atmel lcd display factory

A segmented Liquid Crystal Display (LCD) is made up of segments which can be made visible or invisible by applying a voltage across the liquid crystal. The SAM L22 microcontroller has a Segment LCD (SLCD) controller which is used to drive segmented LCD displays.

This tutorial shows you how to use the SAM L22"s SLCD controller to drive an LCD display. You will use the SAM L22 Xplained Pro Evaluation Kit and Segment LCD1 Xplained Pro extension board (sold separately).

Add code to use the features of the SLCD like ASCII character mapping, software contrast control, hardware blinking, SLCD waking up from standby sleep mode, SLCD lower power consumption and scrolling on the segmented LCD display.

Observe how your code affects the Segment LCD1 Xplained Pro board mounted on SAM L22 Xplained Pro Evaluation Kit, and monitor power consumption using the Atmel Studio Data Visualizer.

The segments in a segmented LCD display have two electrodes with liquid crystal between them. These electrodes are called the common terminal (COM pin) and the segment terminal (SEG pin). When a voltage above a threshold voltage is applied across the liquid crystal, the segment becomes visible.

The SAM L22 SLCD controller is intended for a monochrome passive liquid crystal display with up to eight common terminals and up to 44 segment terminals (maximum of 320 segments). Features such as character mapping, automated characters string display, and autonomous animation are implemented to reduce CPU load and power consumption.

This lab shows you how to use the SAM L22"s SLCD controller to drive the Segment LCD1 Xplained Pro display on the SAM L22 Xplained Pro Evaluation Kit. It also helps you understand and use the following features: ASCII character mapping, software contrast control, hardware blinking, SLCD waking up from standby sleep mode, SLCD lower power consumption, and scrolling characters on the LCD display.

saml22_slcd_lab contains the complete lab solution (saml22_slcd_lab.atsln and related files under sub folder saml22_slcd_lab) and source files to create the lab from scratch.

The following is a tutorial on using the ST7920 LCD with the ATmega328 microcontroller using Atmel Studio via the SPI interface. I have used the U8g2 Library, https://github.com/olikraus/u8g2

There are many tutorials on how to control the LCD using an Arduino, but I couldn"t find many on how to use the LCD in Atmel Studio. There was a great one here, https://github.com/olikraus/u8g2/wiki/u8g2as7 which I used to learn how to do this, but several fine details were missing, which made it hard to follow.

I assume that you have the microcontroller working in Atmel Studio. There are plenty of tutorials on how to set up the ATmega328 on a breadboard and get a simple blink program working in Atmel Studio. These are some great ones:

We are using SPI communication, so we select that setup line and paste it into the Atmel main function as shown in the last image. The following line is copied into the main function, replacing the original setup line.

2. If the LCD does not have a potentiometer soldered to the back, attach a resistor with a value of between 200 to 10000 ohms to pin VO as seen above. Adjust the value of the resistor to achieve an optimal contrast. Alternatively, a potentiometer could be used to adjust the contrast.

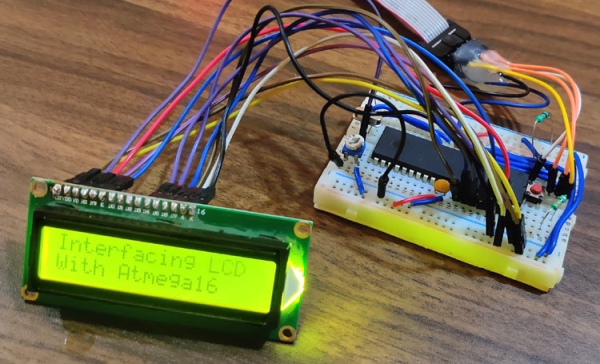

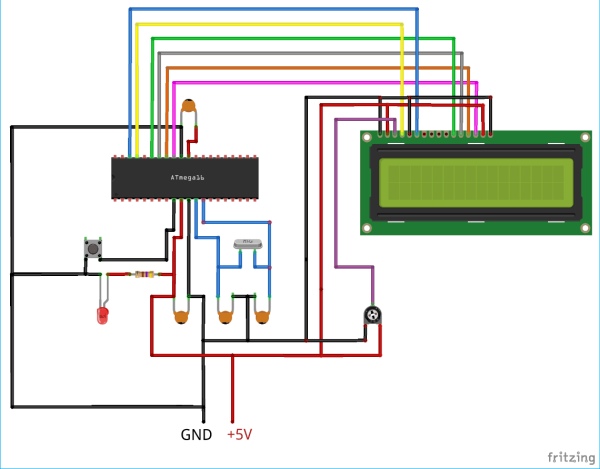

As we all know LCD (Liquid Crystal Display) is an electronic display which is commonly used nowadays in applications such as calculators, laptops, tablets, mobile phones etc. 16×2 character LCD module is a very basic module which is commonly used by electronic hobbyists and is used in many electronic devices and project. It can display 2 lines of 16 character and each character is displayed using 5×7 or 5×10 pixel matrix.

Interfacing 16×2 LCD with Atmega32 Atmel AVR Microcontroller using Atmel Studio is bit complex as there is no built in libraries. To solve this difficulty we developed a LCD library which includes the commonly used features. Just include our header file and enjoy. You can download the header file from the bottom of this article.

16×2 LCD can be interfaced with a microcontroller in 8 Bit or 4 Bit mode. These differs in how data and commands are send to LCD. In 8 Bit mode character data (as 8 bit ASCII) and LCD command are sent through the data lines D0 to D7. That is 8 bit data is send at a time and data strobe is given through E of the LCD.

But 4 Bit mode uses only 4 data lines D4 to D7. In this 8 bit data is divided into two parts and are sent sequentially through the data lines. The idea of 4 bit communication is introduced to save pins of microcontroller. 4 bit communication is bit slower than 8 bit but this speed difference has no significance as LCDs are slow speed devices. Thus 4 bit mode data transfer is most commonly used.

Lcd8_Init() & Lcd4_Init() :These functions will initialize the 16×2 LCD module connected to the microcontroller pins defined by the following constants.

Lcd8_Set_Cursor() & Lcd4_Set_Cursor() :These function will set the cursor position on the LCD screen by specifying its row and column. By using these functions we can change the position of character and string displayed by the following functions.

Lcd8_Write_Char() & Lcd4_Write_Char() :These functions will write a single character to the LCD screen and the cursor position will be incremented by one.

Lcd8_Write_String() & Lcd8_Write_String() :These function will write string or text to the LCD screen and the cursor positon will be incremented by length of the string plus one.

You already seen that by using our header file lcd.h, you can connect your 16×2 LCD to any of the output pins of the microcontroller. More coding is required for this feature which reduces the code efficiency and increases the size of hex file. You can solve this problem by making simple changes in the header file according to your LCD connections. For example consider above sample programs. I have used PORTD for sending data, 6th bit of PORTC as RS and 7th bit of PORTC as EN.

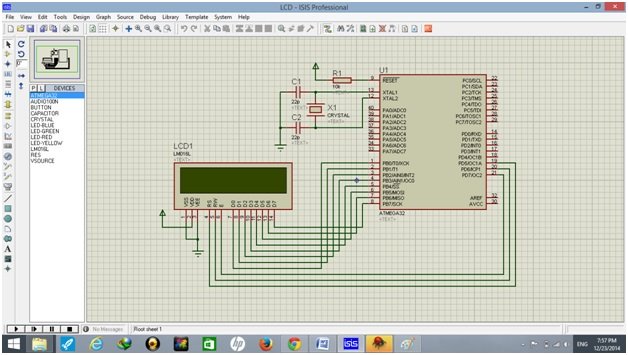

Display is the necessary part of any machine whether it is any home appliance or industrial machines. Display not only shows the control options to operate the machine but also shows the status and output of the task performed by that machine. There are many types of displays used in electronics like 7-segment display, 16×2 LCD display, TFT touch screen display, OLED display etc.

16×2 LCD display is the most basic display module and also used in some small electronics equipment like calculator, digital meter etc. We have done lot of projects using 16×2 LCD including the basic interfacing with other microcontrollers:

Programming doesn’t require any external libraries. Here the Complete Program and Working Video is given at the end of the project, just upload the program in Atmega16 and rotate 10k POT to adjust the brightness of LCD.

Initially define the CPU Frequency and include the necessary libraries which comes with Atmel Studio Package such as

Next step is to construct a function which will accept a command by passing a parameter. There are many LCD HEX Commands. The Hex Commands are used to define the function of LCD. Since we are using the 4-bit Mode of LCD, the byte (8-bit) will be sent in two packets. The one packets will be Upper Nibble (4-bit) and other packet will be Lower Nibble (4-bit).

The next step would be accepting the characters and latching it to the port of LCD. The characters received is then sent to the LCD nibble by nibble. The Function takes the character using pass by parameter and then takes the upper and lower nibble. The ‘rs’ pin is set to high for data register and then a rising pulse is sent to latch the data. Similarly the lower nibble in sent by changing the value of enable and sending the rising pulse for enable.

The command 0c and 06 is used to control cursor position. And finally just clear the screen by sending 01 in hex. This will finish the initialization of LCD.

This finishes the complete tutorial on Interfacing a 16×2 LCD with Atmega16. Note that if you don’t get any image or pixels then either check your wiring according to code and circuit diagram or change the value of the POT attached to V0 pin of LCD. If you have any doubt or suggestion then you can reach us to either by writing to our forum or comment below.

A very nice project cost is a bit high in our country, even hard to find parts Atmel AVR microcontroller series dealing with this type of project is ideal for those who want to… Electronics Projects, ATMEGA162 LCD Oscilloscope Circuit “avr project, microcontroller projects, “

A very nice project cost is a bit high in our country, even hard to find parts Atmel AVR microcontroller series dealing with this type of project is ideal for those who want to learn about

I think part of that is difficult to have the most expensive LCD LMG6402PLF Hitachi LCD Screen LCD Oscilloscope ATMEGA162 microcontroller circuit board have all the details on

The oscilloscope is one of the the most important tools to be used by any electronics hobbyist but not everybody can afford to have one. As commercial scopes are often too expensive, almost every electronics hobbyist thought at a certain time to build one from scratch. The classical oscilloscope (cathode ray tube) is difficult to build at home because of its size, mechanical fragility, high voltages presence, etc. An alternative solution is the modern “PC oscilloscope”, having the advantage of post-processing and recording capabilities, and kind of reduced complexity. However, this solution is often non-portable, expensive (requires an PC) and dangerous for the PC if not isolated from it’s chassis. The third solution, commonly used these days by all commercial oscilloscope manufacturers, is the digital oscilloscope with LCD screen. Therefore, the authors decided to use this solution, and tried to develop it using common parts from today’s component retailers.

source: LCD OSCILLOSCOPE CIRCUIT LCD Oscilloscope Circuit files alternative link:atmega162-lcd-oscilloscope-circuit.rar alternative link3 alternative link4

The Atmel SAM4LC2C is a Core - ARM CortexTM-M4 running at up to 48 MHz - Memory Protection Unit (MPU) picoPower Technology for Ultra-low Power Consumption Memories - Up to to 256Kbytes embedded Flash - 32 Kbytes embedded SRAM System Functions - Embedded voltage linear and switching regulator - 2 Power-on-Reset and 2 Brown-out Detectors (BOD) - Quartz or ceramic resonator oscillators: 3 to 20 MHz main power with Failure Detection low power 32.768 kHz for RTC or device clock - High precision 4/8/12 MHz factory trimmed internal RC oscillator - Slow Clock Internal RC oscillator as permanent low-power mode device clock - High speed 80MHz internal RC oscillator - Low power 32kHz internal RC oscillator - PLL up to 240 MHz for device clock and for USB - Digital Frequency Locked Loop (DFLL) - Temperature Sensor - Up to 16 peripheral DMA (PDCA) channels Peripherals - USB 2.0 Device / Host: 12 Mbps, up to 8 bidirectional Endpoints - Liquid Crystal Display (LCD) Module - 1 USART with ISO7816, IrDA, RS-485, SPI, Manchester and LIN Mode - 3 USART with SPI Mode - Windowed Watchdog Timer (WDT) - Asynchronous Timer (AST) with Real-time Clock Capability, Counter or Calendar Mode - Frequency Meter (FREQM) - 6 16-bit Timer/Counter (TC) - 1 Master/Slave Serial Peripheral Interface (SPI) - 4 Master and 2 Slave 2-wire Interfaces (TWI) - 1 Advanced Encryption System (AES) - 1 16-channel ADC 300Ksps (ADC) - 1 DAC 500Ksps (DACC) - 4 Analog Comparators (ACIFC) - Capacitive Touch Module (CATB) - Audio Bitstream DAC (ABDACB) - Inter-IC Sound (IISC) Controller - Peripheral Event System for Direct Peripheral to Peripheral Communication - 32-bit Cyclic Redundancy Check Calculation Unit (CRCCU) - Random generator (TRNG) - Parallel Capture Module (PARC) - Glue Logic Controller (GLOC) - PicoUART for extended UART wake-up capabilities I/O - Up to 75 I/O lines with external interrupt capability - Up to 6 High-drive I/O Pins.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

AVR is a family of microcontrollers developed since 1996 by Atmel, acquired by Microchip Technology in 2016. These are modified Harvard architecture 8-bit RISC single-chip microcontrollers. AVR was one of the first microcontroller families to use on-chip flash memory for program storage, as opposed to one-time programmable ROM, EPROM, or EEPROM used by other microcontrollers at the time.

Atmel says that the name AVR is not an acronym and does not stand for anything in particular. The creators of the AVR give no definitive answer as to what the term "AVR" stands for.Alf and Vegard"s RISC processor.

The original AVR MCU was developed at a local ASIC house in Trondheim, Norway, called Nordic VLSI at the time, now Nordic Semiconductor, where Bogen and Wollan were working as students.VLSI, the internal architecture was further developed by Bogen and Wollan at Atmel Norway, a subsidiary of Atmel. The designers worked closely with compiler writers at IAR Systems to ensure that the AVR instruction set provided efficient compilation of high-level languages.

The AVR 8-bit microcontroller architecture was introduced in 1997. By 2003, Atmel had shipped 500 million AVR flash microcontrollers.Arduino platform, developed for simple electronics projects, was released in 2005 and featured ATmega8 AVR microcontrollers.

In 2006, Atmel released microcontrollers based on the 32-bit AVR32 architecture. This was a completely different architecture unrelated to the 8-bit AVR, intended to compete with the ARM-based processors. It had a 32-bit data path, SIMD and DSP instructions, along with other audio- and video-processing features. The instruction set was similar to other RISC cores, but it was not compatible with the original AVR (nor any of the various ARM cores). Since then support for AVR32 has been dropped from Linux as of kernel 4.12; compiler support for the architecture in GCC was never mainlined into the compiler"s central source-code repository and was available primarily in a vendor-supported fork. At the time that AVR32 was introduced, Atmel had already been a licensee of the ARM architecture, with both ARM7 and ARM9 microcontrollers having been released prior to and concurrently with the AVR32; later Atmel focused most development effort on 32-bit chips with ARM Cortex-M and Cortex-A cores.

The very smallest of the tinyAVR variants use a reduced architecture with only 16 registers (r0 through r15 are omitted) which are not addressable as memory locations. I/O memory begins at address 000016, followed by SRAM. In addition, these devices have slight deviations from the standard AVR instruction set. Most notably, the direct load/store instructions (LDS/STS) have been reduced from 2 words (32 bits) to 1 word (16 bits), limiting the total direct addressable memory (the sum of both I/O and SRAM) to 128 bytes. Conversely, the indirect load instruction"s (LD) 16-bit address space is expanded to also include non-volatile memory such as Flash and configuration bits; therefore, the Load Program Memory (LPM) instruction is unnecessary and omitted. (For detailed info, see Atmel AVR instruction set.)

Since the number of writes to EEPROM is limited – Atmel specifies 100,000 write cycles in their datasheets – a well designed EEPROM write routine should compare the contents of an EEPROM address with desired contents and only perform an actual write if the contents need to be changed.

Atmel"s AVRs have a two-stage, single-level pipeline design. This means the next machine instruction is fetched as the current one is executing. Most instructions take just one or two clock cycles, making AVRs relatively fast among eight-bit microcontrollers.

The mostly regular instruction set makes C (and even Ada) compilers fairly straightforward and efficient. GCC has included AVR support for quite some time, and that support is widely used. LLVM also has rudimentary AVR support. In fact, Atmel solicited input from major developers of compilers for small microcontrollers, to determine the instruction set features that were most useful in a compiler for high-level languages.

The Program and Debug Interface (PDI) is an Atmel proprietary interface for external programming and on-chip debugging of XMEGA devices. The PDI supports high-speed programming of all non-volatile memory (NVM) spaces; flash, EEPROM, fuses, lock-bits and the User Signature Row. This is done by accessing the XMEGA NVM controller through the PDI interface, and executing NVM controller commands. The PDI is a 2-pin interface using the Reset pin for clock input (PDI_CLK) and a dedicated data pin (PDI_DATA) for input and output.

The Unified Program and Debug Interface (UPDI) is a one-wire interface for external programming and on-chip debugging of newer ATtiny and ATmega devices. The Atmel-ICE and PICkit 4 are capable of programming UPDI chips. It is also possible to use an Arduino thanks to jtag2updi,

Most AVR models can reserve a bootloader region, 256 bytes to 4 KB, where re-programming code can reside. At reset, the bootloader runs first and does some user-programmed determination whether to re-program or to jump to the main application. The code can re-program through any interface available, or it could read an encrypted binary through an Ethernet adapter like PXE. Atmel has application notes and code pertaining to many bus interfaces.

debugWIRE is Atmel"s solution for providing on-chip debug capabilities via a single microcontroller pin. It is particularly useful for lower pin count parts which cannot provide the four "spare" pins needed for JTAG. The JTAGICE mkII, mkIII and the AVR Dragon support debugWIRE. debugWIRE was developed after the original JTAGICE release, and now clones support it.

The Atmel ICE is the currently supported inexpensive tool to program and debug all AVR devices (unlike the AVRISP/AVRISP mkII, Dragon, etc discussed below). It connects to and receives power from a PC via USB, and supports JTAG, PDI, aWire, debugWIRE, SPI, SWD, TPI, and UPDI (the Microchip Unified Program and Debug Interface) interfaces.

The Atmel-ICE supports a limited implementation of the Data Gateway Interface (DGI) when debugging and programming features are not in use. The Data Gateway Interface is an interface for streaming data from a target device to the connected computer. This is meant as a useful adjunct to the unit to allow for demonstration of application features and as an aid in application level debugging.

The AVR ONE! is a professional development tool for all Atmel 8-bit and 32-bit AVR devices with On-Chip Debug capability. It supports SPI, JTAG, PDI, and aWire programming modes and debugging using debugWIRE, JTAG, PDI, and aWire interfaces.

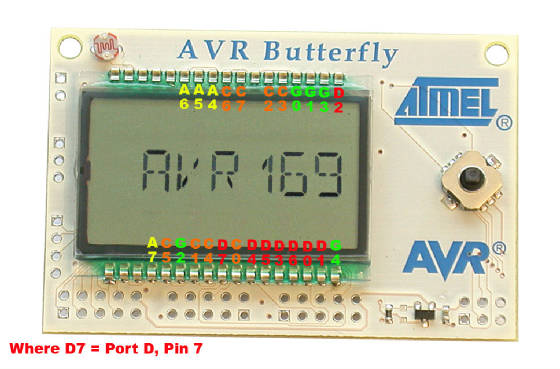

The very popular AVR Butterfly demonstration board is a self-contained, battery-powered computer running the Atmel AVR ATmega169V microcontroller. It was built to show off the AVR family, especially a then new built-in LCD interface. The board includes the LCD screen, joystick, speaker, serial port, real time clock (RTC), flash memory chip, and both temperature and voltage sensors. Earlier versions of the AVR Butterfly also contained a CdS photoresistor; it is not present on Butterfly boards produced after June 2006 to allow RoHS compliance.

The AVR Butterfly comes preloaded with software to demonstrate the capabilities of the microcontroller. Factory firmware can scroll your name, display the sensor readings, and show the time. The AVR Butterfly also has a piezoelectric transducer that can be used to reproduce sounds and music.

The AVR Butterfly demonstrates LCD driving by running a 14-segment, six alpha-numeric character display. However, the LCD interface consumes many of the I/O pins.

The Butterfly"s ATmega169 CPU is capable of speeds up to 8 MHz, but it is factory set by software to 2 MHz to preserve the button battery life. A pre-installed bootloader program allows the board to be re-programmed via a standard RS-232 serial plug with new programs that users can write with the free Atmel IDE tools.

The AVR Dragon can both program and debug since the 32 KB limitation was removed in AVR Studio 4.18, and the JTAGICE mkII is capable of both programming and debugging the processor. The processor can also be programmed through USB from a Windows or Linux host, using the USB "Device Firmware Update" protocols. Atmel ships proprietary (source code included but distribution restricted) example programs and a USB protocol stack with the device.

The RAVEN kit supports wireless development using Atmel"s IEEE 802.15.4 chipsets, for ZigBee and other wireless stacks. It resembles a pair of wireless more-powerful Butterfly cards, plus a wireless USBKey; and costing about that much (under $US100). All these boards support JTAG-based development.

The kit includes two AVR Raven boards, each with a 2.4 GHz transceiver supporting IEEE 802.15.4 (and a freely licensed ZigBee stack). The radios are driven with ATmega1284p processors, which are supported by a custom segmented LCD display driven by an ATmega3290p processor. Raven peripherals resemble the Butterfly: piezo speaker, DataFlash (bigger), external EEPROM, sensors, 32 kHz crystal for RTC, and so on. These are intended for use in developing remote sensor nodes, to control relays, or whatever is needed.

AVRs have been used in various automotive applications such as security, safety, powertrain and entertainment systems. Atmel has recently launched a new publication "Atmel Automotive Compilation" to help developers with automotive applications. Some current usages are in BMW, Daimler-Chrysler and TRW.

Schneider Electric used to produce the M3000 Motor and Motion Control Chip, incorporating an Atmel AVR Core and an advanced motion controller for use in a variety of motion applications but this has been discontinued.

"AVR Hardware Design Considerations" (PDF) (application note). Atmel Corporation. Jun 2015. p. 5. Retrieved 14 Jun 2015. The reset line has an internal pull-up resistor, but if the environment is noisy it can be insufficient and reset can therefore occur sporadically.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey