lcd module 16x2 configuration supplier

Both LCD 16x2 functions provide, and that constitute a larger disturutions for the components. While the 16x2 difference is in terms of the size of the screen,

This allows you to find some of the cheapest lcd display, cheap lcd modules, and even more per piece. Check out Alibaba.com ’ s wholesale prices to find the cheapest lcd display, cheap lcd modules, and more at wholesale prices.

When looking for lcd 16x2 for sale, it ’ s easy to bulk wholesale, browse other suppliers on Alibaba.com to discover a wide range of wholesale LCDs and 16x2 wholesale prices. For other customers, you will find an option to bulk browse at Alibaba.com.

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Nowadays, we always use the devices which are made up of LCDs such as CD players, DVD players, digital watches, computers, etc. These are commonly used in the screen industries to replace the utilization of CRTs. Cathode Ray Tubes use huge power when compared with LCDs, and CRTs heavier as well as bigger. These devices are thinner as well power consumption is extremely less. The LCD 16×2 working principle is, it blocks the light rather than dissipate. This article discusses an overview of LCD 16X2, pin configuration and its working.

The term LCD stands for liquid crystal display. It is one kind of electronic display module used in an extensive range of applications like various circuits & devices like mobile phones, calculators, computers, TV sets, etc. These displays are mainly preferred for multi-segment light-emitting diodes and seven segments. The main benefits of using this module are inexpensive; simply programmable, animations, and there are no limitations for displaying custom characters, special and even animations, etc.

A 16×2 LCD has two registers like data register and command register. The RS (register select) is mainly used to change from one register to another. When the register set is ‘0’, then it is known as command register. Similarly, when the register set is ‘1’, then it is known as data register.

The main function of the data register is to store the information which is to be exhibited on the LCD screen. Here, the ASCII value of the character is the information which is to be exhibited on the screen of LCD. Whenever we send the information to LCD, it transmits to the data register, and then the process will be starting there. When register set =1, then the data register will be selected.

Thus, this is all about LCD 16×2 datasheet, which includes what is a 16X2 LCD, pin configuration, working principle, and its applications. The main advantages of this LCD device include power consumption is less and low cost. The main disadvantages of this LCD device include it occupies a large area, slow devices and also lifespan of these devices will be reduced due to direct current. So these LCDs use AC supply with less than 500Hz frequency. Here is a question for you, what are the applications of LCD?

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

In LCD 16×2, the term LCD stands for Liquid Crystal Display that uses a plane panel display technology, used in screens of computer monitors & TVs, smartphones, tablets, mobile devices, etc. Both the displays like LCD & CRTs look the same but their operation is different. Instead of electrons diffraction at a glass display, a liquid crystal display has a backlight that provides light to each pixel that is arranged in a rectangular network.

Every pixel includes a blue, red, green sub-pixel that can be switched ON/OFF. Once all these pixels are deactivated, then it will appear black and when all the sub-pixels are activated then it will appear white. By changing the levels of each light, different color combinations are achievable. This article discusses an overview of LCD 16X2 & its working with applications.

An electronic device that is used to display data and the message is known as LCD 16×2. As the name suggests, it includes 16 Columns & 2 Rows so it can display 32 characters (16×2=32) in total & every character will be made with 5×8 (40) Pixel Dots. So the total pixels within this LCD can be calculated as 32 x 40 otherwise 1280 pixels.

16 X2 displays mostly depend on multi-segment LEDs. There are different types of displays available in the market with different combinations such as 8×2, 8×1, 16×1, and 10×2, however, the LCD 16×2 is broadly used in devices, DIY circuits, electronic projects due to less cost, programmable friendly & simple to access.

Pin7 (Data Pin): The data pins are from 0-7 which are connected through the microcontroller for data transmission. The LCD module can also work on the 4-bit mode through working on pins 1, 2, 3 & other pins are free.

The basic working principle of LCD is passing the light from layer to layer through modules. These modules will vibrate & line up their position on 90o that permits the polarized sheet to allow the light to pass through it.

At present, LCDs are used frequently in CD/DVD players, digital watches, computers, etc. In screen industries, LCDs have replaced the CRTs (Cathode Ray Tubes) because these displays use more power as compared to LCD, heavier & larger.

The displays of LCDs are thinner as compared to CRTs. As compared to LED screens, LCD has less power consumption because it functions on the fundamental principle of blocking light instead of dissipating.

The registers used in LCD are two types like data register & command register. The register can be changed by using the RS pinout. If we set ‘0’ then it is command register and if it is ‘1’ then it is data register.

The main function of the command register is to save instructions illustrated on LCD. That assists in data clearing & changes the cursor location & controls the display.

The data register is used to save the date to exhibit on the LCD. Once we transmit data to LCD, then it shifts to the data register to process the data. If we fix the register value at one that the data register will start working.

Interfacing of a 16X2 LCD with Arduino is discussed to display “Hello World!” on the screen. A library like LiquidCrystal permits you to manage the displays that are well-matched through the driver like Hitachi HD44780 driver. Here, the following example circuit displays “Hello World!” on the LCD & displays the time in sec once the Arduino board was reset.

The 16×2 display includes a parallel interface which means that the microcontroller used in this has to control different interface pins immediately to control the LCD. The interface includes mainly these pins like RS (Register Select) pin, Read/Write pin, Enable Pin, Data pins from D0 to D7, display contrast pin, LED backlight pins, power supply pins.

The controlling of LCDs compatible with Hitachi can be done using two modes like 4-bit/8-bit. Here, the 4-bit mode needs 7 I/O pins using the Arduino board, whereas the 8-bit mode needs 11 pins. To display the text on the LCD, the 4-bit mode is used. The following example will explain how to control an LCD using 4-bit mode.

Before interfacing the LCD screen to the Arduino board, a pin header strip need to be solder to pin-14 or 16 of the LCD. We can notice this in the following circuit diagram. The following pins need to connect to wire the LCD to an Arduino board.

Thus, this is all about an overview of LCD 16×2, used in a wide range of applications such as different devices and circuits such as calculators, mobile phones, TV sets, computers, etc. These displays are mostly selected for multi-segment LEDs & 7- segment displays. LCDs are extensively used in different electronic applications like different systems to illustrate different statuses as well as parameters. Here is a question for you, what are the different types of LCDs available in the market?

Grove - 16 x 2 LCD is a perfect I2C LCD display for Arduino and Raspberry Pi with high contrast and easy deployment. 16x2 means two lines and each line has 16 columns, 32 characters in total. With the help of Grove I2C connector, only 2 signal pins and 2 power pins are needed. You don"t even need to care about how to connect these pins. Just plug it into the I2C interface on Seeeduino or Arduino/Raspberry Pi+baseshield via the Grove cable. There won"t be complicated wiring, soldering, worrying about burning the LCD caused by the wrong current limiting resistor.

The Grove - LCD RGB Backlight has been well received since its inception. Based on customer feedback, now, we bring more cost-effective monochrome backlight derivative for you.

Except for RGB backlights, these three products are almost identical to the the Grove - LCD RGB Backlight, they are all 16 characters wide, 2 rows with high brightness backlight.

An introduction of What is a Grove - 16 x 2 LCD and How does it work is strongly recommended reading ahead if you are not familiar with it. Please visit our

The platforms mentioned above as supported is/are an indication of the module"s software or theoritical compatibility. We only provide software library or code examples for Arduino platform in most cases. It is not possible to provide software library / demo code for all possible MCU platforms. Hence, users have to write their own software library.

The first version of Grove - 16 x 2 LCD series does not have a built-in pull-up resistor, nor does it provide a pad to solder the optional pull-up resistor. We have redesigned the module, and the new version has built-in pull-up resistors.

The Grove - 16 x 2 LCD shares the same library with the Grove-LCD RGB Backlight. Their usage is almost the same, except that the Grove - 16 x 2 LCD does not support the RGB color API, such as setRGB().

2). Open it in your computer by click the HelloWorld.ino which you can find in the folder XXXX\Arduino\libraries\Grove_LCD_RGB_Backlight-master\examples\HelloWorld, XXXX is the location you installed the Arduino IDE.

Since the Grove - 16 x 2 LCD series are all monochrome backlight, you need to comment out the RGB color related code. In the demo code above, i.e., line 6 and line 17.

Step 2. Make sure that the ArduPy firmware contains the Grove - 16 x 2 LCD ArduPy library using the following commands. For more information, please follow here.

Step 4. Save the ArduPy-LCD1602.py in a location that you know. Run the following command and replace

Range tests made easy with the RE-Mote and LCD:Reduce the number of equipment and preparations required for field testing (2.4GHz and 868MHz), pack everything you need in your hand.

Hello friends! Welcome back to ElectroDuino. This blog is base on What is 16×2 LCD Display Module Sensor | How 16×2 LCD Display Module Works. Here we will discuss the Introduction to 16×2 LCD Display Module, Module pin diagram, Working Principle, Features, and applications.

16×2 LCD is one kind of electronic device used to display the message and data. The term LCD full form is Liquid Crystal Display. The display is named 16×2 LCD because it has 16 Columns and 2 Rows. it can be displayed (16×2=32) 32 characters in total and each character will be made of 5×8 Pixel Dots. These displays are mainly based on multi-segment light-emitting diodes. There are a lot of combinations of display available in the market like 8×1, 8×2, 10×2, 16×1, etc. but the 16×2 LCD is widely used. These LCD modules are low cost, and programmer-friendly, therefore, is used in various DIY circuits, devices, and embedded projects.

3VE (Contrast V)Adjusts the contrast of the LCD display. It is Connected to a variable POT that can provide 0-5V power supply. Connect it to the ground to get maximum contrast.

7D0 (Data Pin 0)These 8 Pins are used to sending commands or data to the LCD. These pins are connected in two-wire modes like 4-wire mode and 8-wire mode. In 4-wire mode, only four pins are connected to the microcontroller data pin 0 to 3. And in 8-wire mode, 8-pins are connected to microcontroller data pin 0 to 7.

These 16 x 2 LCD display modules are constant of 16 Columns and 2 Rows. The 1st row of this module has a total of 16 columns 0 to 15 and the position of the first row is 0. Also, the 2nd row has a total of 16 columns 0 to 15 and the position of the second row is position is 1. So the total numbers of the column are 16 x 2 = 32. Its means 16 x 2 LCD module can display 32 characters at the same time.

It will be a very complicated task to handle everything with the help of a microcontroller. So an Interface IC like HD44780 is used, which is mounted on the backside of the LCD Module. The function of this IC is to get the Commands and Data from the microcontroller and process them to display meaningful information onto the LCD Screen.

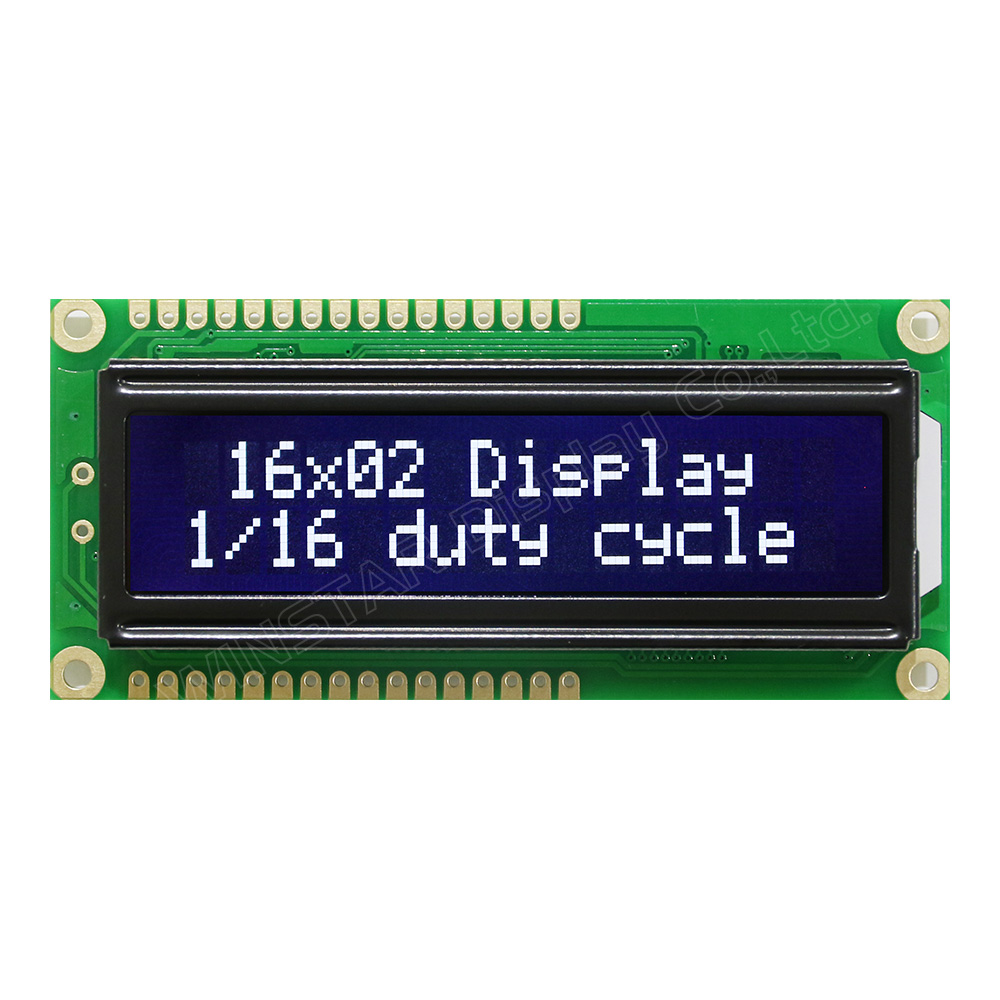

A 16×2 dot matrix Character LCD Module display in STN Negative Blue LCD Mode, Six O’clock viewing direction, Wide Temperature Range (Operating Temp: -20°C to 70°C, Storage Temp: -30°C to 80°C), and White LED Backlight. It has a transmissive polarizer suitable for darker environment. This product is assembled Chip On board with 1/16 Duty and a Controller IC S6A0069 or equivalent. The interface type is Parallel. This is an ROHS Compliant product manufactured with ISO standards and procedures.

A 16×2 dot matrix Character LCD Module display in STN Positive Yellow Green LCD Mode, Six O’clock viewing direction, Wide Temperature Range (Operating Temp: -20°C to 70°C, Storage Temp: -30°C to 80°C), and Yellow Green LED Backlight. It has a transflective polarizer, recommended for applications that will be used both indoor and outdoor. This product is assembled Chip On board with 1/16 Duty and a Controller IC AC780S or equivalent. The interface type is Serial – SPI. This is an ROHS Compliant product manufactured with ISO standards and procedures.

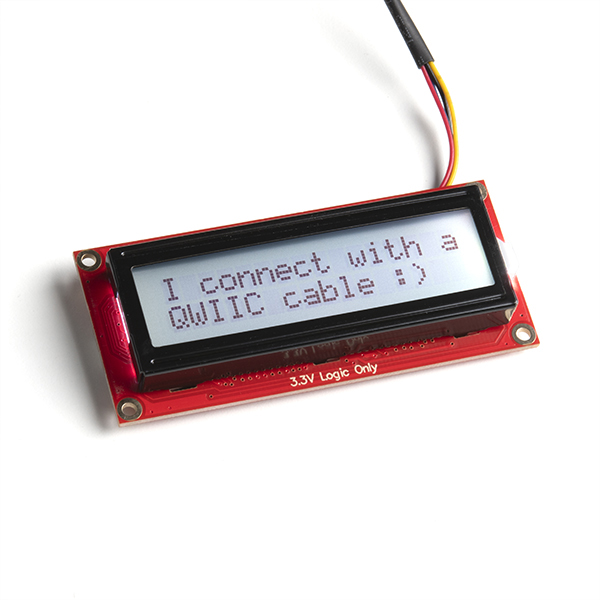

This 2×16 character LCD Module with BLUE Backlight uses an I2C interface to communicate with the host microcontroller. This budget-conscious LCD is used on projects requiring the display of text, data, or ASCII characters of all types. Connect to Vcc, Gnd, SDA (serial data line), and SCL (serial clock line). This is a 5VDC device and will be found on the I2C bus at address 0x27 / 0x3F.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey