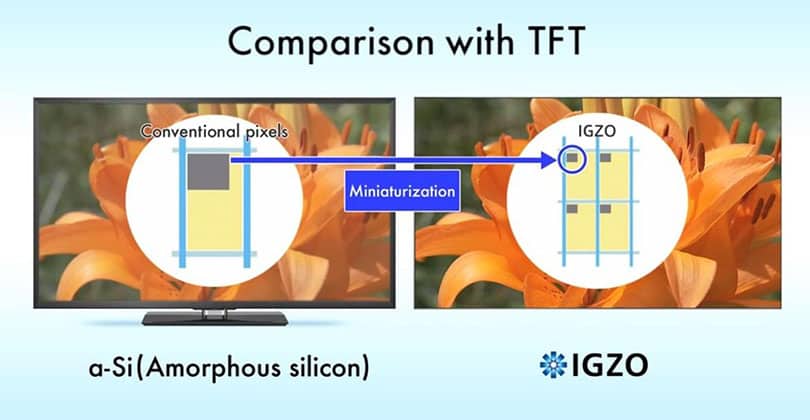

IGZO is an acronym for Indium Gallium Zinc Oxide and it’s actually a different type of semiconductor found in the TFT backplane; it’s not a different panel technology altogether.

In comparison to standard aSi-TFT IPS displays, an IGZO-TFT IPS display greatly saves on power consumption, while giving equally accurate and vibrant colors. However, they are much more expensive.

To clear away the confusion, IGZO is not a type of panel but a different type of transistor in the TFT (thin-film-transistor) backplane. Therefore, it can be implemented in all types of panels including TN, VA, IPS and even OLED.

Standard transistors in most of these panels are made of amorphous silicon. So, in this article, we’ll be comparing aSi-TFT IPS panels to the IGZO-TFT IPS panels.

The IGZO (Indium Gallium Zinc Oxide) compound semiconductor was licensed by Samsung and Sharp. However, it was Sharp who first implemented IGZO into their smartphones, tablets and 32-inch LCDs.

The IGZO transistor is made from rare metals such as the Indium and Gallium, and therefore it is costly. For instance, the NEC PA322UHD is a 4K resolution monitor with a 14-bit Look-Up Table for precise calibration and covers 99.2% of the Adobe RGB color space.

At the moment, the main advantage of IGZO is its very low power consumption. In comparison to the standard a-Si panel monitor, it can be up to 80%-90% more power efficient due to the higher electron mobility, which is 20-50 times faster than that of a regular panel.

While a-Si panel monitors require more power for the backlighting of higher pixel density displays, IGZO does not – in fact, it can create even brighter images at significantly lower power consumption.

This is ideal for portable devices with high pixel density. In short, IGZO can deliver a better resolution, speed and pixel density, no matter the size of the display.

While the difference between the IGZO-TFT and a-Si-TFT IPS panels may not be meaningful now, especially considering the difference in the price, IGZO will certainly greatly contribute to the future development of displays.

Since it can drastically reduce power consumption and offer stunning pixel density, resolution, and speed, high-quality touch-sensitive transparent displays are getting closer and closer to reality.

Liquid crystal displays (LCD) began to replace cathode-ray tube-based televisions in the early 2000s. The pixels in these LCDs were, until 2012, driven exclusively by thin-film transistors (TFTs) that use amorphous hydrogenated silicon (a-Si:H) as the semiconducting channel. But as demand grew for ever larger displays, with better viewing and energy performance, a need for improved TFTs emerged. TFTs block light coming from the display, so they need to be small, which lowers their current-driving ability. Additionally, there was a push to move away from LCD technology and into organic light emitting diodes (OLEDs) in order to capitalize on their better performance, which includes direct emission and richer colours, but OLEDs need to be driven by large amounts of current, at levels a-Si:H TFTs cannot accommodate. What was needed was a new technology that could be used to create TFTs with a high charge carrier mobility, which could drive large currents.

Charge carrier mobility tells us how quickly charge carriers (electrons and holes) can move through a semiconductor, and determines the amount of current we can drive through a TFT of a given size. This is limited by the nature of the path that charge carriers take though a material. This path can be thought of in terms of the atomic orbitals and how they interconnect to make up the conduction and valence bands — the energetic levels at which the electrons and holes are free to move around. The sp3 hybridized orbitals in silicon are highly directional, and in the crystalline state the silicon–silicon bonds properly overlap, providing an efficient path to travel through. However, in amorphous silicon, structural disorder leads to disconnects and conduction cannot occur through the orbitals in the same way. Instead, the charge carriers have to hop across the orbitals, which leads to mobilities of at most 1 cm2 V–1 s–1 — about 2–3 orders of magnitude lower than in crystalline silicon.

After a few years verifying the validity of the hypothesis, we started research on transparent oxide TFTs. To develop high-mobility TFTs using transparent conductive oxides, the major issue was their high carrier concentrations (the TFTs can’t be turned off). Indium oxide is a typical transparent conductive oxide with a large mobility, but reducing its excessive carrier concentration is difficult due the ease with which oxygen vacancies form. We tested InGaO3(ZnO)m epitaxial films, where m = 4 and 5, as I believed the unique local structure around Ga3+ would help lower the carrier concentration. As expected, the carrier concentration in epitaxial InGaO3(ZnO)4 reduced to a suitable level, and when applied in TFTs showed excellent performance, with a mobility of approximately 80 cm2 V–1 s–1. We then fabricated thin films using amorphous InGaZnO4 (a-IGZO). The electron concentrations in the resulting a-IGZO thin films, which were deposited on glass substrates at room temperature, were below 1016 cm–3 and the TFTs exhibited mobilities of approximately 10 cm2 V–1 s–1 — an order of magnitude larger than that of a-Si:H TFTs. We also found that TFTs fabricated on plastic substrates offered almost identical performance (Fig. 1). At this point we applied for patents and then submitted our paper to Nature, which was published in 2004.

Demonstrations of IGZO TFT-based displays began to emerge in 2007, when Samsung Electronics first reported a-IGZO TFT-based high-definition LCDs. Demonstrations of IGZO TFT-based backplane LCDs in smart phones and tablet computers then appeared around 2012. Arguably the most striking application emerged in 2015, when LG Display demonstrated large-sized OLED televisions. Here the a-IGZO TFT was indispensable because of the need for high mobility and simple formation over large areas.

I believe the success of IGZO transistors is due to a number of factors. First is their high mobility, which is an order of magnitude higher than a-Si:H, and the excellent controllability of their carrier concentration. Second, the production process is almost the same as a-Si:H, except for the deposition of the channel layer (chemical vapour deposition is used for a-Si:H whereas sputtering is used for IGZO), making integration into current manufacturing workflows relatively painless. Third, synthesizing large-sized high-quality sputtering targets is relatively easy, which also makes thin-film deposition on large-sized substrates a relatively simple task. With these attributes, IGZO transistors provide a promising backplane technology to drive the future of flat panel displays.

An IGZO display is any display panel that uses indium gallium zinc oxide or IGZO as the primary semiconducting material in its thin-film transistor or TFT. Hence, it is not a display technology but rather, a specific backplane technology for driving and addressing transmissive or emissive components of a particular panel.

Some of the notable examples of a display technology include LCD technologies such as in-plane switching or IPS LCD and twisted nematic or TN LCD, as well as organic light-emitting diode or OLED technology, and microLED technology. On the other hand, there are three major backplane technologies: IGZO TFT, amorphous silicon or a-Si TFT, and low-temperature polysilicon or LTPS TFT.

• Note that a-Si-TFT is not transparent but can be stretched thin enough to allow an adequate amount of light to pass through. An IGZO-TFT is naturally transparent, thus translating to specific advantages such as brighter display panels and energy efficiency, reduced need for backlighting in the case of LCDs, and reduced brightness output in OLED and LED displays.

• Another advantage of IGZO display is that it has 30 to 50 times more electron mobility than a-Si display. Better electron flow means higher resolutions and faster pixel response time to allow the manufacturing of smaller panels with high pixel density. Earlier prototypes using indium gallium zinc oxide featured a 6-inch panel at 2560×1600 pixels or 498 pixels per inch.

• Note that transparency and better electron mobility also mean that these displays are more power-efficient than those based on amorphous silicon. Furthermore, it has a lower leakage current than both amorphous and low-temperature polysilicon TFT, thus allowing it to retain an active pixel state longer, especially when displaying still images such as photographs and documents.

• Manufacturing IGZO displays also require the use of rare-earth materials. More specifically, indium and gallium are rare. They are costly to extract from their point of origin and procure from the suppliers. This drawback introduces cost and supply risks for manufacturers of display panels and consumer electronic devices.

• Another disadvantage is that producing displays based on this semiconductor is more complicated than manufacturing a-Si TFT display panels. The current challenge to mass-producing indium gallium zinc oxide is the relevant synthesis method using Pulsed Laser Deposition or PLD. However, PLD requires expensive equipment and lengthier time. These requirements can hamper large-scale production.

• It is also worth mentioning that LTPS displays have key advantages over IGZO displays and a-Si displays. More specifically, it has better and faster electron flow, allows the production of small-sized screens with high pixel density, and more efficient power consumption.

Miyata, Y., Furuta, M., Yoshioka, T., and Kawamura, T. 1992. “Low-Temperature Polycrystalline Silicon Thin-Film Transistors for Large-Area Liquid Crystal Display.” Japanese Journal of Applied Physics. 31(P. 1, No. 12B): 4559-4562. DOI: 1143/jjap.31.4559

a-IGZO-based TFT fabricated via CL-ES process shows the same mask number to that of BCE process (Fig. 1). Compared with a-IGZO-based TFT with BCE structure, a-IGZO-based TFT with CL-ES structure shows two advantages: (1) a-IGZO-based backplane produced using CL-ES process deposits gate insulator, a-IGZO nano-layer, and ES nano-layer sequentially, then forms a ESL nano-mask through dry-etch method. This newly formed ESL nano-mask with 100 nm can prevent the exposure of a-IGZO nano-film to etchant, stripper, or photoresist. Therefore, the contamination at inter-layer interfaces is effectively prevented [25]. (2) At the same time, a-IGZO nano-film is not protected by ES layer but bombarded by CF4 plasma during the ESL nano-mask formation, thus becomes a conductor. This naturally forms the Ohmic contact between S/D electrode of following process and a-IGZO semiconductor. For another part, a simultaneous etching of S/D and a-IGZO nano-layer can be one overlay allowance of ESL-(a-IGZO+S/D metallization) layer, which could decrease the two overlay process error of the a-IGZO-ESL and ES-S/D metallization layer in the conventional ESL process (Fig. 2). The overlay number of the a-IGZO, ES, and S/D layer is reduced, which resulted in the decrease in the size of TFT device that lowered the parasitic capacitance. The outcome planar structure is similar to the BCE structure (Fig. 3a, b).

(Color online) Schematics of simultaneous formation method for TFT channel and S/D electrode in CL-ES process. a The first step that forms gate electrode. b The second step that forms etch-stopper layer. c The third step that forms S/D photo pattern. d The fourth step that forms S/D electrode and active pattern

Figure 3 shows the SEM images of a-IGZO-based TFTs with CL-ES structure (Fig. 3a, c) and BCE structure (Fig. 3b, d). From the top view, it is difficult to identify the differences between CL-ES structure and BCE structure (Fig. 3a, b). From the side view, an ES nano-layer can be found between the a-IGZO nano-layer and the S/D electrode layer in CL-ES structure (Fig. 3c). Meanwhile, a passivation layer can be found on the top of a-IGZO nano-layer in BCE structure (Fig. 3d). In the presented CL-ES process, an a-IGZO nano-layer with a thickness of 30 nm is deposited. Moreover, the damage during wet etching is negligible. For BCE process, a 70-nm a-IGZO nano-layer is deposited, as a-IGZO layer needs compensation for etching loss. The difference between the thicknesses of a-IGZO nano-layers in CL-ES and BCE structures can be observed in the SEM images (Fig. 3c, d).

The I-V characteristics of a-IGZO-based TFT with CL-ES structure and BCE structure are compared (Fig. 4). The saturation electron mobility, threshold voltage, subthreshold voltage swing (SS) value, and more characteristic values are summarized in Table 1. Note that the values summarized in Table 1 are the average number derived from the center and edge of an 8.5 generation glass substrate. The a-IGZO-based TFT with CL-ES structure realizes Vth of − 0.8 V, SS value of 0.18 V/dec, and saturation electron mobility of 8.05 cm2/V s. In the a-IGZO-based TFT with BCE structure, the corresponding results are Vth of + 0.5 V, SS value of 0.77 V/dec, and saturation electron mobility of 6.03 cm2/V s. Compared to the BCE structure, CL-ES structure shows an improved device performances. However, the on-current characteristic of the a-IGZO-based TFT device with CL-ES structure is lower than that with BCE-structured device. This is due to the fact that TFT channel structures are different in CL-ES and BCE structures. Generally, BCE-structured TFT channel length are the distance between S/D metal electrodes, and the measured channel length in this study is 5 um [21]. In CL-ES structure, electrodes are in contact with the a-IGZO nano-film that is stretched at the side of ESL nano-mask. Therefore, the channel length is decided by the distance between the a-IGZOs defined at the etch-stopper’s sides, but not determined by the distance between the electrodes. The channel length of the present CL-ES-structure device is measured to be 10 um.

(Color online) Comparison of I-V characteristic of a-IGZO TFTs with CL-ES and BCE structure on the center (a) and edge (b) of 8.5 generation glass substrate

As shown in Table 1, the measured values of Ion/Ioff ratio (~ 106, see Table 1) are approximately 10 times smaller than the typical value (> 107) of a-IGZO-based TFTs. This is because the measuring equipment used here is for the 8.5 generation mass production. Long cables are necessary for these measurements, as the size of the industrial equipment is large. The long cables resulted in an increased measurement noise. In the following reliability testing, smaller-scale measuring equipment is utilized, and the individual TFT devices is used as specimen for measurement. In this way, the measured Ion/Ioff ratios are all upper 107 (see below).

CL-ES process is carefully designed to prevent a-IGZO channel layer being exposed to etchant, photoresist, or stripper. During the process that produces CL-ES process, gate insulator, a-IGZO nano-layer, and ES nano-layer, each inter-layer interface is in contact with only DI water for cleaning purpose. Hence, the chemical contamination is negligible in insulator layer and a-IGZO nano-layer [25, 26]. However, the BCE process not only exposes channel layer to the chemicals but also involves Cu ion diffusion contamination, as the a-IGZO channel is directly exposed to Cu metal. This is also avoided in device with CL-ES structure. The channel region of the a-IGZO nano-film is well protected by ESL nano-mask. The low chemical contamination in CL-ES process may lead to a low carrier trap density at the interface between a-IGZO nano-layer and insulator layer, resulting in an excellent SS value. This low chemical contamination of a-IGZO-based TFT device via CL-ES process also helps improve the uniformity and reproducibility of a-IGZO TFT, which are highly important in industrial production [27, 28].

Figure 5 shows the measured I-V characteristic of TFTs with CL-ES structure and BCE structure derived from 42 measuring points on an 8.5 generation substrate. a-IGZO-based TFT with CL-ES structure has a Vth range of 0.72 V, while that of BCE-structured device is 2.14 V (Table 1). In other words, the uniformity of device performance is significantly improved by CL-ES structure.

(Color online) a CL-ES structure. b BCE structure’s TFTs I-V transfer characteristic. c 42 measuring points. d the photo of TFT. All measured on an 8.5 generation substrate

Figure 6a, b show the I-V characteristic shift of CL-ES-structured device and BCE-structured device obtained in NBTIS testing, respectively. The NBTIS testing results are summarized in Table 2. Under the stress condition described in the Table 2, the Vth shift of CL-ES-structured device and BCE-structured device are − 0.51 and − 3.88 V, respectively. Additionally, the on-current shift, off-current shift, and SS value variance of the CL-ES-structured device are all lower than those of the BCE-structured device (Table 2); this is because a-IGZO-based device with CL-ES-structure can effectively prevent the contamination of a-IGZO and lower carrier trap density of a-IGZO TFT channel. Especially, when looking at the result from first 1000 s of stress, no SS value change is observed in CL-ES-structured device. This phenomenon is comparable to the 0.16 V/dec increase in SS value of BCE-structured device, as it shows that defect sites, which can form carrier traps on the surface of a-IGZO nano-film constituting CL-ES TFT back channel, are not additionally created by electrical and illumination stress. These results fully prove that CL-ES-structured device is much more stable than BCE-structured device. Figure 6c, d show the I-V curve shift of CL-ES- and BCE-structured TFTs obtained from PBTS testing. The detailed PBTS testing results are summarized in Table 3. Both CL-ES-structured TFT and BCE-structured TFT have decreased in ion current during PBTS evaluation. This is caused by the shift in Vth to the positive direction. During PBTS evaluation, residual ion current ratio [(last ion/initial ion) × 100] of the CL-ES-structured TFT with relatively smaller Vth positive shift (+ 1.94 V) is in the level of 88.2%. When compared to the BCE-structured TFT"s residual ion current ratio of 41.3%, CL-ES-structured TFT is significantly superior. This shows the important capacity difference during designing of gate drive on array (GOA) circuit. Different from NBTIS, SS value of CL-ES-structured TFT does not have significant variation ((∆SS 0.06 V/dec), or rather decreases (∆SS − 0.86) like as BCE-structured TFT. This is perhaps due to the carriers, accumulate in the inner space and interface between gate insulator and a-IGZO nano-film by positive gate bias, filling the carrier trap site at the early stage, causing decrease in carrier trap phenomenon. Moreover, the threshold voltage shift phenomenon occurs by carrier charge trapped near the interface between gate insulator and a-IGZO nano-film. Small threshold voltage shift of CL-ES-structured TFT represents that the interface and the inner space of a-IGZO are remarkably clean. In conclusion, PBTS testing also suggests that CL-ES structure and process lead to a better device reliability.

The development history of a-IGZO FPDs up to 2008 is summarized in [4] and more recent data are included in figures figures33 and and4.4. As mentioned above, the first AOS TFT was reported in late 2004. Development research began in 2004 and Toppan Printing Co. Ltd first reported an AM display using AOS TFTs in the form of a flexible black-and-white e-paper in 2005 [40]. LGE has collaborated with ETRI on oxide TFTs and focused mainly on ZnO TFTs [20, 21]. After that, LGE started working on AOSs, and reported the first AM-OLED display in 2006 [41]. Following them, Samsung SDI and Samsung Advanced Institute of Technology (SAIT) reported AM-OLED displays in mid-2007 [42, 43]. The largest displays by the end of 2008 were a 12.1’’ AM-OLED [44, 45] and a 15’’ AM-LCD operating at 240 Hz with integrated gate drivers, as reported at the Society for Information Display (SID) meeting [46].

Development history of prototype displays using AOS TFTs. The panel size (diagonal size) and resolution (note that ‘# of pixels’ does not count RGB pixels separately, and is simply the product of the horizontal resolution and vertical resolution) are plotted for different companies and research groups.

From late 2008, more companies started activities involving AOSs. Hitachi Ltd, reported the low-voltage operation of AOS TFTs [47]. AU Optronics Corp. (AUO) started AOS TFT research in 2008 [48] and displayed a 2.4’’ QVGA (see table table22 for the abbreviations of the resolutions) AM-OLED at FPD International (FPDI) 2009, where a 19″ QFHD AM-OLED was reported by Samsung Mobile Display Co. Ltd (SMD) [49] and a 17″ SXGA AM-LCD by Samsung LCD. LG Display (LGD) reported a 6.4″ VGA AM-LCD, which was produced using a four-mask process similar to that used for a-Si:H LCD panels at FPDI2009, demonstrating that the production cost of AOS-based FPDs can be comparable to or even lower than those of present a-Si:H devices. Semiconductor Energy Laboratory (SEL) demonstrated source/gate driver integration in a 4″ QVGA AM-LCD [50, 51] and an AM-OLED [52]. Source/gate drive-integrated AM-LCDs were also reported by Sharp Corp. in the form of a 12.1″ WXGA AM-LCD [53]. The largest FPD driven by oxide TFTs was a 37″ FHD AM-LCD presented by AUO at TAOS2010 [3]. At the same conference, LGD reported a 15″ FHD AM-OLED [54].

Flexible displays have also been reported by several companies. The first reported display was the black-and-white e-paper by Toppan [40]. They have since developed more sophisticated displays such as a black-and-white e-paper with a larger size of 5.35″ for a 150 ppi (pixel per inch) resolution and a 2″ black-and-white e-paper with the world"s highest resolution of 400 ppi [55]. The first flexible FPD was an AM-OLED (3.5″, QCIF+) fabricated on stainless steel foil presented by LGE [56]. SMD reported a very flexible 6.5″ WQVGA AM-OLED fabricated on a polyimide substrate, which is bendable up to a curvature radius of 2 cm [57]. Dai Nippon Printing Co. Ltd also reported a flexible 4.7″ QVGA AM-OLED on stainless steel, which combines a white OLED and a flexible color filter array on a polyethylene naphthalene sheet [58].

Another interesting application is transparent electronic devices. Toppan proposed an attractive idea that utilizes the transparency of AOS TFTs [59]. In conventional color AM e-papers and displays, a color filter array is formed on the front plane and a TFT array is formed on the back plane. Therefore, the fine alignment of these planes through liquid crystal or E-Ink microcapsules is necessary to avoid color misfit. However, the thickness of a liquid crystal is only 4–6 μm, while that of the E-Ink microcapsules is much larger (40–50 μm), which hinders the horizontal alignment. This problem is critical for flexible displays because bending the display inevitably causes misalignment of the components on the front and back planes. Toppan solved this problem by fabricating a transparent TFT array on a color filter array and integrating them into the front plane. This structure can minimize the optical transmission/reflection loss owing to the transparency of the a-IGZO TFTs.

An important application of this is expected to be in transparent displays. DENSO demonstrated a transparent monocolor passive-matrix inorganic display at FPDI2006. Toppan presented a dual-sided black-and-white display at FPDI2009. Moreover, several companies have developed transparent OLED displays. For example, LGD presented a transparent AM-OLED display having an aperture ratio of ∼30% at FPDI2009 (they claim a ∼65% aperture ratio for passive-matrix OLED), partly because they employed opaque LTPS TFT arrays. Samsung SDI reported a 4.1″ transparent dual-emission QCIF AM-OLED using a-IGZO TFTs [60], but its transparency was only ∼20%. LGE and ETRI have developed 2.5″ QCIF+ transparent OLED displays using ZnO TFT backplanes with a panel transmittance of 60% [20, 21], and they displayed a 1.5″ QQVGA transparent AM-OLED driven by AOS TFTs with a transparency of 45% at IMID2009. Transparent displays became a hot topic at SID2010; Samsung LCD displayed a 46″ transparent LCD driven by a-Si:H TFTs with an integrated touch panel and LGD presented a 47″ window TV at the exhibition. At the SID2010 conference, SMD presented a 14.1″ transparent OLED driven by LTPS TFTs with a transparency of up to 38% [61], and AUO featured a 2.4″ transparent OLED driven by a-IGZO TFTs with an integrated touch panel [62].

One of the main advantages of AOS TFTs is their high carrier mobility. This advantage is exploited in more sophisticated glass-based devices known as ‘system-on-glass (SOG)’ or ‘system-on-panel (SOP)’ devices. In these devices, electronic circuits such as pixel drivers and other peripheral circuits are integrated with TFT arrays on the same glass substrate. SEC first demonstrated a gate driver-integrated 15″ AM-LCD [46]. SEL integrated source and drain drivers in a 4″ QVGA AM-LCD [50] and an AM-OLED [51]. More recently, Sharp reported a source/driver-integrated 12.1″ AM-LCD [53]. Transparent and flexible nonvolatile memories have also been developed by several groups using a-IGZO as active layers [63–65]. These memories are expected to be integrated in AOS-based SOPs.

Large-area fabrication techniques are required for the mass production of FPDs. Although the first AOS TFT was fabricated by pulsed laser deposition, Canon later demonstrated the fabrication of a-IGZO TFTs by radio-frequency (RF) magnetron sputtering [66]. Nowadays, most displays and AOS TFTs are fabricated by RF/dc sputtering. Some companies have attempted to develop large-size sputtering systems. For example, Oregon State University (OSU) and Applied Materials (AMAT) have been collaborating to develop metal-oxide TFTs since 2008 [67], and AKT announced a sputtering system for a 2200×2500 mm2 glass substrate at FPDI2007 (designed mainly for ITO). SEL reported a 3.4″ QHD 326 ppi AM-OLED display based on a-IGZO TFTs and fabricated by a 3.5th-generation (3.5G) process (0.6×0.72 m2; see table table33 for the glass size of different LCD process generations) [68]. AUO uses a 6G sputtering target, which was used to produce the 37″ [3] and 32″ AM-LCDs [48]. More recently, ULVAC Inc. reported the good uniformity of a-IGZO TFTs over a G4 size (0.73×0.92 m2 area) using a multicathode ac sputtering system (figure (figure5(a))5(a)) [69], and they also developed an 8G-size a-IGZO sputtering target (figure (figure5(b)).5(b)). Target manufactures, such as Nippon Mining & Metals Co. Ltd, provide sputtering targets of InGaO3(ZnO)m larger than 2 m in size, which are compatible with the 8G process (figure (figure55(c)).

Facilities targeting mass production of AOS FPDs. (a) Multicathode AC sputtering system, and 8G-size a-IGZO sputtering targets manufactured by (b) ULVAC and (c) Nippon Mining and Metals Co. Ltd.

To minimize the fabrication cost, it is important to reduce the number of photolithography masks. The current a-Si:H LCDs employ 4–5 masks (table (table4).4). One mask step can be eliminated by using a gray mask (also called a half-tone mask) to pattern the source/drain electrodes and the channel in a single masking step. LGD presented a 6.4″ VGA a-IGZO AM-LCD fabricated with a 4-mask process at FPDI2009, and AUO has developed a 5-mask process [71]. SMD presented a 7-mask process (table (table4)4) [2, 72], but it was designed for an AM-OLED with an etch-stopper structure and is essentially similar to a-Si:H processes (table (table11).

A future critical issue is the material of bus-line electrodes. A-Si:H TFTs have used tough metals with high melting points such as Ta, Cr and Mo/Ta. Large, high-resolution and fast-frame-rate panels require higher-conducting electrodes such as Al and Cu. However, Al has poor adhesion to glass and Cu easily diffuses by electromigration as is well known in silicon ultra-large-scale integrated circuit (ULSI) technology. SEC applied Cu-based bus lines to a 15″ AMLCD [46] and AUO applied Ti/Al/Ti electrodes to 37″ AMLCD [3], in which the Ti layers improve the adhesion of the Al layer. In the case of using Cu electrodes, a group from Tohoku University examined a Cu–Mn alloy for a-IGZO TFTs and found that a self-forming MnOx layer acts as a good passivation and diffusion barrier [73]. Toppan also studied Al and Mo bus lines for e-papers because e-papers larger than 10″ will require a thick ITO layer (above 1 μm) [74].

Other future issues are solution processes and printing technologies. These issues are thought to be the largest drawback of AOS TFTs compared with organic TFTs because, in general, oxide materials have high melting points and require high synthesis temperatures. Despite this, solution processes have been intensively studied and improved as summarized in table table5.5. The pioneer of this field is the HP and OSU group, who fabricated amorphous In–Zn–O (a-IZO) TFTs from halide precursors and obtained high mobilities of 16.1 cm2 V-1 s-1 for spin-coated TFTs and 7.4 cm2 V-1 s-1 for printed TFTs, however, these TFTs required a rather high annealing temperature of 400 °C [75]. SAIT has intensively studied solution processes [76] and reported the first solution-processed oxide TFT panels in the form of a 2.2″ QQVGA AM-OLED, a 4″ color QVGA LCD [77] and a single-color 4″ QVGA AM-OLED [78]. Taiwan TFT LCD Association (TTLA)/Inpria Corp./OSU also reported a 4.1″ QVGA AM-LCD [79]. They chose amorphous In–Zn–O (a-IZO) because the solution process becomes rather complex for multicomponent materials such as a-IGZO. Toppan succeeded in fabricating a high-mobility (5.4 cm2 V-1 s-1) AOS TFT at a rather low temperature of 270 °C from a solution supplied by Evonik Industries and also fabricated a 400 ppi VGA e-paper [74]. Lim et al [80] reported solution-processed a-IGZO TFTs and found that their a-IGZO films contained fine microstructures including pores. The development and selection of new precursors and the improvement of microstructure are important current issues in solution-processed AOS TFTs, and the goals are to lower the process temperature and increase the TFT mobility.

The above activities indicate that AOS TFTs can be fabricated using very similar processes to those of present a-Si:H technology, and that the key technology steps, such as large-area sputtering targets and deposition systems, are being rapidly developed for their mass production. AUO announced at FINETECH JAPAN 2010 that they are ready to use a-IGZO TFTs for FPDs, and other companies also imply production of AOS-based FPDs.

An IGZO display is a not a type of a display panel. To be more specific, an IGZO display is any display panel that uses a backplane thin-film transistor or TFT made of indium gallium zinc oxide or IGZO semiconductor material. Hence, IGZO display technology is compatible with different types of display panels such as twisted nematic or TN LCD, in-plane switching or IPS LCD, and organic light emitting diode or OLED display. To understand further what an IGZO display is, it is important to understand its properties or characteristics and thereby, it benefits or advantages, as well as its limitations and disadvantages.

Note that more light passes through an IGZO-based TFT than silicon-based TFTs such as amorphous silicon or aSi-TF because it is naturally transparent and more compact. Nonetheless, the primary advantage of an IGZO display is its natural transparency.

This transparency translates to energy efficiency. To be more specific, compared to an LCD equipped with an aSi-TFT, an LCD based on an IGZO TFT uses less power due to the reduced need for backlighting intensity. In the case of an OLED, an IGZO TFT reduces the brightness output of individual organic diode. Display panels based on arguably consumes less power than an aSi display while still producing brighter images.

An IGZO semiconductor has 30 to 50 times more electron mobility than amorphous silicon, thus allowing a smaller physical footprint without compromising conductivity. This higher electron mobility corresponds to more specific benefits.

For instance, note that the size of transistors affects the size of the pixel. Due to a higher electron mobility, another advantages of IGZO display when compared to an aSi display is higher pixel density within a smaller display real estate. Earlier IGZO display prototypes had crammed 498 pixels per inch within a six-inch footprint.

It is also worth mentioning that backlighting is obstructed in high pixel density LCD based on aSi-TFT. To compensate, these aSi-based displays consume more power for a more intense backlighting. Power consumption requirement increases with an increase in thepixel density of an aSi-TFT LCD. This is not a problem in IGZO-based TFT LCDs.

IGZO has electron mobility that is nearly as high as low-temperature polysilicon or LTPS. However, LTPS has a higher current leakage that results in high power consumption. On the other hand, although aSi has lower current leakage, remember that it also has lower electron mobility than both IGZO and LTPS

The low current leakage and high electron mobility of IGZO give it a more advantageous current flow than aSi and LTPS. This advantage means that the transistors in an IGZO display do not have to be refreshed continuously while displaying a still image because it can retain the active state of its pixels longer due to its advantageous current flow.

On the other hand, displays based on aSi or LTPS need to overwrite still image data through a continuous refresh. Hence, when compared to an IGZO display, an aSi-TFT or LTPS-TFT display consumes 80 to 90 percent more power, particularly when displaying still images such as photographs or documents.

Another benefit of IGZO TFT and thus, another advantage of IGZO display is less noise influence. This characteristic is based on the fact that an IGZO is an intermittent type of semiconductor.

To understand further, note that the drive in an IGZO display does not need to be continuous. This allows touch input to be more sensitive or responsive. Although noise is a consequence of touch-sensitive displays, the noise generated by touching an IGZO display is very brief, thereby resulting in a more accurate detection of even the faintest signal.

An IGZO display with a higher degree of touch sensitivity can pick up thinner and finer lines than non-IGZO displays, notably silicon-based TFT displays. Writing on an IGZO display has a closer feel as writing on a paper, thus mimicking natural handwriting input.

Note that IGZO is a metal oxide. The high reactivity of oxygen increases susceptibility to very low voltage sensitivity, thus resulting in operation disruption and possible internal failures.

Another disadvantage is lower uniformity of electron mobility when compared to aSi and LTPS that may result in differences in product quality across similar products or batch of units. The same low uniformity of electron mobility may result in operation disruptions or inconsistencies of an individual IGZO-based product.

IGZO is made from rare-earth metals indium and gallium. The rarity of these metal introduces risks in costs and procurement that could affect mass production and subsequently, expansive applications and standardization in consumer electronic devices due to supply shortages.

Other manufacturing issues collectively represent another disadvantage of IGZO display. To be specific, the current obstacle to mass-producing IGZO is synthesis. The most common used synthesis method in the industry, the Pulsed Laser Deposition or PLD, requires expensive equipment and a considerable amount of time for each output to adapt to environmental conditions. A possible alternative to PLD is combustion synthesis, but its feasibility and practicality needs more research.

Remember that one of the advantages of IGZO display is a better response time than aSi-TFT and other silicone-based TFT displays. However, transmissive display technologies such as TN LCD and IPS LCD inherently have slow response times when compared to emissive display technologies, thus rendering this advantage almost negligible. An OLED display based on IGZO TFT can still take advantage of this faster response time.

The advantages of IGZO display revolve around its physical properties that enable it to operate under lesser power requirements than its silicone-based counterparts while featuring higher density display regardless of size. These advantages benefit consumer electronic devices such as smartphones and portable computers.

It is also important to reiterate the fact that IGZO is not a type of display panel but rather a type of display technology or manufacturing configuration. This configuration applies to different types of display panels such as TN LCD and TN IPS, as well as OLED or AMOLED displays.

There is also no considerable difference between an LCD or OLED based on aSi-TFT and an LCD or OLED based on IGZO, specifically when it comes to image quality and color reproduction accuracy. However, as discussed above, IGZO-based display panels have considerable advantages such as substantial power saving and smaller physical footprint without compromising pixel density and brightness.

A hybrid between IGZO and LTPS is possible. Apple Inc. demonstrated in its Apple Watch devices that it is possible to combine silicon-based and oxide-based materials with the so-called low-temperature polycrystalline oxide or LTPO display.

The thin-film transistor (TFT) became commercially available slightly more than 30 years ago in the form of a switch for the Liquid Crystal Display. It all started with an amorphous silicon (a-Si) TFT. Compared to the traditional crystalline silicon CMOS transistor, the a-Si TFT can be produced on large substrates and at low processing temperatures, below 300 °C, enabling integration on glass substrates and even flexible substrates.

A-Si TFTs are mainly implemented as simple pixel switches due to their low charge carrier mobility (0.5-1 cm²/Vs). An alternative semiconductor on glass substrates is low-temperature polycrystalline silicon (LTPS), outperforming a-Si TFTs by a 100x larger mobility (50-100 cm²/Vs) and often used for high-end displays and imagers. Despite the advantages, fabrication of an LTPS TFT takes more process steps, is limited in substrate size, and requires a larger process temperature. Oxide-based semiconductors as indium-gallium-zinc-oxide (IGZO) fill this gap between a-Si and LTPS nicely, exhibiting low processing temperatures and a decent charge carrier mobility of 10 up to 40 cm²/Vs [1].

Figure 1: Example cross-section of an IGZO TFT with a dual-gate fabricated on a glass substrate. The top and bottom gates can be connected by vias through the first metal layer (M1). Silicon dioxide (SiO2) is used to insulate the gates from the active IGZO layer, to achieve the field-effect transistor. After fabrication, the glass can be detached from the polyimide layer resulting in a flexible circuit.

With such characteristics, the IGZO TFTs can be used to fabricate relatively complex circuits on flexible substrates. Consequently, IGZO TFTs are evolving beyond displays and entering the fields of wearable devices and the Internet of Things (IoT). Some highlights include an ultra-flexible circuit for recording electrocardiograms [2], radiofrequency identification (RFID) tags and near-field communication (NFC) tags [1]. Even the memory field has noticed IGZO and its extremely low OFF current and recently demonstrated a capacitor-less IGZO-based DRAM cell with a retention time longer than 400 seconds [3]. We can expect the first IGZO products beyond display applications to emerge in the near future.

As with a large majority of products, electrostatic discharge (ESD) protection is an important concern. If we are to see IGZO products enter the fields of IoT or biomedical engineering, they will have to include ESD protection.

Perhaps ESD protection is not a great concern for wireless products, for example, NFC and RFID tags which have no wired input and output ports. Here the sensitive electronic parts will not be exposed to the user as they are electrically insulated. In this case, like for displays [4,5], a good ESD control program might be enough to protect the IGZO components during assembly. The full display will, in any case, include ESD protection circuits at the system level, even perhaps at the peripherals where the electrical connections leave the display, but not necessarily at the IGZO component level. On the other hand, some wearables like the electrocardiogram patch, might not be able to affordsystem-level ESD protection circuits fabricated in a different technology other than IGZO. Since the electrodes have direct contact with the end-user, they may require ESD protection circuits at the device level. The same will be true for displays and imagers if their peripheral circuits are implemented using IGZO – to enable a fully flexible display, for example.

Yes, like any digital or analog circuit, also IGZO TFT circuits are susceptible to ESD. Even though the IGZO TFT technology nominal voltage can be as high as 10 V, degradation and breakdown can be observed already at 20 to 30 V [6]. To avoid damage to performance, the IGZO circuit should never be exposed to voltages higher than 20 V. This means the eventual ESD protection circuits should have a clamping voltage lower than 20V, which is only twice the nominal voltage. These limits depend on the IGZO technology and could change as the technology improves.

There are several challenges when designing IGZO TFT circuits in general, but perhaps the most prominent one is the fact it is a unipolar technology. Unlike the complementary metal-oxide-semiconductor (CMOS) technology integrating two types of transistors, n-type and p-type, the IGZO TFT only provides n-type transistors. Research on p-type oxide-based TFTs to complement the IGZO n-type transistor exists. Unfortunately, the p-type transistors generally have a much lower charge carrier mobility and would make the complementary design less efficient than the unipolar one [1]. Since ESD protection circuits can rarely dictate the technology evolution, ESD protection designs will most likely have to be made with unipolar circuits too.

The second challenge of the IGZO TFT technology for ESD circuit design is that there are usually no diodes available. Even though it is possible to make diodes in the IGZO TFT technology, it also increases the process cost and is not a commodity in this industry. Therefore, the best next choice would be a diode-connected transistor. The technology options to improve the ESD performance of the diode-connected transistor would be to smartly use the back-gate or to optimize the channel material resulting in larger mobility.

Luckily, the negative threshold issue that was observed in the early IGZO TFT technology improved significantly. Therefore, the significant leakage at the zero-volt bias that would be present in IGZO TFT ESD protection circuits can be solved from the technology side.

Figure 3: Drain-to-source current as function of the gate-to-source voltage measured on a dual-gate IGZO transistor shows a positive threshold voltage (top) and leakage currents below the measurement setup noise level (bottom). These data have been measured on a 5 µm by 100 µm TFT with a drain-to-source bias voltage of 50 mV.

Nevertheless, given the limited IGZO TFT conductivity, to achieve a product-worthy ESD protection level, the ESD circuits will have to be in the millimeter or even centimeter size range [5][2]. Given the IGZO TFT technology is optimized for large areas, spending these kinds of areas for ESD protection should not be a showstopper.

Unlike the silicon integrated circuit technology, there is a very limited choice of devices in IGZO, which also limits the possible solutions of ESD protection circuits. Passive devices could help with that. Inductors, capacitors, and resistors could be used as ESD protection or to complement the active devices. A spark gap could be a compact ESD protection option too.

IGZO TFT technology is a good candidate for future wearable and flexible electronic devices. If it is used in a wireless or non-contact way, consumer-side ESD protection should not be a great concern. However, if it will be used as a wearable with electrically exposed pads, it will certainly require ESD protection designs and ESD testing. In this case, the ESD testers might need to be adapted. Take the Human Body Model (HBM) ESD tester, for example. Most HBM ESD testers today target small, packaged devices in millimeter or centimeter sizes. HBM ESD testing of an IGZO TFT product might imply pins to be more than 10 cm apart. That might be challenging indeed, but perhaps some ingenious test fixtures or packaging could overcome this. Bending the flexible wearable device for ESD testing purposes could be an example.

The Transmission Line Pulse (TLP) ESD tester could be an alternative to HBM testing. Since the TLP tester is of a more academic nature than the HBM tester, it could perhaps offer more flexibility in connecting to the large IGZO circuit. Even though the TLP is a 50-Ohm tester while HBM has a typical series resistance of 1500 Ohm, we have observed comparable ESD testing results with both testers [6]. Since there is no universal conversion rule, care needs to be taken when interpreting TLP measurement results as HBM protection values.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey