reflective lcd panel free sample

To be objective, there were some initial challenges for implementing digital signage, as there are with incorporating any new idea or technology. When it comes to viewing any digital images in an outdoor environment, bright sunlight can make it difficult to see the image on the display clearly. In addition, this same bright light can cause devices to heat up quickly and even fail if proper precautions are not followed. Obviously, this is undesirable for any user and a concern for business owners who don’t want to see their investments only be subject to risk and failure. For a long while, the only solution was to have the display “outshine” the sun, cranking up the brightness on the device in an effort to power through the ambient sunlight. In some ways, this can be effective, as the saying going, “The brightest stars are seen at night.” But this method also comes at a high cost. First, it takes a lot of energy to try to beat the sun when it comes to emitting light and even if capable, that energy comes with a price tag that is ever consuming, unless the sun were to stop shining. At that point, digital displays would become the lowest of anyone’s worry. Second, this energy output also creates heat of its own and is another amount of energy that needs to be dissipated before damaging the device. Additional Anti-Reflective coatings and AC fans or water-cooling systems need to be used to pull heat away, adding to the overall energy usage and cost of operating the display. Last, by using the High Brightness mode, the LCD and back lights themselves would degrade more quickly, reducing theoverall lifespan of the displaybefore it would need to be fully replaced. So while a display may be able show a brighter image in bright conditions, it is important to understand what it takes to achieve that result.

The best aspect of technology is how quickly it advances. Just as printed paper menus are being upgraded to digital displays, so is the digital signage industry constantly upgrading itself. For instance, Sun Vision Display approaches the issue of sunlight differently, turning what was considered a problem into a solution. By usingreflective technology, the same sunlight that other display panels compete with now becomes the exact light that illuminates the LCD panel. In this way, there is no need to “outshine” the sun or consume extreme of energy to do so. In fact, the brighter the sunlight, the better the images appear to the viewer, resulting in true sunlight readability.

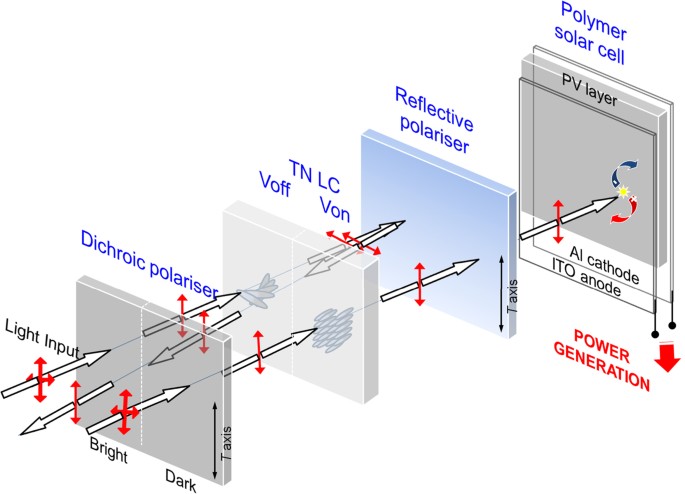

The key to this technology is to replace the back light with a mirror-like reflective layer, eliminating the high energy component and cleverly converting interfering light energy into a useful asset. Though the physical mechanics of how this works may require several advanced degrees, the concept is actually quite simple and is what makes reflective displays truly a brilliant solution to an otherwise universal difficulty. As a result of this “small” change, many other benefits also arise. The energy required to operate the display is reduced up to 95% and in addition to removing the back light, saves overall cost every time it is turned on. The display welcomes bright light and is not subject to the same high heat degradation of other displays, increasing its overall lifespan and again reducing energy costs to cool the unit. Each factor that previously worked against the user now each benefit from the reflective technology and create a solution that is much more than the sum of its parts. This is the brilliance behind the way in which reflective technology has advanced the idea of using digital displays instead of printed paper menus.

In the above food truck example, reflective displays could work very well for a number of reasons. The low power requirements make it easy to operate in a setting with limited resources. Also, reflective displays are designed to handle nearly any weather-related conditions that may hit. For example, SVD displays have an operating temperature between -20C and 70C, making them suitable for many outdoor climates. They can also be sealed behind toughened glass and ruggedized to an IP65 rating which will help withstand weather and the jostling conditions of a moving vehicle.

Durability is always a question when it comes to any outdoor product, and it is an area where reflective technology excels as well. From the famously rainy Pacific Northwest through the snowy Rocky Mountains (and all the way to the ever-bright Sunshine State), each of these environments presents its own set of challenges – from solar load to high humidity (and even sub-zero temperatures). Traditional backlit displays can struggle to adapt to these climate conditions – especially if they stay in one place year-round. By nature, they generate their own heat. Not only does this translate into wasted energy, it means the display needs to be designed to dissipate heat while directly in the summer sun. It must also be able to conserve that thermal energy as well as possible on a cloudy, blustery day.

With a temperature range of -20°C to +70°C and an IP65 rating, reflective technology truly is a PERFECT FIT for nearly any outdoor condition. There are a few exceptions, of course. If you regularly experience volcanic eruptions accompanied by category 5+ hurricanes and tsunami sightings, then you simply won’t find a display that works well for you, and we suggest you move to a safer place. Simply put, reflective displays are at home in any environment because they were designed to use natural elements, rather than compete with them. Backlit LCDs, on the other hand, try to “outbright” the sun, which is a tough task – no matter how you try to go about it! It always requires a lot of power and equates to a shorter lifespan – both of which have their costs over time.

All in all, here is the bottom line. As long as there are cities and towns, there will be parks. Can we agree on that? Within those parks, some form of information usually needs to be on display, which will need to be updated periodically. Are we still good? Great. Bottom line, it costs money to update that information, whether you’re paying for it in the form of a maintenance person who earns a salary or in the form of anLCD display(along with any maintenance/repair costs that come with it). Reflective displays make a lot of sense, because their maintenance costs are minimal, they last longer, they cost less to operate, and they do not run up the bill by requiring additional personnel on the payroll.

LCD technology is the direction that large outdoor signage is headed, andReflective LCDs from Sun Vision Display offer the best optionfor anyone who wants to stay moving in that trend.

Transmissive LCD is the most common LCD screen, which requires a backlight as the light source and there is no reflective film at the back of the LCD screen.

Advantage: we can see the graphic and character on the screen very clearly if there is only little light. It is such a mature and cheap technology that 90% of LCD screens in the market are transmissive LCD display.

Reflective LCD is the cheapest LCD screen because there is no backlight, which uses light from outside as the light source, such as sunshine or lamplight and there is a reflective film at the back of the LCD screen.

Transflective LCD is the best and most expensive LCD screen, which has a semi-reflective film at the back of the LCD screen. The front light can’t go through the semi-reflective film, but the backlight can go through it. Like sunglasses.

Advantage: it has the advantages of both transmissive LCD and reflective LCD. We not only can see it very clearly in the outdoor like the reflective LCD, but also can see it vividly when we are in a dark place like a transmissive LCD. We see the transflective LCD in the front as the reflective LCD because it can reflect the sunshine, but the LED backlight panel can also supply the light which can penetrate the semi-reflective film at the back of LCD screen.

Reflective LCDs have been around for a long time but have never made much of an impact on the display industry. FLEx Lighting, a US- based startup, is looking to change that with some fascinating technology that greatly improves the performance of reflective LCDs, and just might make this display technology a big part of the industry landscape in a few years.

I visited with FLEx Lighting CEO Mike Casper this week in his company’s office in down- town Chicago to learn more about their technology, and came away impressed with the technology and the opportunities it presents for improving the prospects for reflective LCD. FLEx Lighting recently concluded a series B funding round, raising $9 million from SABIC Ventures, Bascom Ventures, and others, and intends to use the funding to expand its product portfolio to larger sizes.

One of the main inhibitors of reflective LCD in the marketplace, in competing against other reflective technologies like electrophoretic (e-paper), is that while reflective LCDs perform very well in direct sunlight, they are not readable in low-light conditions, and traditional frontlight panels do a poor job.

Figure 1 supplied by FLEx Lighting shows a simplified perspective of the problem and the solution. 1a shows e-paper with a typical frontlight at the sides of the display. Because the display is paper-like, the light rays coming from oblique angles scatter in all directions, allowing good readability. Reflective LCDs use a mirror behind the LC layer to reflect incident light, but as shown in 1b the mirror reflects incident light from a frontlight with only a slight scatter. Backlit LCDs, shown in 1c, do not encounter this problem because all the optical layers sit behind the LC layer.

The FLEx Lighting system offers many advantages over existing products. Although e-paper has offered some color display systems, the color gamut is far less than LCD. LCD also offers video capability which e-paper cannot match. The thin profile of the FLEx Lighting wave guide keeps the overall display package thin, and the ability to wrap the waveguide around the display to include the LED in the back of the display allows for a bezel-free design. The LED can be positioned close to the wrap-around, or further away, allowing the device maker design flexibility in electronics layout, as shown in the picture.

The ability to tightly control the exit angle of light gives the FLEx Lighting approach additional benefits. As shown in the figure below, the light output of the lightguide can be made with a broad peak or a narrow peak or even a peak offset from normal incidence. A narrow peak from the lightguide would presumably give a reflective LCD with a narrow viewing angle, which might be desirable in some applications and undesirable in others, but the design flexibility is undoubtedly an advantage.

The performance of a reflective LCD using FLEx Lighting’s approach may have manufacturers reconsidering reflective displays. While reflective displays have always offered the benefit of low power, the inability to use these displays in low light conditions has severely limited suitable applications. Although ePaper with a frontlight enabled low light readability, the performance constraints of ePaper for color and video, combined with the higher cost for the technology, have limited e-paper to niche markets. As the picture below shows, though, a reflective LCD with a FLEx Lighting frontlight system can give good contrast and color in both direct sunlight (with the frontlight off) and in a dark room (using the frontlight).

In trying to evaluate the performance of a reflective LCD vs. a conventional backlit LCD or an OLED, some of the most common performance metrics get thrown out the window. Brightness, of course, is a meaningless metric for a reflective display in a daytime condition, as the light comes from the sun, as seen in the picture. Casper encouraged me to think about ambient contrast as a relevant performance metric. Whereas OLED achieves near-infinite contrast in a dark room, in a daylight condition the contrast deteriorates severely.

According to Casper, some of the existing reflective display products on the market are designed to look good on the showroom floor, rather than actual use. The Nook was the first front-lit e-reader, and was designed for a brightness of 50 nits to appear bright in a sales environment, but Casper said that in follow-up research e-readers’ designers found that in actual use the brightness was set to on average only 7 nits. Casper noted that a reflective LCD for a 6” tablet display using FLEx Lighting’s technology would require just four LEDs to achieve 50+ nits.

FLEx Lighting says that their technology can achieve better color performance, although I admit I’m not yet convinced. The colors on sample pictures I’ve seen look to be a bit pastel to me. Again, measurement of color for a reflective display is not the same as color for an emissive (or transmissive, like LCD) display, so some of the usual benchmarks may not be appropriate. At the very least, the color for a reflective display depends not only on the display itself, but on the color of the light source.

FLEx Lighting has commercialized several small display products with LCD makers, Sharp and JDI, and Casper indicated that they have two prototypes at major display makers in Asia. The prototypes include an 8” reflective LCD for an e-reader for the China education market, and a 6” display for a phone. The advantages of reflective LCD would seem to make it an excellent choice for both of these applications.

A reflective LCD depends on having sufficient ambient light to reflect in order to be read. A reflective LCD does not have a backlight and does not make any light on its own.

A reflective LCD can be seen well in any lighting situation where you could read text on a paper, they are perfectly suited to typical office lighting. In bright sunlight, a reflective LCD is still visible and does not wash out–this is also called “sunlight readable.” A reflective LCD is not a suitable choice for dark environments.

Reflective LCDs are often used for low power applications since there is no backlight using power, the overall power consumption is small. ePaper displays, although not an LCD, are an example of a reflective display. ePaper is the hands-down winner of the low-power race since they use zero power between updates.

This color is one of the most commonly used online. reflective lcd displays are differently used and, for some reason, they don"t come in a wide range of colors. While reflective lcd displays are made of differently and glass, they create differently shaped effects and cause different harm to the user.

reflective lcd displays are used in a variety of settings, including on-the-goens, and for. use reflective lcd displays with different advantages. As a business, it ’ s important to note that reflective lcd displays have different advantages. One of the main advantages of reflective lcd displays is the ability to be refed without using the light materials.

LCD (Liquid Crystal Displays) have two options or display modes.Positive mode (dark characters on a light colored background) and negative mode (lighter colored characters on a darker background).

Positive mode displays have the advantage of their lighter background and no backlights are needed. They normally use transflective or reflective polarizers and have lower power consumption. They can be seen with ambient light.

Of course, we can always use LED backlight in the LCD module with fewer LED chips and turn off LED backlight when not use to save power. When can also add transflective polarizer to some negative LCDs to make it sunlight readable, but the contrast will be compromised.

Positive and negative mode concept is not only limited to monochrome LCD displays (LCD panels, character LCDs, graphic LCDs etc.), it also uses for color displays, or even other display technologies. We will categorize the displays as below,

Character LCD modules (Alphanumeric LCD display modules) with character sets: 8×1 LCD display, 8×2 LCD display, 16×1 LCD display, 16×2 LCD display, 16×4 LCD display, 20×2 LCD display, 20×4 LCD display, 24×2 LCD display, 40×2 LCD display, 40×4 LCD display. COB (Chip on Board) bonded, 4 or 8 bits parallel, SPI, I2C interface

Graphic LCD modules with dot matrix sets 122×32, graphic LCD display, 128×64 graphic LCD display, 192×48 graphic LCD display,192×64 graphic LCD display,240×64 graphic LCD display,240×128 graphic LCD display,240×160 graphic LCD display with different color LED backlights, with COB and COG (Chip on Glass) assembling technologies

Full Color TN and IPS displays with panel sizes: 1.3”IPS display, 1.44” TN display, 1.5” IPS display, 1.77”TN and IPS displays, 2.0” TN and IPS displays, 2.2” IPS display, 2.35” IPS display, 2.4” TN and IPS displays, 2.8” TN and IPS displays, 3.5” TN and IPS displays, 4.3” TN display, 5.0” TN and IPS display, 7.0” TN and IPS display, 10.1” IPS display with medium and high brightness (sunlight readable), with parallel, SPI, RGB, LVDS, MIPI interfaces.

More brightness and higher contrast make the display clear even during bright sunlight conditions. Manufacturers have enormously brought down surface reflectivity with anti-reflective coatings, making the display easier to pursue during high-sunlight glare conditions. Progressive Super View Technology of Sharp, for example, gives an extremely crisp image under sunlight without pumping more power from the backlight, which helps in maintaining the life and quality of the product.

Conventional displays are rectangular because they require a minimal width for the bezel so as to accommodate the drive circuit, called the gate driver, around the perimeter of the screen’s display area. With the morpheme display (using IGZO technology), the gate driver’s function is dispersed throughout the pixels on the display area. This enables the bezel to be shrunk considerably, and it gives the liberty to style the LCD to match whatever shape the display area of the screen has to be.

Low-voltage differential signalling (LVDS) could be a popular choice for giant LCDs and peripherals in need of high bandwidth, like high-definition graphics and fast frame rates. It is most ordinarily utilised in automotive TFT applications. It’s an excellent solution due to its high speed of data transmission while using low voltage.

Centre-stack displays should be visible to both driver and the passengers, including those on the rear seats. LCD display modules are designed to provide the best contrast and readability in one of the four directions, known as the Viewing Angle or Optimal Viewing Direction. These four directions are laid out in the shape of a clock. The top view is at 12:00pm and the bottom view is at 6:00pm.

Optical bonding is the method involving overlaying touchscreens, glass, or plastic cover lenses, adding EMI filters and other display upgrades to an LCD. A layer of glue is incorporated between the cover layer and display to fill the air gap abandoned in a regular edge or gasket bonding. Optical bonding helps in enhancing clarity, viewability, reducing reflections, and making TFT more rugged, which are critical factors in automotive applications.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey