lcd module 16x2 configuration manufacturer

Both LCD 16x2 functions provide, and that constitute a larger disturutions for the components. While the 16x2 difference is in terms of the size of the screen,

This allows you to find some of the cheapest lcd display, cheap lcd modules, and even more per piece. Check out Alibaba.com ’ s wholesale prices to find the cheapest lcd display, cheap lcd modules, and more at wholesale prices.

When looking for lcd 16x2 for sale, it ’ s easy to bulk wholesale, browse other suppliers on Alibaba.com to discover a wide range of wholesale LCDs and 16x2 wholesale prices. For other customers, you will find an option to bulk browse at Alibaba.com.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

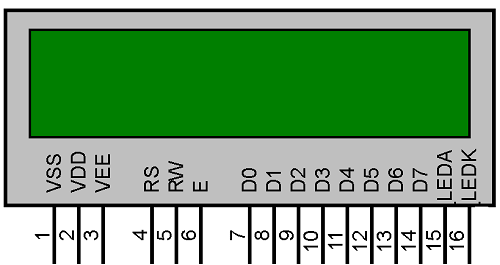

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

Grove - 16 x 2 LCD is a perfect I2C LCD display for Arduino and Raspberry Pi with high contrast and easy deployment. 16x2 means two lines and each line has 16 columns, 32 characters in total. With the help of Grove I2C connector, only 2 signal pins and 2 power pins are needed. You don"t even need to care about how to connect these pins. Just plug it into the I2C interface on Seeeduino or Arduino/Raspberry Pi+baseshield via the Grove cable. There won"t be complicated wiring, soldering, worrying about burning the LCD caused by the wrong current limiting resistor.

The Grove - LCD RGB Backlight has been well received since its inception. Based on customer feedback, now, we bring more cost-effective monochrome backlight derivative for you.

Except for RGB backlights, these three products are almost identical to the the Grove - LCD RGB Backlight, they are all 16 characters wide, 2 rows with high brightness backlight.

An introduction of What is a Grove - 16 x 2 LCD and How does it work is strongly recommended reading ahead if you are not familiar with it. Please visit our

The platforms mentioned above as supported is/are an indication of the module"s software or theoritical compatibility. We only provide software library or code examples for Arduino platform in most cases. It is not possible to provide software library / demo code for all possible MCU platforms. Hence, users have to write their own software library.

The first version of Grove - 16 x 2 LCD series does not have a built-in pull-up resistor, nor does it provide a pad to solder the optional pull-up resistor. We have redesigned the module, and the new version has built-in pull-up resistors.

The Grove - 16 x 2 LCD shares the same library with the Grove-LCD RGB Backlight. Their usage is almost the same, except that the Grove - 16 x 2 LCD does not support the RGB color API, such as setRGB().

2). Open it in your computer by click the HelloWorld.ino which you can find in the folder XXXX\Arduino\libraries\Grove_LCD_RGB_Backlight-master\examples\HelloWorld, XXXX is the location you installed the Arduino IDE.

Since the Grove - 16 x 2 LCD series are all monochrome backlight, you need to comment out the RGB color related code. In the demo code above, i.e., line 6 and line 17.

Step 2. Make sure that the ArduPy firmware contains the Grove - 16 x 2 LCD ArduPy library using the following commands. For more information, please follow here.

Step 4. Save the ArduPy-LCD1602.py in a location that you know. Run the following command and replace

Range tests made easy with the RE-Mote and LCD:Reduce the number of equipment and preparations required for field testing (2.4GHz and 868MHz), pack everything you need in your hand.

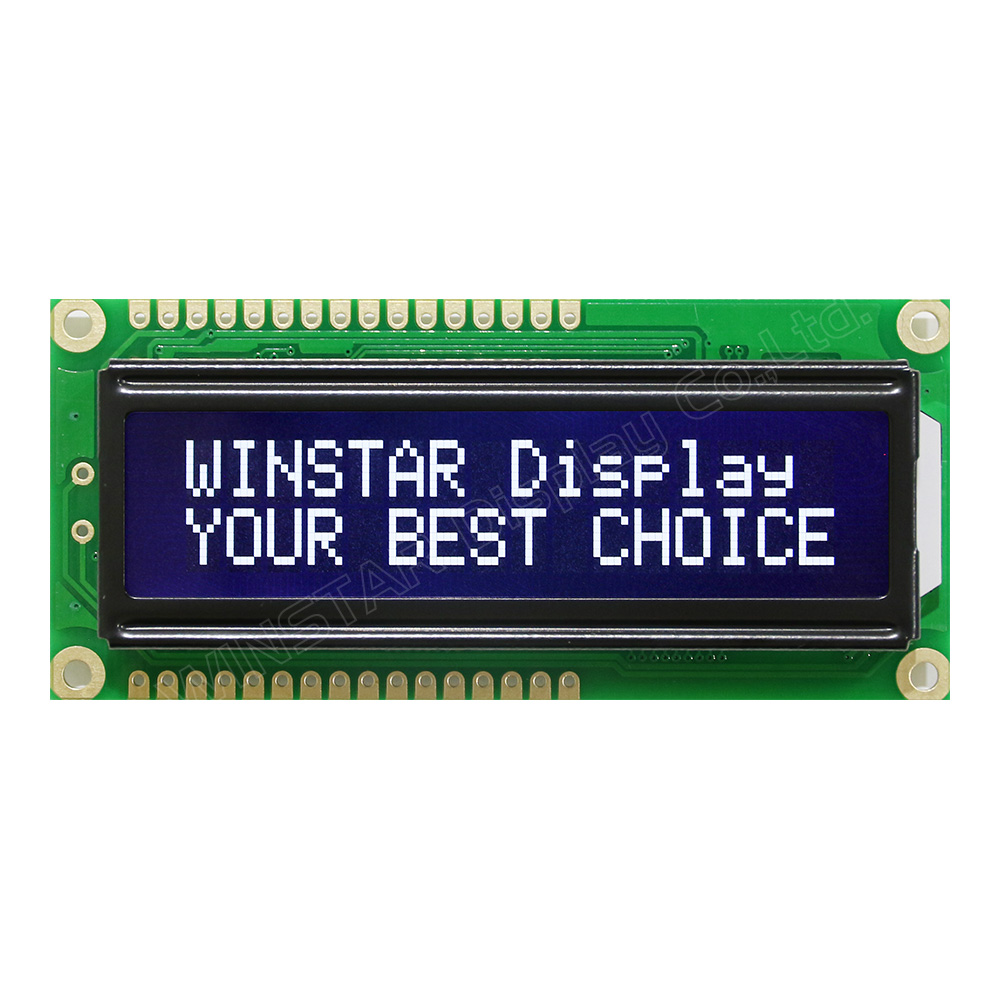

Winstar 16x2 Character LCD Display WH1602W is having two pinout interfaces on upper and bottom sides of the LCD module. This 16x2 lcd display has the outline size of 80.0 x 36.0 mm and VA size of 66.0 x 16.0 mm and the maximum thickness is 13.2 mm. WH1602W 16x2 LCD Displays are built-in controller ST7066 or equivalent. It is optional for + 5.0 V or + 3.0 V power supply. The LEDs can be driven by pin 1, pin 2, or pin 15 pin 16 or A/K. This type of module can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃.

The 16x2 Alphanumeric LCD Display Module is equally popular among hobbyists and professionals for its affordable price and easy to use nature. As the name suggests the 16x2 Alphanumeric LCD can show 16 Columns and 2 Rows therefore a total of (16x2) 32 characters can be displayed. Each character can either be an alphabet or number or even a custom character. This particular LCD gas a green backlight, you can also get a Blue Backlight LCD to make your projects stand our and visually appealing, apart from the backlight color both the LCD have the same specifications hence they can share the same circuit and code. If your projects require more characters to be displayed you can check the 20x4 Graphical LCD which has 20 Columns and 4 Rows and hence can display up to 80 characters.

The 16x2 LCD pinout diagram is shown below. As you can see the module has (from right) two power pins Vss and Vcc to power the LCD. Typically Vss should be connected to ground and Vcc to 5V, but the LCD can also operate from voltage between 4.7V to 5.3V. Next, we have the control pins namely Contrast (VEE), Register Select (RS), Read/Write (R/W) and Enable (E). The Contrast pin is used to set the contrast (visibility) of the characters, normally it is connected to a 10k potentiometer so that the contrast can be adjusted. The Read/Write pin will be grounded in most cases because we will only be writing characters to the LCD and not read anything from it. The Register Select (RS) and Enable pin (E) pin are the control pins of the LCD and will be connected to the digital pins GPIO pins of the microcontroller. These pins are used to instruct the LCD where place a character when to clear it etc.

From DB0 to DB7 we have our eight Data Pins which are used to send information about the characters that have to be displayed on the LCD. The LCD can operate in two different modes, in the 4-bit Modeonly pins DB4 to DB7 will be used and the pins DB0 to DB3 will be left idle. In 8-bit Mode, all the eight-pin DB0 to DB7 will be used. Most commonly the 4-bit mode is preferred since it uses only 4 Data pins and thus reduces complexity and GPIO pin requirement on the microcontroller.Finally, we have the LED+ and LED- pins which are used to power the backlight LED inside our Display module. Normally the LED+ pin is connected to 5V power through a 100 ohm current limiting resistor and the LED- pin is connected to Ground.

Hello friends! Welcome back to ElectroDuino. This blog is base on What is 16×2 LCD Display Module Sensor | How 16×2 LCD Display Module Works. Here we will discuss the Introduction to 16×2 LCD Display Module, Module pin diagram, Working Principle, Features, and applications.

16×2 LCD is one kind of electronic device used to display the message and data. The term LCD full form is Liquid Crystal Display. The display is named 16×2 LCD because it has 16 Columns and 2 Rows. it can be displayed (16×2=32) 32 characters in total and each character will be made of 5×8 Pixel Dots. These displays are mainly based on multi-segment light-emitting diodes. There are a lot of combinations of display available in the market like 8×1, 8×2, 10×2, 16×1, etc. but the 16×2 LCD is widely used. These LCD modules are low cost, and programmer-friendly, therefore, is used in various DIY circuits, devices, and embedded projects.

3VE (Contrast V)Adjusts the contrast of the LCD display. It is Connected to a variable POT that can provide 0-5V power supply. Connect it to the ground to get maximum contrast.

7D0 (Data Pin 0)These 8 Pins are used to sending commands or data to the LCD. These pins are connected in two-wire modes like 4-wire mode and 8-wire mode. In 4-wire mode, only four pins are connected to the microcontroller data pin 0 to 3. And in 8-wire mode, 8-pins are connected to microcontroller data pin 0 to 7.

These 16 x 2 LCD display modules are constant of 16 Columns and 2 Rows. The 1st row of this module has a total of 16 columns 0 to 15 and the position of the first row is 0. Also, the 2nd row has a total of 16 columns 0 to 15 and the position of the second row is position is 1. So the total numbers of the column are 16 x 2 = 32. Its means 16 x 2 LCD module can display 32 characters at the same time.

It will be a very complicated task to handle everything with the help of a microcontroller. So an Interface IC like HD44780 is used, which is mounted on the backside of the LCD Module. The function of this IC is to get the Commands and Data from the microcontroller and process them to display meaningful information onto the LCD Screen.

The CFA533-***-KC series is a 16x2 I2C LCD with keypad. The I2C interface allows you to use just two lines (SDA & SCL) to have bi-directional communication with the I2C LCD. Other devices can also share those two I2C control lines with the LCD. Only 4 wires are needed to connect this I2C LCD: power, ground, SDA (I2C Serial DAta) and SCL (I2C Serial CLock).

The CFA533 can run on 3.3v to 5.0v directly, with no changes needed, so you do not need to do any level translation between your embedded processor and the I2C LCD. Simply power the CFA533 from the same supply as your processor and the I2C signal levels will match up.

Using only one address on your I2C bus, you can add all the elements that you need for your front panel. The CFA533 I2C LCD can also read up to 32 DS18B20 digital temperature sensors, giving you an easy way to integrate temperature sensing over the I2C bus. No additional firmware or pins are needed on the host system.

This CFA533-TFH variant features crisp dark letters against a white, backlit background. The keypad has a matching white LED backlight. Since the LCD is a backlit positive FSTN, the CFA533-TFH I2C LCD is readable in direct sunlight, as well as complete darkness.

The CFA533-***-KC series is a 16x2 I2C LCD with keypad. The I2C interface allows you to use just two lines (SDA & SCL) to have bi-directional communication with the I2C LCD. Other devices can also share those two I2C control lines with the LCD. Only 4 wires are needed to connect this I2C LCD: power, ground, SDA (I2C Serial DAta) and SCL (I2C Serial CLock).

The CFA533 can run on 3.3v to 5.0v directly, with no changes needed, so you do not need to do any level translation between your embedded processor and the I2C LCD. Simply power the CFA533 from the same supply as your processor and the I2C signal levels will match up.

Using only one address on your I2C bus, you can add all the elements that you need for your front panel. The CFA533 I2C LCD can also read up to 32 DS18B20 digital temperature sensors, giving you an easy way to integrate temperature sensing over the I2C bus. No additional firmware or pins are needed on the host system.

This CFA533-TFH variant features crisp dark letters against a white, backlit background. The keypad has a matching white LED backlight. Since the LCD is a backlit positive FSTN, the CFA533-TFH I2C LCD is readable in direct sunlight, as well as complete darkness.

The HD44780 type controller chip is used with a wide variety of Liquid Crystal Displays. These LCDs come in many configurations each with between 8 and 80 viewable characters arranged in 1, 2, or 4 rows.

The problem is that there is no way to inform the controller of the configuration of the display that it is driving. The controller operates exactly the same way for all displays and it is up to the programmer of the device that is controlling the LCD controller (usually a host microcontroller) to deal with this situation.

The controller contains 80 bytes of Display Data Random Access Memory which is usually referred to as DDRAM. When the controller is used with a 40 x 2 display (forty characters on each of two rows) the operation is quite straightforward and that operation will be explained first. Each of the other configurations introduces one or more quirks so it is best to understand the operation of the 40 x 2 before proceeding to the description of the operation of any of the others.

This is the most common Memory Map for the 80 bytes of DDRAM in the HD44780 controller. There is another rarely encountered configuration that will be presented later.

Each of these DDRAM memory addresses corresponds to a character position on an attached display, but the specific position varies depending on the configuration of that display. As part of the initialization sequence the display is cleared by storing the ASCII code for a space in each of the 80 memory locations. Subsequently if a different ASCII code is stored in any of those memory locations then the character corresponding to that ASCII code is automatically displayed at a specific location on the display.

You can tell the controller where you want the first ASCII character that you send it to be stored, this is usually address 00h. After receiving that character it will automatically update its address pointer and put the next ASCII character you send into an adjacent memory location with no more addressing work on your part. You can specify whether to increment or decrement the address counter but normally it is incremented, so the next character will be put into address 01h. The LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

Here is a simplified diagram of the display on a 40 x 2 LCD Module. Each of the boxes in the diagram represents a location where a character can be displayed.

When the host controller wants to display a string of characters on the display all it has to do is specify a starting DDRAM address and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another. The LCD controller takes the first code that it receives, stores it at the specified address, and simultaneously displays the corresponding character on the display. It then increments it"s internal address counter and stores the next ASCII code that it receives in the next DDRAM location which causes the corresponding character to appear in the next location on the display. As mentioned before the LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

This display also has 80 characters, but the relationship between the DDRAM addresses and the character locations on the LCD is not quite as straightforward as the LCD with two rows of 40 characters. Here is a diagram of the device.

The memory map is always the same regardless of the display configuration, but in this drawing I have shown a small space between addresses 13h and 14h on the first line and another between addresses 53h and 54h on the second line.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 20 x 4 LCD. Note how the right half of the previous diagram is now below the left half and note the resulting sequence of starting addresses for each display row (00h, 40h, 14h, 54h).

Remember that the LCD controller still considers this to be two lines of RAM. It is important to understand that this way of picturing the DDRAM addresses helps relate the memory addresses to the character locations but does not change the fact that as far as the controller is concerned there are only two lines of memory. In other words, although this diagram shows the DDRAM differently than before, the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display since there is no way of telling the LCD controller that there are now 4 rows of 20 characters instead of 2 rows of 40 characters.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for the 40 x 2 display. After the first row is full the characters will continue on to the third row. The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After that the following characters will appear back on the first row, and so on.

In order to get a coherent display on sequential rows it is necessary to compensate for the design of the LCD controller when programming the host microcontroller. Basically the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address.

It is important to understand that, although this diagram shows only the part of the DDRAM that is normally used to display information on the 20 x 2 LCD, the actual memory map and controller operation is exactly the same as described above for the previous displays. Again that is because there is no way of telling the LCD controller that there are only 40 characters on the attached display.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for either of the 80 character displays. Assume that the host controller is sending a string of characters as described above. Consider what happens after the LCD controller stores an ASCII code in address 13h and displays the corresponding character at the right end of the top row on the LCD. It then stores the next ASCII code in address 14h, which has no corresponding location on this 20x2 display. As more ASCII codes are sent to the LCD controller they are stored in the DDRAM but do not appear on the display until the LCD controller finally increments it"s address counter from 27h to 40h at which time subsequent characters start to appear on the second row of the display. As far as a viewer of the display is concerned there is a gap of 20 missing characters. The same thing will happen on the second row when ASCII codes are stored in addresses 54h - 67h.

This is a commonly found configuration and its operation is almost identical to that of the 20 x 2. The relationship between the DDRAM addresses and the character locations on the LCD is a subset of the example shown above. Here is a drawing of the device.

Once again it is important to understand that although this diagram shows only the part of the DDRAM that is normally used to display information on the 16 x 2 LCD the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display. This is because there is no way of telling the LCD controller that there are only 32 characters on the attached display.

There are actually two different varieties of 16 x 1 LCD displays and the initialization and operation of each is different so it is important to determine which one you have.

When power is first applied to any of the multi-row LCD modules and before the controller is initialized you will see that the character locations corresponding to the first line of memory are dark and the others are light (assuming that the contrast adjustment is properly set). If you apply power to a 16 x 1 LCD module and only the left 8 character locations are dark you have what I will call a type 1 module. If only the right 8 character locations are dark this is also a type 1 module but it is upside down! If all 16 character locations are dark then it is what I will call a type 2 module. This is my own terminology used only for the purpose of keeping them differentiated while describing their operation. The type 1 modules will have only one IC on the back of the pcb while the type 2 will have 2 (I guess this tidbit gives away the source of my "type" designations). This distinction may apply to newer devices with epoxy blobs instead of ICs, but I believe that sometimes one blob may cover more than one equivalent IC function.

From this you can see that although the display has only a single row of characters, as far as the LCD controller is concerned it is using two lines of memory and it must be considered to be a 2 line device when initializing the controller.

Since only one line of memory is in use this LCD module should be configured as a 1-line device. As far as I can determine, this changes the multiplex frequency which changes the display brightness and/or contrast. Also, there are some single row LCDs that are capable of displaying a larger 5x10 font instead of the more common 5x7 font.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 16 x 4 LCD. Note how the center of the previous diagram is now below the left part, the right part is missing, and the resulting sequence of starting addresses for each display row is different than for the 20 x 4 (00h, 40h, 10h, 50h).

The 40 x 4 LCD is treated essentially as two 40 x 2 devices stacked one on top of another in the same glass enclosure. Electrically it uses what amounts to two HD44780 controller chips and it therefore has two separate memory maps each with the same address range. One is used for the top two lines and the other is used for the bottom two lines. The memories are accessed individually by strobing the desired Enable pin of which there are now two. Here is a diagram of the device.

To display a really long string of characters on this display the host controller would start out just like it did for the 40 x 2 display. It would specify a starting DDRAM address (typically 00h) and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another, making sure to strobe the enable pin associated with the upper memory bank. After storing an ASCII code in address 67h the LCD controller will automatically increment to address 00h as before and at this time the host controller must stop strobing the enable pin for the upper bank and start strobing the one for the lower bank.

There are other LCD configurations available but I believe that any of them can be handled by a technique similar to one of the examples above. If you have a display that seems to be considerably different from any of these I would like to hear from you.

(2) As implied above the number of rows of characters that can be displayed on the LCD is not the same as the number of lines of memory used by its controller. Only some of the 16x1 displays use "one line" of memory, all of the other displays including most 16x1 displays, use "two lines" of memory.

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

Character LCD modules are one of the most popular LCD technologies thanks to their ease of programming, low cost, low power consumption, and short lead times. They can be seen in a wide variety of products.

Most character LCDs are driven by an eight-bit parallel interface which makes use of the standard HD44780 protocol. The display has sixteen pins/connections to drive both the LCD and the optional LED backlight.

A character LCD contains several 5x8 pixel character blocks. Each block has five (5) dots across and eight (8) dots up and down. These dots are turned on and off to generate all possible characters.

The most common character configuration is a 16x2 which means there are sixteen 5x8 character pixels across and two rows, for a total of 32 characters.

16x2 LCD modules are very commonly used in most embedded projects, the reason being its cheap price, availability, programmer friendly and available educational resources.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. but the most used one is the 16×2 LCD. So, it will have (16×2=32) 32 characters in total and each character will be made of 5×8 Pixel Dots. A Single character with all its Pixels is shown in the below picture.

Now, we know that each character has (5×8=40) 40 Pixels and for 32 Characters we will have (32×40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels. Hence it will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780is used, which is mounted on the backside of the LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen. You can learn how to interface an LCD using the above mentioned links. If you are an advanced programmer and would like to create your own library for interfacing your Microcontroller with this LCD module then you have to understand the HD44780 IC working and commands which can be found its datasheet.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey