stm32f429 tft lcd schematic quotation

Ahh yeah look at that! If you look closely, top right of the LCD, that’s obviously a flex connector for a resistive touch overlay (4 contacts running to the 4 sides of the LCD overlay).

A fair number of inexpensive baseboards/motherboards/accessories have also appeared for earlier versions. I hope Olimex puts out a couple nice STM32F429/427 boards.

I can see there is only a STLINK usb connector on board, so there is even no FS to expect. beside HS, I suppose does mean High Speed (480mbps). but HS anyway needs a separate physical layer USB chip for addition to STM32F4 chip and most likely this is chip is not present on this board anyway, because this is STM32F4+LCD+SDRAM demoboard and there is no need for USB at all.

I think Farnell’s 21€ will be accurate, as ST’s suggested USD price is $24. The placeholders for the STM32F429I-DISCO on element14 (a division of Farnell) and mouser show $42, which I think predates the later ST announcement. I think the ST announced $24 will hold, and the distributor prices will match that, as they have in the past.

I wouldn’t expect TI to hack profits from their calculator range, and HP have always been expensive, but ST could easily change their format to calculator-friendly. Clamshell design, LCD & battery in top half, CPU & keypad in bottom half, expansion pins to left / right of keypad makes a self contained unit.

HP Palm – Love the idea, hate the baguette (french bread loaf) layout. If I could get custom key covers, and surface-mount key switches, I’d be designing my own low-profile keypad to go with an LCD module. Top side keypad, bottom side CPU / RAM / USB / LCD driver / power regulation / expansion port.

Great find, thanks! Man, could they have buried the details on that guy any farther down into the document? I can’t help but feel like a quick pointer in the LCD section to “oh by the way there’s a touch screen, here’s how to talk to it” would have been a good idea.

It’s certainly useable in any other project where you have an onboard LCD controller. Especially any other project that happens to use a STM32F4. What difference would it have made if it had an external controller? Surely it’d have been on the same PCB. Were you hoping for a removeable SPI-interfaced module?

Look in the UM1670 user manual, paragraph 4.8: the tft includes an ILI9341 controller. The ILI9341 has it’s own graphics ram inside, it is not mapped into the STM32 address space. It is connected to the STM32 via a parallel bus. The ILI9341 and similar controllers are common on cheap chinese tfts. So it is no problem to source similar tfts for your final product after developing on the discovery board.

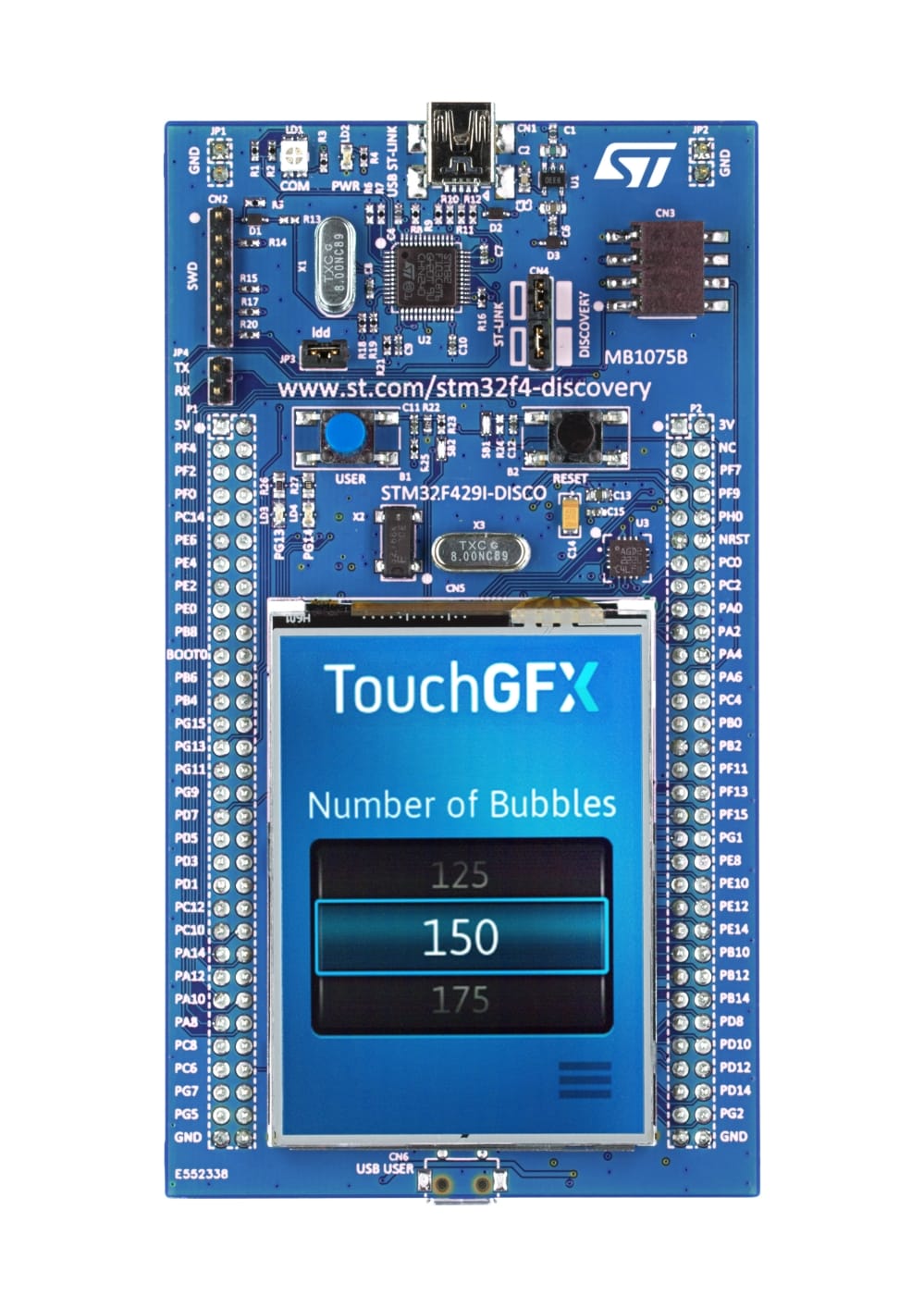

UM1670 in paragraph 4.8 also says that “The TFT LCD is a 2.41″ display of 262 K colors. Its definition is QVGA (240 x 320 dots) and is directly driven by the STM32F429ZIT6 using the RGB protocol”. ILI9341 has multiple modes of operation including direct RGB/HSYNC/VSYNC mode which bypasses internal GRAM. I don’t have the board yet but I assume display buffer is located in external SDRAM which is also on the board. The whole point of this kit is to show TFT and SDRAM interface in new STM32F4x9.

I’ve checked this discovery board firmware available from ST’s site (“STM32F429 discovery firmware package UM1662” number: STSW-STM32138, btw. finding it is a bit difficult – ST’s site is terrible):

Check again martin. Those lines have pullups to vdd and are connected to cpu pins. I have this board for some time and I can confirm that lcd is driven by lcd controller from cpu and frame buffer is in external dram which is also on the board.

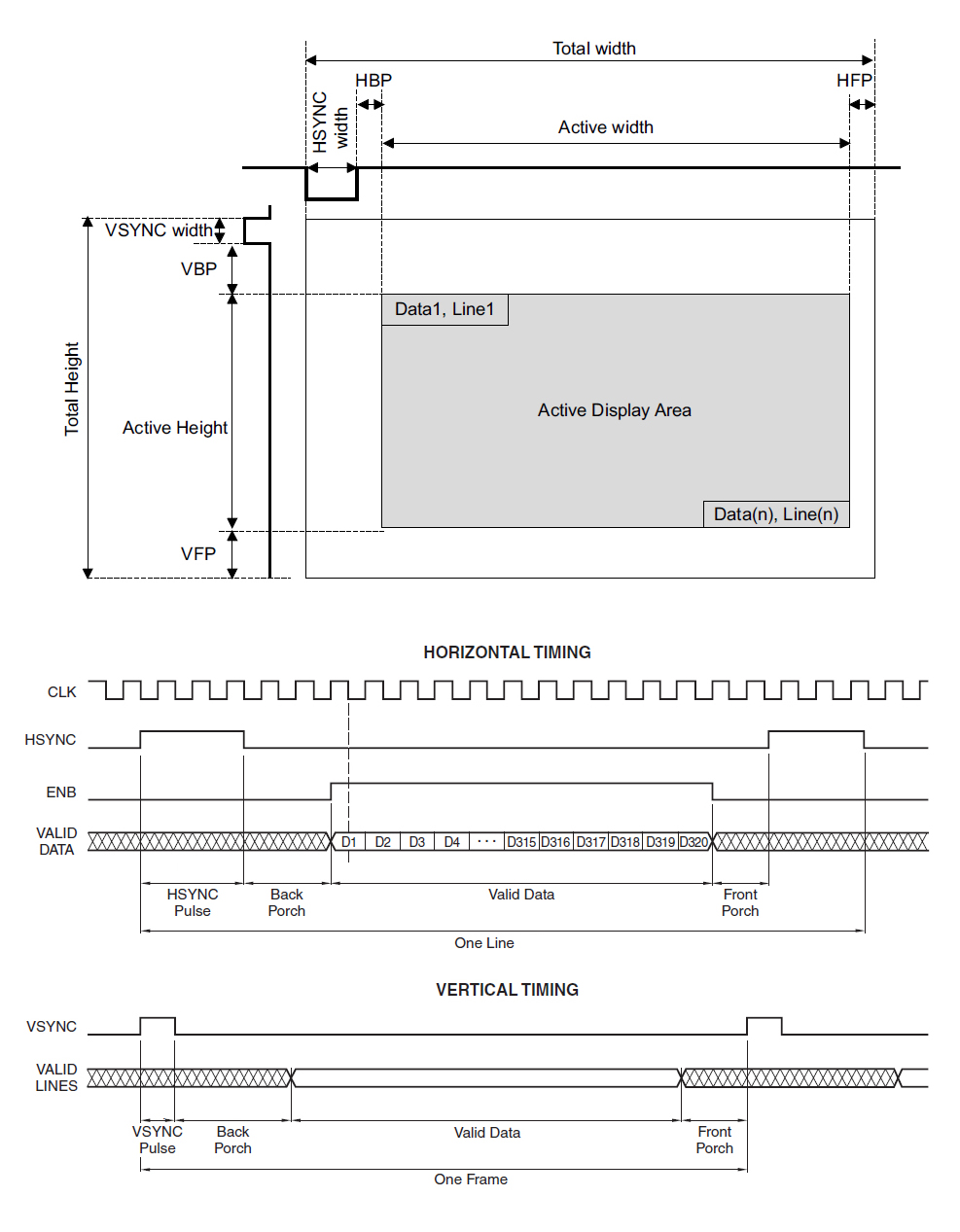

The STM32 LTDC has a peripheral called LTDC LCD TFT Display Controllerwhichprovides a digital parallel interface(DPI) for a variety of LCD and TFT panels. It sends RGB data in parallel to the display and generates signals for horizontal and vertical synchronization (HSYNC, VSYNC), as well as pixel clock (PCLK) and not data enable (DE) signals:

In this example I use the display on the STM32F429-Discovery board, which is driven by the ILI9341 display controller. The ILI9341 can drive a QVGA (Quarter VGA) 240×320 262,144 colors LCD display. The controller can be configured via SPI (or parallel interface, depending on the panel settings) to use a digital parallel 18 bit RGB interface (since only 6 lines per color channel are wired on the board to the LTDC). Since the display pixel format is less than 8 bit per channel (RGB666 in this case), the RGB display data lines are connected to the most significant bits of the LTDC controller RGB data lines:

Before enabling the LTDC we must configure the clock system. The LTDC uses a specific clock LCD_CLOCK to generate the pixel clock signal and it must be configured and enabled during the system initialization phase:

To display an image we must convert an image file to an array (possibly a const one, so it can be stored in flash memory) of bytes. To do this I used LCD image converter, a simple but powerful application that can convert a file to a variety of different pixel formats:

In this example the framebuffers have a RGB888 color depth and for a 240×320 display that makes 225 KiB of memory for each buffer (3 bytes per pixel x 240 x 320 pixels) so they must be stored in external SRAM (the STM32F429I-DISCOVERY has a 64Mbit external SRAM so we’re good). The FMC Flexible Memory Controller has to be initialized and the address of the two frame buffers has to be configured. Drawing on the framebuffer is a matter of writing the right bytes in order to change the color. Once all pixels are drawn (bytes are written) the buffers are switched and the code can draw the next frame:

All the cellphone LCDs that I’ve seen have a default refresh rate of approximately 60 frames per second (fps) so I decided on a target of 30 fps for the main engine. This means that I can spend 1/60s preparing the next frame in a frame buffer and then the next 1/60s sending it to the LCD.

The LCD retrieves data from its internal memory from top to bottom, left to right. If we happen to be updating an area of the screen at the same time as the LCD is retrieving data from it to push to the panel then we’ll see an ugly effect called tearing where the image on the display consists partly of the previous and next frames.

Luckily the LCD provides a signal that they often call ‘Tearing Effect’ (TE). TE goes active during a part of the display known as the ‘vertical blanking period’ which is a few lines at the top and bottom of the panel that you can’t see.

The timing here is a critical part of the design. The LCD controller must offer a write speed that allows a complete frame to be written in less time than the display refresh rate and our graphics accelerator must be able to write data out at that speed.

Of course we also need an LCD to display the actual image and I’m going to choose the highest resolution device that I can possibly get away with given the space and time constraints imposed by the other resources.

Just like in my previous project, the halogen reflow oven, I’ve selected the 640×360 LCD from the Sony Vivaz U5 cellphone. You can read all about my initial reverse engineering effort for this display in this article.

This is a small part with a critical task. If I’m going to squeeze my design into the limit of 63 FPGA user IOs then I need to take steps to reduce the pin count wherever I can. The 8-bit latch will be used to reduce the pins required by the LCD data bus from 16 to 9 (1 extra pin is required for the ALE signal).

Of those 100 pins, 63 are available for user IO. That might seem like a lot but once you start adding up the SRAM address and data buses, the MCU interface and the LCD bus it doesn’t look so generous after all. You’ll see how I squeeze it all in as you read the rest of this article.

The MCU is going to be the STM32F429VIT6. It’s a 180MHz 32-bit ARM Cortex M4 MCU from ST Microelectronics that comes with 2Mb of flash memory, 256Kb of SRAM and a hardware FPU capable of single-cycle add and multiply operations on single-precision floating point numbers.

The SRAM IC that I chose is the ISSI IS61LV5128AL 4Mb device arranged in a 512Kb x 8-bit layout with an access time of 10ns (100MHz). The LCD pixels are 16-bits wide so I’ll need to do two SRAM accesses to read or write a full pixel but I’ll save 8 pins from my FPGA budget.

4 megabits is enough to hold 262,144 pixels. My LCD has 640×360 = 230,400 pixels so there’s 31,744 to spare. I don’t have a use case for those extra bits so they’re just going to be left unused in this design.

The 10ns access time means that I’ll have no trouble doing a full pixel write in the same time frame that a 16-bit pixel is read out from the flash IC. Conversely, I’ll be able to read out a full pixel in the same time period that it takes to write out a pixel to the LCD. FPGAs are designed to do multiple tasks concurrently with nanosecond precision so everything should line up nicely.

There are no fewer than five different levels on this board, six if you count the output from the LCD backlight boost converter. A 5V external power supply feeds the LDO regulators that supply power to the rest of the system. Nearly all the components are powered off an AMS1117 3.3V regulator except, predictably, the FPGA. It requires 2.5V and 1.2V for its auxiliary and internal operations in addition to the 3.3V level that we use for all the IOs. The last level is the 2.8V required for the LCD panel supply.

When running in sprite mode with the LCD backlight at 90% the system will draw nearly 400mA down the 5V line. For this reason I chose 3.3V, 2.5V and 1.2V regulators that have a big margin in the amount of current that they can supply. I didn’t want to be left with an iffy power supply at the end of the day. The 2.5V and 1.2V regulators are both from the Taiwan Semiconductor TS1117 family and the 2.8V regulator is the ZXCL280H5TA by Diodes Inc.

All of the selected components must work together within the timing constraints imposed by how fast we can get data out of the flash IC, into the SRAM frame buffer and subsequently to drive into the LCD. Here’s a diagram that shows a high level overview of the timing from the point of view of the game developer.

During the second frame the FPGA takes the data in the frame buffer and writes it out to the LCD as a complete frame. During this period it is safe for the MCU to upload the new state of the world to the FPGA. In fact it’s safe to do so as soon as the busy signal goes low.

I’m planning to provide two operating modes for the FPGA. In passthrough mode the FPGA will send data that it receives from the MCU directly through to the LCD bus. This allows the MCU to directly drive the embedded Renesas R61523 controller in the LCD at a decent speed but not as fast as if it were directly connected. This mode is used to initialise the LCD controller, display introduction and high score screens and to send the command sequence that prepares it for entering sprite mode.

The limiting factor that governs how many sprites I can display is the LCD frame timing. The rendering of the sprites into the frame buffer by the FPGA must finish within one frame, or 16.2ms. Let’s see how that timing budget can be spent.

Now that I know the parts I’m going to use I’m going to create the schematic that links them all together. Click on the thumbnail to view a full-size PDF of this design.

The LCD signals include the 8 bit data bus, the latch control line (LE) and the RS and WR lines. Going the other direction is the vital TE signal that will allow us to synchronise to the LCD frame output.

All of the control signals are connected to the FPGA except LCD_RES which is the reset signal. This one is connected to the MCU. There’s no need for us to bother the FPGA with the burden of the LCD reset sequence, this is best performed by the MCU.

The backlight for this LCD consists of six white LEDS in series so we need a boost converter to generate the high voltage required to overcome the combined voltage drop of each LED.

The cool thing is that we don’t even need to supply a PWM signal to the EN pin to control the backlight brightness because the LCD has a function to do that for us. All we need to do is tell the R61523 controller the duty cycle that we’d like to use and it’ll do the rest. That saves us a pin and a timer resource on the MCU.

What we do is write out the first 8 bits of data, lock the latch and then write out the second 8 bits. As you can see from the schematic this will result in all 16-bits being driven. What’s really helpful is that the FPGA design can be coded to output any bit to any pin so I can tailor the design so that the data bus can be laid out in parallel on the PCB without any vias.

The Rohm 32 Kbit IC has a simple 2-wire I2C interface. Nothing much to say here, it’s hooked up to the I2C peripheral on the MCU. I2C is a bi-directional single-wire bus that provides protection against being accidentally driven by multiple drivers by operating in open-drain mode. That means that the bus (and clock) must have pull-up resistors somewhere. I provide those 4.7kΩ pull-ups close to the MCU as you can see in the MCU schematic.

I envisage that the graphics data will be much larger than I could program into the core of the MCU so some sort of external interface is required. SD cards are the most convenient way to do that and the MCU has a built-in SDIO peripheral that will allow me to access the card in the high-speed 4-bit mode. SDIO is another bus that requires pull-ups on its data and command lines, presumably because it’s also running in open-drain mode. I provide these 10kΩ resistors in the MCU schematic screenshot.

The first component to go down was the LCD connector because it must physically sit in a specific place so that the LCD can be mounted on to the board in a position that allows the other connectors to be placed around it. The LCD connector is actually on the bottom of the board which, when sitting on my desk is facing upwards.

Putting it all together required a bit of forward planning. I wanted to reflow the majority of the components using my halogen reflow oven but the problem was that the 34 pin, 0.4mm pitch LCD connector on the other side would also need reflow.

In the end it wasn’t so hard. I zoned off the area underneath the LCD connector that thankfully only housed a few small ICs for the backlight driver and reflowed the entire remainder of the component side in my reflow oven. For the second stage I turned the board over and reflowed just the LCD connector on my hot plate by holding the PCB with just the aforementioned zoned off area over the plate.

And the back side, which will actually be the topmost side when in use shown here before the LCD is attached. The array of decoupling capacitors that belong to the FPGA are clearly visible.

And the top side again, now with the LCD and 10mm standoffs in place. The LCD itself is held down and lifted clear of the PCB and the exposed capacitors with a set of double-sided sticky pads. The debug cable is shown in place, just missing that capacitor by a few millimetres (phew!).

If you review the schematic you’ll see that the flash IC is only connected to the FPGA and not the MCU therefore I needed to create an FPGA design for programming it. A simple approach would have been to configure the FPGA to just pass through all signals from the MCU to the flash. The FPGA would function as little more than a buffer and all the logic would be in the MCU.

The actual commands that I’ve implemented allow the MCU to write raw data to the LCD in passthrough mode, put the FPGA into sprite mode and execute commands to load, move hide and show sprites. You can see the documentation for the commands here on github.

In the initial design I explained how I was going to use even frames to write data from the SRAM to the LCD and odd frames to load up the SRAM from the flash. frame_counter monitors the LCD TE signal and each time it spots a rising edge it flips the bit that indicates odd or even frames.

lcd_sender is a utility component that outputs a 16-bit value to the LCD data bus, taking care of the interaction with the latch and the correct timing for the LCD WR strobe. I call it from mcu_interface when the design is in passthrough mode and I need to write out a value from the MCU to the LCD. It takes exactly 70ns to execute and has a ‘busy’ output signal and a ‘go’ input signal to allow synchronisation with its operation.

frame_writer is the component responsible for doing all the work during the even frames when the FPGA is in sprite mode. It reads the rendered frame from SRAM and writes it out to the LCD. It operates a pipeline, reading out a pixel from SRAM and writing the previously read pixel to the LCD simultaneously during a core 70ns loop. There are 640×360 = 230,400 pixels on the display which means that this whole operation takes exactly 16.128ms. The LCD is reading from its internal GRAM and writing to the physical display at a rate of one every 16.2ms so we come in just within the required timing.

frame_writer does impose a few small requirements on the MCU before sprite mode is engaged. The display window must have been set to the full screen, the write mode must have been set to auto-reset to the start of the display window and the last LCD command to have been sent must be the ‘write data’ command. With this prep done by the MCU the FPGA can just let rip with the continual flow of graphics data. My AseAccessMode class takes care of all this.

My decision to support passthrough and sprite modes means that there are potentially two different parts of the design that want to write data to the LCD bus. mcu_interface will write data via the lcd_sender class in passthrough mode and frame_writer will want to write data when we’re in sprite mode.

The first sample application is a test that ensures we can use the LCD in passthrough mode. To do this I’ll use the stm32plus graphics library to display some test colours. The stm32plus graphics subsystem is built using a tiered approach that separates the responsibility for the high-level drawing algorithms from the LCD driver which is itself separate from the method used to access the driver.

Up until now I’ve provided access modes that work either by using the STM32’s FSMC peripheral or by using GPIO pins to drive the LCD. To make this custom board work with all the existing stm32plus infrastructure all I had to do was write an access mode class that handles the work of writing to the 10-bit bus that I designed. I called it AseAccessMode where Ase stands for Andy’s Sprite Engine.

I’ve designed passthrough mode to require just two transfers to send either a complete 16-bit data or command value to the LCD or to ‘escape’ into sprite mode.

The first transfer sends either the first 8 bits of the 16-bit LCD data value or, if the high bit is set it will immediately escape into sprite mode and the second transfer never happens.

You can see the source code to the passthrough test here on github. I must say I was very pleased when this test worked because it was the first time that I’d seen the LCD fire up and display data whilst under the control of the FPGA, even though that control is heavily martialled by the MCU in this passthrough mode.

The STM32F429 turned out to be just the overkill that I thought it would be and it’s the most expensive part on this board. My guess is that the sweet spot would be the new 84MHz F401 device that retains the important SDIO peripheral and FPU core while running plenty fast enough to execute game logic and costing half the price of the F429.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

LTDC interface setting are configured in CubeMx. In the program lcd data buffer is created with some values and it"s starting address is mapped to the LTDC frame buffer start address.

At this moment display doesn"t react to data sent by the LTDC. It only shows white and black strips, after i connect ground and power for digital circuit to the 3 volts source. VLED+ is connected to the 9 volts source. The VSYNC, HSYNC and CLOCK signals are generated by the LTDC and they match with specified values. I measured them on LCD strip, so the connection should be right. I also tried putting pulse on the LCD reset pin, but that doesn"t make any sense.

Maybe signal polarity is wrong or i am missing something else. The program i am using now, worked on stm32f429-discovery build in LCD i just changed the timings. Any suggestions?

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey