spots on lcd screen factory

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Any TV with a liquid crystal coating, even the most expensive and proven as a reliable technology, may be malfunctioning or quickly deteriorate if used improperly. In this article, we will try to figure it out and find out what needs to be done if a dark spot appears on the LCD TV screen.

Such “blots” and dots are often first slightly visible and invisible, and then grow and interfere with viewing TV shows, distorting or closing the panel. In this section, we will try to understand the causes of the malfunction.

Often a dark spot formed on the liquid crystal coating indicates a malfunction of the most important part - the matrix. Basically, these are factory defects.

The defect appeared at the factory itself. If you purchased an LCD device and found a dark growing spot on it, immediately bring the device back to the store, provided that the warranty has not expired.

The appearance of a dark unpleasant spot on the plasma TV screen indicates a problem with the blocks themselves, the image being edited. Most likely, these blocks have already worn out. Also, in rare cases, the device manufacturers themselves are to blame.

Important! During operation, scratches can form on any item, and the TV screen is no exception. In our separate review, we described in detail howremove screen scratches.

Such “blots” often appear on such a model; the most common cause is the shedding of the phosphor deposited on the inside of the monitor. It also provides viewing of TV channels.

This defect occurs as a result of shock, pressure, falling of the picture tube or its wear. Here only the replacement of the tube itself can help, but it costs a lot of money. It happens that it is impossible to change it. Only buying a new TV will help.

Important! Remember that if the warranty for the equipment has not yet been issued and may still be valid for some time, then immediately contact a service center in your city and hand over the equipment according to the warranty sheet.

If the warranty is over, try to write a letter with claims to the manufacturers. In extremely rare cases, in order not to lose their reputation, factories can replace faulty equipment.

Important! For the future: for the warranty period and the manufacturer’s obligations to work for sure, buy the equipment of reputable companies. These are mainly brands such as SAMSUNG, LG, SONY, PHILIPS.

Important! Some owners of Smart TV have problems connecting the Internet to the TV. Our site of useful tips will help you solve this problem, read the special post “How to connect the Internet to Smart TV?”

It also happens that for no reason color stripes and “blots” appear on the monitor, which terribly distort the image. Such a story only happens with old picture tubes.

When you witness the appearance of such spots on the TV screen, do not rush to run to the store, take the equipment or write angry letters to the manufacturers, because such a problem is very simple to fix yourself.

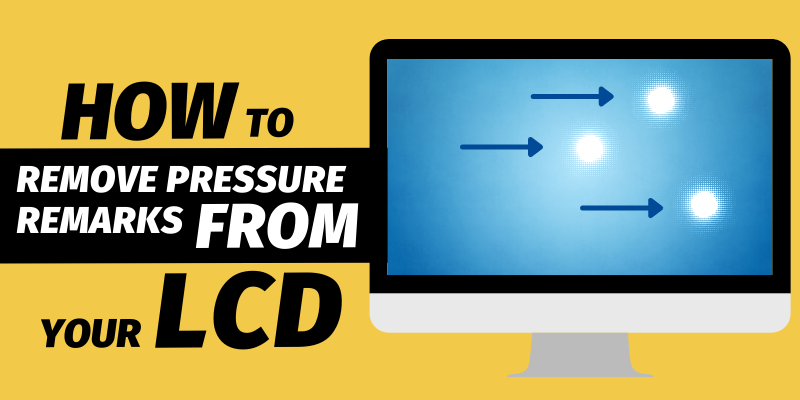

So, we figured out the reasons, but what to do to make the strange glow disappear? It’s not necessary to call the master to the house, the whole problem can be eliminated independently:

The most popular and easiest way is to unplug the appliance for several hours and turn it on again. If the problem persists, try again. For prevention, this procedure can be carried out once a month.

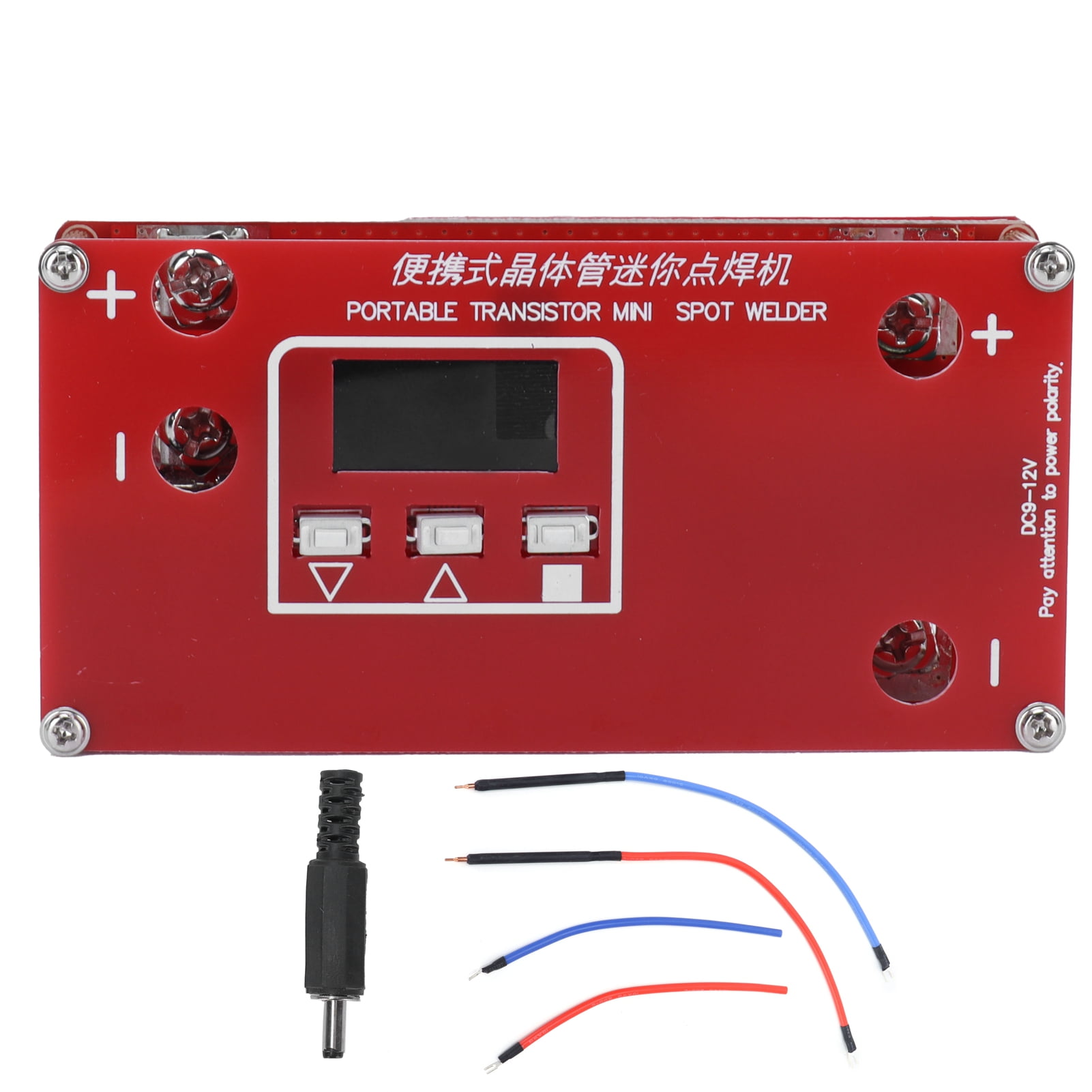

If the method presented above did not work, most likely your posistor burned out. In this case, you need to replace the thermistor with a working one, but this is not an easy task. We recommend involving a master in this, so as not to break through your technique.

In the proposed article, we figured out the causes and methods of eliminating various spots on TV screens of any shape and size. Remember that even a well-proven technique requires special vigilance.

With an LCD TV you can watch your favorite movies, cartoons, and series in excellent quality with high definition and good sound. However, owners of LCD monitors may encounter the problem of dark spots appearing on the screen. Let’s take a closer look at the reasons for their appearance and what are the best solutions to repair them.

So What Causes Dark Spots on TV Screen?Dark (black) spots on LCD TVs are typically caused by either debris or superficial dirt, a dead pixel, or a stuck pixel. Of all these problems, the easiest problem to fix is debris or superficial dirt. On the contrary, stuck pixels are harder to fix, while dead pixels are the hardest problem to fix.

It is very often, that dark spots appear on LCD TV screens, including popular brands such as Samsung, Sony, LG, and others. They can be localized in one corner, centered, or in several places at once.

Spots do not disappear when switching channels. Even when your TV is off, you can notice that glare is visible in their place. Moreover, blackouts can be not only black or dark gray but also white or colored. This most likely indicates the color errors or other problems.

Manufacturing defects. It is quite rare and manifests itself immediately. The reason is a violation of the assembly technology, leading to damage to the display matrix. The specialists of the warranty service center should eliminate such a malfunction free of charge. And in order not to buy a bad TV, you need to carefully examine the equipment in the store.

Mechanical damage. An especially common reason is when there are children in the house playing with a ball in the apartment. A strong blow or pressure will stain the CRT. Broken pixels first appear in the affected area, then spread across the screen.

Ingress of moisture or air under the protective glass. The reason is poor transportation or improper care. Do not wipe the monitor with water or a heavily dampened cloth.

The effect of high temperature. The presence of a heat source near the device leads to various malfunctions, including the appearance of yellow spots due to the delamination of the matrix.

Dust getting under the case. If you take care of household appliances incorrectly, one small black dot can develop into a large dark spot, which only the masters of the SC (service center) can remove.

Before trying to disassemble an LCD TV or hand it over to a service center, it is worth excluding software failures that are possible with digital broadcasting. The test scheme for Samsung, Sony, and LG are common. There may be some nuances depending on the TV model.

If the black spots on your LCD TV screen disappear, the cause was most likely a software failure. In such a situation, it is not necessary to disassemble or repair the device in the service. If the malfunction remains, it is better to contact a professional to repair an expensive modern TV.

One of the reasons for the appearance of spots in the external adhesion of dirt, dust. In such a situation, it is not necessary to disassemble the equipment or reboot it. It is enough to wash the screen surface. For this:

If a defect appears due to water ingress, rinse the matrix. This requires a special detergent. Running water is not suitable. It contains a large number of invisible impurities, abrasive particles that will settle on the matrix and make the situation even worse.

Cleaning should be done in a well-ventilated area with good ventilation to remove dark spots from the TV matrix. It is advisable to turn on a humidifier, if available. Use soft cotton gloves to clean.

If you wish, you can carry out the replacement yourself if you have the skills to work with household television appliances. The repair instructions are as follows:

Important! If the TV is still under warranty, you do not need to disassemble it yourself. After any of your interventions, the warranty card will expire. And the repairs will be carried out for you free of charge or with a big discount and at the service center.

Rarely wiping the surface from dirt and dust leads to the ingress of microparticles on the matrix. Over time, a large dark spot is born from a small black dot. With the following actions you can save your TV from manifestations:

If the dark spots have not disappeared after all the manipulations, the Sony, Samsung, or any other manufacturer’sTV must be carried to the workshop for a full diagnosis and repair.

If a dark (black) spot appears due to moisture or dust, you can easily fix this problem by yourself. If on the other hand streaks appeared due to mechanical stress or strong exposure to high temperatures, which in most cases led to matrix delamination or failure of loops, then it is necessary to carry that equipment to the workshop.

In most cases it takes from 1 to 5 working days to repair and remove dark spots on a TV screen, depending on the workload of the wizard and the availability of parts in the service. The cost of repairs depends on the degree of damage and the price of spare parts.

Proper care of household appliances is the key to their correct operation for a long time. To avoid the appearance of dark spots, streaks on the screen of a plasma, liquid crystal TV, follow these recommendations:

Do not overheat the equipment. TVs can work around the clock, but this has a bad effect on their performance, color rendition, and image playback speed.

Taking care of your LCD or plasma TV in this way will save you from the appearance of dark spots on the screen. Try to avoid mechanical damage. Explain to the children that technology is not a toy. And enjoy digital TV for years on end.

Light, colored spots and streaks are removed by other methods. General repair method only in cases with software failure. Therefore, if any screen defects appear, just try to completely restart the equipment and reset the router to factory settings.

With the development of LCD screen manufacturing technology, although the display effect of the LCD screen has been greatly improved, the phenomenon of dead pixels and bright spots on the LCD screen is still difficult to avoid. So when we buy industrial LCD screens, LCD monitors, etc. in the end how to check the LCD screen is there any dead pixels? The following Xiao Bian will like you briefly introduce some methods to detect the LCD screen dead pixels.

1 After purchasing the LCD, make sure to check whether the LCD is dead before receiving the goods. Can use special test discs for testing, such as "AVIA", "HiviCast", "DigitalVideoEssentials", etc., are available for sale in general audio and video stores.

2 Full-screen displays pure black, pure white or pure red, pure green, and pure blue monochromatic backgrounds. Carefully check whether black, white, and different colored light spots appear under solid monochromatic color. If yes, the liquid crystals are Bad point.

The common problem with the dead pixels is that the colors are not controlled, and only solid colors such as black and white are displayed, and images cannot be formed in accordance with the appearance of dark changes.

Highlights: Highlights are also a kind of dead pixels, which means that only one or two drive tubes in the three liquid crystal cells of the corresponding pixel have failed, then they will appear in red, green, and blue in a black background. Pixels; or points that originally should be red, green, and blue, appear white, and these can be judged as bright spots and also as a kind of dead pixels.

General bad point: A pixel that appears as a pure black or pure white on any color background is a dead pixel. This may be due to a failure of the three liquid crystal cell drive tubes of the corresponding pixels.

I got this strange ‘dust problem’ on my Mac. In December 2009 my dream came true and I purchased new lovely Apple iMac 27”, 2.66, i5. One day I have noticed dark grey smudges on both sides of the screen (left and right). I actually didn"t notice any spots until I changed the background to pure white (or any other solid color really). At first, I thought it was fingerprint smudges or something. I cleaned the entire screen and it still remains.

I contacted with Apple service and they said iMac is very sensitive to dust. They call it ‘interlaminar dust’in matrix. As time passes, dust accumulates inside the machine and irreversibly penetrates the LCD itself, causing the dark stains. They blamed environment in my room! My Mac is placed on a normal work desk with lots of space around it and not more dust then in a normal house. Not that I am surprised that iMac is very sensitive to dust but I am so woefully disappointed.

Most people believe it was a factory defect on the LCDs. The only trouble they say is how to convince Apple Service to make a replacement of LCD under Apple repair program. They say if you pushy enough might get lucky and Apple might fix it for you.

You have discovered a black spot on your laptop screen, and you are not alone! Finding a black mark on your LCD can be disheartening, but there are steps you can take to get rid of it. So, if you are here to know how to fix black spots on a laptop, do not skip any part of this article and read until the end.

The black spots are just surface blemishes that appear when dirt or other particles lie on the glass of your screen or due to some defects with the LCD pixels. They are not cracks or tears that may cause the display to fail in the near future, and it’s certainly not an indication of broken glass. Although these can easily be fixed, it is crucial to have a proper understanding of what causes the spots so you can take measures to prevent them from appearing again in the future.

A laptop or LCD monitor’s screen is like a mirror, and it reflects the light from your computer’s display back at you. Black spots on display occur when small amounts of dirt and dust or smudges gather and are stuck to the surface.

Sometimes, dirt or debris may accumulate on your laptop screen, which leads to black spots that become visible to the naked eye and grow larger over time and can cause problems with screen resolution if left untreated.

These spots are typically easy to remove without damaging the monitor. However, failing to clean the dirt or debris on a regular basis, more of them will appear and gradually obscure more of your laptop’s screen, making the rest of the screen appear duller by comparison.

Though such black marks will not reduce the quality of the display of your LCD screen and cause any damage to the internal circuit of the monitor, they are very annoying.

The easy solution to get rid of these spots is to clean your screen with a moderately dampened microfiber cloth or soft eraser. Make sure you do not apply pressure while rubbing the display; instead, wipe it with gentle and circular strokes to avoid scratches and leftover marks.

Different types of pixel defects happen on LCD screens, including dead pixels and stuck pixels. Identifying the problem correctly will help you to choose the right methods to fix it that will not result in damaging the screen any further.

Most laptops have some pixel problems in them. The number of defective pixels you see depends on the screen resolution – the smaller the resolution, the larger they seem. In most cases, they are not noticeable during regular use as they are not bright spots, and if your laptop is free from pixel issues when you buy it, consider yourself lucky.

LCD manufacturing technology has improved dramatically over the years, and today’s panels almost don’t come with any such problem. However, as earlier as a few years back, there were times when defective pixels or vertical/horizontal lines would be let out into the market for lower-cost models.

When a pixel gets permanently damaged, it fails to receive power, resulting in a dark or black spot on your laptop display. This specific malfunction can occur during the manufacturing process of LCD monitors, and it is sort of permanent, which does not recover over time.

However, one can rarely experience such defects on their laptop screens out of the box since manufacturers strive to follow stringent quality control processes to make sure they deliver a flawless product. On the other hand, it’s quite normal to notice dead pixels appearing on the screen over time, depending on multiple usage factors.

Unlike dead pixels, stuck pixels are able to be powered on, which leads to a permanently colored pixel. They can be any of these three colors – red, blue, or green. While dead pixels are pretty much a permanent condition, a stuck pixel might just go away on its own.

Every modern laptop comes with a built-in LCD diagnostic mode that can successfully identify any pixel malfunction on your laptop’s screen. Follow the step-by-step method as below –

Now, turn the laptop on while pressing and holding the D key at the same time, and you will be taken to the self-test mode. Do not release the D key until the color bars appear on the LCD.

The monitor should display multiple color bars that constantly change from one color to another, which you want to inspect carefully in order to find out any distortion or irregular pixels.

On the contrary, stuck pixels are not dead and can receive power like other normal pixels; however, they get stuck on a single color always (hence, the name), which is either red, blue, or green.

However, it’s tricky to differentiate between dead and stuck pixels by naked eyes; therefore, you may want to look for other ways. If you are using a Windows laptop, install a free software named “InjuredPixels” – you can Google for its official website and download from there. Or if it’s a Mac, “LCD DeadPixel Test” is a browser-based tool (so nothing to download or install) that can help.

Spotting any defective pixel is relatively easy using these apps. They run single solid colors on your display so that you can quickly find out the malfunctioning pixel that doesn’t match the color of the rest of the screen real estate. You can further ensure whether it is a dead or stuck pixel before you attempt to fix it.

The common causes of an LCD monitor having a bad pixel are the following: extremely high or low temperature, a sudden drop in voltage, high levels of humidity, and static display over an extended period.

Keeping your laptop unprotected close to a heating source can force the pixels on the LCD to get solidified. Even lower temperatures below the allowed limit can lead to the same result.

Read the user manual for the ideal range of humidity levels within which you should operate your laptop. Keeping your LCD screen powered on in a high level of humidity may cause tiny droplets of moisture to enter the inside exposed areas of your display, resulting in a pixel malfunction.

Alternatively, you can let the laptop be turned off for about an hour and then turn it on. Repeat the process a few times and check for any changes in the pixels. This simple method is especially beneficial in case the stuck pixel shows when running a specific program and not other times.

In contrast, a black spot due to dead pixels is a more complex problem and hard to fix. You can find the few expert-recommended methods with comparatively higher success rates below.

If you find that your LCD panel display has dead pixels, there are a few things you can try. One of the simplest things to try is rubbing it gently, particularly if the dead pixel is on the edge of your screen where it is barely noticeable.

Before you try this technique, your LCD panel must be clean and free of dust and debris. Simply wiping with a soft cloth should remove most dirt and smudges. Also, using an object with a circular end, such as a smartphone stylus, and placing a soft microfiber cloth over the problem spot during the process will greatly reduce the risk of causing more harm to the screen.

JScreenFix is a website that can help you with your dead or stuck pixel issues. No expensive equipment or software is required as using the site is 100% free. All you need is just your laptop and an internet connection, and you are good to go. Below is a step-by-step guide that will walk you through the steps to solve the problem!

Once you have it on your laptop – open it up, move the red box to the area where you marked the dead pixel, set the timer, and click the “Start Flashing” button.

You would be in luck if your laptop was still under warranty period when you noticed the pixel defect. Take the unit to the official service center or the retailer you purchased it from and ask about the warranty claim process. In the majority of cases, any such pixel damages are considered manufacturing defects, and the company will simply replace the LCD.

No, both are different conditions. While dead pixels mean literally dead or not able to be activated or powered on and hence display no color, a stuck pixel does turn on and sticks to a single color instead of constantly shifting to red, green, and blue as required like a healthy and working pixel.

It depends. If you are experiencing a stuck pixel problem on your screen, it will likely recover by itself after a while in the majority of cases, without any user input. On the other hand, a dead pixel is more or less a permanent condition.

For stuck pixels, you have little to worry about as they usually disappear over time. However, dead pixels are mostly not user repairable. With that’s being said, JScreenFix and PixelHealer are two incredibly effective software solutions that you can use to restore your stuck and dead pixels – experts found their success rates pretty high.

Before you start looking for how to fix black spots on a laptop, it’s crucial to figure out exactly what caused the condition. Typically the issues people face are minor, and the black spots on their screens are a result of dust and dirt accumulation, which can be fixed with a simple cleaning.

However, sometimes it might be a symptom of a larger problem, including dead and stuck pixels that may require professional help. Unless you know what you are doing, we recommend you take your laptop to an authorized repair shop or claim a replacement from the brand if it’s still under the warranty period.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure. Accidental damage is not covered under the standard warranty of the product. Such damage is often the result of a drop or an impact on the LCD screen or any other part of the product which may render the device non-functional. Such types of damage are only covered under an Accidental Damage service offering which is an optional add-on to the basic warranty of the product. Accidental Damage must not be confused with an occasional dead or stuck pixel on the LCD panel. For more information about dead or stuck pixels, see the Dell Display Pixel Guidelines.

No, accidental damage is covered for Dell computers or monitors which are covered under the Accidental Damage Service offering for that specific product.

For more information about Dell Limited Hardware Warranty and Dell"s Accidental Damage service offering, see the Dell Warranty & Support Services page.

NOTE: Other damages may be considered customer induced if determined by Dell Technical Support, an on-site field engineer, or at the mail-in repair center.

The LCD glass on the display is manufactured to rigorous specifications and standards and will not typically crack or break on its own under normal use. In general, cracked, or broken glass is considered accidental damage and is not covered under the standard warranty.

Internal cracks typically occur due to excessive force on the screen. This can be the result of some object hitting the screen, a drop, attempting to close the lid while an object is on the keypad area, or even holding the laptop by its screen.

Spots typically occur due to an external force hitting the screen causing damage to the LCD panel"s backlight assembly. While the top layer did not crack or break, the underlying area was compressed and damaged causing this effect.

If your Dell laptop LCD panel has any accidental damage but the laptop is not covered by the Accidental Damage service offering, contact Dell Technical Support for repair options.

Dell monitors cannot be repaired by an on-site field engineer or at the mail-in repair center. If you notice any damage to the monitor, you must purchase a new monitor.

Laptop users can strive to make the most of their laptops to maximize stability, longevity, and usability. Understanding and implementing a few best practices for the safe handling of their laptop will enable them to enjoy their laptop for many years to come. For more information, see the Dell knowledge base article Dell Laptop Best Practices for Care, Use, and Handling.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

Next, a photoresist is applied to the glass on which ITO film is deposited, and a uniform photoresist layer is formed on the ITO glass. After baking for a period of time, the solvent of the photoresist was partially volatilized to increase the adhesion of the photoresist material to the ITO glass.

Ultraviolet light (UV) is used to illuminate the surface of the photoresist through a pre-made electrode pattern mask, which causes the photoresist layer to react. The photoresist is selectively exposed under ultraviolet light by covering the photoresist on the glass coated with the photoresist.

The exposed part of the photoresist is then washed away with the developer, leaving only the unexposed part, and the dissolved photoresist is then washed away with deionized water.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

Stripping: High concentration of alkali solution (NaOH solution) is used as a stripping solution to peel off the remaining photoresist on the glass so that ITO glass can form ITO graphics exactly consistent with the photolithography mask.

Rinse the basic label of glass with an organic solution and remove the photolithographic tape after reaction to keep the glass clean. This completes the first thin-film conductive crystal process, which generally requires at least five identical processes to form a complex and sophisticated pattern of electrodes on the glass.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Then, the organic polymer directional material is coated on the surface of the glass, that is, a uniform directional layer is applied to the appropriate position of ITO glass by the method of selective coating. Meanwhile, the directional layer is cured.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

A polarizer is an optical plate that allows only light from a certain direction to pass through. It is an optical element that converts natural light into straight polarized light. The mechanism of action is to make the vertical direction light pass through the straight incident light after passing through the vertical polarizer, and the other horizontal direction light is absorbed, or use reflection and scattering and other effects to make its shade.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

If the screen flickers, make sure the display settings in Windows match the native resolution and refresh rate for the display. Find the native resolution of a flat panel display on the box, in the specifications, or in the printed material that came with the display. Some common native resolutions are 800 x 600, 1024 x 768, 1920 x 1200, and 1680 x 1050. The most common refresh rate for LCD displays is 60 Hz. This normally cannot be changed for flat panel displays using Plug and Play settings. However, if you are using special video software to increase or decrease the refresh rate, change the refresh rate to match the default refresh rate specification of the display.

If your screen flickers in Windows 10, it is usually caused by incompatible apps or display drivers. To find out whether an app or driver is causing the problem, check to see if Task Manager flickers. Then, based on that information, you"ll need to either uninstall the app or update the display driver.

If you cannot select the native resolution after updating the video drivers, the graphics adapter in the computer might not support that resolution and might need to be upgraded.

Check the video cable connections. Unplug the cable and inspect the cable for damage. If the cable is damaged, replace it with a new cable. Try to use cables less than 3 meters (10 feet).

Check the environment around the display. Displays are sensitive to magnetic fields. Speakers, florescent lights, fans, cell phones, radios, and any other electrical device can cause flickering. Temporarily move electrical items away from the display to see if they is producing a field that causes the flicker.

To see if the video coming from the computer is causing the problem, temporarily connect the display to another computer, such as a notebook computer.

If the flicker is gone when the display is connected to another computer, the graphics adapter hardware on the first computer might need to be upgraded to use the display.

To find the app that causes issues, uninstall recently downloaded apps one by one. After you remove the app that causes the problem, you can reinstall the other apps you removed.

Slowly drag your finger to the bottom right corner without lifting. Try to move your finger slowly enough that you can count to 10 before reaching the opposite corner of the screen.

IMPORTANT: A factory data reset will remove all data from your phone. While any data stored in your Google Account will be restored, all apps and their associated data will be uninstalled. Before you perform a factory data reset, we recommend backing up your phone.

Tip: Airplane mode is automatically turned on when you enter safe mode. We recommend turning airplane mode off in order to continue using features such as GPS, Wi-Fi, and making phone calls.

Tip: Airplane mode is automatically turned on when you enter safe mode. We recommend turning airplane mode off in order to continue using features such as GPS, Wi-Fi, and making phone calls.

Slowly drag your finger to the bottom right corner without lifting. Try to move your finger slowly enough that you can count to 10 before reaching the opposite corner of the screen.

Under your Pixel 5 phone’s screen, at the top center, you can see a white dot. This white dot is your proximity sensor. When your proximity sensor is on, the dot shows through the display. The dot can blink or stay solid.

Your proximity sensor keeps your phone’s screen off while you hold your phone near your face during a call, when your screen is locked, and when used by certain apps. Keeping the screen off helps save battery and avoid accidental taps on the screen.

All Pixel phones have proximity sensors. Because the Pixel 5’s display goes almost to the edge, you can see the Pixel 5’s sensor under the screen. Check our Pixel 5 phone diagram.

IMPORTANT: A factory data reset will remove all data from your phone. While any data stored in your Google Account will be restored, all apps and their associated data will be uninstalled. Before you perform a factory data reset, we recommend backing up your phone.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey