are lcd touch screen controls better than touch controls in stock

Intuitive: Buttons are very intuitive, you see a button you know it is there to be pressed. Touchscreens need content that makes it clear that the display is touch-sensitive and where to touch.

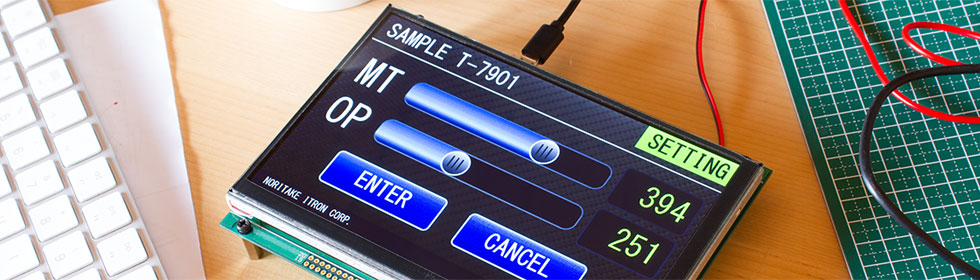

Dynamic function: With a touch screen it is relatively easy to make the button function context sensitive. Buttons can have on-screen descriptions (as with ATM cash machines) but that can lead to alignment issues.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The liquid crystals are made up of a part solid, part liquid substance that can be "twisted" by applying an electrical voltage to them. They block the polarized light when they are off, but reflect red, green, or blue light when activated.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Capacitive surface touch screens work by using the electrical signal from the operator’s finger instead of force to complete the action of the interface.

The key benefits of using a capacitive touch screen is that they are temperature resistant and waterproof. Many home appliances like refrigerators and dishwashers use capacitive touch keypads.

However, while capacitive touch screens can only be used with the user’s finger, Projective Capacitive Touch Screens are the new standard for capacitive touch screens and allow for users to control the device even while wearing gloves.

While technically a type of Capacitive Touch Screen by its name, Projective Capacitive (PCAP) Touch Screens are the most common type and the ones used most on the market today.

PCAP touch screens get their name from the way they “project” a small electric field out past the top layer which senses the user’s input even before they come into contact with the screen. In a way, they function much like a proximity sensor. They have mutual capacitance which supports multi-touch activation.

Because of this, users can control the device with a stylus or while wearing thin surgical gloves, food service gloves, or cotton gloves. They also support excellent clarity with high light quality. They’re a great option for incorporating into outside equipment or machinery, as users don’t need to remove their gloves in a cold or rainy climate, and can still see the screen well in the sun.

They can be used in control panels, industrial automation, consumer devices, and commercial applications in retail, gaming, and signage. They are more costly than resistive touch screens.

Selecting the most suitable type of touch screen for your project can improve device functionality and durability, which can mean a significant increase in customer adoption.

This article highlights the unique advantages and drawbacks of common touch screen technology, to help product design engineers make an informed decision.

Resistive touch is a legacy form of touch screen technology that was broadly popular for many years, but has been replaced by capacitive touch for many applications. Currently, resistive touch has a smaller range of common uses, but can still capably address certain needs.

The core elements of a resistive touch screen are two substrate layers, separated by a gap filled with either air or an inert gas. A flexible film-based substrate is always used for the top layer, while the bottom layers substrate can be either film or glass. A conductive material is applied to the inner-facing sides of the substrate layers, across from the air gap.

When a user applies pressure to the top surface, the film indents and causes the conductive material on the top layer to make an electrical contact with the conductive surface of the bottom layer. This activity creates a difference in voltage that the system registers as a touch. The location of this contact is pinpointed on the X and Y axes, and the touch controller then interprets the action. Because physical force is needed for a resistive touch screen to function, it is similar to a mechanical switch.

Resistive touch screens must be calibrated before they are used to ensure accurate and reliable operation. A user must apply pressure to the four corners of the screen, and sometimes on its center, to calibrate the screen with the rest of the system via a lookup database.

Because resistive touch screens interpret physical pressure as a touch, they are effective in a variety of environments using single touch. Any object capable of applying force to the screen can be used with the same result. For example, in applications where end users wear gloves, resistive touch screens offer reliable single-touch functionality.

Since resistive touch screens area actuated via mechanical force, they continue to function as intended even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens. For example, on single-touch applications within agricultural equipment, boats and underwater machinery.

Besides the functional advantages of resistive touch screens, price is a common reason why OEMs select this option. In projects where cost is a top concern, companies can use this option to realize savings that may not be possible with alternatives.

The configuration of a resistive touch screen removes the possibility of gestures, such as pinching and zooming, or any actions requiring multi-touch functionality. These screens cannot determine the location of a touch if more than one input is present.

In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens were invented before resistive touch screens. However, early iterations of this technology were prone to sensing false touches and creating noise that interfered with other nearby electronics. Due to these limitations, resistive touch screens and other options, like infrared touch screens, dominated the industry.

With more development and refinement of controller ICs, projected capacitive (PCAP) touch screens became the preferred touch technology for a majority of applications. For example, this technology is now commonly used on tablets, laptops and smartphones. Though PCAP stands for “projected capacitive (PCAP) touch”, it’s more commonly referred to as “capacitive touch”.

The foundation of PCAP touch screens is an array of conductors that create an electromagnetic field. As a user touches a PCAP screen, the conductive finger or object pulls or adds charge to that field, changing its strength. A touch controller measures the location of this change and then instructs the system to take a certain action, depending on the type of input received.

For a device with PCAP touch technology to acknowledge an input, users simply need to touch the screen. No physical pressure is required, unlike resistive touch screens.

Another key difference from resistive touch technology is that PCAP screens can accommodate a variety of inputs, with different gestures and more contact points instructing the system to take a variety of actions. PCAP touch can support multi-touch functionality, swipes, pinches, and zoom gestures which aren’t possible with resistive touch screens.

A PCAP touch screen is very similar to a solid state switch, as its mechanism of action requires a change in the electrical field over a control point.

The value that comes with recognizing multiple inputs is a clear and positive differentiator for PCAP touch screens. Users can initiate a variety of commands, providing more functionality in devices where this technology is used. Consider how consumers now expect smartphones, tablets, and interactive laptop screens to support actions requiring two fingers, like pinching and zooming. In more specialized settings, such as multi-player gaming applications, PCAP touch screens can support more than 10 inputs at a single time.

PCAP touch screens do not require initial calibration, offering a simpler experience than resistive touch screens. Additionally, PCAP touch screens are highly accurate even as they support a variety of gestures and subsequent actions by the system.

Since their top layer is usually made of glass, PCAP touch screens offer a high degree of optical transmission and avoid the appearance of haze to users. Additionally, the glass top layerprovides improved durability compared to the film top layer of resistive touch screens – even for the largest sizes of up to 80 inches (and growing).

Operation in environments where a PCAP screen may be exposed to liquids or moisture — including conductive liquids like salt water — is possible through specialized controller algorithms and tuning. PCAP technology has evolved to support medical glove and thick industrial glove operation, as well as passive stylus operation.

PCAP touch screens can be customized with different cover lens materials (soda lime, super glasses, PMMA) based on application specific needs. Cover lenses can be ruggedized with chemical strengthening and substrates that improve impact resistance. This can be especially valuable for public-facing applications, like ATMs, gas pump displays, and industrial applications. Specialized films or coatings – such as AG (anti-glare), AR (anti-reflective), AF (anti-fingerprint) – can be added to the cover lens substrate to improve optical performance.

Unlike resistive touch screens, PCAP touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can’t.

If cost is a top concern for a project, PCAP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

The below table compares the advantages and disadvantages of projected capacitive touch vs resistive touch screens.CharacteristicsPCAP TouchResistive TouchRequires calibrationNoYes

As a leading manufacturer of touch and display products, New Vision Display can help you determine the specific needs of your project and tune your PCAP touchscreen controllers to meet them. Our PRECI-Touch® products are based primarily on PCAP touch technology and can be customized for a variety of applications using a wide range of materials, stacks, and controllers.

Whether your product will be used in a life-saving medical device, the center console of an automobile, or the navigation controls on a yacht – we can deliver an effective solution for your application. To get started on your project, contact our specialists today.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

The present study examined the effects of button size, gap, and the presence of disability on user performance (miss, error, and timing) during a 4-digit entry task. User performance was impacted by button size and presence of disability. On average, user performance improved as button size increased. Overall, the disabled group had more misses and errors than the non-disabled group. In addition, the disabled participants took 2.2 times longer, on average, than the non-disabled participants to complete a four-digit entry task. In general, performance for the non-disabled group plateaued at button size 20mm, with minimal, if any, gains observed with larger button sizes. In comparison, the disabled group demonstrated improvement in misses and errors until the 30mm button size; improvement in timing plateaued at the 25mm button size.

Several existing standards provide guidelines for touch screen interfaces. The ANSI/HFES (2007) standard recommends that the touch areas should be at least 9.5mm square and the gap between touch areas be at least 3.2mm. This standard also notes that button size greater than 22mm square does not result in an improvement in performance (ANSI/HFES, 2007). However, ISO9241-9 suggests that the size of a touch sensitive area should be at least equal to the breadth of the index finger of the 95th 258 percentile male, which is 2.28cm (Greiner, 1991; ISO 9241-9, 2000). Monterey Technologies (1996) recommends the button size to be at least 19.05mm with 6mm button gap between the touch areas. In comparison, the results of the current study found that user performance for the non-disabled group improved for both errors and misses up to 20mm; with a slight reduction in errors occurring at 25mm. While the difference in the percent of trials with errors at 15 mm, 20mm and 25 mm are small (2.8% at both 15 mm and 20mm, and 1.7% at 25 mm), depending on the type of task and application, relatively small improvements in error may be important. For the disabled group, an improvement in errors occurred up until button size 30mm. However, improvements between 25 and 30mm were small (8.8% at 25 mm and 7.5% at 30mm).

In addition, other researchers have explored touch interfaces designs. Previous studies examined the effect of button size on errors, and found that 25mm button size yielded the least number of errors in young, adult users; however percent error was not statistically significant between 20 and 25mm, and 20mm button size was sufficient to achieve optimal performance (Colle and Hiszem, 2004). Also, a larger key size (2.27cm) on a touch screen keyboard had significantly fewer corrected errors than a smaller key size (0.57cm) for college-aged students (Sears et al., 1993). In healthy older users, a 19.05mm button size yielded the least number of errors (Jin et al., 2007). Compared to the results of the current study, non-disabled users demonstrated an improvement in errors until the 25mm button size, with only minimal improvement noted between 20mm to 25mm. However, for the disabled group, errors decreased from 11% to 8.7%, and then to 7.5% as the button size increased from 20, to 25, and then 30mm, respectively. When accounting for performance of users with varying abilities, the suggested button sizes from prior studies were smaller than the 30mm button size indicated in the present study.

In addition to errors, percent trials with misses were also evaluated in the present study. As button size increased, the percent trials with misses decreased. Misses for the non-disabled group plateaued at the 20mm button size, but the disabled group demonstrated a decrease in misses from 19% at 20mm, 12% at 25mm, and 8% at 30mm. Gap size was marginally significant (p=0.067) with the 1 mm gap resulting in fewer misses than the 3 mm gap. Although missed button touches may not result in conditions as serious as button activation error, a missed touch can still impact performance by slowing task completion time.

The findings of this study demonstrated that users with varying operating capabilities perform differently at different button size levels. Touch interface and button designs may be dependent on the touch screen sizes and the type of task that the user performs. From a safety critical standpoint and to accommodate users with varying abilities, touch interfaces for tasks with low error tolerances should have button sizes with at least 30mm to minimize errors. On the other hand, it may not be feasible to implement 30mm size buttons with limited screen real estate. The tradeoff between performance and button size is an important issue for designers and engineers to consider.

In addition to the objective measures of user performance, user preferences of button sizes were also studied. The subjective data of the participants indicated that the majority (84%) of disabled participants preferred button size greater or equal to 20mm, yet, 60% of the non-disabled participants preferred button size smaller or equal to 15mm. Users appeared to favor button sizes that were smaller than the button sizes that yielded optimal user performances in the present study. User preferences were previously examined in healthy college-aged students in a touch screen typing study, and the participants preferred typing with the 2.27cm square buttons (Sears et al., 1993). Another touch interface kiosk study indicated that young, healthy users preferred 20mm square buttons to the smaller sizes (Colle and Hsizem, 2004).

Although we did not evaluate user discomfort, recent research found that users reported greater levels of subjective discomfort with touch screen use than with keyboard use (Shin and Zhu, 2011)). Collectively, information on subjective discomfort, as well as user preference and performance should be used to help guide touch screen design to improve performance of users with varying abilities while minimizing the risk of user discomfort.

A limitation of this study is that participants only performed the digit entry task in a seated posture. It is unknown whether user performance would be affected by performing the task in a standing posture. Moreover, the users performed a simple four-digit entry experimental task. The use of more cognitively challenging tasks may affect our results. Another limitation is that a greater percentage of the non-disabled users self-reported more frequent touch screen usage than the disabled users. While practice trials were provided, this difference in experience may affect the results of this study.

Button size and the presence of disability significantly affect trials with miss, error, and the time to complete tasks on a touch interface. The disabled group had more trials with miss and error, and also spent more time to complete digit entry tasks. While the user performance of the non-disabled group plateaued at a button size of 20mm, the disabled group demonstrated continued improvement as button size increased. Understanding how people (including those with disabilities) interact with touch screens may allow designers and engineers to ultimately improve usability of touch screen technology.

Touch screens are found everywhere from our smartphones to self-serve kiosks at the airport. Given their many uses, it should come as no surprise that there are several touch monitor types. Each has its advantages and disadvantages and is suited to specific tasks.

That’s right. Long before your precious smartphone entered the market in the late 00s, touch panels had already been an established technology for nearly 4 decades.

It’s quite possible that you’re not clear on exactly what a touch panel is, what the touch panel types are, or how they’re applied in your daily life, beyond that of your smartphone. For that and more, we’re here to help.

Quite simply, touch panels, which are also known as touchscreens or touch monitors, are tools that allow people to operate computers through direct touch. More specifically, via the use of internal sensors, a user’s touch is detected, then translated, into an instructional command that parlays into visible function.

Delving deeper into the technical side of things, touch panels are not as cut-and-dry as they may seem. In fact, the way they sense and react to touch can widely differ based on their inherent designs. As such, there are 4 touch panel types in regular use – Resistive, Optical Imaging, Projected Capacitive, and Infrared. Below, we’ll dig into their specifics, which include their advantages, disadvantages, and real-life product applications.

Resistive touch panels are cost-effective variants that detect commands by way of pressure placed on the screen. This pressure sensitivity is generally limited to single-point touch, with a 20-inch maximum screen, which is fine for many usage cases. These range from styluses to fingertips. As a result, if used correctly, resistive touch panels will remain functional even if a water drop has landed on the screen.

As a result of this versatility, however, many will find that resistive touch panels are less durable than their competitors. Moreover, with its reliance on single-point touch, this touch panel type is not actually capable of multi-touch functionality. Regardless, resistive touch panels are often found in grocery stores, where stylus-based signatures are typically required after credit card purchases.

Some like it hot and some don’t. Infrared touch panels definitely fall into the latter category. By setting up a grid of infrared beams across the panel, which may be up to 150-inches, touch is detected by way of this panel’s disruption.

Although infrared touch panels are durable and support multi-touch functionality, it does possess one potential drawback. Depending on where you sit, literally.

Despite infrared implying heat, infrared touch panels actually perform rather poorly in it, particularly in direct sunlight. In those circumstances, the infrared light beams can be disrupted by the sun’s rays, as opposed to your fingers. As such, be sure to place your infrared touch panel device in an appropriately dark location.

Light, and the disruption thereof, is not just a great way to produce a shadow, but also to design a touch panel type. To take advantage of this principle, optical imaging touch panels are designed to sense touch through infrared cameras and the disruption of light strips. This can be achieved through any input you want, across its 100-inch maximum size, from gloves to bare hands, and beyond.

All in all, optical imaging touch panels are just about the most versatile option the touch-based world can offer. From durability to multi-touch, and universal input prospects, the possibilities may truly be endless. Although its only disadvantage may be its non-compact design, common applications of optical imaging touch panels include certain varieties of interactive whiteboards.

If you identify with the phrase, “go with what you know”, then projected capacitive touch panels are the touch panel type for you. For now, you can guess where you know it from.

By way of their electrical-based touch detection, Projected Capacitive touch panels are known for their high precision and high-speed response times. What’s more is that they possess multi-touch functionality and can be used within small, compact, yet expensive, devices. Due to their underlying technology, it has proven challenging to scale up to larger sizes. Figured it out yet?

Assuming you haven’t, or would like to enjoy the gratified feeling associated with being right, allow us to reveal where you interact with projected capacitive touch panels on a daily basis – Smart Phones! What’s more is that they’re not alone, with tablet computers and GPS devices also utilizing projected capacitive touch screens.

It would be a mistake to assume that the applications of all these touch panel types are limited to that of consumer-level devices, or even those that have been previously mentioned. Really, these touch panel types can be found throughout everyday life and in a variety of industries.

What’s more is that in many of these industries, these touch panel types are used less to market products to consumers, and more to sell solutions to businesses. Whether it be in regards to finance, manufacturing, retail, medicine, or education, there is always a need for touch-based solutions. In conjunction with the so-called ‘Internet-of-things’, these touch-based solutions play a key role in practices related to industry 4.0.

In practice, these solutions largely offer a form of personnel management. In hospitals, stores, or banks, for instance, these touch panel types can be used to answer basic questions, provide product information, or offer directions, based on the user’s needs. When it comes to manufacturing, on the other hand, these solutions enable employee management in the possible form of workplace allocation or attendance tracking.

At the end of the day, touch panels are here to stay. In the four decades since their inception, the level of adoption this technology has experienced is remarkable. They transform how we teach in classrooms and collaborate with colleagues.

Although you may not have been clear on the specific details of each touch panel type, we hope that you are now. This knowledge will absolutely serve you well, particularly if you’re interested in ViewSonic’s selection of touch-based solutions.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

Touchscreen, controller, controller cable and driver software are required. In addition, a host computer in which the driver software can be installed and a monitor on which the touch screen can be mounted are necessary.

Standard touch screens are always in stock and prompt delivery is our policy. *Be advised, however, that in the unlikely event that stocks are low, delivery may be delayed.

DMC offers single-touch and multi-touch types. Please check "Search by Method & Type" in "PRODUCT" on the menu for details on the basic structure of each type.

DMC offers single-touch and multi-touch types. Please check "Search by Method & Type" in "PRODUCT" on the menu for details on the basic structure of each type.

4- and 5-wire resistive single-touch type can detect one touched point only. When two points are touched at the same time, the middle point is detected.

DMC offers single-touch and multi-touch types. Please check "Search by Method & Type" in "PRODUCT" on the menu for details on the basic structure of each type.

Yes, you can operate the MTR series with pens and gloves, which makes these suitable for FA and medical devices, and environments where it is hard to input data with bare hands.

Yes, DMC touch screens can be adjusted to the environment. We can make proposals for materials and glove thickness depending on customer needs and use environment.

It’s well known that keyboards, mice and other pointing devices are impractical in certain environments. They are fragile, vulnerable to abuse, susceptible to liquid and dust contamination, and contribute to repetitive-motion injuries.

Touch screens offer ease of use, speed, accuracy, and negate the need to become proficient with a handheld device. General Digital offers the option of equipping your LCD monitor with a variety of touch technologies, such as:

In 1977, we created the world’s first touch responsive industrial terminal, the VuePoint™. It didn’t have a true touch screen; rather, the VuePoint was equipped with a circuit board onto which infrared LEDs were mounted. The LEDs were arranged to form a 12 x 40 grid and when the screen was touched, the infrared beams were broken, indicating the touch location to the terminal. Thus, an operator could control a system right at the terminal.

As touch screen technology evolved (along with monitor technology), we incorporated various touch panels into our LCD monitors, starting with our SlimLine™ series of flip-up LCD monitors. Over time and based on demand, our Saber RackMount, PanelMount and Standalone Series became the next logical candidates for touch integration. This was due to increased use of flat panel technology in human-machine interface applications.

Featuring pure glass construction, Surface Acoustic Wave (SAW) touch screens will almost never physically “wear out” due to a superior scratch-resistant coating. Excellent light transmission ensures that the image clarity of the display remains sharp and vibrant. The stable, “drift-free” operation means that the touch response is always accurate. They work well with a finger, gloved hand or a soft stylus. And SAW touch screens have a sensitive touch response—they recognize the touch location and the amount of pressure applied.

Being an all-glass design, light transmission of surface capacitive touch screens is improved, when compared to resistive touch screens. This improves display viewability and reduces eye fatigue. Featuring a scratch-resistant top coat, durability in heavy-use environments is easily maintained. This type of touch screen is ideally suited for rugged, industrial or military applications.

Infrared touch technology doesn’t rely on an overlay or a substrate to register a touch, so it cannot physically “wear out,” thus ensuring a long product life cycle. Possessing superior optical performance and excellent gasket-sealing properties, an infrared touch screen is ideal for harsh industrial environments and outdoor kiosks. They work with a finger, gloved hand, stylus, and most any object wider than 1/10". They adjust to changing light conditions, even direct sunlight. And they benefit from stable, no-drift calibration performance.

Working in tandem, two optical sensors track the movement of an object close to the surface by detecting the interruption of the touch screen’s infrared light source, which is emitted in a plane across the display surface and can be either active (infrared LED) or passive (special reflective surfaces).

Optical touch screens use a controller board that receives signals from the optical sensors, then compensates for optical distortions and triangulates the position of the touching object with extreme accuracy.

The infrared light source and optical sensors of the touch screen are synchronized using a sophisticated algorithm that also reduces the effect of ambient light, thus creating a very clear, accurate touch selection.

Developed specifically for interactive digital signage applications, Dispersive Signal Technology determines a touch point by measuring the mechanical energy (bending waves) within a substrate created by the pressure of a finger or stylus. As these bending waves radiate away from the touch location, the signal spreads out over time due to the phenomena of dispersion. The “smeared” signals are then interpreted by a complex set of algorithms to precisely pinpoint the exact touch location on the screen.

DST is a passive technology, waiting for a signal created by a touch impact. Therefore, contaminants such as dirt, grease, and other solids can accumulate on the surface and edges of the display screen without significantly affecting touch responsiveness. In addition, surface damage, such as scratches, has no significant impact on touch performance.

The sophisticated and optimized controller that continuously monitors for a touch impact is the fastest and most responsive technology available for large format displays, offering greater than 99% touch location accuracy.

General Digital’s Sales Engineers are quite knowledgeable at determining what will best suit your particular application. Contact us at 800.952.2535 today and we will be happy to take the time to understand your needs and make our recommendations.

The touch screen Status / Control component provides the connection between the physical touch screen and the Q-SYS Designer User Control Interface (UCI). In order to make the connection, you must specify the hardware"s hostname, network redundancy status, and assign a UCI. Once the physical hardware is identified, the touch screen component provides the hardware status.

When the ID / Identify button, in the Q-SYS Designer Status component, or the Configurator"s Network Configuration for the hardware, or on the physical hardware is pressed, the ID buttons in the Configurator and Status component flash, and the LCD on the physical Hardware flashes to indicate the association between the three.

Unknown: This status appears during a Core reboot (for example, during a firmware update), or when a design is being uploaded to the Core and before it has started running.

When this control is activated, the keypad that displays when you touch a numeric-type control (Gain knob, Fader, Time, and so on) is disabled. The keypad does not display when a numeric-type control is touched.

Identifies the Touchscreen component in Q-SYS Designer, enabling the connection between the design and the physical Touchscreen. This name should be the same as the Touchscreen Device Name in the Configurator. Click in the Name property and type the Name.

TSC-7t only: If "Is Network Redundant" is set to Yes, the "USB Audio Endpoints" for the selected TSC-7t are not available. If the "USB Audio Endpoints" Speakerphone or Soundcard is set to Yes, the "Is Network Redundant" property is not available.

Indicates that this virtual component can be paired with the same type of hardware without changing the network id of the hardware, or the name of this component. Refer to the Q-SYS Core Manager Dynamic Pairing topic for more information.

Select the orientation to match the touchscreen physical installation. To prevent the need of reinstalling the unit, you can select one of the "flipped" orientations.

Note:When installing a touchscreen in portrait orientation, the Orientation property in the touchscreen Status/Control component and the User Control Interface Properties must both be set to "Portrait".

An infrared touchscreen uses the same magic-eye technology that Tom Cruise had to dodge in the movie Mission Impossible. When your fingers move up close, they break invisible beams that pass over the surface of the screen between LEDs on one side and photocells on the other.

A surface-acoustic wave screen is a bit like an infrared screen, but your finger interrupts high-frequency sound beams rippling over the surface instead of invisible light beams.

With a near-field imaging screen, small voltages are applied at the corners, producing an electric field on the surface. Your finger alters the field as it approaches.

Drawing on a screen with a light pen back in 1973. Although you can"t see it from this photo, the light pen is actually connected to the computer by a long electric cable. Photo by courtesy of NASA Ames Research Center (NASA-ARC).

Photo: Touchscreens are widely used in outdoor applications, such as ticket machines at railroad stations and bank ATMs ("cashpoint" machines). Unlike keyboards, they have no moving parts so they"re robust: safe, vandal-proof, and weatherproof.

Photo: Look, no keyboard! The Sony ebook Reader features an infrared touchscreen (described in more detail below). That eliminates the need for a separate keyboard and allows the gadget to be smaller, more portable, and more reliable. You press the screen to turn pages and create bookmarks, and you can use a pop-up on-screen keyboard to make notes in the books you"re reading.

but they"re very useful where pointing and dragging makes more sense than typing and clicking. This photo shows a US Navy system called DSIMS (Deployable Ship Integration Multitouch System), used for training people in managing the movements of planes and other equipment onboard aircraft carriers. You simply click a plane and drag it where you want it to move to on the flight deck.

that touch technologies would feature prominently in future versions of the Windows operating system—potentially making computer mice and keyboards obsolete. Four years later, it unveiled its Surface range of

Though most of us happily swipe away at our smartphones and tablets every day of our lives, when it comes to work, we"re still largely locked into our old-style desktop computers and operating systems, and the old ways of using them—namely keyboards and mice. In other words, it"s important to recognize that touch technology makes more sense for some applications than others. It"s great to point and click on a smartphone app when you"re doing something as simple as ordering a pizza or checking your bank balance, but if you want to edit an essay, write complex computer code, debug a broken website, or anything that requires quite a lot of fiddly input, touchscreen interfaces can slow you down and frustrate you: they"re just too clumsy and imprecise. Most of us who write a lot will find an ordinary computer keyboard far quicker and more accurate than the pop-up keyboards on tablets and smartphones—and it"s telling that so many people find the need to improve their phones using plug-in keyboards. Rather than trying to be all things to all people, touchscreen devices need to be optimized for those applications where they make most sense. Keyboards, mice, pen tablets, joysticks, speech recognition, and other forms of input will continue to work happily alongside them for many years to come.

A touch screen is a display device that allows users to interact with a computer using their finger or stylus. They"re a useful alternative to a mouse or keyboard for navigating a GUI (graphical user interface). Touch screens are used on various devices, such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks. Some touch screens use a grid of infrared beams to sense the presence of a finger instead of utilizing touch-sensitive input.

The idea of a touch screen was first described and published by E.A. Johnson in 1965. In the early 1970s, CERN engineers Frank Beck and Bent Stumpe developed the first touch screen. The physical product was first created and utilized in 1973. The first resistive touch screen was developed by George Samuel Hurst in 1975 but wasn"t produced and used until 1982.

Today, all PCs support the ability to have a touch screen, and most laptop computers allow users running Microsoft Windows 10 to use a touch screen. Also, many all-in-one computers are capable of using a touch screen. Computer manufacturers with touch screen products include Acer, Dell, HP, Lenovo, Microsoft, and other PC manufacturers.

There are also some high-end Google Chromebooks with touch screens. However, to help keep the costs lower, many Chromebooks do not have touch screens.

To help keep costs lower, not all computers and laptops come with a touch screen. If a touch screen interests you, make sure that it"s mentioned in the product specifications. If it"s not listed, the computer likely does not have a touch screen.

If your laptop screen is not touch-capable, there is no way to change the screen to be a touch screen. The laptop must come with a touch screen when originally purchased to have that functionality. When purchasing a laptop, and you want touch screen functionality, check if it includes a touch screen before buying.

If your desktop computer monitor is not touch-capable, there is no way to change the monitor to be a touch screen. You need to purchase a new monitor that includes touch functionality. Before purchasing a new monitor, verify the operating system on your computer also supports a touch screen.

Tap - A single touch or tap on the screen with a finger opens an app or selects an object. Compared to a traditional computer, a tap is the same as clicking with a mouse.

Double-tap - A double-tap can have different functions depending on where it is utilized. For example, double-tapping the screen zooms the view centered at the tap location in a browser. Double-tapping in a text editor selects a word or section of words.

Touch and hold - Pressing and holding your finger to a touch screen selects or highlights an object. For example, you could touch and hold an icon and drag it somewhere else on the screen. See our long press page for further information on this term.

Drag - Pressing and holding your finger on a movable object, such as an icon, you can drag your finger to "pull" the object to a different location. The same action, used with text, lets you highlight text. Lift your finger when you are done moving or highlighting.

Swipe - Swiping your finger across the screen scrolls in a certain direction or change pages. For example, pressing your finger at the bottom of the screen and quickly moving it up (swiping) scrolls the screen down. See our swipe page for further information and related links.

Pinch - Placing two fingers on the screen in different spots and then pinching them together zooms in. Pinching your fingers together and then moving them away from each other zooms out on the screen. See our pinch-to-zoom page for further information on this term.

Any computer device (including a touch screen) that takes input from the person operating the device is considered an input device. The way you use your finger on a touch screen is very similar to how you use a computer mouse on a desktop computer.

Technically speaking, a touch screen is an input/output device. Not only is it capable of accepting input, but it also displays the output from the computer.

One of the most significant differences between a mouse and a touch screen is the ability to hover. Almost all touch screens can only detect input when your finger is in direct contact with the screen. However, a computer mouse uses a cursor that allows the user to view the information by moving the pointer over an object but not clicking it. For example, this link to Computer Hope shows the text "Visit the Computer Hope Page" when hovered over using a computer mouse. However, a user with a touch screen cannot see this text because it opens the link if they place their finger on the link.

Some web pages and apps may simulate the hover feature by making the first tap do the hover feature and the second tap open the link or app. Also, some Apple devices use Force Touch, which offers features similar to hovering.

Not all touch screens are the same. Different technologies are used to allow a user to interact with a screen. Some technologies may work with only your finger, while others may allow other tools, like a stylus. Below is a brief description of each of these technologies.

A capacitive touch screen is coated with a special material that stores an electrical charge monitored by circuits at each corner of the screen. When you touch a capacitive touch screen, a small amount of the electrical charge is drawn from the point of contact to indicate where you touched the screen.

To use a capacitive screen, you must use your bare finger or a specially designed capacitive stylus. Most users experience this type of screen technology when attempting to use a smartphone touch screen while wearing gloves and cannot do anything.

A resistive touch screen is coated with a metallic electrically conductive and resistive layer that detects the pressure of your finger or another object. This technology is often a more affordable solution than capacitive but can be damaged by sharp objects touching the screen.

A SAW (surface acoustic wave) or surface wave touch screen sends ultrasonic waves and detects when the screen is touched by registering changes in the waves. This technology is more advanced than the other two but does not work with hard materials and can be affected by outside elements.

Infrared touch screens utilize a matrix of infrared beams transmitted by LEDs with a phototransistor receiving end. The infrared beam is blocked when a finger or other object is near the display. That interruption gives the device input to where your finger or another object is positioned.

Touch screens utilize a virtual keyboard to input letters and numbers that allow the user to tap the virtual keys with their finger. Also, devices like smartphones and tablets have voice recognition that inputs information into the device.

In all forms of writing, touch screen and touchscreen are both valid spellings. If used as an adjective, the word may be hyphenated, e.g., "touch-screen devices."

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey