lcd panel t con board free sample

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

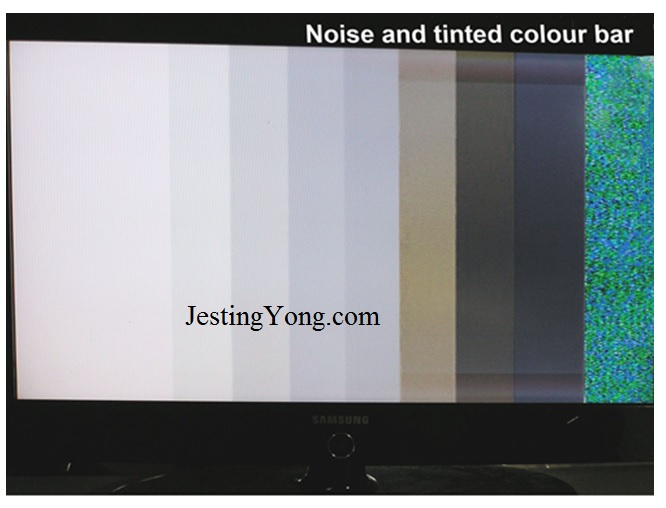

Color problems, like a “negative image” look or a gradual shift to white or dark “low contrast” picture, can be fixed on multiple TV models by replacing the T-Con board (for “timing controller”).

The following guide will show you an example picture failure which could hint to a problem with the T-Con board, and focus on the replacement of such board in a Samsung LE37A659 TV. It has been known to work with many other TV models.

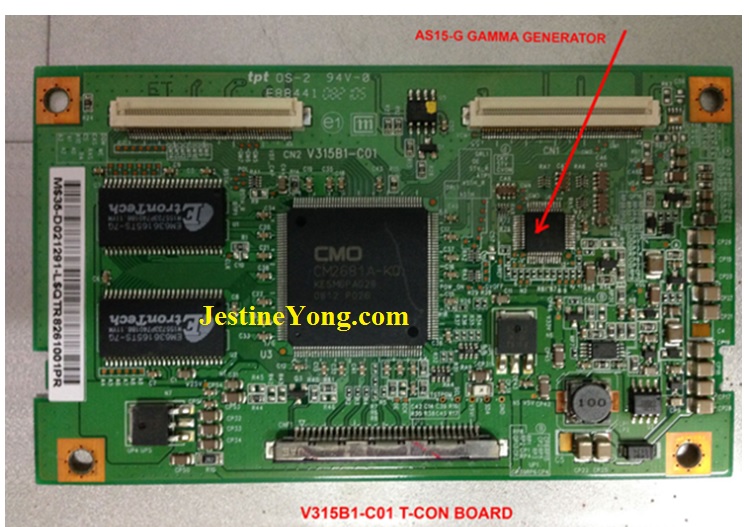

The guide also links to another guide which shows you how to replace the gamma controller chip on the T-Con board itself (the AS15-F IC chip), but you should only try this if you have lots of experience with SMD soldering.

This video is related to LCD LED TV repair.#tconboard #dctodc #gamma #sequenceOur some other playlist -T Con Board Repair voltages (Panel Repair)-https://www...

TV Boards, Parts & Components└ TV, Video & Audio Parts└ TV, Video & Home Audio└ Consumer ElectronicsAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Different displays use different types of TCONs. In this article we will be talking about TCONs for the IT market: LCD (Liquid Crystal Display) notebook PCs and monitors.

An LCD panel has millions of Red, Green, and Blue (RGB) liquid crystals that are used to block a white backlight when electrical voltage is applied to them. High voltage signals to each individual pixel control how much of the backlight to block. A white display means nothing is being blocked. A black display means all three colors are blocked at maximum effort.

The strength of the filtering determines the Contrast Ratio. The brightness of the backlight determines the intensity of the display. Varying levels of filtering produce the different colors. The speed of the voltage adjustment affects the pixel response time.

TCONS direct the high voltage driver chips that move the color filters and are usually found on a circuit board that sits below the glass panel (Fig. 1).

eDP was developed to be used specifically in embedded display applications such as notebooks, noteback PCs, all-in-one PCs. It is based on VESA DisplayPort ™ standard, same electrical interface and can share the same video port on the GPU (Fig. 2).

eDP connections are fast, use few wires, and are flexible for size, bandwidth and adding features eDP provides all panel connections in one plug, including power, data, and control signals. This is Analogix’s specialty.

ARM processors usually use MIPI connections. MIPI connections require more wires but are lower power than eDP. They usually only work for screen sizes up to 10 inches

While the GPU is responsible for transforming mathematical equations into individual pixels and frames, a TCON takes the individual frames generated by the GPU, corrects for color and brightness, then sends out parts of the image to each individual driver at the panel’s specific timing.

The human eye has an incredible dynamic range. That means we can see both very dark images and very bright images, at the same time. However, neither camera sensors nor display panels can display that range. Your camera generates HDR images by using images from multiple exposures to combine the brightest and darkest parts of the picture. This increases the contrast (dynamic range) between light and dark, pulling out details from darkened or washed out areas.

HDR accurately maps real world color and luminance to a display panel. VESA DisplayHDR™ standard specifies HDR quality, including luminance, color gamut, bit depth, and rise time.

Display panels have difficulty displaying a wide range of brightness. Normal sunlight can reach 10,000 nits, but the backlight on most notebooks today is around 250 nits

VESA DisplayHDR requires the panel to meet minimum brightness, contrast, and color. No panel can reach 10,000nits of natural light. The brightest a 250nit notebook panel can produce is 250nits and any image above 250nits is washed out. Also, no details from 250 nits to 10,000nits can be seen.

The HDR400 specification requires 1000:1 contrast ratio. This is difficult because even at full voltage, the liquid crystals cannot block 100% of the backlight. That is why you always know when your TV is on, even if there is nothing on the screen.

The HDR400 specifications require a dimmable backlight which helps with both producing darker blacks and lowering the power consumption. Tone mapping is used to map the whole range of 10,000 nits down to what the panel can handle, so the details can be seen. Tone mapping does not increase the brightness of the panel; it only makes the details visible.

VESA DisplayHDR600 Requires local dimming. No LCD panel can reach the VESA DisplayHDR600 requirement of 6000:1 contrast ratio. However, this can be overcome with local dimming.

For example, a 750:1 contrast panel requires 8 different backlight power settings to reach 6000:1 contrast ratio. However, unless there are thousands of separate regions, local dimming always produces halos around the bright areas. In order to reduce the halos, the following are recommended:

Limit the adjacent segment difference (in TCON). This reduces contrast ratio and power savings for reduced halo. It’s recommended cutting backlight power by half on each adjacent segment;

Monitors can use a direct backlight with many regions. An extra layer of liquid crystal can be used to dim the backlight at a specific location but this often results in a panel that is too thick for a notebook.

Notebook backlights use LEDs on the edge of the panel to reduce panel thickness. These can be on 1 side, 2 sides, or all 4 sides. Each edge adds to cost and bezel size.

Global Dimming Power Savings - Figure 6 shows a 15.6” UHD panel with 400nit maximum brightness. Figure 7 shows a comparison of backlight power consumption values between 400nit, 50nit and, respectively 5nit.

The primary goal of color management is to obtain a good match across color devices; for example, the colors of one frame of a video should appear the same on a computer LCD monitor, on a TV screen, and as a printed poster. Color management helps to achieve the same appearance on all of these devices, provided the devices are capable of delivering the needed color intensities. Color management cannot guarantee identical color reproduction, as this is rarely possible, but it can at least give more control over any changes which may occur.

A PC in HDR and SDR modes use different color gamut but the same screen. Dual-panel phones and notebooks need the color of the two sides to match perfectly. Graphic artists for web sites, movies, video games, etc., need to know what they are creating looks the same on their screen as on their customers’ screens.

As panels improve, the color space of new panels may exceed the color space from Windows. This results in displays which look oversaturated. There is a trend towards low blue light or “night shift” panels, while still retaining color accuracy for the other colors. Today, low blue light panels are created by measuring each individual panel, then hoping that the yield is high enough.

Analogix’s Advanced Color Blocking (ACB) technology is used to create consistent image quality across different panels and change color space for different usage modes (Fig. 8). It allows for 3D color gamut rotation in the optical color domain rather than the RGB domain and color space change on the fly, such as color mapping of BT.2020 source to sRGB or DCI-P3 panels. It includes LUT shadow registers and hardware transition calculations (to smooth changes).

Color conversion in the TCON can dynamically and continuously adjust the incoming signal from the GPU for a low blue light color space. This way, no individual panel measurement is needed and yields should increase. While this can also be done by the GPU itself, that takes GPU bandwidth and 500x more power.

Panel Self-Refresh (PSR) – frame buffer in a TCON can maintain a display image without receiving video data from the CPU. For a still image, this allows the GPU to enter a low-power state and the eDP main link to turn off. Allowing the GPU to power down between display updates will save significant power and extend battery life.

Except when watching a movie or playing a game, there are many times when the video does not change for multiple frames. PSR saves power for full-screen images.

Panel Self-Refresh with Selective Update (PSR2) is a superset of the panel self-refresh feature and it allows the transmission of modified areas within a video frame with obvious benefits when watching a movie or playing a game. PSR2 identifies when only a portion of the screen is static, which is a selective update. In PSR2, when the full screen is static, the refresh rate can be lowered for further power savings as done by Intel Low Refresh Rate (LRR). Intel LRR lowers the refresh rate by changing pixel clock or by changing vertical blank depending on the scenario such as idle, playing video, browsing, etc. All Analogix TCONs support Intel LRR.

Displays are refreshed at a frequency of 60Hz. However, GPUs refresh displays whenever they are ready. This technology synchronizes GPU output with display refresh by dynamically changing the refresh rate without needing any mode change with a focus on reducing stuttering, tearing, and input lag.

Dynamic overdrive changes the overdrive parameters depending on the situation. Overdrive and PSR can share the same frame buffer. This enhances the experience of all kinds of applications including gaming and video editing.

In-Cell Touch embeds the touch function in the display itself, the panel including all the touch sensors, controllers, and needed processing. This simplifies the production process and reduces weight and reflection by removing the cover glass. It also allows for thinner bezels as there is no need for daughter cards and no separate wires for touch, as well as lighter devices as the cover glass is removed.

Analogix has pioneered the in-cell touch notebook panel TCONs. About 15% of notebooks support touch and we expect the touch attach rate to increase as more active pen support is introduced.

The term ‘flat screen’ applies to a wide range of TV types, from LCDs to the latest 4K and Smart models. A flat screen means the TV’s screen surface is flat rather than convex like older models. There can be several different types of flat-screen TVs, from older LCD to the newest Smart and 4K TVs. The type impacts the repair costs because more advanced and expensive TVs have more costly components to replace or fix. In addition, some TV repairs may not always be possible on that type. For example, it is not possible to replace the screen on a plasma TV if it cracks and begins to leak. The table below shows common television types and average repair costs for each:

Repairs for LCD TVs cost between $60 and $400. LCD televisions are one of the most popular options on the market, available in a wide range of sizes and styles. They use an LCD (liquid crystal display) with backlights to produce images. The backlights, screen, and other components may get damaged over time and need repairing.

LED TV repairs range from $60 to $400, depending on the scale of the problem. LED televisions are a specific type of LCD TV that use LED backlights to illuminate the liquid crystal display. These TVs usually produce more colorful and vibrant images and are more energy-efficient, but the LED backlights may need to be repaired or replaced over time.

4K TV repairs range from $100 to $275. A 4K television provides some of the clearest and most detailed images because of the very high resolution of its screen, providing more engaging viewing experiences. There are different types of 4K TVs, including some that use LED and others that use OLED. Basically, a television is considered 4K if it has ultra high definition. These models can be expensive to purchase and repair, but in many cases, repairs may not be possible on these units. So, their overall repair costs may be lower simply because some repairs may not be offered.

OLED TV repairs cost between $100 and $400 on average. They are the next step up from a standard LED TV, with OLED standing for organic light-emitting diodes. OLED televisions can achieve deeper blacks and higher contrast compared to standard LED screens. However, they can be very expensive to purchase and repair.

Plasma TV repairs average $100 to $400. These televisions are made up of pixels filled with gas that light up when an electrical current is applied. They are less popular today, and most companies have stopped making them. But they can still be found in many homes and are subject to problems like screen burn and distorted colors. While some repairs on these TVs are possible, many issues cannot be repaired due to their design.

Smart TV repairs cost between $100 and $400. These TVs have Smart technology and connect with your home’s WiFi network to download updates and access apps and the internet. They are more advanced than other TVs but still have various components that can break and require repairs. Many Smart TVs can have basic components. So even though they may be more expensive to purchase, they are not necessarily the most expensive to repair. That comes down to how the television is made and what makes it Smart.

TVs are made up of various parts and components, all working together to produce lights, colors, pictures, and sounds for your entertainment. Over time, accidents may happen that damage these parts, or they might just wear down over the years through repeated use. The table below shows common TV repairs and the costs for each.

HDMI port repairs for a TV costs between $60 and $250. Sometimes, HDMI ports fall out of position and may simply need to be repositioned. In other cases, one might stop working due to a more serious fault and require technical repair work.

TV speaker repairs range from $75 to $250, depending on the type and damage done to the speaker. Faulty speakers may simply need rewiring or minor adjustments, or they could need to be cleaned or replaced, so the exact costs and amount of work vary.

Backlight repairs average $100 to $150. The backlight is what illuminates the display of your television, providing the brightness and color. It may be in the form of LED light strips or fluorescent lights, depending on which television type you have. If these lights develop a problem, a repairman must open it up and make adjustments to get them functioning again.

TV inverter repairs cost between $100 and $200 each. The inverter powers up the backlights for your television, and they can stop working if their capacitors break down. Repairs are made by fitting new capacitors in place.

Water damage repairs on a TV range from $150 to $400. In some cases, if too much water has gotten into the TV, it may be beyond repair. In less severe situations, a repairman will take the television apart, dry it out, and put it back together successfully, repairing any damaged components.

TV screen repairs cost between $200 and $400, but in many cases, repairing the screen is not possible. Since the screen is usually the most expensive part of the television and one of the most sensitive to impacts and other damage, an expert may advise you to simply buy a new television instead of having it repaired. It is worth getting a diagnosis if the screen issue is not too severe because issues like flashing pixels or distorted colors may be fixable.

TV panel repairs average $200 to $400 in some cases, but some panels cannot be repaired. For this reason, many companies do not offer panel repair. So if your television gets a crack in the panel, you may be better off buying a new unit instead.

Power board repairs cost between $200 and $400. The power supply board allows it to turn on and function, and if it breaks down in any way, it may simply stop turning on. Often, a repairman can replace some of the capacitors and make other adjustments to repair a faulty board, rather than having to replace it entirely.

In some cases, your TV components may not be able to be repaired, or it might be more cost-effective to replace them with new ones. The repair price includes the cost of new parts, plus the labor required to fit them into place and remove the broken components. While some components can be replaced, they may be extremely expensive or cost-prohibitive to do so. This is mainly in the case of panels and screens because they often contain too many parts to replace on their own. The table below shows average costs for a variety of common replacements:

Fuse replacement in a TV costs between $60 and $150 and is one of the easier replacement jobs for a repairman. Glass and ceramic fuses on your TV’s power supply board may blow in certain situations and need replacing. To replace a fuse, the repairman opens the TV to access the power panel and swaps out the fuse.

Replacing a TV capacitor is inexpensive, starting at $60 up to $200. If more than one capacitor needs replacing, it is usually less expensive to replace the entire board. Capacitors cannot be repaired, so replacement is the only option.

TV bulb replacement costs average $75 to $200. Bulbs are usually found only in older models of LCD TVs or projection TVs. They are used to illuminate the display so that the picture can be seen. Bulbs are relatively easy to replace, but the material costs are a little higher with bulbs when compared to other components, leading to varied replacement prices from model to model.

TV backlight replacements cost between $100 and $200 on average, depending on the television size and scale and the type and number of lights required. If you have LED lights, parts may be more expensive, leading to higher total costs. Usually when backlight problems occur, the bulbs or diodes are dead and need to be replaced.

Picture tube replacements range from $200 to $300 on average. Picture tubes, also known as cathode ray tubes or CRTs, are only used in older TVs. So, this is not a replacement job you need to worry about with an LED or LCD TV.

HDMI port replacement on a TV costs between $200 and $300. Damaged or broken ports may simply stop working or be incompatible with certain HDMI cables. In this case, a new port must be fitted and connected to the circuit board, requiring a couple of hours of labor.

TV motherboard replacements average $200 to $400. Often when a problem occurs with a motherboard, it needs to be completely replaced rather than repaired. The motherboard controls the TV’s functions and features, and a broken motherboard makes your television completely unusable.

TV screen replacement costs at least $400 to $1,000 and often much more. The screen is the most expensive part of a TV. So usually, the cost of replacing it is higher than just buying a new unit. In some cases, this is because the screen cannot be replaced without also replacing most of the other components, particularly for TVs like LED, LCD, or plasma. Most professional repair companies do not offer screen or panel replacement as a service.

TV panel replacement costs a minimum of $400 to $5,000 and often a lot more on some of the high-end 4K and Smart screen displays. Because the cost of a replacement panel is so high, it is usually more cost-effective to simply purchase a new television. Like the screen, this is due to the number of components involved. Therefore, most repair places will not offer panel replacement as a service.

You might not know exactly which part of your TV is broken or damaged at first. The symptoms of a broken television vary from vertical colored lines across the screen to audio issues, power problems, and even situations where the television starts normally but then turns itself off. For this reason, most repairs start with a diagnostic so that the problem can be found and a plan made for repair. For some repairs to be made, the part will need to be replaced, while in other cases, repair or replacement of that part may not be possible. The table below shows common problems and average repair costs for each.

Repairing a TV that will not turn on costs between $60 and $400 because there are many potential causes. It might be something as simple as a blown fuse, which can be replaced quite cheaply. Or, it could be a motherboard or power supply issue, which is more costly to fix.

Damaged cables on your TV can be repaired for between $75 and $200 in most cases. Over time, cables can get frayed, twisted, or broken, but professionals can cut away the damaged parts, add in new connectors and repair the damage, or simply replace the bad cables with new ones.

Expect to pay between $75 and $400 to repair a television with no sound. There are various reasons why your TV’s sound stopped working. It is most likely a fault with a speaker, which can be repaired or replaced. Or, it could be a deeper issue associated with the motherboard, which may also need fixing or replacing.

Repairs for this problem cost between $100 and $200. If your TV’s picture appears for a moment and then vanishes, it is most likely an issue with the inverter. A repairman will open it up, diagnose the issue, and decide on the most efficient solution.

Repairing vertical lines on the screen averages $150 to $400. This is usually an issue associated with your TV’s control board or motherboard, which may be damaged and need to be either repaired or replaced. It could also be caused by a loose cable, but it will need to be opened up to diagnose the issue and repair it.

Repairing horizontal lines on your TV costs between $150 and $400. It might be an issue with the motherboard, or it could be a problem with loose cables between the panel and the control board. To fix this issue, the television needs to be opened up and analyzed by a professional repairman.

Repairing a cracked TV screen costs from $400 to $1,000 or even more. Cracked screens cannot be repaired, they can only be replaced, and they are very expensive, sometimes exceeding the cost of a new TV. For this reason, if you have a cracked screen, it will probably have to be replaced entirely.

There are many different brands and companies that make TVs. Some brands specialize in certain types, while others make a wider range of products. It is common for the brand to impact the cost of repair because there may be specific issues or costs related to that brand.

While you may choose a specific brand based on the technology, cost, or resolution, keep in mind that brands may also have varying costs for repairs and the repairs types that may be available. Regardless of brand, most TV repairs fall between $60 and $400, although some repairs may be higher.

The cost to fix a Philips TV is $60 to $100. The typical issue with Philips televisions seems to be that they have a mind of their own. They turn on and off and sign in and out of apps randomly. While a solution doesn’t seem to be forthcoming, Philips is steadily losing customers due to a firmware problem.

Fixing a Sony TV will cost you about $60 to $400. This popular brand has a reputation for simply becoming disabled with no power or sound. Unfortunately, the customer service at Sony isn’t always the best. Customers are often frustrated when it comes to warranty work.

To fix your TCL TV blank screen, you should expect to pay about $60 to $400. One characteristic repair of the TCL brand is a black screen with no picture. This can be a fuse that has blown, or it may require a major change, such as a new main board.

Damaged cables can cause a TV to flicker or grow dim. Repair prices for damaged cables are $75 to $200. Samsung TV owners cite this flickering or dimming of the screen as a common issue with this brand. Sometimes the settings for the eco sensor1 or the energy-saving feature create this problem. Turning either of those off may fix the issue.

Some of the most common issues with this brand are banding at a repair cost of $100 to $200 or sound with a cost of $150 to $400. Color problems may be related to adjustment and can be fixed for a low cost of $75 to $100, HDMI connections are often fixed at the cost of $200 to $300, and streaming problems may be corrected with a software update. Software updates can be done by the owner, but a repairman will most likely charge a minimum fee of $75 to $100. Banding presents as sections of bands where it should be smooth. Sound and color can go out over time in the LG brand. HDMI and streaming can become difficult as technology emerges and changes.

Hisense TVs have a history of display difficulties and could cost you about $100 to $200. Typically, it means you need a new inverter, or it could signal the beginning of the end for your Hisense television.

Panasonic TV owners often experience the power clicking on and off and may need a new main board at the cost of $200 to $400. The reset button may help. The repairman will need to replace the motherboard of the TV if that fails.

The Vizio TV is known for its screen of death (a blank or black screen) and usually costs about $200 to $400. The problem is most often a blown motherboard, and replacement is the only option. A factory reset may be a solution. If that doesn"t work, the motherboard is the best possible answer.

Labor costs for TV repair vary depending on whether you have the television repaired in your home or drop it off at a repair center. Having someone come to your home will have higher costs than taking it to a technician.

A television repair technician has earned a career certificate or Associate’s degree in electronics technology or a related field. Expect to pay between $40 and $60 per hour in labor for someone to fix your television. Some technicians have minimum costs for some repairs, particularly if they travel to you. In this case, you may find that even if the repair only takes an hour, you may need to pay a minimum of two hours of work.

The amount of time to repair your TV depends on what the problem is and the availability of parts. Most jobs can be completed in 1 to 3 hours when the parts are on hand.

Most technicians charge you a diagnostic fee upfront. This fee is for determining what the problem is and can run between $75 and $150. The cost is often waived if you allow the shop’s technicians to make the repairs for you.

Often, you must decide whether it is worth repairing your TV because in many situations, the cost of repairs is higher than the price of a new TV. For example, when screens are cracked or damaged, the cost of replacing a panel is usually much higher than simply buying a new TV.

Consumer Reports recommends replacing electronics whenever the cost of repairs equals or exceeds half the cost of a new purchase. It is also recommended that you replace your television if the new version is less than $200, or if your screen is smaller than 32”. For example, it costs around $150 for a new motherboard in an LG Model 24LF452B 24” TV, which takes around one hour to repair. As a result, you would pay between $190 and $210 to repair your old set, while it is possible to purchase a new one for less.

If you invested a lot of money in your television, the costs of repairing an inverter or getting new backlights may be far cheaper than replacing it. This is why it is often best to ask a professional to diagnose the problem and give you a quote for the repair work. Then, you can compare the price of repairs against the cost of a new TV and decide what makes sense. If your TV breaks down repeatedly, you have multiple repair bills over the course of a year. It might be time for a new television even if a single repair does not seem too expensive.

To minimize repairs and help your TV stay in working order for as long as possible, take care of it as well as you can. Here are some useful TV maintenance tips:Do not leave the TV on if you are not actually watching it. They can run for tens of thousands of hours, but there is no need to waste those hours. So, avoid leaving it on in the background, and make sure to turn it off when you leave the room.

Try not to leave your TV on for too long at a time. Like other appliances, televisions can start to get very hot the longer they are left on. They need to be turned off now and then to get a chance to cool down and rest before being switched back on.

Keep your TV clean. Over time, dust, pet hair, and bits of dirt can build up on the screen and get inside the television via vents and ports. This dust accumulation can affect a TV’s operation and make it more likely to break down.

Consider using a surge protector to keep your TV and associated devices and appliances safe. This can be especially important in areas that experience a lot of storms or frequent power cuts because sudden cuts and surges easily damage your TV’s components.

When positioning your television, leave space around it to provide airflow. This helps prevent the TV from overheating and cools it down more quickly when you turn it off.

Additional Considerations and CostsDIY. In some cases, television repair can be performed as a DIY project. There are numerous how-to videos available that are easy to watch and understand. Parts for most sets are also available online. However, if you are not comfortable with the process, always call a technician rather than attempting the repair yourself.

DIY issues. While DIY repair is often possible, it is not frequently recommended. There is some risk of electrocution, and you might also damage the TV even more by improperly installing a t-con board or ribbon connectors. If you are in doubt, it is best to leave this job to a professional.

Obvious solutions. Before seeking repairs, first look for the obvious. If your set will not power on, it could be a problem with your outlet and not your TV. Try plugging your television into a different outlet to see if that resolves the problem. If that does not fix it, ensure you have not tripped a breaker, and check that the power cord is fully seated.

Remote control. A set that powers on and off at random is sometimes caused by issues with the remote. Try removing and replacing the batteries or using a different remote if possible.

Warranty. When purchasing a new television, buying an extended warranty can spare you the unwanted expense of repair bills in some cases. An extended warranty is largely based on the price of your television. Expect to spend between 10 and 20 percent of your set’s cost on an extended warranty to help cover damage. Ordinary warranties only cover manufacturer’s defects and, therefore, cannot be used to pay for damage due to neglect or accidents.

Warranty repairs. When having warranty repairs made, drop the set off at a local shop whenever possible or have them come to you. If you need to ship the television off, get a tracking number so that you can locate your set if it gets lost.

Scams. Television repair scams are quite common. Before hiring someone to fix your set, find out what experience and training that person has. Check references and online reviews as well.

In-shop repairs. In-shop TV repair services may involve a pick-up and delivery charge if you do not take it in yourself. While some may do this for free, others charge between $40 and $75 to pick-up and deliver the TV back to you. Additionally, customers that live in rural areas may have to ship the television. If you do this, make sure you obtain a tracking number and proof of delivery. The repair service will contact you with the list of recommended repairs and the cost and request a debit or credit card to pay for the repairs before completing them.

Television repair costs vary widely, but the average consumer pays between $100 and $300. Prices depend on the make, model, and size of your set, as well as the availability of parts. It is generally more expensive to repair an older model than it would be to replace it. New televisions are becoming more affordable every year, but the price of parts remains steady or even increases as older parts become rarer.Can a flat-screen TV be fixed?

Yes, flat-screen TVs can frequently be fixed, including issues with the screen, sound, lighting, cables, and interior components. However, there are some situations where flat-screen TVs cannot be fixed, such as when the screen is severely cracked.How do you fix a broken TV screen?

Not all TV screens can be fixed or replaced. Certain types have components behind the screen that can be damaged by its removal. However, if you choose to proceed, remove all external cables, unplug your set, and lay it face down on a flat, soft surface. Remove any screws holding the frame in place and then gently remove the frame and set it aside. Put your new screen in place and reconnect the internal cables in the same manner you disconnected them. It is usually best to get a professional to handle TV repairs, and the cost of replacement screens is often very high. So, it may be more cost-effective to get a new TV.How many years will a flat-screen TV last?

This depends on the make and model of your TV and your viewing habits. Many modern TVs last 60,000 viewing hours or more, equating to 30+ years for a typical person. However, its lifespan can be reduced if it is not properly maintained and cared for.Does turning the TV off shorten its life?

No, turning a TV off will not usually shorten its life in any way. It is actually recommended to turn TVs off when you are not using them, allowing them to cool down and extend their lifespan.Is it okay to leave a TV on all night?

This is not recommended. If you leave a TV on for too long, it may overheat, which could damage interior components like the motherboard. It may also do damage to the screen and risk ‘burning’ an image into the display, as well as damaging the backlights.Do Smart TVs use more electricity?

Generally, no. Most modern Smart TVs are designed to be as energy-efficient as possible, with some models even using less energy than conventional TVs. It all depends on the TV make and model.

Televisions contain various complex parts that are imperative to the device’s overall function. The main component that falls into this category is the T-Con board. To better understand this impactful electronic device, read on to learn everything you need to know about the T-Con board in a TV.

T-Con stands for timing controller. Professionals may also refer to T-Con boards as a “controller board” or “control board.” It is the smallest board inside an LCD TV.

A T-Con board is responsible for generating the horizontal and vertical timing panel signals as well as providing panel bias and enabling signals. It controls the logic signal of gate and serves as a source for driving the thin-film transistor (TFT) liquid crystal display (LCD).

The main part of a T-Con board is a T-Con chip. This chip receives pixels from the scaler in a sequential format before driving the LCD collection’s individual pixel components. This interface takes place internally. As such, there is a wide number of connections that can take place. Between a scaler and a T-Con board, there are often many parallel links—contrary to a typical monitor-source connection which usually requires just one single cable to carry an entire image.

If your TV is currently displaying signs of a T-Con board issue, ElectroParts can help you out. We offer a wide range of HDTV T-Con boards for various TV models. Browse our collection to find LG, Akai, Emerson, Element, Fujitsu, Insignia, and Sony T-Con boards. To learn more about our products, contact us today.

LCD panels have steadily evolved over the last several years. New designs of the physical structure of the LCD crystals have greatly improved the contrast ratio and viewing angle. Quicker response times and increased refresh rates have helped to reduce the motion “smear” associated with LCD displays. Backlighting design has also aided in producing a picture with color temperatures to make the images as true as possible. With all these design improvements, one aspect of the LCD panel remains relatively the same: Processing of the video signal. A typical LCD panel and the associated video

processing circuits as found in the WAX3 chassis. The various formats and resolutions of video signals are processed on the BU1 board. All video signals exit the video processor in the native resolution of the LCD panel. In this design, the resolution is for a 1366 by 768 at 60HZ refresh rate panel. 48 horizontal lines are discarded to match up to the 720p resolution

of the ATSC specifications so the video will exit as 720p. The LCD panel used in this model processes 8-bit RGB video data. Before the video information can be sent to the TCON board it must be converted to a format that allows for practical and noise-free transmission. The large number of parallel lines to transmit the 8-bit RGB data would need to be sent on differential lines for noise reduction. This would require 48 lines just for the video. The TCON circuit also requires B+, ground connections, a communications bus, sync, and a clocking line transmitted differentially so we can see that up to 60 lines would be required for an 8-bit video signal and significantly more lines for a 10-bit processor. The practical way to transmit this information is to convert the parallel video data to a serial stream and this is accomplished by the Low-Voltage Differential Signaling (LVDS) transmitter.

The LVDS transmitter contains a circuit to serialize the parallel data. The parallel video information along with sync and clocking data are transmitted via twisted line pairs. Depending on the logic level, current is sent along one or the other of the twisted pair of wires. The receiving end of the wires is loaded with a resistor (usually around 100 to 120 ohms). The receiver detects the polarity of the voltage drop across the resistor to determine the logic level. The current level swings in the wire are about 3ma with a voltage differential of around 350mv. This allows for transmission of the video signal with minimal EMI. The LVDS receiver on the TCON board converts the serialized data back to parallel. This data is processed by the timing control IC to allocate the RGB data into serial streams for processing by the LCD panel. The TCON transmits the pixel control data to the panel via flat, flexible circuit board cables which can number 2 or 4 depending on the bit rate and refresh timing of the panel. A 1366 X 768 panel requires about 180 lines to transmit control information and B+ from the TCON. This number of control lines is not even close to the number of horizontal or vertical rows of pixels so the LCD panel must use this information to further expand the ability to turn on each individual crystal. The process will be explained in the gate and source driver paragraphs. All of this is accomplished by the TCON board. The term “TCON” is short for Timing Control. Other LCD panel manufacturers may have a different name for this particular circuit but the term used by Sony will always be TCON.

Referring to Figure 4-5, note the IC’s located along the side of the panel. These IC’s are mounted on a flexible cable(s) which are bonded to the LCD panel. Their function is to activate each row of pixels one at a time starting with the first line at the top. As each line is activated, the source drivers turn on the appropriate liquid crystals for the frame of video about to be displayed. This continues from top to bottom until the entire frame of video is displayed. The process is repeated for the next frame. This rate can vary from 60 times per second or be increased to 120 or 240 as found in the high-frame-rate panels.

These IC’s provide the control voltages to turn on each RGB segment of the vertical rows of pixels. In this example, the panel has a horizontal resolution of 1366 pixels. Each pixel is made up of a red, green and blue liquid crystal which means there are 4,098 columns to control. The source drive IC’s contain shift registers along with buffer switches. Shift registers are used to convert serial data to parallel. By using this method, the TCON is able to transmit control information to each of the source drivers using serial data lines. If the TCON is transmitting 8-bit data to the panel, each data line is capable of controlling 256 lines exiting the source drivers. Understanding how the gate and source drivers work together makes it easier to observe a problem on the screen and determine if the failure is panel or TCON related.

In order for this concept to move forward successfully, it is important that the service industry be able to properly identify the symptoms of TCON issues to avoid unnecessary service calls and repair costs. Accurate analysis of TCON failures will reduce costs significantly (both in parts costs and time) when warranty repairs are involved and will reduce the number of COD repairs that are lost. A good approach when determining a TCON failure is a good understanding of which symptoms ARE NOT caused by the TCON. Examples are as follows:

Video Process Failures: All video inputs received by the video process circuits are handled on a frame-by-frame basis. The video frames are converted and scaled to 8 or 10-bit RGB information. It is virtually impossible for the video process circuits to cause a problem on a specific area of the screen. Failures on this board usually appear as distortions, color level shifts, video level shifts, noise that involves the entire picture, or no picture at all. The TCON can generate symptoms that appear to be video process related but the video process circuits cannot produce the symptoms of a failed TCON circuit.

LVDS Cable Failures: Although problems with the LVDS cable or connectors can generate symptoms of TCON failures this usually tends to be intermittent and wiggling of the connectors will usually provoke a change in the symptom on the screen. LVDS cables and connectors have become rather robust over the past few years and most problems are caused by one who works with it damage them and this is generally quite obvious upon close examination.

LCD Panel Failures: Some LCD panel failures could possibly be mistaken for TCON issues. Other than damage to the LCD glass, most panel failures are isolated to a particular area of the screen. Since the TCON disperses the pixel data to groups of line and column drive IC’s situated on the outer edges of the panel, it is unlikely that more than one of these IC’s would fail at the same time. Multiple columns of stuck on or stuck off pixels are, therefore, more likely to be the fault of the TCON circuits. The same applies to a single row of lit or unlit pixels. The TCON simply cannot cut out a single line of information.

• Physical damage such as cracks in the panel, a single pixel or group of pixels that always on or off, or random sections of the panel which are completely dark.

• Source driver failure. This symptom appears as a single vertical band around 1 to 2 inches (depending on the panel size) and can be black, white, or any other color. It can also contain video information with distortion. A single vertical line that is dark or colored. This may be due to a tab bonding failure from the IC to the panel but either cause requires the replacement of the panel.

• Gate driver failure. These IC’s operate in a “bucket brigade” fashion. As mentioned earlier, the gates drivers scan each horizontal line starting at the top. If any one of the gate drivers fails, all of the subsequent drivers below it will fail to operate properly. This symptom is usually indicated by normal video on the upper portion of the screen followed by distorted video from the point of the failed IC and downward.

• Any horizontal lines. The gate drivers are activated by a single source of timing information so any single horizontal line or groups or random horizontal lines are caused by an output failure from a gate driver or a loss of the tab bond to the panel.

Failures in the timing control circuits of the TCON can produce symptoms of absolutely no video or generate lines and patterns that usually cover all or a substantial part of the screen. Determining if the TCON is the cause of a “no video” condition is a bit more difficult since there are no indications on the screen to analyze.

many of the Sony television models over the last few years will detect a TCON that has completely failed. The communications data between the video process circuits and the TCON will cease to communicate if the TCON fails completely. This will cause the television to shut down and display a diagnostics code indicating a failure of the TCON. Not all chassis designs have this feature and it is not found on older models.The typical scenario when this failure arises is for the technician to bring a video process board to the repair location. It is usually safe to assume that the problem lies on the TCON board if the replacement video board does not remedy the problem since it is highly unlikely that a replacement board with the same failure was received. One trick to check most TCONS for functionality is to loosen the LVDS connector at the TCON (as shown In Figure 4-3) while the unit is turned on. Handle the LVDS connector with care and be certain to fully release the lock tabs. Gently rock the cable in and out of the connector while observing the screen for any response. Depending on the chassis, the symptoms of the screen may be gentle white flashes, intermittent colored lines, or a screen full of random patterns. The idea at this point is to provoke some kind of response on the screen. TCON boards that have failed will not usually generate any type of response on the screen. Another helpful procedure is to rapidly heat and/or cool the TCON with hot air devices or circuit coolant and watch for patterns to appear on the screen.

Illustrates 2 examples of a loss of control data to the drive IC’s. In the first example, an entire group of column drivers has lost the data stream for red. The second example involves the complete loss of drive data for all RGB information to the right side of the screen. This is sometimes caused by the flat cable connecting the TCON to the LCD panel coming loose. The area of missing video can be dark or completely white depending on the panel design. Service Tip: Select an inactive input (or one that is known to be a 4:3 SD source) and toggle between the “normal” and “zoom” modes. If the lines follow the zoom changes, the problem is located on the video process board. If they stay in the same place, they are originating in the TCON Or LCD panel.

Ever had your TV showing nothing but a black screen even if the audio was working? Unfortunately, that’s a common issue with low/middle-end LCD/LED TVs these days… Even more frustrating, this issue often comes from a rather tiny and cheap component that can be easily replaced. Most common issues are:

One of my relatives had this exact symptom happening all of a sudden. This problem on low-end TVs often occurs within the first couple years. As the repair costs for that kind of TV is pretty low, considering repairing it yourself might be a good idea!

The first step into repair is to find the root cause of the issue. As backlight failure is a very common issue, this is the first thing to test. To do so, the easiest way is to power on your screen, put a flashlight very close to it and check if you can see the image through. The image would be very dark, like turning the brightness of the screen very very low.

That implies disassembling the TV to access the backlight which is between the LCD screen in the front and the boards in the rear. In my case, with a Samsung F5000, I had to process as follows:

First we have to remove the back housing to reveal the boards (from left to right: main board, T-CON, power supply) and disconnect the LCD panel from the T-CON board.

Note: Older TVs have neon tubes for backlight, which is thicker and less exposed to this kind of failure. LED backlight is the most common thing these days, but do not mistake an LED TV with an OLED TV. The first one is a classic LCD panel with a LED backlight, whereas the second is an OLED panel that doesn’t need any backlight as it is integrated in each pixels (making the spare parts much more expensive by the way).

As we can see, the backlight system is made of 5 LED strips. First thing to do is look for burnt LEDs. Most LED backlight systems have strips set in series, meaning that if one of the them fails, all the system goes dark…

Using a multimeter, we can confirm that the strips are indeed set in series, so now we have to test each strip individually. Professionals use LED testers such as this one (about 40$ on amazon) but as I didn’t had one at the time, I decided to make one, McGyver style!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey