spots on lcd screen supplier

Dark spots or patches may occasionally appear on some liquid crystal display (LCD) panels. This clouding phenomenon is recognized in the industry as YOGORE or "Mura", a Japanese term for "unevenness." This term is used to describe a low-contrast, irregular pattern or region that causes uneven screen uniformity under certain conditions. Mura is a result of the deterioration of the liquid crystal (LC) alignment layer; most commonly caused by long-term operation under high ambient temperatures. It is an industry-wide phenomenon and Mura is not repairable.

Elo Mura specificationsMura-like image retention is not covered by the Elo TouchSystems product warranty.The visual performance of liquid crystal displays (LCDs) has usually been evaluated by visual inspection. One of the visual problems hardest to recognize are regions of low contrast and non-uniform brightness or Mura. The accurate and consistent detection of Mura is extremely difficult as it can appear in various shapes and sizes and the inspection results tend to be subjective and based on opinion. As Mura does not lend itself to quantitative measurement, no specification for Mura is available.KB#000002625

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

LED video wall solution with advanced video wall processing, off-board electronics, front serviceable cabinets and outstanding image quality available in 0.9mm pixel pitch

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

CTL display products are manufactured to rigorous standards. Our display products are consistently recognized as among the highest quality display products in the industry. Nevertheless, due to the nature of LCD technology, an LCD display may exhibit a small number of very small bright or dark spots on the screen. Often, these spots are noticeable only when the screen continuously displays a certain solid color such as an all-white or all black background. This type of background can be present when initially turning a computer on, or when a computer switches the display to a specific screen-saver.

Occasionally, these spots can seem to appear when a user switches to a different desktop background image. In actuality, these spots are pixels or sub-pixels that are stuck always on (viewable as a bright spot on a dark background) or always off (viewable as a dark spot on a light background).

An LCD display is made up of tens of thousands of individual pixels, and each pixel is made up of 3 individual sub-pixels (red, blue and green). In-fact, a 17" LCD has over 1,300,000 pixels and almost 4 million sub-pixels! Each sub-pixel is controlled by an individual transistor which turns the individual sub-pixel that it controls either on or off to create the image on your screen. An anomaly occurring during the manufacturing process can cause an individual transistor to continuously light or fail to light an individual pixel element, causing one of these small spots on the screen. Although this anomaly occurs relatively rarely in individual transistors, there are millions of sub-pixels on each LCD screen, and it is not uncommon for an LCD screen from any manufacturer to contain a few of these transistor anomalies and their associated bright or dark spots. For a manufacturer to sell only LCD""s with no transistor anomalies would result in a prohibitive cost to you, the consumer…one many times higher than it is today. Most people and applications are tolerant of a small number of these transistor anomalies on an LCD screen, and prefer the lower cost of LCD""s that existing standards allow.

CTL sets simple & strict limits as to the allowable number of non-performing pixels or sub-pixels on our LCD display and laptop computer screens. These criteria supplement our existing Warranty and are applicable during the warranty period for all CTL and 2go LCD displays as follows:

The LCD display of products under warranty will be replaced if CTL determines that it has 6 or more bright sub-pixels, 6 or more dark sub-pixels or a combination of 6 or more bright and dark sub pixels.

Please note that it is possible that any replacement display may also have some non-performing pixels or sub-pixels. This should be considered when requesting a warranty exchange.

CTL offers on certain models a No Dead Pixel Warranty. A monitor purchased with this warranty will be replaced in the warranty period if one (1) or more dark or bight pixels are found.

Having black spots on a TV screen can be very confusing and annoying for most TV owners. If you just spotted a black spot on your TV screen, you are probably worried that you’ll need to replace the entire set. But this should not be the case, especially since you spent a handsome figure getting the best TV available.

Perhaps the most common cause of black spots is dirt and debris that have accumulated on the surface of the TV screen over time. If ignored, it will lead to black spots.

Most TV owners would consider sending their TVs back to their manufacturer when they spot a black spot, like sending your best Vizio TV back to Vizio. Unfortunately, this can be time-consuming and expensive, especially if you’ve invested in one of the highest-rated OLED TVs and/or large models like the top 70-inch TV. While most new TVs sold are smart TVs, you can still buy what is referred to now as “dumb TVs”. If you want a TV without apps and an internet connection, this is the TV for you. If that interests you, check out these top-rated dumb TVs. But keep in mind, unlike most new TVs, dumb TVs will usually be smaller like a 24-inch size TV for example. Regardless if the TV is smart or dumb it can develop black spots, however. Fortunately, fixing a black spot is relatively easy. As a result, we have compiled a guide on how to fix a black spot on a TV screen.

Black spots can be a pain, especially if you just bought a wide color gamut TV and are looking to have enjoyable weekends. Regardless of where the black spot is located on your TV screen, it will stand out like a sore thumb. It’ll be the first thing you spot when your TV screen lights up. Black spots on your TV screen are caused by debris, dead pixels, or stuck pixels. This can be especially annoying if you invested in the best anti-glare TV and depend on good visuals for a good TV experience.Dirt or Debris: Perhaps the most common cause of black spots. Dirt and debris accumulate on the surface of the TV screen over time, and if ignored, will lead to black spots. If you have the best outdoor TV, be sure to keep up with maintenance and regularly clean it.

Manufacturer defect: Black spots will appear due to a violation of the assembly. They don’t appear immediately and often lead to damage to the display matrix. Black spots caused by manufacturer defects are usually covered by a warranty.

Stuck Pixel: A stuck pixel is a pixel on the TV display that cannot change color. Display pixels are designed to change color depending on the image projected on display. When the color doesn’t change, it’s called a stuck pixel.

Dead pixel: It’s pretty different from a stuck pixel but often gets confused for one. While a stuck pixel will light up when the TV is turned on but does not change color, a dead pixel doesn’t light up at all. This is because all of their sub-pixels are turned off permanently, and since they don’t light up, they look like black spots on the TV screen. You can read our article on how to fix dead pixels on a TV to learn more about dead pixels.

Fixing black spots on your TV screen is quite simple.First, turn off your television and unplug it from the power source for a few hours. Sometimes, turning off the power on your TV will force the stuck pixel to become unstuck when you finally plug your TV back to the mains.

Next, verify that the black spot issues aren’t caused by any devices plugged into your TV, like a console or cable box. Remove all cables connecting your TV to components, and then plug them back in. Sometimes, loose connections cause distorted images that look like dead pixels.

If a black spot is still visible, contact your manufacturer or repair shop for repair service. Depending on the time and nature of the black spot, The TV manufacturer might cover the repair under warranty. You can also try the clouding LED TV fix, which solves the black spot problem that is common among new TVs but often disappears as time goes by.

Regardless of where the black spot is located on your TV screen, it will stand out like a sore thumb. It’ll be the first thing you spot when your TV screen lights up.

While a stuck pixel will light up when the TV is turned on but does not change color, a dead pixel doesn’t light up at all. This is because all of their sub-pixels are turned off permanently, and since they don’t light up, they look like black spots on the TV screen.

Perhaps the most common cause of black spots is dirt and debris that have accumulated on the surface of the TV screen over time. If ignored, it will lead to black spots.

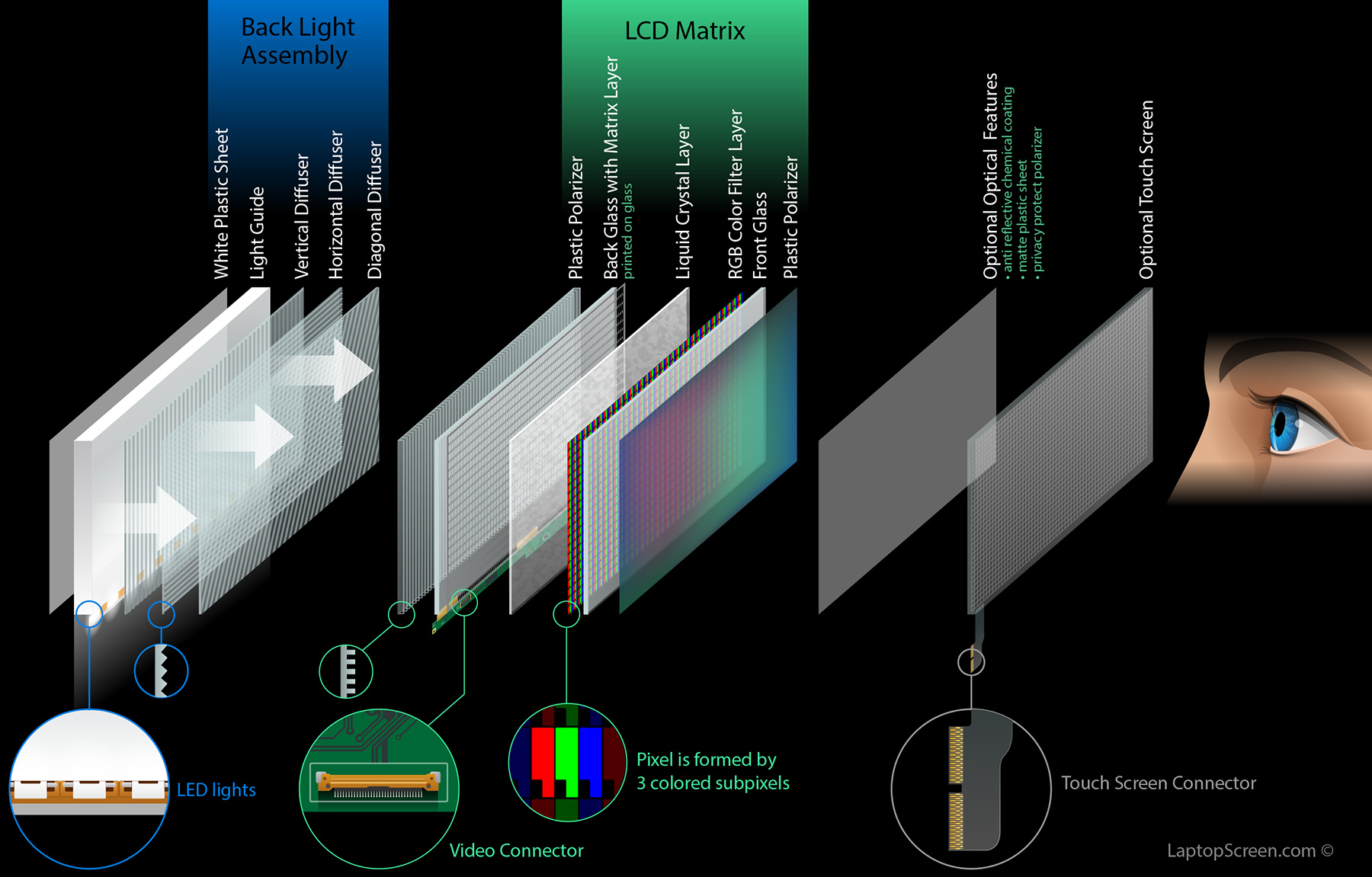

Choosing a backlight system for LCD screen displays is a major consideration. It will determine a lot about your experience of the display and requirements during production. Different backlight options provide widely different effects in the contrast and brightness of the display. Also, depending on which backlight option you choose, it will affect some or all of the following: the cost of the overall product; how many products you will have to order due to manufacturing constraints; and how environmentally friendly the component parts are that make up the product.

The word LCD has been used to describe many display technologies. Often people believe that LCD screen displays are the same as a CRT (Cathode Ray Tube), an LED Display (Light Emitting Diode) or a Plasma display. This is not the case! Let’s discuss what an LCD is and what it is not.

Think of the liquid crystal display (LCD) as a window blind. Positioned in one direction the blinds allow light to pass through, or turned another direction they block the light. Just like a window blind, the LCD does not create its own light, it only blocks or allows it to pass through.

As you know, you can adjust the blinds to alter the amount of light desired. When fully closed, the blinds block light completely; when open, all light passes through; and when angled, partial light comes in. An LCD works similarly to this, with one significant enhancement: an LCD has the ability to block light in some areas and allow light to pass in other locations of the glass. An example of this is the display used on a gas pump. The customer sees numbers where the light is blocked, and a clear area where the light is allowed to pass through.

LCD’s are not CRT’s, LED’s, nor are they Plasma displays. Each of these types of displays produces their own light and are called emissive displays. Emissive displays require more power than an LCD.

Emissive displays have a distinct advantage in that they can be seen clearly at night whereas LCD’s cannot. However, the solution to this problem of low-light visibility is to install a backlight behind the LCD. Backlights do require more power than the LCD itself, but they can be turned on only when necessary. Many products that are powered by batteries will have the backlight dim or shut off after a certain amount of time. This can be seen on cell phones and watches. Consequently, even though a little more power is used for the backlight than used in a stand-alone LCD, because it is not constantly on, the LCD’s with backlights wind up using less power than their emissive display competitors. LCD screen displays using backlights become the clear choice.

This option is the most popular for products that have a lower power budget. Products that run on battery need to conserve power and the lowest powered backlight available is to have no backlight at all.

The Amazon Kindle is a perfect example. The Kindle makes use of a display technology called ‘e-paper’, which looks more like a printed page than any other device on the market currently. This specific e-book reader does not contain a backlight. Because it omits the backlight it can operate up to one month without recharging. Imagine, you could take it on a cruise to Fiji and back and never have to worry about recharging it!

Thinking back to your product, not all products can omit a backlight; in fact it may require one. If it does need a backlight the most popular option is an LED.

A light emitting Diode (LED) is a semiconductor that produces light when current is passed through the device. Light is created from the energy conversion that takes place in the LED die. The advantages of an LED are:LED lights are much more rugged and can handle shock much better than other types of lights.

The majority of the LED backlight colors will operate with a half-life of 50K to 70K hours. (Remember, half-life is when the light will be half as bright as when it was first turned on. This is not when the LED will burn out.) Blue and white LED’s do have a shorter half-life than other colors. Presently, they are rated at 30K hours. That means that if you turned them on today and left them on, in 3.4 years they would be half as bright as they are today! One thing to take into account is that as technology improves, the lifetime of the LED’s will become longer, which will also increase the half-life. Below is a photo of a blue LED backlight.

To make LED’s display correctly, they are placed behind the LCD screen display in an array pattern. The challenge is that LED’s, similar to a light bulb, project a beam of light which can show spots of light. These spots are called hot spots. This can be an issue with LED’s since they will make the display look like it has polka dots. Below is a photo of a LED behind the LCD glass. This problem will be solved with the use of a diffuser.

A diffuser is like a lamp shade and is placed between the glass and the LED’s. The goal is to disperse the light or make it more even. Below is a photo of a diffuser. At the bottom of the diffuser you will see the LED’s. This is where you can see hot spots. But as the light travels further into the diffuser, the light becomes more even. The diffuser solves the issue with hot spots and makes LED’s a very attractive option.

EL (Electro Luminescent) backlights, also known as ELP’s (Electroluminescence Panel), have been used as a backlight for LCD’s for several years. They are available in a range of colors with white being the most popular. EL technology makes use of colored phosphors to generate light. They require AC (alternating current) rating of 100VAC @ 400Hz.

In the last three to four years, EL backlights have decreased in popularity. There are several reasons for this drop in popularity.The EL backlight requires an inverter to convert DC to AC. The cost of the inverter increases the cost of the overall LCD Display.

The half-life of an EL is an estimated 3,000 to 5,000 hours. (Once again, half-life is when the backlight is half as bright as when it was first turned on.)

LCD screen display manufacturers now require an MOQ (Minimum Order Quantity) of no less than 500 displays for orders that include EL backlights. This MOQ number is likely to increase in the future as this type of backlight becomes less popular. Additionally, as the demand drops the price will naturally increase.

A Cold Cathode Fluorescent Lamp (CCFL) is similar to the long fluorescent light bulbs you see in the ceilings of offices. Below are photos of various types.

This technology has been in use for many years, but in the last few years the popularity of this type of backlight has decreased. There are a few reasons why this is so.Similar to EL backlights, this technology operates on AC.

The majority of LCD screen display manufacturers no longer offer CCFL as an option. There are too many negatives and not enough positives to their use. The suppliers that do offer this now require a very high MOQ (Minimum Order Quantity).

When choosing the type of backlight for your LCD screen displays it is important to keep in mind MOQ’s and future availability. Make sure you are choosing a technology with a future so that your product has one too!

A few days back I had opened up my iMac to replace the HDD with an SSD and while reassembling the iMac, I booted up the system only with the LCD in place without putting on the glass panel to make sure that the issue was not being caused by any dust stuck between the glass panel and the LCD but the spots were still there on the LCD display. So, the issue exists within the LCD panel itself. Also, I noticed some part of the black tape stuck on the backside of the LCD had yielded from the top (circled in red in the picture below).

As the insides of the iMac were extremely dirty with literally layers of black dirt as visible in the picture above, could this have caused dust to get inside the LCD panel causing the dark spots or is something else causing this problem?

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I recently got the Olympus OMD EM10 MII and while I was trying to take some pics last night, I saw two very tiny white spots on the LCD screen of the camera when I faced the night sky. When I took few pics, the spots didn"t show up on my photos (I did not look the photos in my computer but on my LCD screen). But, when I try to view on the LCD, the two tiny spots are still there. I was wondering if this is common and can be fixed or is the camera faulty and I need to return it? If it can be fixed, can someone please guide me. Appreciate the help!

Your suppliers for iPhone LCD screens are everywhere to be found within the USA and Asia. Broken iPhone repair locations ultimately make their decision based on two main factors: price versus quality.

Supplier Advertising: Many LCD suppliers will use catchy phrases and advertising to relate the quality of their parts. These tactics are used to avoid the use of “OEM” or “Original,” instead replacing these with words such as “AAA Quality” or “Grade A+.” More importantly, the suppliers would be violating Apple’s trademark and patent laws by advertising LCDs in this manner.

Fruitless Up-Sell: Suppliers will often attempt to upsell New Original OEM LCD screens by a few bucks to buyers who took the advertising bait. In most cases, you’ll receive the same quality LCD screen that was a bit cheaper. Most buyers won’t catch onto this.

There are many ways to tell fake iPhone LCD screens from original OEM without having to put each one under a microscope or taking up too much of your time. Many identification methods are out-dated and the factories that manufacture the fake iPhone LCDs are always coming up with new methods to mask known visual inspection methods.

You can identify fake iPhone screens easily with a few simple techniques that will cover 98% of product, no matter how much a supplier tries to replicate the real thing.

Resolution Quality – Cell phone LCD screen resolutions are being manufactured with higher resolutions in a rapid way. Cutting corners on resolution quality is the number one way for factories to reduce costs. Being that most new models have retina or HD quality DPI, you should be able to easily identify a fake iPhone screen from the original. Make sure you have a known, real, original LCD to compare with and download a high resolution photo for testing comparison.

Flex Cable Markings: The second most common way to identify a fake iPhone LCD is through markings on the digitizer and LCD flex cables. The main one I look at is just the digitizer flex because it wouldn’t make sense for anyone to manufacture a fake LCD with an original digitizer. That would be like putting V8 engine in a VW Beetle. Additionally, Apple does work with customs officials in various countries to size fake poor quality refurbish screens. It’s a way that custom agents can spot fake iPhone parts without Apple having to provide a field manual that’s difficult to enforce.

The chart above can be used for iPod, iPad and iPhone 2G, 3G, 3GS, 4 and 4s LCD screens. I haven’t confirmed this for the iPhone 5 yet, but I will update this article shortly with my findings.

You’ll know you have a fake iPhone LCD (or at best poor quality refurbished original) if the upside-down triangle is missing from the IC chip. One would think the copy factories would enjoy reducing their cost by removing a chunk of raw material on this cover, but they don’t. I would assume it’s more costly to cut out the triangle design on the cover than to save the material cost.

Ask your suppliers directly if the product is “Genuine, original Apple digitizer and flex cable.” If their response still leaves questions, ask them to add a guarantee on your invoice. I’ve never had an LCD supplier willing to write that on an invoice no matter what wording tactics they use.

Return defective and misrepresented product. RMAs to China or the USA can be easy to neglect. Ensuring that your supplier knows you’re going to return items will better your chances that they screen your product more closely before shipping next time.

The truth is: not so many fake iPhone LCD screens are on the market these days. There are so many broken LCD screens being reclaimed that it costs less to refurbish a used cracked iPhone screen than it does to manufacture a new fake iPhone screen. No matter what the LCD model, the trends to spot fake iPhone parts tends to stay the same. LCD screens are becoming larger and smarter, and it shows in the more expensive parts costs for models such as the iPhone 5, Note II, etc. Neglecting to keep your suppliers product in check is a recipe for being taken advantage of and wasting money. By knowing how to spot fake parts, it will ensure you’re staying competitive in the cell phone repair business.

Hi. It´s very good instruction. I could repair my multimeter YF-3503 Yufong. Thank U a lot of. My problem was exactly like in this video, Images of then.

Great fix - I was just about to bin my meter when I googled this. Followed the instructions, used UHU glue instead of a glue gun, now the display is perfect - many thanks! Pity I didn"t take a before pic but there was a big black oval covering most of the screen.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey