mini lcd touch screen for use with arduino supplier

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Find the different arino touch screen and Alibaba.com products at wholesale prices. Find the wide wholesale suppliers on Alibaba.com to provide more products to your customers.

However, for arino touch panels that have tougher tactile elements, the screen suppliers may offer options that provide more information for a complex display of different products. Find an arino touch screen from wholesale suppliers on Alibaba.com to provide different products for your customers" needs.

There are four main types of arino touch screen: aruino lcdds. They give the user an option to display their products for a more natural-looking experience and at the same time. Now, when choosing the arinoino touch screen based on your consumers" needs and preferences. Hence, for your customers to choose the arino touch screen based on their preferences and the ones that are built with them.

But I"ve been happily surprised. Everything works smoothly, and the touchscreen is accurate in reading points across the entire surface. (There is NO calibration issue as you control the offset in code yourself)

The card - being a shield - means you can just line up the pins on the board to the mount holes on the Arduino, and the card pushes firmly into place.

The build quality is excellent - the surface mount chips are all soldered well, the display is mounted cleanly on the PCB. You even get a little plastic stylus for the capacitive touchscreen.

Warning! You might need to power your Arduino board along with the USB power. I found my little laptop couldn"t power the bright white screen LED"s, RGB screen, and Arduino all at the same time. The Arduino would repeatedly "unplug", and then "replug".

We realize a change is not always welcomed but we feel it"s the best way to move forward. The new Workshop4 IDE supports 4 development environments, to cater for different user requirements and skill levels and the Serial environment you"ve mentioned is one of them. The Serial environment is basically a 4DGL application that uses a very simple protocol and makes the display act as a slave and it works well when the host and the display are in close proximity, i.e. both on the same application PCB or the distance of the host is within a foot or two from the display. In most cases this works real well as long as the transmission path is free of external noise. There are many high end commercial products designed by many thousands of customers using just the serial platform. If the environment is noisy or the distance between the display and the host is far apart, then why not use the Designer environment and roll out your own top notch serial protocol with many different levels of error checking? Many customers also employ this method. A good outcome for any application always starts by proper understanding of what"s required and a good feasibility study of all the factors involved. You mention you"ve used many of our displays (thank you for your support), but have you tried seeking help from our very helpful team of tech support engineers? If not, please do so, I"m sure you"ll find they"ll be able to resolve most of your problems.

Edit: I have just been informed that a user reported a crashing problem on Friday the 22nd of February, he was supplied with a Fix on Saturday the 23rd and Workshop was shipping with the fix integrated on Monday the 25th. If you are that user we apologize for any inconvenience. This problem was only limited to the Goldelox based displays and not on the Picaso.

The Arduino board has a wide variety of compatible displays that you can use in your electronic projects. In most projects, it’s very useful to give the user some sort of feedback from the Arduino.

With the TFT display you can display colorful images or graphics. This module has a resolution of 480 x 320. This module includes the SD card socket and SPI FLASH circuit.

This is a tiny display with just 1 x 0.96 Inch. This display has a black background, and displays characters in white. There are other similar displays that can show the characters in other colors.

I"ve done a bit of research on LCDs around 3.0" in size. It seems that one can never find all he needs to know. I would like minimum hustle LCD, so that it takes minimum number of pins and it has decent Arduino library for easy use. I do not really have time to write Arduino library from scratch and there is no point in LCD taking all the input pins, so none are left for sensors and controls.

Touchscreen displays are everywhere! Phones, tablets, self-serve kiosks, bank machines and thousands of other devices we interact with make use of touchscreen displays to provide an intuitive user interface.

Today we will learn how touchscreens work, and how to use a common inexpensive resistive touchscreen shield for the Arduino. Future videos and articles will cover capacitive touchscreens, as well as a touchscreen HAT for the Raspberry Pi.

Although touchscreens seem to be everywhere these days we tend to forget that just a few decades ago these devices were just science fiction for most of us. For many people, the touchscreen concept was introduced 30 years ago in the television seriesStar Trek: The Next Generation.

Eric A Johnson, a researcher at the Royal Radar Establishment in Malvern UK is credited for describing and then prototyping the first practical touchscreen. HIs device was a capacitive touchscreen, and it’s first commercial use was on air traffic control screens. However, the touchscreens used then were not transparent, instead, they were mounted on the frame of the CRT display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreen. This device used a 16×16 array of LEDs and phototransistors, mounted on a frame around a CRT display. Placing your finger, or another solid object, on the screen would break two of the light beams, this was used to determine the position and respond accordingly.

The first transparent touchscreen was developed atCERNin 1973. CERN is also home to the Large Hadron Collider, and this is where Tim Berners-Lee invented the World Wide Web.

The first resistive touchscreen was developed by American inventor George Samuel Hurst in 1975, although the first practical version was not produced until 1982.

In 1982 theUniversity of Toronto’sInput Research Group developed the first multi-touch touchscreen, a screen that could interpret more than one touch at the same time. The original device used a video camera behind a frosted piece of glass. Three years later the same group developed a multi-touch tablet that used a capacitive touchscreen instead.

The first commercial product to use a touchscreen was a point-of-sale terminal developed by Atari and displayed at the 1986 COMDEX expo in Las Vegas. The next year Casio launched theCasio PB-1000 pocket computerwith a touchscreen consisting of a simple 4×4 matrix.

LG created the world’s first capacitive touchscreen phone, theLG Pradaused a capacitive touchscreen and was released in early 2007. A few weeks later Apple released its first iPhone.

Most early touchscreen devices were resistive, as this technology is generally less expensive than capacitive screens. However, nowadays capacitive screens are more common, being used in the majority of smartphones and tablets.

Although they were invented after capacitive touchscreens, resistive touchscreens are probably the most common type used by hobbyists. The reason for that is the price and performance, resistive touchscreens are cheaper than capacitive ones and they are generally more accurate.

A resistive touchscreen consists of two thin layers of material, separated by a tiny gap. Spacers are used to maintain the gap and keep the two sheets apart.

In operation, the resistance between the two sheets is measured at different points. Pressing down upon the tip sheet will change that resistance, and by comparing the measurement points it can be determined where the screen was pressed. Essentially, it creates a pair of voltage dividers.

In a 4-Wire Analog touchscreen, there are two electrodes or “busbars” on each of the conductive layers. On one layer these electrodes are mounted on the two X-axis sides, the other layer has them on the two y-axes.

This is the most inexpensive method of designing a resistive touchscreen. The touchscreen display that we will be working with today uses this arrangement.

In a 5-Wire Analog touchscreen, there are four wires, one connected to a circular electrode on each corner of the bottom layer. A fifth wire is connected to a “sensing wire”, which is embedded in the top layer.

Touching any point on the screen causes current to flow to each of the bottom electrodes, measuring all four electrode currents determines the position that the screen was touched.

This 8-Wire Analog touchscreen uses an arrangement of electrodes identical to the 4-Wire variety. The difference is that there are two wires connected to each electrode, one to each end.

Capacitive touchscreens are actually older technology than resistive displays. They are commonly used in phones and tablets, so you’re probably familiar with them.

The capacitive touchscreen makes use of the conductivity of the human body. The touchscreen itself consists of a glass plate that has been treated with a conductive material.

The surface capacitive touchscreen is the most inexpensive design, so it is widely used. It consists of four electrodes placed at each corner of the touchscreen, which maintain a level voltage over the entire conductive layer.

When your finger comes in contact with any part of the screen, current flows between those electrodes and your finger. Sensors positioned under the screen sense the change in voltage and the location of that change.

This is a more advanced touchscreen technique. In a projected capacitive touchscreen transparent electrodes are placed along the protective glass coating and are arranged in a matrix.

One line of electrodes (vertical) maintain a constant level of current. Another line (horizontal) are triggered when your finger touches the screen and initiates current flow in that area of the screen. The electrostatic field created where the two lines intersect determine where it was touched.

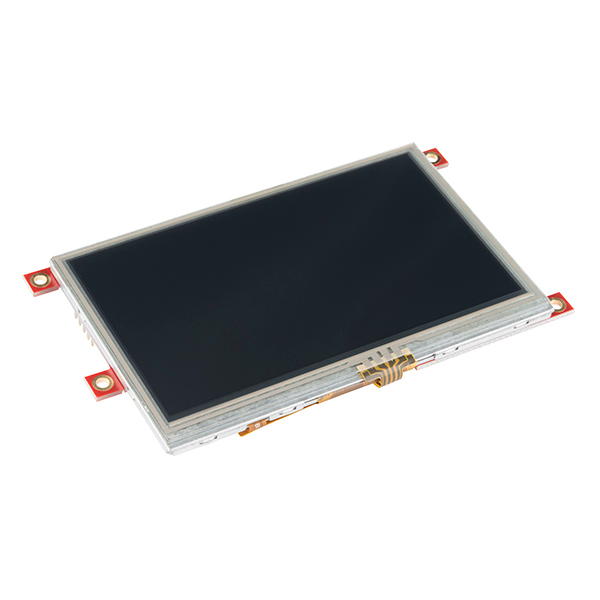

The module we will be experimenting with today is a very common Arduino Shield, which is rebranded by many manufacturers. You can easily find these on Amazon, eBay or at your local electronics shop.

You can also just use the shield as an LCD display and ignore the two other components, however, if you intend on doing that it would be cheaper just to buy an LCD display without any touchscreen features.

This is a TFT orThin Film Transistordevice that uses liquid crystals to produce a display. These displays can produce a large number of colors with a pretty decent resolution.

You do need to be looking directly at the display for best color accuracy, as most of these inexpensive LCD displays suffer from distortion and “parallax error” when viewed from the side. But as the most common application for a device like this is as a User Interface (UI) this shouldn’t be a problem.

This shield uses a 4-wire analog resistive touchscreen, as described earlier. Two of the wires (one X and one Y) are connected to a couple of the analog inputs on the Arduino. The analog inputs are required as the voltage levels need to be measured to determine the position of the object touching the screen.

The microSD card socket is a convenience, it’s normally used for holding images for the display but it can also be used for program storage. This can be handy for holding things like calibration settings and favorite selections.

You should note that the microSD card uses the SPI interface and is wired for the Arduino Uno. While the rest of the shield will function with an Arduino Mega 2560, the SPI connections on the Mega are different, so the microSD card will not work.

The last paragraph regarding the microSD card may make you think that an Arduino Uno is the best choice for the Touchscreen Display Shield. And it you require the microSD card then it probably is a good choice.

But using an Arduino Uno with this shield does have one big disadvantage – a limited number of free I/O pins. In fact there are only three pins left over once the card has been plugged in:

If your product is self-contained and doesn’t need many (or any) I/O pins then you’ll be fine. But if you need more pins to interface with then an Arduino Mega 2560 is a much better choice. It has a lot of additional analog and digital pins.

So if you don’t require the microSD card, or are willing to hook up a separate microSD card, then the Arduino Mega 2560 is a better choice for most applications.

As there are three devices on the shield you will need libraries for each of the ones you want to use. TheSD Libraryis already installed in your Arduino IDE, so you will just need libraries for the display and touchscreen.

For the LCD you will have a lot of choices in libraries. Most of these shields come with a CD ROM with some sketches and libraries, so you can use the LCD libraries there. Bear in mind however that code on these CD ROMs tends to be a little dated, you may have better lick on the vendors website.

This useful resource contains code, libraries and datasheets for a wealth of LCD displays, both touchscreen and non-touchscreen. You’ll also find code for some common OLED displays as well.

I ran my touchscreen through all of the code samples I obtained from the LCD Wiki. It’s an interesting exercise, and by examining the sketch for each demo you can learn a lot about programming the display.

The first example is a very simple color “sweep” test. Navigate to theExample_01_Simple_testfolder and open the folder for your Arduino controller. Navigate down until you find the “ino” file and load it.

This test does not make use of any of the extra libraries, it drives the LCD directly. It is only a test of the LCD display, it does not make use of the touchscreen membrane.

You’ll find this example in theExample_02_clear_screenfolder, the sameclear_Screen.inoexample is used for both the Uno and Mega so there are no separate folders.

This example does use the custom libraries, and is a very good way to learn how to use them. You’ll note that theLCDWIKI_GUI.hlibrary is loaded, which is the graphics library for the LCD display.

Another library, LCDWIKI_KBV.h, is loaded as well. This is a hardware-specific “helper” library that provides an interface to the actual hardware for the other libraries.

When you run this example the results will be similar to the first one, a series of colors will sweep across the screen. In this case the colors are different, and they vary in speed.

A look at the loop will show how this is done. TheLCDWIKI_GUI.hlibrary has a “Fill_Screen” method that fills the screen with an RGB color. You can specify the color in both hexadecimal or decimal format, the example illustrates both ways.

This sketch uses a number of functions from theLCDWIKI_GUI.hlibrary, along with some custom functions to draw geometric shapes. It then displays a cycle of graphs, shapes, and patterns on the LCD display.

One way in which this sketch differs is that most of the graphics routines are executed in the Setup function, so they only run once. The loop then displays some text with a selection of colors and fonts. The orientation is changed as it cycles through the loop.

This example makes use of a second file that contains fonts. The Display Scroll sketch illustrates a number of different methods of scrolling characters, in different fonts, colors and even languages.

Unlike the previous examples that put the text in with a number of graphics, this example is a pretty simple one with just a block of text in different sizes and colors. This makes it very simple to understand how the text is positioned on the display.

The result of running the sketch is the display screen fills with rows of hexadecimal values while the background alternates between blue and black and the orientation (or “aspect”) changes. If you stand back to see the “big picture” you’ll note that the color values form “number patterns”.

In addition to the graphics and “helper” libraries that have been used in the previous examples this sketch also uses theTouchScreenlibrary to read screen interaction. This was one of the libraries included in the original ZIP file.

Note that this demo will only work on the Arduino Uno, as the microSD card uses the SPI bus and is wired to the Arduino Uno SPI port. The Arduino Mega 2560 board uses different pins for SPI.

The image needs to be in bitmap format as this format defines several bytes for each individual pixel in the image. There are four 320×480 sample images included in the code sample, you can also use your own if you (a) keep them the same size and (b) give them the same names.

The images will show off the display resolution, which is reasonably impressive. You’ll also note that to see them at their best, you need to be directly in front of the display, viewing the display at an angle causes the display to distort colors.

Another thing you will notice is the speed at which the images draw, which is not particularly impressive. The clock speed of the Arduino has a lot to do with this, as does the method used to extract each individual pixel from the image.

This example draws some small “switches” on the display. The switches are active and respond to touch. There are slide switches, a push button, some radio buttons and some text-based expandable menus to test with.

The Touch Pen example is actually a pretty decent little drawing application. You can draw whatever you want on the main screen area. A set of buttons allow you to set the stylus color and pen width.

While the sample code is a bit difficult to follow it’s worth the effort, as it shows you how to create a dynamic menu system. Touching the stylus color button, for example, will open a new menu to select colors. This is a handy technique that you’ll need to know when developing your own user interfaces.

The Calibration utility lets you calibrate the resistive touchscreen. It achieves this by placing a number of crosses on the screen. You can calibrate the screen by using the stylus to touch the center of one of the crosses as accurately as you can.

After you touch one of the cross points the sketch runs through a calibration sequence, during which time you need to continue to touch the cross point. You’ll be informed when it is finished.

After calibration, the sketch will display a number of calibration values for the resistive touchscreen. These values can be used in your future sketches to make the touchscreen more accurate.

For the best accuracy, you should repeat the test several times using different cross points, noting the results each time. You can then average those results and use the values in your sketches.

The examples are a great way to demonstrate the capabilities of your touchscreen. But to really put your interface to work you’ll need to write your own interface code.

Writing a touchscreen interface can be challenging. I would suggest that you start by modifying one of the example codes, one that is closest to your desired interface.

For my experiment, I will be using an Arduino Mega 2560 to drive three LEDs. I used a Red, Green and Blue LED but really any colors will work – I just wanted my LED colors to match my button colors.

The digital I/O connector at the back of the Mega is still accessible even when the touchscreen display shield is installed, so I used three of those connections for the LEDs. I hooked up each LED anode through a 220-ohm dropping resistor and connected them as follows:

Of course you can use other pins, just remember to change the sketch to match. The pins I selected happen to all be PWM-capable, but in this simple interface I’m not dimming the LEDs.

TheAdafruit GFX Libraryis a comprehensive graphics library that can be used in a variety of display applications. It is a “core library”, meaning that it is called by other Adafruit libraries.

TheAdafruit TFTLCD Libraryis used. It uses the previous library to provide an easy method of drawing on the LCD display. It works with LCD displays that use driver chips like the ILI9325 and ILI9328.

TheTouchScreenlibrary comes in the code that you downloaded from the LCD Wiki or from the CD ROM included with your touchscreen shield. As its name implies it is used to interface with the touchscreen.

TheMCUFRIEND_kbvlibrary is also included in the software you obtained for your display shield. It takes care of supplying the correct hardware information for your display shield to the other libraries.

We also define some “human-readable” colors to use within our code, it’s a lot simpler and more intuitive than providing RGB values. I’ve includes all of the colors from the phone sketch I used as the basis for this code, so if you want to change button or background color you can easily do it.

Next, we define some touchscreen parameters. You can ‘fine-tune” your code here by using parameters from your own display, which you can obtain from the Calibration Sketch we ran from the sample code. Otherwise, just use the values here and you should be fine.

Now onto the button definitions. These are set up using arrays, which is a great technique to use for multiple buttons with similar dimensions and properties. If you want to change the button colors or text this is the place to make your changes.

In Setup, we initialize the serial monitor, which we can use to monitor the button press and release events. We also set up the three LED pins as outputs.

Now, still in the Setup, we set up the LCD display rotation and fill the background in black. Next step is to draw our buttons. Once we are done that the Setup is finished, and our screen should be displaying the three buttons on a black background.

The loop is where we will be monitoring the screen for keypresses. If we get one, and if its position corresponds to a button location, then we need to toggle the correct LED.

We start by triggering the touchscreen, which is done by toggling pin 13 on the Arduino high. If something is touching the screen we read it and assign it to a TSPoint object named “p”.

We then need to reset the pin modes for two of the touchscreen pins back to outputs. This is done as these pins get shared with other LCD display functions and get set as inputs temporarily.

Now we check to see if the pressure on the screen was within the minimum and maximum pressure thresholds we defined earlier. If it makes the grade then we determine where exactly the screen was pressed.

Now that we know where the screen was pressed we need to see if the pressure point corresponds to one of our buttons. So we cycle through the button array and check to see if the pressure point was within 10 pixels of our button location.

If we find a corresponding button we let it know it has been pressed, this lets the button respond visually to the keypress. We then look at the button ID number to see which LED we need to control. We reverse the value of the toggle boolean and then drive the LED appropriately – 1 for on, 0 for off.

Load the code into your Arduino IDE and upload it to your Arduino Mega 2560. Make sure you have the correct processor-type set in your Arduino IDE, especially if you are used to working with the Uno!

This is a pretty simple demo but it does illustrate how to create a simple IDE. You can expand upon it to add more buttons, or to change the button colors or shapes. And, of course, you don’t have to light LEDs with your buttons, they can control anything that you can connect to your Arduino.

Touchscreen interfaces are used in a number of products, and now you can design your own devices using them. They can really make for an intuitive and advanced display and will give your project a very professional “look and feel” if done correctly.

This is not the only time we will look at touchscreen displays. Next time we’ll examine a capacitive touchscreen and we’ll explore the Adafruit Graphics libraries further to create some very fancy displays with controls and indicators.

Let"s learn how to use a touchscreen with the Arduino. We will examine the different types of touchscreens and will then create a simple interface using an inexpensive Arduino touchscreen shield.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey