lcd screen manufacturer free sample

With all the advantages and disadvantages, lcdds are essentially a good choice for those who see the TV starting from 4k smartphone. Nowadays, in addition to the wholesale models, lcdds are essentially a good option for those that don ’ t have the capacity of a device.

A lot of end-users embrace screen customization when purchasing LCD screens for use in their products. This is because a client’s own product often has a unique design, which necessitates the incorporation of a customized LCD screen.

This step involves the end-user providing their requirements, including the required screen size, resolution, brightness, interface, shape size, AA area size, PIN definition, temperature range, service life, and any specific requirements for the touch screen.

End-users need to carefully review these drawings before giving their assent to proceed. This will involve reviewing the outline design drawings, any modified drawings, the mold-making process, layout design, photoresist film making (electrode x2, frame, silver dot, PI, test PCB), and screen-printing screen, relief plate, and the test stand. After the client has approved the drawings, the LCD manufacturer can begin the process of sample production.

LCD screen manufacturers will arrange production after confirming the drawings. The lead time is dependent on several factors, including the difficulty of the design. Under normal circumstances, however, the lead time of the module is about 20 days, and the lead time of the assembly is about 25 days.

LCD manufacturers will ensure the sample undergoes strict tests before anything is shipped to the client. Following the completion of testing and final approval from the client, the LCD manufacturer will begin to prepare for small-batch production.

As you can see, the steps involved in producing a customized LCD screen are not complex. We at Panox Display are able to offer professional advice and guide you through the process from start to finish.

1. First of all, the customer needs to provide the size of the LCD backlight, including its length, width, and thickness. Because the thickness will affect the choice of lamp as well as the lamp board, this measurement must be provided.

2. It is necessary to provide the color of the LED light, because the work will be carried out in a variety of places where there are certain requirements regarding the color of the LED light. The most common colors are white, red, blue, etc. Of course, if the brightness of the LCD backlight has different requirements, it may affect the number of lights, so those special requirements must be explained.

3. A very important parameter is the conductive connection of the LCD backlight, which needs to be provided by the customer regarding the situation of their own products. It’s usually an FPC connection, PCB pin connection, lead connection or pin connection that’s used to conduct. But of course, the most used is a pin connection.

4. Secondly, the customer also needs to provide voltage. The effects of different voltages varies in terms of how bright or dim the light is. In order keep the LCD backlight from burning or having a poor effect, the voltage must be provided.

5. The last parameter is the shape, the most common is the rectangular LCD backlight, but there are some other relatively grotesque shapes. A strangely shaped backlight is difficult to make, and the diaphragm will also be hard to make. So, if the client wants us to make it we need to confirm whether our factory can make this uniquely shaped LCD backlight in advance

A lot of end-users embrace screen customization when purchasing LCD screens for use in their products. This is because a client’s own product often has a unique design, which necessitates the incorporation of a customized LCD screen.

This step involves the end-user providing their requirements, including the required screen size, resolution, brightness, interface, shape size, AA area size, PIN definition, temperature range, service life, and any specific requirements for the touch screen.

End-users need to carefully review these drawings before giving their assent to proceed. This will involve reviewing the outline design drawings, any modified drawings, the mold-making process, layout design, photoresist film making (electrode x2, frame, silver dot, PI, test PCB), and screen-printing screen, relief plate, and the test stand. After the client has approved the drawings, the LCD manufacturer can begin the process of sample production.

LCD screen manufacturers will arrange production after confirming the drawings. The lead time is dependent on several factors, including the difficulty of the design. Under normal circumstances, however, the lead time of the module is about 20 days, and the lead time of the assembly is about 25 days.

LCD manufacturers will ensure the sample undergoes strict tests before anything is shipped to the client. Following the completion of testing and final approval from the client, the LCD manufacturer will begin to prepare for small-batch production.

As you can see, the steps involved in producing a customized LCD screen are not complex. We at Panox Display are able to offer professional advice and guide you through the process from start to finish.

1. First of all, the customer needs to provide the size of the LCD backlight, including its length, width, and thickness. Because the thickness will affect the choice of lamp as well as the lamp board, this measurement must be provided.

2. It is necessary to provide the color of the LED light, because the work will be carried out in a variety of places where there are certain requirements regarding the color of the LED light. The most common colors are white, red, blue, etc. Of course, if the brightness of the LCD backlight has different requirements, it may affect the number of lights, so those special requirements must be explained.

3. A very important parameter is the conductive connection of the LCD backlight, which needs to be provided by the customer regarding the situation of their own products. It’s usually an FPC connection, PCB pin connection, lead connection or pin connection that’s used to conduct. But of course, the most used is a pin connection.

4. Secondly, the customer also needs to provide voltage. The effects of different voltages varies in terms of how bright or dim the light is. In order keep the LCD backlight from burning or having a poor effect, the voltage must be provided.

5. The last parameter is the shape, the most common is the rectangular LCD backlight, but there are some other relatively grotesque shapes. A strangely shaped backlight is difficult to make, and the diaphragm will also be hard to make. So, if the client wants us to make it we need to confirm whether our factory can make this uniquely shaped LCD backlight in advance

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure. Accidental damage is not covered under the standard warranty of the product. Such damage is often the result of a drop or an impact on the LCD screen or any other part of the product which may render the device non-functional. Such types of damage are only covered under an Accidental Damage service offering which is an optional add-on to the basic warranty of the product. Accidental Damage must not be confused with an occasional dead or stuck pixel on the LCD panel. For more information about dead or stuck pixels, see the Dell Display Pixel Guidelines.

The LCD glass on the display is manufactured to rigorous specifications and standards and will not typically crack or break on its own under normal use. In general, cracked, or broken glass is considered accidental damage and is not covered under the standard warranty.

Internal cracks typically occur due to excessive force on the screen. This can be the result of some object hitting the screen, a drop, attempting to close the lid while an object is on the keypad area, or even holding the laptop by its screen.

Spots typically occur due to an external force hitting the screen causing damage to the LCD panel"s backlight assembly. While the top layer did not crack or break, the underlying area was compressed and damaged causing this effect.

If your Dell laptop LCD panel has any accidental damage but the laptop is not covered by the Accidental Damage service offering, contact Dell Technical Support for repair options.

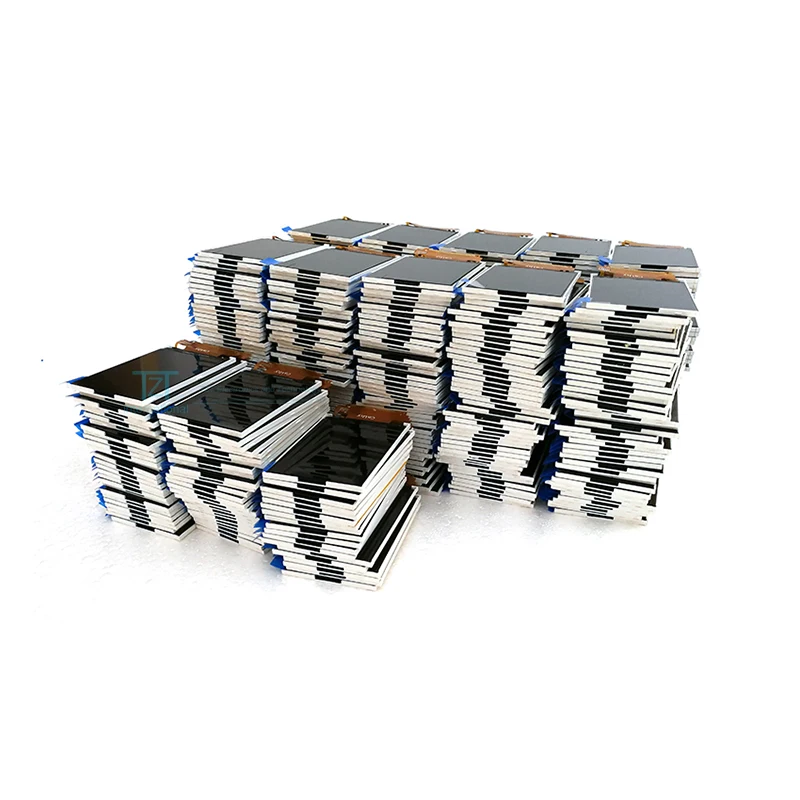

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Dr Pan: Hello, Greg. STN is the abbreviation for Super Twisted Nematic. The main difference between TN, HTN, STN and FSTN LCD is the view angle. From the definition, the maximum view angle of STN LCD is 210~255 degree. Take this STN positive LCD for example. The view angle is 12 o’clock direction and it can be seen very clearly in the full view angle: 12 o’clock direction, 3 o’clock direction, 6 o’clock direction, 9 o’clock direction and the front side.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey