are lcd touch screen controls better than touch controls factory

It"s probably a little early to be warning of extinction, but in some new cars, buttons are becoming hard to find. Given that a screen has to go into the dashboard anyway (thanks to things like backup camera requirements) and the fact that people increasingly won"t consider a car without Android Auto or Apple CarPlay, touchscreens make life easier for automakers in terms of design and assembly.

It"s just that they don"t make life easier for drivers. Instead, we"re treated to bad interfaces that don"t create muscle memory but instead distract us while we should be driving. And now, Swedish car publication Vi Bilägare has the data to prove it.

VB tested 11 new cars alongside a 2005 Volvo C70, timing how long it took to perform a list of tasks in each car. These included turning on the seat heater, increasing the cabin temperature, turning on the defroster, adjusting the radio, resetting the trip computer, turning off the screen, and dimming the instruments.

VB says that "one important aspect of this test is that the drivers had time to get to know the cars and their infotainment systems before the test started." With my devil"s advocate hat on for a second, most drivers who drive regularly will regularly drive the same car, building more familiarity over months and years than a journalist will after even a week with a new model. But that kind of long-term adaptation is the user conforming to the vehicle"s wishes, and shouldn"t good design be the opposite of that? Advertisement

VB lays the blame for the shift from bottons to screens with designers who "want a "clean" interior with minimal switchgear." That"s fair, but I don"t think we can count out the accountants either. If everything can be achieved by touching the screen, then the company doesn"t also have to pay for the plastic and wires that buttons are made from, nor the time it takes someone to make that into buttons or install them in a car.

Even with touchscreens, though, we can see in the spread of scores VB gave to different all-touch cars that design matters. You"ll find almost no buttons in a Tesla Model 3, and we called out the lack of buttons in the Subaru Outback in our review, but both performed quite well in VB"s tests. And VW"s use of capacitive touch (versus physical) for the controls on the center stack appears to be exactly the wrong decision in terms of usability, with the ID.3 right at the bottom of the pack in VB"s scores.

I"m not surprised that the BMW iX scored well; although it has a touchscreen, you"re not obligated to use it. BMW"s rotary iDrive controller falls naturally to hand, and there are permanent controls arrayed around it under a sliver of wood that both looks and feels interesting. It"s an early implementation of what the company calls shy tech, and it"s a design trend I am very much looking forward to seeing evolve in the future.

Again, there are examples of automakers doing this better than others. Over the past couple of weeks I"ve spent time in an Acura MDX and Mazda CX-50, neither of which uses a touchscreen infotainment system. Neither managed to do better than 19 mpg either, which is frankly appalling in 2022, but the CX-50 did at least distinguish itself for ease of use when it came to the infotainment system. Advertisement

Mazda"s latest system has been criticized for being bare-bones, but odds are, a driver is using Apple CarPlay or Android Auto, and it"s actually quite easy to use with the rotary controller and its hard buttons, which, again, are right where your right hand expects them to be (or left hand, in a right-hand-drive car).

Volkswagen"s infotainment software in the ID.3 can be frustratingly laggy, and while there are permanent controls for the climate and audio, they"re capacitive touch, not real buttons or dials or knobs.

The more expensive Acura also places the infotainment screen far out of reach. It"s a much higher-resolution display befitting a much more expensive car, and the MDX"s infotainment system is much more capable than the CX-50"s in terms of apps and features. I also quite like the layout and fonts, although obviously that"s a pretty subjective thing.

I won"t subject you to the depth of my current feelings about Acura"s "true touchpad," just a high-level, mostly polite version. It has a 1:1 relationship between the screen and the pad, so it doesn"t work at all like any other trackpad in any other car you might have driven. And that means it requires a lot of concentration to use, particularly if you"re trying to interact with CarPlay. And it doesn"t need saying that "requires concentration to use" is likely the last quality anyone wants in an infotainment system.

I"m not that surprised that the old Volvo won, dating from a time when most functions were controlled by individual buttons and when infotainment didn"t really yet exist. And in some ways, the tests played to its strengths—there"s no Android Auto or CarPlay, and the only safe way your phone is showing you directions is if you bring a suction mount. Do be careful what you press if anyone"s sitting in the back seat, though. In Volvos of that vintage, one of those buttons drops the rear headrests, which are rather heavy and very much wish to return to a horizontal orientation with absolute disregard for the skulls of anyone sitting in their way.

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The liquid crystals are made up of a part solid, part liquid substance that can be "twisted" by applying an electrical voltage to them. They block the polarized light when they are off, but reflect red, green, or blue light when activated.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

Capacitive surface touch screens work by using the electrical signal from the operator’s finger instead of force to complete the action of the interface.

The key benefits of using a capacitive touch screen is that they are temperature resistant and waterproof. Many home appliances like refrigerators and dishwashers use capacitive touch keypads.

However, while capacitive touch screens can only be used with the user’s finger, Projective Capacitive Touch Screens are the new standard for capacitive touch screens and allow for users to control the device even while wearing gloves.

While technically a type of Capacitive Touch Screen by its name, Projective Capacitive (PCAP) Touch Screens are the most common type and the ones used most on the market today.

PCAP touch screens get their name from the way they “project” a small electric field out past the top layer which senses the user’s input even before they come into contact with the screen. In a way, they function much like a proximity sensor. They have mutual capacitance which supports multi-touch activation.

Because of this, users can control the device with a stylus or while wearing thin surgical gloves, food service gloves, or cotton gloves. They also support excellent clarity with high light quality. They’re a great option for incorporating into outside equipment or machinery, as users don’t need to remove their gloves in a cold or rainy climate, and can still see the screen well in the sun.

They can be used in control panels, industrial automation, consumer devices, and commercial applications in retail, gaming, and signage. They are more costly than resistive touch screens.

Intuitive: Buttons are very intuitive, you see a button you know it is there to be pressed. Touchscreens need content that makes it clear that the display is touch-sensitive and where to touch.

Dynamic function: With a touch screen it is relatively easy to make the button function context sensitive. Buttons can have on-screen descriptions (as with ATM cash machines) but that can lead to alignment issues.

Touch control and display technology is becoming an indispensable part of industry and today almost all industrial embedded solutions have some sort of graphical user interface. Manufacturers now integrate commercial PC technologies to provide customised solutions for users. This is achieved by incorporating the latest technology solutions and control automation methods into commercial products, manufacturing equipment and test stations.

Transparency Market Research (TMR) says that industries, such as automotive manufacturing and food and beverages, are the main drivers for these touch-screen displays. Key players include: Advantech Co., Ltd, Cypress Semiconductor Corporation, Dell, Inc., B&R Industrial Automation GmbH, Elo Touch Solutions, Inc., Fujitsu Ltd., Hewlett Packard Enterprise, LG Electronics, Panasonic Corporation, Planar Systems, Kontron AG, Schneider Electric S.E., Siemens AG, Beckhoff Automation GmbH & Co. KG, Captec Ltd., and American Industrial Systems.

At the end of February, Bopla Gehäuse Systeme GmbH, the East Westphalia Germany based developer and producer of touch screens and membrane keyboards will showcase in Nuremberg its latest examples of products that integrate displays and touch-screens in industrial embedded applications. The company says it supports its customers through all procurement, manufacturing, assembly and integration steps up to the finished, functional and ESD-compliant device.

“We specialise in the implementation of complex HMI [human machine interface] projects and integrate screens with input functions into housings. In the case of capacitive touch displays, we can print the glass pane as well as connect the pane and display using optical bonding,” it says.

At the end of January, Emerson the technology and engineering company announced that it had released a new display for industrial applications. The new portfolio of RXi industrial display and panel PC products for monitoring are designed to work with both Emerson’s programmable logic control (PLC) and programmable automation control (PAC) solutions, and third-party control systems. The display portfolio features standardised physical designs to minimise the variety of enclosure cut-outs required for OEM applications, making each display easily replaceable and upgradeable in the field with no need to modify existing cabinets or install new ones.

Displays are available in sizes ranging from seven to 24 inches, providing a single, scalable platform for a multitude of operations and applications. Key features for all models include vivid projective capacitive multi-touch screens that can operate in temperatures from 20 to 65 degrees Celsius and optional sunlight readable screens on select sizes. The portfolio carries multiple certifications and is IP66-certified for protection against dust and strong jets of water.

At the end of last year,GSR Technology Europe Limited, provider of standard and custom made optoelectronic solutions, introduced the new 7.8-inch High Resolution thin film transistor (TFT) module with projective capacitive multi-touch technology as an optional extra. The extremely compact design makes it suitable for many industrial applications. It also introduced two new high resolution TFT modules. The 5.0 inch and 8.0-inch modules come with projective capacitive multi-touch technology as standard.

GSR Technology also works closely with its partner EETI, the Taiwan based provider of eGalaxTouch touch technologies, to provide a full range of touch controllers that are designed to optimize the performance of projected capacitive touch technology. The EXC range of touch controllers and IC chips are specifically designed for commercial, industrial and medical applications. EETI touch controllers support USB, RS232 and IC interfaces and offer high voltage driving signal to achieve high signal-noise-ratio and better interference susceptibility for demanding applications.

Display Technology is supplying TFT LCD monitors to a rail company for its CCTV system. It has so far supplied 300 of its ‘Litemax’ 1068E, 10.4 TFT LCD, LED Backlight 1600 displays. A further 500 is to be supplied over the next 2 years. The display comes with 4 options: Finished monitor; Open frame monitor; Full AD Card Kit with no metalwork; and Panel only plus LED driver. The company has alsosupplied and fitted 12.1-inch industrial touch monitors for use in cranes at Felixstowe Docks.“We made various design improvement suggestions which the customer decided to implement.

This included connector exit position, change in analogue pot, and stronger umbilical conduit. After pre-production the touch-screen was mounted using an alternative method to increase ruggedness in such a harsh operating condition,” Display Technology said.

The analysis by TMR predicts a CAGR of over 6.5% in the global industrial touch-screen display market to 2026. This would give it a valuation of $835.3 million. Among end-use industries, the automotive segment is anticipated to constitute a significant market share. It is expected to be driven by rising demand for ‘next-generation’ touch-screen display panels that can withstand harsh environments as well as a rise in demand for custom touch panels with full display enhancements such as sunlight readability and custom rugged cover glass with logos and graphics.

Touch screens will hopefully never make it into any critical pilot systems, because safety and stability matters to airline manufacturers, current ongoing scandals notwithstanding. I only wish automobile manufacturers took their job equally seriously.

Even so, a program for processing a switch or dial can be really short and simple. You can print it out on a sheet and check and double check every line of code for to make sure it"s correct and all possibilities are accounted for.

A program handling a touchscreen will be complicated. Millions of lines of code. Maybe even billions. The best you can hope for is empirically verifying it"s mostly correct most of the time.

I do some. And the last device we built, we still fight with a simple rotary switch. You have to do things like debounce inputs that seem like obvious binary switches. Getting the debounce windowing right can be just as "guessy". And guess what the highest point of failure on said device is. That selector switch. Had similar experience with buttons. I think the software part is just two forms of the Law of Conservation of Ugly.

It"s entirely possible to get multiple mouse down/move/up/click events per render frame, if the system has frozen or stalled for any reason (which happens all the time in the real world). But polling just can"t deal with that, so it sometimes ignores legitimate user input (often at a critical time, when other things are happening).

So it"s still unfortunately quite common for many apps to sometimes miss quick mouse clicks or screen touches, just because the system freezes up for an instant or lags behind (like when the CPU overheats and the fan turns on madly and SpeedStep clocks the CPU waaaay down, or even the web browser opens up another tab, or anything else blocks the user interface thread), and it just doesn"t notice the quick down/up mouse button transition that it would have known about if it were actually tracking operating system events instead of polling.

Hardware debouncing works well for most applications but may not be financially rewarding at scale. With time and effort software debouncing can render sometimes better/good or good enough results as hardware..

It"s the kinda problem that will tend to bite you in the butt if you aren"t aware of all the gotchas. Difficulty is they are application specific. But I wouldn"t describe the code as particularly complicated.

Now keep in mind that these hundreds of components exist in many many possible configurations so the system needs to handle having certain hardware available or not, and also handle a multitude of failure modes gracefully.

With cars, there are certainly many things where it did improve things: satnav, reverse camera, traction control etc, but also some where it made a perfectly working system worse (ie the “fixed” something that wasn’t broken): touchscreen dashboards.

They are, by very definition, an additional point of failure as you"re always adding an additional interface. They"re good for scaling, not for redundancy, and even that"s wishful thinking for most applications.

A modern touch screen is superbly reliable because it has no moving parts, and it can be tested. The (consumer grade) iPad touchscreen is very reliable.

In an aircraft flying through turbulences I"d feel a lot more comfortable knowing that all switches are pyhsical. Try to use your smartphone while jogging...

Yeah they’re both switches, but size is incredibly important, and small mechanical devices are finicky and don’t produce nice clean digital output (that’s a lie that electronic engineers tell software engineers to keep things simple).

But I do agree with your point on using a touchscreen in turbulence. A counter point is that there are probably hundreds of controls or settings on a plane that you never touch during turbulence, possibly that you never touch in flight (like telling the flight computer how much cargo you’re carrying). Stuff like that is ideal for a touchscreen.

Ummm, you think they put known failed parts back in planes? I think not. They do fix major parts, but the QC for that would be insane. You would make a switch to be hermetic and add anti-tampering - a manufacturer of any safety related device doesn’t want it to be “fixed”. Items are designed to be maintained (with proper schedules), or replaced.

If you have a variety of 50 switches and knobs, then the reliability is worse than 50x worse, because every item has it’s own reliability curve, and it only takes one failure to muck up your day.

Worth noting that a significant amount of the information pilots use in the cockpit (at major US carriers, at least), things like flight plans, are on an iPad.

Just because it"s on a touchscreen doesn"t mean it has to be tiny and hard to touch. A 17" touchscreen could have fewer controls than the same hardware panel. And the controls could be bigger on the touchscreen.

With hardware controls, most (if not all) of them are immediately accessible at all times. With proper training, body movement and tactile feedback will train your muscle memory which will help you find the right control without much of a hassle.

Back to the topic - in car, unless specifically intended for other passengers, driver should never stare on some stupid screen in a place way off the line of sight for driving. Whenever I do that even for a split second in my 15-year old bmw (checking if that knob is really for what I want), there can be an atomic blast in front of me and I wouldn"t see it.

A plane at cruise altitude is rarely less than minutes away (unless, in some planes, you are actively trying to crash the plane/make the wings fall off)

Well designed physical UI allows pilots to use touch and haptic feedback independent of sight. Whether the switch/dial/whatever is analog behind the scenes or is a digital input to the control infra is not the important thing.

I also imagine that there are other reasons for both airliners and cars to replace buttons with touchscreens, namely that of cost instead of prioritizing safety and stability, and in general I am not a fan of that trade-off. But I"m also not claiming to be representative of the automobile market in general.

It"s not just Boeing, who you accused of being backwards who are doing this, Airbus is too, along with every other manufacturer. Garmin and BendixKing now offer touch screens and it"s clearly the future of GA as well not just commercial aviation.

The idea that this is to save money is totally absurd! A 777X is $350 million dollars. Any accident would cost an astronomical amount compared to the cost of switches. Even leaving that aside. The touchscreens are actually far more expensive than the old instruments.

This is just a way for Honda to cover up the fact that they can"t write software, can"t design a reasonable UX, don"t want to spend money on it, and want to live as if it"s 1999 forever.

Furthermore, tactile feedback is safety. The fact that each switch has a feel, a size, a position - that let"s your brain know what you are doing without having to take eyes off the road.

Still, if you’re borrowing your wife’s car it’s easy to realize you don’t have great blindspot visibility at which point looking at a touch screen is very distracting.

I can imagine people would need to tune a radio panel more often, so at least basic functionality would be good to have as physical inputs. But even then basic radio functions are usually accessible via steering wheel buttons.

The theory I thought was reasonable for why the OP had troubles, was that Mac touch pads are sensitive enough to treat the separate pads of the paws as multitouch.

(That"s not to say that OP is wrong, of course, just that their argument isn"t really a valid one. My belief is that touch screens would suck for flying a plane, but I"m not a pilot.)

You can say the civilian oversight groups that seek to regulate the industry are risk averse, but the companies that build the planes themselves, if they had their say, we"d be flying mach 3 upside down all day.

I mean, the other point of a dynamic interface is that you can now have more controls than would fit on a static interface. Touchscreen fit-to-purpose controls might suck more than hardware fit-to-purpose controls, but either option is better than a single set of generic controls that control multiple systems that "should" have different control paradigms, translating to the generic controls being a compromised bad fit for any use-case.

E.g. a hardware English-language keyboard is probably better than a touchscreen English-language keyboard (though people with modern Blackberries might dispute this); but both are better than entering English text through T9 on a dial pad. And the touchscreen has the benefit of allowing you to have more keyboards (for e.g. the multiple native languages you type that use different alphabets), which wouldn"t even fit on the phone as hardware keyboards.

I bring this up, because eventually you run out of space to stuff additional controls. As airplanes become ever-more advanced, their cockpits will approach that point. At that point, dynamic affordances may be necessary, just so you can have some kind of "pagination" allowing you to squeeze more controls in. (Hopefully it"d just be for the non-time-critical switches to flip.)

It"s the best or worst of both worlds depending on your perspective, but they do offer superior hands-free operation over a pure touch device, but at the sacrifice of interface flexibility.

MFDs combine the durability of physical controls with the configurability and flexibility of screens, and it"s completely beyond me why they are not standard equipment in all cars.

I think this point is lost sometimes, but is also useful. My car has a lot of physical controls. Some of the ones that are useful during driving are tucked inconveniently below my left knee!

Information - the user is already looking at the screen, so they can touch virtual buttons. And that is probably the best approach, as they are manipulating information that is being displayed and they can see.

For actions, you won"t necessarily have your attention on the screen. The information may not even be displayed in the screen yet, so now you have to divert attention and manipulate the system to get it to a state you can then change(eg, moving to the climate control screen).

You could argue that an onscreen keyboard is significantly less mental load for the pilot than having to scroll letter by letter on a "dumb" interface.

Where do accidents happen? It"s fairly rare for a plane to just break. And even then, if your electronics fail there are usually mechanical backups for the critical instruments. It"s much more common for pilots to reach task saturation and make mistakes.

I don"t buy that argument. What kind of keyboard? QWERTY or something else? What language? English is the language of aviation, but if you"re not a native speaker who uses keyboards all the time then chances are you"re going to have a LOT of mental load using a keyboard. Even something like the French or German keyboards, which use mostly the same letters, may be different enough to cause frustration -- and when you have an engine on fire you don"t need to be struggling with those details.

With a touch screen? What if the glass breaks and the capacitive layer fails? Or the software running the screen crashes? Or a bug prevents you from switching from the "Climate control" tab to the "Landing gear" tab?

It is even totally possible to gravity drop landing gear on nearly all commercial airliners, I would expect, though I can only speak on the types I’ve rated on. I don’t see you asking “what happens if the landing gear lever fails?” which is actually a totally reasonable question, and one manufacturers have thought of. Touchscreens aren’t magic devices, they’re just another type of input to build redundancy behind.

It sounds like a horrible idea because you probably haven’t flown an aircraft and don’t know this. That isn’t an indictment of you, just a request to not judge so soon. I like the idea of screens that adjust to phase of flight so what I need is where I need it, because pilot workload is a real problem that automation has addressed for decades.

Thanks for the explanation -- This makes me feel much safer as a passenger if the touch screen is provided to you as a convenience instead of a replacement. Yep, I haven"t flown an aircraft. I was thinking that it was like a car where they are getting rid of physical knobs and replacing them with touchscreen-only interfaces which I hate.

You use the other screen, which is controlled by the other computer. There are also knobs to switch which computer controls each screen. In the worst case, there are the standby instruments.

Touch screens in the cockpit seem like madness to me. Cockpits sometimes fill with smoke and the pilot has to be able to find and operate the controls.

Ever notice that the flap levers have little flaps on top of them? The nosewheel steering control has a little tire on the top? That"s so the pilot knows without looking what his hands are on. These designs were not the result of some study group following fashion, but were the result of accidents.

If you want, you might think of radio, climate controls, etc as having negative values on the safety axis. You still want to shift them to the right as far as you can.

Yes, the basic controls do not change. But more advanced functionality is easier presented through menus and screens which guide you through a process -- instead of adding tons of switches for every possible function.

You are right that they are flaky. Here"s Martin Pauly (great YouTube channel!) using his touchscreen transponder and it just stops working: https://youtu.be/bopcQSJKcD8?t=732

Otherwise I agree. You need the use of the interface to be as automatic as possible, and exploiting muscle memory & tactile feedback are very important for that. Touch screens fail there.

They also enable the completion of hardware design before the interface design is completed. While the plastic molds and mechanical designs are worked out, the interface and software development can continue.

I"m reminded as well of web "app" interfaces. In the early days, with relatively fixed controls, one could often navigate sites more easily since there just weren"t that many ways they could work. Now, with a blizzard of JS UI kits and an oh-so-wonderful variety of ways of doing everything, each site works differently. And it"s not an improvement.

We went for a few iterations where the button would light up when the laser was on. There were tons of issues--the state of the laser was not stored in the hardware, so every time the button would disconnect briefly, the state would get reset and lost. After months of back and forth dealing with algorithms to save the state and deal with spurious button presses when the device disconnected, we ended up with a completely useless button, as disconnects would happen very often inside helicopters, rendering the button useless due to the spurious presses near disconnect/reconnect.

For one, you"re too late, touchscreens are prevalent in modern avionics, and unlabeled buttons on the border of a screen that change function depending on what screen you"re viewing are the second most common. The more relevant part to the Honda discussion is that there are different considerations for a car and airplane interfaces, and they are so different it"s not a good argument to say "planes don"t/shouldn"t do this so cars shouldn"t either."

The issue with a car isn"t the interface, it"s the fact that people look inside their vehicle for too long to fiddle with the radio. Even if the buttons/knobs could be operated entirely without looking, most people would still stare at their radio while they are doing it. Pilots learning to fly are trained to look outside after pretty much any action, they shouldn"t ever stare inside the plane. They do a quick instrument scan and look outside. They glance at their chart and look outside. If they need to change frequency they do it and then look back outside. It"s kind of hard to break the habit of looking outside when you start instrument training.

But most car drivers don"t have the same amount of training and fixate on things inside the car, like the radio or climate controls. TBH, pilots still get fixated on things, it"s just that they usually snap out of it and regain situational awareness before anything bad happens because the skies are pretty spacious. But car drivers don"t have spacious roads. There"s another car right next to you going 75 mph and if you drift out of your lane you"ll cause an accident.

The issue isn"t the design of the buttons at all. That matters to a fighter pilot, but the issue for a car driver is the fact that the screen is even on and the radio is accessible while driving down the road. The real critical safety feature would be disabling the screen while driving, and either locking out controls or only allowing voice control. But people would never buy a car that doesn"t let them fiddle with the radio or stare at their little screen, so the actual safety feature that needs to be implemented won"t happen.

Edit: When I say "fiddle with the radio" I"m including all activities that take place in a car"s center stack- audio, navigation, climate control, etc. I"m also a pilot, have designed tests for avionics upgrades for multiple fighter jets, and own my own plane. I have lamented the introduction of touchscreens into modern avionics at a professional level and the personal level. I own three cars with varying levels of touchscreen invasion. So I"ve thought about the issues surrounding touchscreen quite a bit, and have concluded that the interfaces in a car are so simple that the issue isn"t whether you can operate it without looking, it"s the fact that people aren"t trained to do so.

I’m still glad for what Honda is actually doing, which is not unilaterally removing touch screen controls but instead moving climate control back to physical buttons. These are things a driver ought to be able to operate safely while in motion, and touch controls only ever made them more complicated I think.

And as a student pilot nothing scares me more than touch screen controls. Maybe I spend too much time down low in the thermals but it"s so much easier to hold on to a knob and turn it, while counting clicks, than trying to press a touch screen and hope you hit the right finger sized button the right number of times to change radio frequencies. Different story on heavy planes since they don"t bounce around as much as GA planes but it sucks to fight the fight while trying to maintain control/coordination.

Have you heard of the auto industry doing anything remotely similar on this scale? Instead, they push away much better alternatives offered by Apple and Google for their own proprietary solution no customers asked for.

Aviation very much uses touch screens quite extensively. The difference usually is that more thought is put into when and how to use them; you"re not just replacing all the buttons with a touchscreen and letting some underpaid intern design the interface for it.

Interactive touch screens have become such an integral part of everyday life that they’re almost as likely to be found in the playroom of a preschool-age child as on the factory floor or in the field. And as touch screens become increasingly integrated with consumer and industrial IoT, their demand continues to grow across every market sector.

At Pivot International, we are the global one-source partner helping companies worldwide successfully design, engineer, manufacture, distribute, and deploy the latest in consumer and industrial touch screen technologies and IoT innovations. With more than 50 years of experience, in-house DFM expertise that spans fourteen industries, and 320,000 square feet of tricontinental manufacturing capability (including domestic options), we deliver a smooth, seamless, highly collaborative approach to NPD and successful product launch.

There are five types of touch screen technologies: resistive, capacitative, near-field imaging, infrared, and ultrasound. Each is differentially suited for various consumer and industrial applications. Let’s take a look at each.

Resistive touch screens are the most common industrial touch screen technology. They are constructed of two interfacing glass sheets or specialized films that respond to direct pressure. Traditionally, the glass sheets or films used in this type of touch screen are coated with indium tin oxide (ITO), a transparent conductive material. But this material is increasingly being replaced with more advanced materials, including copper microwires, silver metal mesh, silver nanowires, and graphene.

The switch from ITO to these other materials results from the need to integrate touch functions into the LCD panel rather than manufacturing a transparent touch screen overlay. This makes for a thinner, lighter device with enhanced optical benefits. Because resistive touch screens respond to pressure, they are more reliably responsive to touch than the capacitative versions we’ll discuss below. However, resistive touch screens offer lower resolution image quality than their capacitative counterparts. They are also slower to respond to touch and can register only one pressure point at a time, therefore precluding multi-touch functionality.

Capacitive touch screens were first invented in the 1960s but didn’t appear in the consumer market until the advent of the iPhone. The strength of capacitative technology lies in its instant responsiveness and superior image quality. Capacitive touch screens function on electrical conductivity that alters the screen’s electrical field. Multi-touch functions (think “pinch-to-zoom”) are made possible by triangulating electrical alterations to calculate paired coordinates that “read” the touch location. Unlike resistive touch screens, capacitive touch screens are unresponsive to touch that does not emit an electrical charge. (Which is why it’s almost impossible to use an iPhone while wearing a glove.)

Some capacitive touch screens include a protective layer that protects the display from moisture, extreme temperature, impacts, and solvents, making it suitable for industrial and outdoor applications. For example, our teams at Pivot created a control system for dairy farms with IoT data reporting and touch screen technology that controls milk tank temperatures and wash cycles.

Like capacitative touch screens, near-field imaging touch screens read touch commands by measuring an electrostatic field. The difference is that NFI touch screens feature a corner-configured electrostatic charge, making them more responsive to touch from almost any source. (Even if you’re wearing a glove, NFI devices will instantly register and respond.) A primary advantage of NFI touch screens is that they can withstand extreme field conditions. This makes them a perfect fit for the industrial and security and defense applications that Pivot brings specialized experience in.

Infrared touch screens rely on a grid of LEDs and light-detector photocells placed at opposing positions. The LEDs beam an infrared matrix across the screen that, when “broken” by touch, provides the basis for the device to detect the input location. Infrared touch screens require dozens of components and precision manufacturing. Despite being more expensive to produce, they are often the ideal product solution for applications that include ticketing kiosks, ATMs, office automation, medtech, and even beverage dispensers like the one Pivot created with an integrated processor and customizable I/O system.

Ultrasound technology has enjoyed cross-industry applications for more than a century. But today’s surface acoustic wave touch screens are light years beyond their earlier incarnations and make it possible to make almost any surface responsive to touch. SAW touch screens work by projecting ultrasound waves across the surface of a screen. As the soundwaves are absorbed by whatever comes in contact with the surface, the screen’s controller chip can instantly identify, read, and accurately respond to commands.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

There are a variety of touch technologies available today, with each working in different ways, such as using infrared light, pressure or even sound waves. However, there are two touchscreen technologies that surpass all others - resistive touch and capacitive touch.

There are advantages to both capacitive and resistive touchscreens, and either can be suited for a variety of applications dependent on specific requirements for your market sector.

Resistive touchscreens use pressure as input. Made up of several layers of flexible plastic and glass, the front layer is scratch resistant plastic and the second layer is (usually) glass. These are both coated with conductive material. When someone applies pressure to the panel, the resistance is measured between the two layers highlighting where the point of contact is on the screen.

Some of the benefits of resistive touch panels include the minimal production cost, flexibility when it comes to touch (gloves and styluses can be used) and its durability – strong resistance to water and dust.

In contrast to resistive touchscreens, capacitive touchscreens use the electrical properties of the human body as input. When touched with a finger, a small electrical charge is drawn to the point of contact, which allows the display to detect where it has received an input. The result is a display that can detect lighter touches and with greater accuracy than with a resistive touchscren.

If you want increased screen contrast and clarity, capacitive touch screens are the preferred option over resistive screens, which have more reflections due to their number of layers. Capacitive screens are also far more sensitive and can work with multi-point inputs, known as ‘multi-touch’. However, because of these advantages, they are sometimes less cost-effective than resistive touch panels.

Although capacitive touchscreen technology was invented long before resistive touchscreens, capacitive technology has seen more rapid evolution in recent years. Thanks to consumer electronics, particularly mobile technology, capacitive touchscreens are swiftly improving in both performance and cost.

At GTK, we find ourselves recommending capacitive touchscreens more regularly than resitive ones. Our customers almost always find capacitive touchscreens more pleasant to work with and appreciate the vibrancy of image that cap touch TFTs can produce. With constant advancements in capacitive sensors, including new fine-tuned sensors that work with heavy duty gloves, if we had to pick just one, it would be the capacitive touchscreen.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Why put a large, touchscreen stereo in your dash? Fantastic looks are a great starting point, but there’s so much more you can get from a big screen stereo. You can see all the information you need at a quick glance, letting you get your eyes back on the road faster. You’ll also have expansion options like smartphone integration, navigation, and additional cameras available to you.

But, it’s all about the screen real estate and what it can show you. The large display and touchscreen controls make it easier to do anything on the stereo. Let’s talk about some ways to get the most out of a touchscreen receiver.

With a large screen acting as your receiver"s display, it"s a whole lot easier to read than the single-line displays of traditional car stereos. You can quickly see what’s playing, who’s calling, and where you’re going.

Many of these receivers offer the functionality of Apple CarPlay™ and Android Auto™, which emulate your smartphone experience right on the receiver’s touchscreen display – great for keeping your phone out of your hand.

A rear-view or backup camera can help make your touchscreen stereo a valuable tool for staying safe while backing up and to help avoid accidents. Its wide field of view offers a whole lot more of what’s behind you than using your mirror, including areas that your vehicle"s body blocks from view. Many new stereos also offer multiple camera inputs, so you can incorporate factory cameras or add aftermarket cameras for areas like your side view – all viewable on the touchscreen display.

Are we there yet? Touchscreen stereos with built-in GPS navigation offer incredible convenience and assistance. But if you don"t want to spend the extra money for built-in navigation and future map updates, look for a touchscreen stereo that has Apple CarPlay or Android Auto. Both of these options get your smartphone involved to use navigation apps, such as Waze and Google Maps. They appear beautifully on the stereo"s large display.

In addition to the music and caller info that you can see on the display, many touchscreen receivers let you customize the background and layout. So not only can you make a personal statement on the look in your dash, but you can organize the functions that you use the most.

When you’re looking for that perfect sound, you can dive into a receiver’s tone controls and see them clearly (while parked). We also offer iDatalink Maestro interfaces for many vehicles that can show off vehicle diagnostics in your vehicle, depending on the receiver you choose. It can even include climate controls in some vehicles.

We’ve heard comments from customers who worry that touchscreen receivers are a distracting hindrance rather than a help. And hey, we get it; we’re on the road, too. Here are some keys to using them safely (and maybe some things you didn’t know about): Adjust your screen settings before you drive. In the excitement of installing and turning on a new receiver (which we completely appreciate), some people will hit the road and try to adjust the settings on the fly. Simply put, don’t. In fact, most touchscreen stereos won"t let you access the menus while the car is moving. Before you put your vehicle in gear: Set the display the way you want it. That includes the contrast, backlighting, dimming, and variable color controls. Sure, you can reset them later if you need to…while you’re parked.

Call us with any questions you have about setting up your receiver. When you buy from Crutchfield, you get lifetime tech support, which includes helping you figure out the controls and set up.

There’s usually a one or two button sequence that can disable the display completely and quickly. The audio still works, so your music will keep playing, and navigation apps can still tell you where to go. And it"ll automatically turn back on when you touch it.

Get used to the controls. Many folks have mentioned that there are no “muscle memory” buttons and knobs on touchscreen receivers that can be reached without looking, which is a great point. But many models actually do have handy knobs or easy-to-find toggle buttons for volume control or other important adjustments. Some of the knobs are multi-functional for a variety of settings, not just the volume.

JVC incorporates a feature called "Gesture Control" for simple, quick controls for less distraction. Some receiver makers provide for some simple “no-look” controls on the display itself. For example, JVC’s "Gesture Control" lets you swipe the touchscreen display to the right for track forward, left for track back, and a circular motion to adjust the volume – all with your eyes still on the road.

Keep your steering wheel controls in play. Since you’re probably already familiar with these factory controls, why not use them with a new receiver? We offer steering wheel control (SWC) adapters for a wide variety of vehicles and receivers. In many cases, you can actually program more functions you’d use more often into your controls.

Example: I programmed a “Pause” on my steering wheel controls to simply stop the music without reaching for the screen. It’s great for keeping my eyes on narrow drive-thru lanes.

Take advantage of voice controls like Siri and Google Assistant. While talking to your stereo can seem a little weird at first, they really do help in finding you info on the fly without a lot of distraction. Read more about voice control in the car.

Add a compatible remote control. Many touchscreen receivers work with a trusty handheld remote control. Sometimes it"s included, sometimes it"s optional. For example, once he learned the remote button layout, my Dad loved using the remote to control his stereo without looking at or touching the stereo. This from a person who asked “Why do I need a remote control for a car stereo?”

Know the driving laws in your state. It’s a good idea to reach out to your local governments to see what the rules are governing smartphone and touchscreen display use. Read our article about phone safety in the car.

Regardless of which one you choose, the elegance of a touchscreen receiver makes them fun to use and incredibly handy. Use our handy vehicle selector tool to see which stereos will fit your vehicle. And our Advisors are available by phone or chat to help you choose the right touchscreen receiver for you.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

Touch screens are found everywhere from our smartphones to self-serve kiosks at the airport. Given their many uses, it should come as no surprise that there are several touch monitor types. Each has its advantages and disadvantages and is suited to specific tasks.

That’s right. Long before your precious smartphone entered the market in the late 00s, touch panels had already been an established technology for nearly 4 decades.

It’s quite possible that you’re not clear on exactly what a touch panel is, what the touch panel types are, or how they’re applied in your daily life, beyond that of your smartphone. For that and more, we’re here to help.

Quite simply, touch panels, which are also known as touchscreens or touch monitors, are tools that allow people to operate computers through direct touch. More specifically, via the use of internal sensors, a user’s touch is detected, then translated, into an instructional command that parlays into visible function.

Delving deeper into the technical side of things, touch panels are not as cut-and-dry as they may seem. In fact, the way they sense and react to touch can widely differ based on their inherent designs. As such, there are 4 touch panel types in regular use – Resistive, Optical Imaging, Projected Capacitive, and Infrared. Below, we’ll dig into their specifics, which include their advantages, disadvantages, and real-life product applications.

Resistive touch panels are cost-effective variants that detect commands by way of pressure placed on the screen. This pressure sensitivity is generally limited to single-point touch, with a 20-inch maximum screen, which is fine for many usage cases. These range from styluses to fingertips. As a result, if used correctly, resistive touch panels will remain functional even if a water drop has landed on the screen.

As a result of this versatility, however, many will find that resistive touch panels are less durable than their competitors. Moreover, with its reliance on single-point touch, this touch panel type is not actually capable of multi-touch functionality. Regardless, resistive touch panels are often found in grocery stores, where stylus-based signatures are typically required after credit card purchases.

Some like it hot and some don’t. Infrared touch panels definitely fall into the latter category. By setting up a grid of infrared beams across the panel, which may be up to 150-inches, touch is detected by way of this panel’s disruption.

Although infrared touch panels are durable and support multi-touch functionality, it does possess one potential drawback. Depending on where you sit, literally.

Despite infrared implying heat, infrared touch panels actually perform rather poorly in it, particularly in direct sunlight. In those circumstances, the infrared light beams can be disrupted by the sun’s rays, as opposed to your fingers. As such, be sure to place your infrared touch panel device in an appropriately dark location.

Light, and the disruption thereof, is not just a great way to produce a shadow, but also to design a touch panel type. To take advantage of this principle, optical imaging touch panels are designed to sense touch through infrared cameras and the disruption of light strips. This can be achieved through any input you want, across its 100-inch maximum size, from gloves to bare hands, and beyond.

All in all, optical imaging touch panels are just about the most versatile option the touch-based world can offer. From durability to multi-touch, and universal input prospects, the possibilities may truly be endless. Although its only disadvantage may be its non-compact design, common applications of optical imaging touch panels include certain varieties of interactive whiteboards.

If you identify with the phrase, “go with what you know”, then projected capacitive touch panels are the touch panel type for you. For now, you can guess where you know it from.

By way of their electrical-based touch detection, Projected Capacitive touch panels are known for their high precision and high-speed response times. What’s more is that they possess multi-touch functionality and can be used within small, compact, yet expensive, devices. Due to their underlying technology, it has proven challenging to scale up to larger sizes. Figured it out yet?

Assuming you haven’t, or would like to enjoy the gratified feeling associated with being right, allow us to reveal where you interact with projected capacitive touch panels on a daily basis – Smart Phones! What’s more is that they’re not alone, with tablet computers and GPS devices also utilizing projected capacitive touch screens.

It would be a mistake to assume that the applications of all these touch panel types are limited to that of consumer-level devices, or even those that have been previously mentioned. Really, these touch panel types can be found throughout everyday life and in a variety of industries.

What’s more is that in many of these industries, these touch panel types are used less to market products to consumers, and more to sell solutions to businesses. Whether it be in regards to finance, manufacturing, retail, medicine, or education, there is always a need for touch-based solutions. In conjunction with the so-called ‘Internet-of-things’, these touch-based solutions play a key role in practices related to industry 4.0.

In practice, these solutions largely offer a form of personnel management. In hospitals, stores, or banks, for instance, these touch panel types can be used to answer basic questions, provide product information, or offer directions, based on the user’s needs. When it comes to manufacturing, on the other hand, these solutions enable employee management in the possible form of workplace allocation or attendance tracking.

At the end of the day, touch panels are here to stay. In the four decades since their inception, the level of adoption this technology has experienced is remarkable. They transform how we teach in classrooms and collaborate with colleagues.

Although you may not have been clear on the specific details of each touch panel type, we hope that you are now. This knowledge will absolutely serve you well, particularly if you’re interested in ViewSonic’s selection of touch-based solutions.

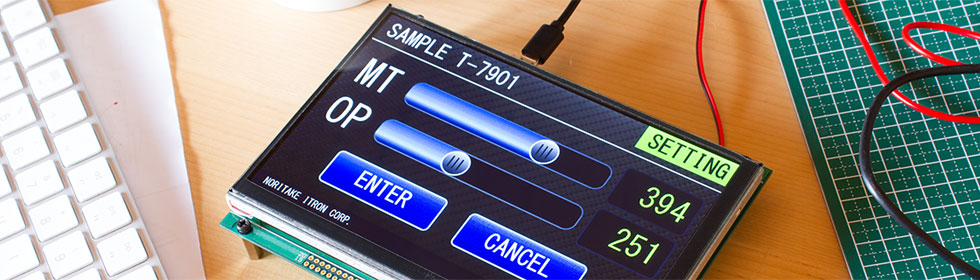

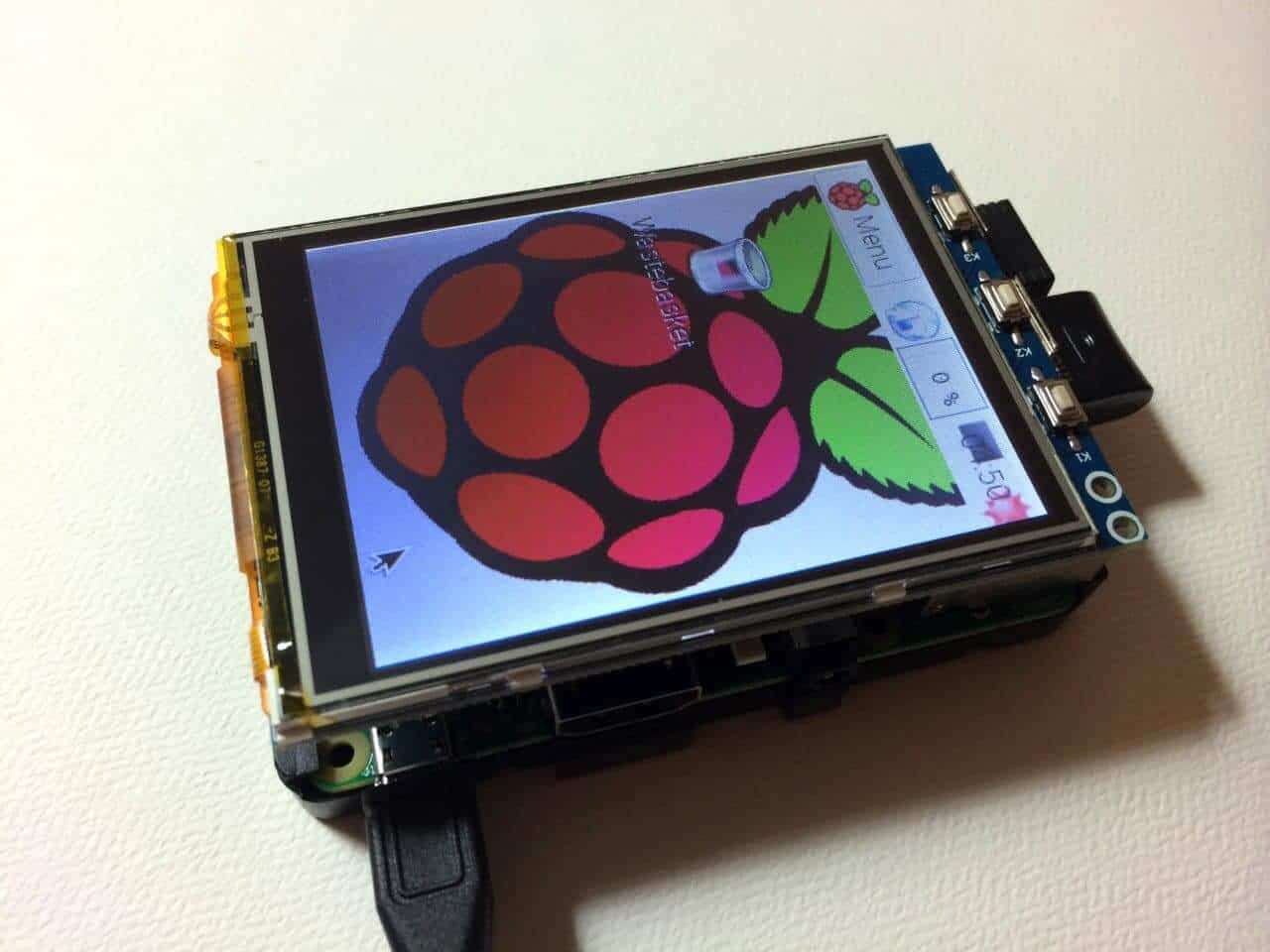

The 7" and 10" Tabletop Touch Sceens bring total system control to your fingertips through a stylish, industrial design. It can be completely portable or affixed to the rechargeable docking station. It"s an ideal int

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey