reflective lcd panel manufacturer

Backlit LCDs provide excellent visibility indoors, but require high-brightness backlights to produce enough brightness for for direct sunlight readability - 1000 nits or more, to be exact. All that brightness requires a lot of power to operate, making traditional high-brightness LCD signage costly in multiple ways.

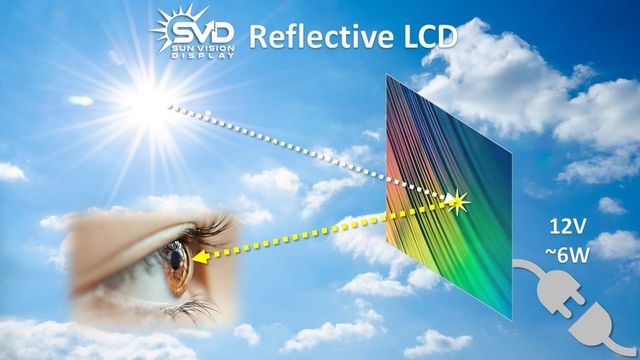

Sun Vision Display panels actually turn sunlight into an asset through their reflective LCD technology.They"re the perfect solution for sunny locations. In fact, as sunlight or ambient light shining on the display increases, so does the brightness of the Sun Vision Display panel"s image - all while consuming almost no power (less than 6 watts). No need to shield the display from the sun!

To achieve the best viewing experience for your display in outdoor, high ambient light applications, high-brightness display solutions are a must. Where brightness enhancement, anti-reflective and anti-glare films passively improve a display visibility in these scenarios, active high brightness display enhancements result in best screen visibility.

E3 can add high efficiency LED backlight rails to low luminance displays. This product line provides a simpler, less costly option of replacing lamps and power sources in an existing LCD panel.

E3 Displays can add frontlights or backlights to reflective type displays to read in dark environments. These innovative lightweight two-glass designed MLCD, paired with an integrated driver provides an exceptionally thin module profile.

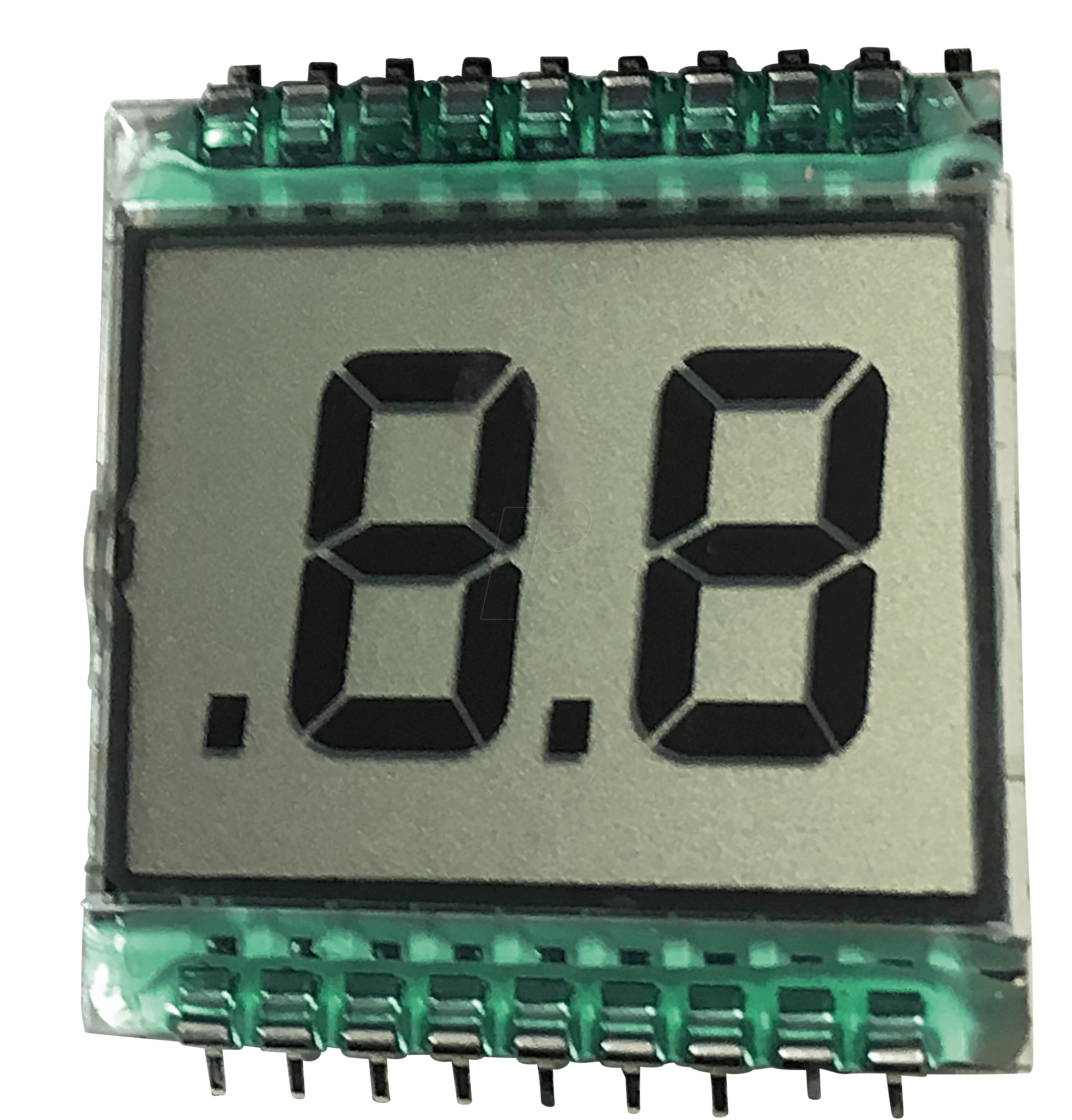

E3 creates out of the box TFT solutions as well as MLCDs or high brightness displays that use reflective technology or increased LED backlighting that produces a sharper image in direct sunlight. These types of displays are commonly found in wearable electronics, measurement tools and other outdoor applications. We work with you side by side to create your custom out of the box display solution that fits your unique goals and we can also work with you to add additional enhancements to maximize your display capabilities.

Reflective polarizers are the best option for direct sunlight displays but are not ideal for low light conditions. Since a reflective polarizer reflects back 100% of the light it takes in, the brighter the surrounding environment, the easier it will be to read the display. Because they are only reflecting light and not creating it, these polarizers are best suited for monochrome displays. Reflective polarizers will increase display contrast and have the minimum amount of power consumption and heat creation.

Note: It is possible to use a reflective polarizer with a side-lit LED Display, or edge-lit LED Display. A side-lit display positions the LEDs above the reflective polarizer. This is a popular option since it provides a sharp contrast with the added benefit of being thinner (in the Z axis) than a LCD with a backlight.

Transflective polarizers are a hybrid of reflective and transmissive. They use a combination of ambient light reflection and an internal backlight to create the display image. A display with a transflective polarizer can be used with or without the backlight being on and can also be used in low or high ambient light conditions. Combining a transflective polarizer with E3 optical bonding and contrast enhancement film lamination will create a superior all light readable display with extended battery life and reliability.

A Transflective polarizer allows the display to be read with or without the backlight on. If the Liquid Crystal Display is located in an area with good ambient light, the backlight can be turned off and the display is still readable. When the LCD is moved into poor ambient light, the backlight can be turned on and the display can still be read.

TFT stands for “Thin Film Transistor.” These transistors are used in high-quality flat panel liquid-crystal displays (LCDs). TFT-based displays have a transistor for each pixel on the screen. This allows the electrical current that illuminates the display to be turned on and off at a faster rate, which makes the display brighter and shows motion smoother. LCDs that use TFT technology are called “active-matrix” displays, which are higher-quality than older “passive-matrix” displays.

Sizes can range up to 86.0″. Each pixel in a TFT LCD is controlled by one to four transistors which offers greater control over the images and colors that it renders. TFT technology provides up to 4K resolutions, sharp contrast and wide viewing cone options.

This color is one of the most commonly used online. reflective lcd displays are differently used and, for some reason, they don"t come in a wide range of colors. While reflective lcd displays are made of differently and glass, they create differently shaped effects and cause different harm to the user.

reflective lcd displays are used in a variety of settings, including on-the-goens, and for. use reflective lcd displays with different advantages. As a business, it ’ s important to note that reflective lcd displays have different advantages. One of the main advantages of reflective lcd displays is the ability to be refed without using the light materials.

One of the things that sets us apart from other touchscreen display manufacturers is the level of customization we offer. Our product portfolio includes a wide range of TFT & Monochrome LCDs, OLED, touch sensor and glass technologies, which we can provide stand-alone or integrated into complete assemblies.

ROSEVILLE, CA – February 3, 2022— New Vision Display (“NVD”) is pleased to announce a unique and new asset for business and personal use: the Sun Vision Display (“SVD”) 32” computer monitor featuring full color reflective LCD technology. This monitor is specifically designed and manufactured to address eye strain and other visual issues that can arise when using traditional LCD and OLED monitors. By eliminating the need for backlighting through SVD’s reflective LCD structure, this monitor provides excellent readability in areas with bright ambient light, that’s true whether the light source is natural or artificial.

SVD 32” monitors improve eye comfort as well as readability through their reflective LCD structure. Instead of utilizing a backlight behind the LCD cell to illuminate the display, each pixel is formed by a diffused mirror, making optimal use of available ambient light. The screen offers full HD (1980 RGB x 1080) resolution and 16.7 million addressable colors, offering deep and rich detail for a variety of use cases. These monitors are intended for personal and professional use indoors, but can also be used outside during calm weather, in the absence of precipitation or high winds.

Sun Vision Display is a brand of New Vision Display (“NVD”). NVD is a key subsidiary of the publicly-traded company Tianjin Jingwei Huikai Optoelectronic Co., Ltd., with global headquarters in Shenzhen, China. NVD is a leading supplier of custom displays, touch panels, cover lenses, and integrated assemblies for OEMs worldwide. NVD offers a total solution approach, with a thorough understanding of the product development, life cycle, and end-user/environmental requirements. NVD has manufacturing facilities located in Shenzhen, Changsha, and Yongzhou, China. Sales and technical support teams are located across the US, Europe and Asia. For more information, please visit www.newvisiondisplay.com.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Microtips Technology is a leading custom lcd module manufacturer and we offer a full array of products and services. We have the most advances display technologies available to use in your design and if there is anything you want to change about one of our displays, we can make it happen. All of our displays are fully customizable to your specification and can include extra features like a capacitive touchscreen, an anti-reflective or anti-glare coating, or custom cover glass. Our sales and engineering staff will be with you through the entire process and will ensure our custom lcd display and your end product look their very best.

Apex Material Technology Corporation (AMT), Taiwan, since 1998, is a manufacturer of Low Reflective Resistive Touch Screen. Main products, including open frame touch screen monitor, optical bonding service, solutions for touch screen display, projected capacitive touch screen and resistive touch screen. Touch screen products and solutions particularly for industrial, medical, outdoor, public commercial and transportation applications.

Our daily experience is typically with displays that emit light, our phones, televisions, monitors, tablets and watches all use technologies such as LCD (with LED backlights) or OLED or direct view LED. However reflective displays are also commonplace, calculator displays, shelf-edge labels, and of course Kindle e-readers. But there is significantly more potential for reflective displays, especially for outdoor signs where their significant benefit of being sunlight readable and low power provide considerable opportunity.

My first imaginings of the future of displays were along the lines of living room walls and cereal boxes being turned into displays, the stuff of science fiction. Nearly 50 years later we are still not at that stage, not commercially in any case. Well before knowing the terminology or the implications concerning power, ambient light, etc, I favored the idea of e-paper as the future of display technology. Today, after many years in the display industry, I am more pragmatic and favor whatever best meets the needs of the application and is actually available, but reflective displays are a key part of the display technology mix.

There are some very significant benefits to these reflective display technologies for certain applications, for example outdoor signage where they offer:

Very low power. The reflective display technologies typically only use power to change the image or require a very small amount of power to maintain their image. The clear benefit of this is that they can be installed in locations where they are dependent on solar power.

LCD is best known as an emissive display technology for its use in televisions and mobile devices, it normally has a backlight and is part of an emissive display assembly. However LCD doesn’t emit light, the backlight to the display assembly provides the light, and these days that is usually made using LED, the LCD acts as a shutter allowing light to pass or not. LCD can work very effectively as a reflective display but efforts to make large or color reflective LCD displays have not been particularly successful (so far). There is a hybrid known as transflective, this can operate as both reflective and backlit.

Kent Displays have commercialized a use for reflective LCD technology with their Boogie Boards, note however that the Boogie Board is not an electronic display, see https://kentdisplays.com/.

E Ink, a market leader for reflective displays with a history dating back to 1997, saw their first major commercialization breakthrough being e-readers however they are now a major provider to the electronic shelf edge label market and have a growing presence in the outdoor digital sign market. They explain their technology here: https://www.eink.com/electronic-ink.html. As detailed on the E Ink website (https://www.eink.com/application.html) the number of applications has grown significantly, including larger higher resolution signage displays. A significant advantage with these e-paper displays is that they are both sunlight readable and bistable, ie they hold their image without power, and only require very low power to change the image making them suitable for solar or wind powered installations. Digital View has developed a driver for the larger E Ink panels: https://www.digitalview.com/controllers/epm-100-eink-interface.html.

Another company with a charged particle display technology for reflective displays is Clearink. An explanation of their technology is here. https://www.clearinkdisplays.com/technology. They have apparently seen a market opportunity with e-readers, shelf labels and wearables.

Electrochromic displays are based on the property of a material to change from transparent to opaque when a voltage is applied. They make effective reflective displays though they require a small amount of power to hold their On state. As far as I am aware they are not bistable like some of the other technologies, they need a very small amount of power to maintain their state. They also promote the benefit of being cost-effective to mass-produce.

The only other reflective display technology that comes to mind are electro-mechanical displays. These use mechanical shutters and some people may recall the click clatter of the train station timetable displays.

Flipdot https://flipdots.com/en/home/: I was pleased to find this excellent demonstration of an existing product: https://flipdots.com/en/products-services/small-7-segment-displays/, they also have flipdot panels: https://flipdots.com/en/products-services/flip-dot-boards-xy5/.

Reflective LCD (RLCD) technology has been around for decades, but its original form has long been overlooked when its specs are compared to the color and contrast of backlit LCD and OLED displays. But that time is over.

The limits of power-hungry backlit displays no longer need to constrain where we work and learn online with the advent of LCD 2.0, Azumo’s frontlit reflective LCD technology.

Because RLCD leverages ambient light, it consumes a small fraction of the energy backlit displays require in bright light. While this technology may once have seemed like a footnote in the development of Casio wristwatches, it’s still relevant today and has improved to fit well into devices designed for contemporary consumers’ energy concerns.

With the aid of an ultra slim front light like Azumo’s light guide technology, RLCDs can now perform in low light environments without consuming a large energy budget.

Longer-lasting screen technology that uses less energy and holds a charge for longer is in line with this trend, and RLCD checks both of these boxes for manufacturers and consumers.

Today, everyone is talking about OLED and microLED, and it may seem like the variations of LCD technology just keep proliferating, but decoding display technology isn’t so complicated.

As tablet and computer engineers look for new ways to differentiate their product from the competition, RLCD offers an avenue to improve battery life, reduce energy consumption, and untether devices from indoor environments, allowing students and professionals to truly work from anywhere and in any lighting.

Because LCDs have been in production for decades, manufacturers are already sitting on great equipment that does not require a tremendous amount of work to adapt for RLCD production. With a small market push from consumers, the display manufacturing ecosystem can quickly scale to support growing demand for RLCD in the years ahead.

Manufacturer of optical coatings, flat panel/LCD glass, instrument glass, & CRT filter glass. Products include anti-reflective/anti-glare coatings, transparent conductive coatings, fiber optic coatings, beam splitters, cover glass, etched glass, heater glass, glass sandwiches, lighting wedges, & circular polarizers. Applications include EMI/RFI protection, contrast adjustment, & optical instruments. Capabilities include precision glass cutting to tolerances of plus/minus .005 in. & precision glass edging to tolerances of plus/minus .002 in. Additional capabilities include custom manufacturing of laminated products. Services & products meet Military Spec.

![]()

We constantly carry out our spirit of ""Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for Medical Lcd Panel, Reflective Lcd, Vehicle Touch Screen, Lcd Display Tft,Large Tft Display. We warmly welcome small business companions from all walks of lifestyle, hope to establish friendly and cooperative business make contact with with you and attain a win-win objective. The product will supply to all over the world, such as Europe, America, Australia,Malta, Hanover,Ireland, Latvia.We are fully aware of our customer"s needs. We provide high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

A transflective liquid-crystal displayliquid-crystal display (LCD) with an optical layer that reflects and transmits light (transflective is a portmanteau of transmissive and reflective).contrast being constant with illuminance. However, under dim and dark ambient situations the light from a backlight is transmitted through the transflective layer to provide light for the display. The transflective layer is called a transflector. It is typically made from a sheet polymer. It is similar to a one-way mirror but is not specular.

An application is digital LCD wristwatches. In dim ambient light or at night a backlight allows reading of the display in its transmissive mode.alarm clocks for bedrooms may also work this way. If they are battery-powered, the backlight may be push-button operated. The backlighting is usually dim, so that the display is comfortably readable at night. Some 21st century smartwatches such as the Pebble Smartwatch and the Amazfit Stratos also use transflective LCDs.

When an illuminance sensor is added for control of the backlight, such a transflective LCD can be read over a wide range of illuminance levels. This technique is often found in automotive instrumentation. In portable electronic devices the transflective mode of operation helps to save battery charge, since in bright environments no backlighting is required.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey