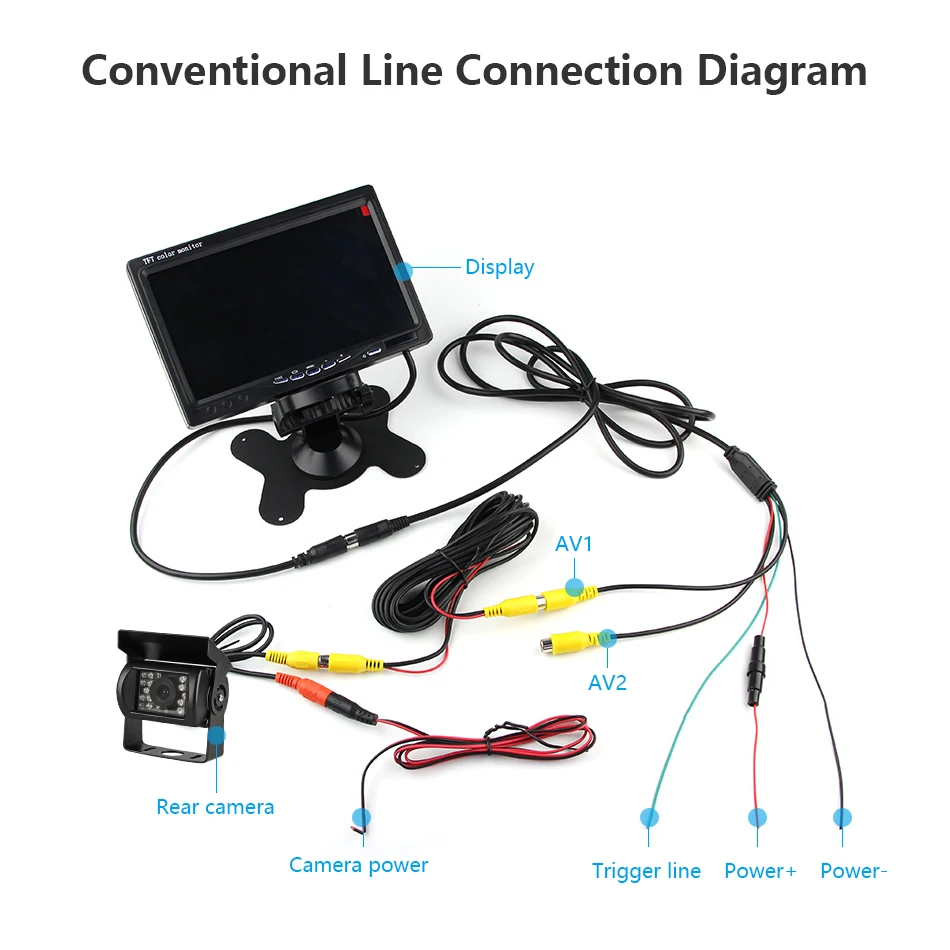

tft lcd color monitor wiring diagram quotation

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

Hi guys, welcome to today’s tutorial. Today, we will look on how to use the 1.8″ ST7735 colored TFT display with Arduino. The past few tutorials have been focused on how to use the Nokia 5110 LCD display extensively but there will be a time when we will need to use a colored display or something bigger with additional features, that’s where the 1.8″ ST7735 TFT display comes in.

The ST7735 TFT display is a 1.8″ display with a resolution of 128×160 pixels and can display a wide range of colors ( full 18-bit color, 262,144 shades!). The display uses the SPI protocol for communication and has its own pixel-addressable frame buffer which means it can be used with all kinds of microcontroller and you only need 4 i/o pins. To complement the display, it also comes with an SD card slot on which colored bitmaps can be loaded and easily displayed on the screen.

Due to variation in display pin out from different manufacturers and for clarity, the pin connection between the Arduino and the TFT display is mapped out below:

We will use two libraries from Adafruit to help us easily communicate with the LCD. The libraries include the Adafruit GFX library which can be downloaded here and the Adafruit ST7735 Library which can be downloaded here.

We will use two example sketches to demonstrate the use of the ST7735 TFT display. The first example is the lightweight TFT Display text example sketch from the Adafruit TFT examples. It can be accessed by going to examples -> TFT -> Arduino -> TFTDisplaytext. This example displays the analog value of pin A0 on the display. It is one of the easiest examples that can be used to demonstrate the ability of this display.

The first thing, as usual, is to include the libraries to be used after which we declare the pins on the Arduino to which our LCD pins are connected to. We also make a slight change to the code setting reset pin as pin 8 and DC pin as pin 9 to match our schematics.

Next, we create an object of the library with the pins to which the LCD is connected on the Arduino as parameters. There are two options for this, feel free to choose the most preferred.

All the functions called under the void setup function, perform different functions, some draw lines, some, boxes and text with different font, color and size and they can all be edited to do what your project needs.

Uploading the code to the Arduino board brings a flash of different shapes and text with different colors on the display. I captured one and its shown in the image below.

Hi guys, over the past few tutorials, we have been discussing TFT displays, how to connect and use them in Arduino projects, especially the 1.8″ Colored TFT display. In a similar way, we will look at how to use the 1.44″ TFT Display (ILI9163C) with the Arduino.

The ILI9163C based 1.44″ colored TFT Display, is a SPI protocol based display with a resolution of 128 x 128 pixels. It’s capable of displaying up to 262,000 different colors. The module can be said to be a sibling to the 1.8″ TFT display, except for the fact that it is much faster and has a better, overall cost to performance ratio when compared with the 1.8″ TFT display. Some of the features of the display are listed below;

TheTFT Display, as earlier stated, communicates with the microcontroller over SPI, thus to use it, we need to connect it to the SPI pins of the Arduino as shown in the schematics below.

Please note that the version of the display used for this tutorial is not available on fritzing which is the software used for the schematics, so follow the pin connection list below to further understand how each pin of the TFT display should be connected to the Arduino.

In order to allow the Arduino to work with the display, we need two Arduino libraries; the sumotoy TFT ILI9163C Arduino library which can be downloaded from this link and the popular Adafruit GFX Arduino library which we have used extensively in several tutorials. Download these libraries and install them in the Arduino IDE.

For today’s tutorial, we will be using the bigtest example which is one of the example codes that comes with the sumotoy ILI9163C Arduino library to show how to use the TFT display.

The example can be opened by going to File–>Examples–>TFT_ILI9163c–>bigtest as shown in the image below. It should be noted that this will only be available after the sumotoy library has been installed.

Next, we define some of the colors that will be used along with the corresponding hex values. If you’ve gone through any of our previous tutorials where we used the Adafruit GFX library, you would have noticed that this code contains a lot from the GFX library and it should be easier for you to follow.

Next, an object of the ILI9163c library named “display” was created with CS and DC parameter as inputs but due to the kind of display being used, we need to include the pin of the Arduino to which the A0 pin of the TFT display is connected which is D8.

The DT022BTFT uses the same connections as the DT022CTFT, with the exception of the backlight (which has connections shown in the Displaytech datasheet).

Note that the WR pin becomes the D/CX signal in serial mode. CS is used to initiate a data transfer by pulling it low. At the end of the data transfer, pull the CS pin high to complete the transaction. The timing diagram indicates that you can pull the CS pin high in between the command byte and data bytes within a transfer, but it is unlikely needed if the display is the only device on the SPI bus. To keep things simple, we suggest to leave it low during the entire transaction.

The D/CX pin tells the ILI9341 that the current byte is either command or data. Pull the D/CX pin low when the current byte is a command, and pull high when it is data. The timing diagram indicates only needing to set D/CX on the last bit of a byte, but it is much simpler to just leave it high or low during the entire byte.

Note that the WR pin becomes the D/CX signal in serial mode. CS is used to initiate a data transfer by pulling it low. At the end of the data transfer, pull the CS pin high to complete the transaction. The timing diagram indicates that you can pull the CS pin high in between the command byte and data bytes within a transfer, but it is unlikely needed if the display is the only device on the SPI bus. To keep things simple, we suggest to leave it low during the entire transaction.

The D/CX pin tells the ILI9341 that the current byte is either command or data. Pull the D/CX pin low when the current byte is a command, and pull high when it is data. The timing diagram indicates only needing to set D/CX on the last bit of a byte, but it is much simpler to just leave it high or low during the entire byte.

General Specification Product Pictures 4.3 inch TFT LCD with 540*960 High Resolution 4.3 inch High Resolution TFT LCD with Portrait Mode and MIPI Interface

General Specification NMLCD-43480272-CTP-IPS is a 4.3 inch IPS type TFT LCD with a Capacitive Touch Panel which is 1:1 scale with the LCD module, with 480*272 resolution. This product accords with RoHS. Product Pictures 4.3 inch 480*272...

General Specification This type is a 4.3"" 480*272 full view angle TFT LCD with a Capacaitive Touch Panel with full bonding. Product Picture 4.3"" TFT LCD with Capacitive Touch Panel with Full Bonding 4.3""...

General Specification This product is a 4.3"" color active matrix LCD module incorporating amorphous silicon TFT (Thin Film Transistor). It is composed of color TFT-LCD panel, driver IC, FPC and a back light unit and with a...

General Specification NMLCD-43480272-RTP-IPS is a 4.3 inch IPS type TFT LCD with a Resistive Touch, with 480*272 resolution. This product accords with RoHS. Product Pictures 4.3 inch IPS Type TFT LCD with 480*272 Resolution with...

General Specification NMLCD-43800480-IPS-850 is a TFT LCD with all view angle with high brightness. It is composed of a colour TFT-LCD panel, driver IC, FPC and a back light unit and with/without a Resistive/Capacitive Touch Panel (RTP...

General Specification NMLCD-43480272-IPS is a 4.3 inch IPS type TFT LCD, with 480*272 resolution. This product accords with RoHS. Product Pictures 4.3 inch IPS Type TFT LCD with WQVGA Resolution 4.3 inch 480*272 TFT LCD with All Viewng...

General Specification The NMLCD-43M15 is a color active matrix thin film transistor (TFT) liquid crystal display (LCD) that uses amorphous silicon TFT as a switching device. It is composed of a TFT LCD panel, a timing controller,...

General Specification NMLCD-43480272-CTP-CLB-IPS is a 4.3 inch IPS type TFT LCD with Capacitive Touch and Cover Lens Bezel, with 480*272 resolution. The touch panel is driven by FT5446. This product accords with RoHS. Product Pictures...

NMLCD-43480272-SB is a colour active matrix LCD module incorporating amorphous silicon TFT (Thin Film Transistor). It is composed of a colour TFT-LCD panel, driver IC, FPC and a back light unit and without a Touch...

Vin: PWB input voltage (12V)VDD: ASIC, source IC, gate IC driving power (3.3v)VGH: TFT component switching voltage (~30V)VGL: TFT component turn-off voltage (~ -6v)VAA: step control voltage (~17V)VCOM: liquid crystal reversal reference voltage (~7V)

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

General Specification NMLCD-43480272-CTP-IPS is a 4.3 inch IPS type TFT LCD with a Capacitive Touch Panel which is 1:1 scale with the LCD module, with 480*272 resolution. This product accords with RoHS. Product Pictures 4.3 inch 480*272...

The traditional mechanical instrument lacks the ability to satisfy the market with characters of favorable compatibility, easy upgrading, and fashion. Thus the design of a TFT-LCD (thin film transistor-liquid crystal display) based automobile instrument is carried out. With a 7-inch TFT-LCD and the 32-bit microcontroller MB91F599, the instrument could process various information generated by other electronic control units (ECUs) of a vehicle and display valuable driving parameters on the 7-inch TFT-LCD. The function of aided parking is also provided by the instrument. Basic principles to be obeyed in circuits designing under on-board environment are first pointed out. Then the paper analyzes the signals processed in the automobile

instrument and gives an introduction to the sampling circuits and interfaces related to these signals. Following this is the functional categorizing of the circuit modules, such as video buffer circuit, CAN bus interface circuit, and TFT-LCD drive circuit. Additionally, the external EEPROM stores information of the vehicle for history data query, and the external FLASH enables the display of high quality figures. On the whole, the accomplished automobile instrument meets the requirements of automobile instrument markets with its characters of low cost, favorable compatibility, friendly interfaces, and easy upgrading.

The digital instrument has functions of vehicle information displaying, chord alarming, rear video aided parking, LED indicating, step-motor based pointing, and data storage. The instrument adopts dedicated microcontroller MB91F599, a 7-inch LCD, and two step-motors to substitute for the traditional instrument. All the information generated by other ECUs can be acquired via not only the sample circuits but also the CAN bus.

The CAN bus interface and the 7-inch TFT-LCD make it more convenient to upgrade the instrument without changing the hardware. If the software needs to be upgraded, we need not bother to take the instrument down and program the MCU. Instead, we can upgrade the instrument via the vehicle’s CAN network without taking the instrument down, which makes the upgrading more convenient. Most of the information from other ECUs can be transmitted via the CAN bus; so, we do not have to change the hardware circuits if some of the ECUs’ signals are changed in different applications. Besides, since most of the driving parameters are displayed on the TFT-LCD, and the graphical user interface can be designed with great flexibility by programming, only the software needs to be revised to meet different requirements of what kind of driving parameters to display and so forth. These characters, together with the reserved interfaces, enhance the instrument’s compatibility in different applications.

On the one hand, there are some automobile instruments which adopt 8-bit MCUs or 16-bit MCUs which have limited peripherals, so it is difficult for them to meet some requirements such as rearview video and high real-time data processing performance. And many extra components are needed if the designer wants to accomplish some functions such as video input. On the other hand, there are some advanced automobile instruments which adopt high performance MCUs (such as i.MX 53, MPC5121e, and MPC5123) and run Linux on them. They even use larger TFT-LCDs (such as the 12.3-inch TFT-LCD with a resolution of 1280 × 480 pixels) to display driving parameters. These automobile instruments show higher performances than the instrument in this paper. However, they are more expensive than this automobile. This instrument is able to provide almost all the functions of the advanced automobile instrument with a lower cost.

The instrument receives signals from other ECUs via the sampling circuits or the CAN bus interface. It can also receive commands from the driver via the button interface. The signals are then processed by the MCU, after which the MCU may send the vehicle information to the LCD or light the LEDs and so forth, according to the results. Therefore, the automobile instrument can be viewed as a carrier of the information flow. And the design of the system can be viewed from two aspects: the hardware system and the information flow based on it.

Respecting the above mentioned factors, we finally chose the MB91F599 produced by Fujitsu as the microcontroller. The MB91F599 is particularly well-suited for use in automotive instrument clusters using color displays to generate flexible driver interfaces. It integrates a high performance FR81S CPU core which offers the highest CPU performance level in the industry. Besides, it has a graphics display controller with strong sprite functionality, rendering engine, and external video capture capabilities. These greatly reduce the need for extra components and enhance the stability of the system. The rendering engine can operate in combination with the video capture to enable image manipulation. Overlaid graphics such as needles or parking guidelines can be rendered in conjunction with captured video, which helps to accomplish the aided parking. What is more, multiple built-in regulators and a flexible standby mode enable the MB91F599 to operate with low power consumption.

Since the FLASH size of the microcontroller is only 1 MB which is limited for the storage of pictures displayed on the LCD, external FLASH is needed to store different kinds of meaningful pictures such as the background of the dial. Two S29GL256N chips with a memory capacity of 256 Mb are chosen for picture data storage for their high performance and low power consumption. The application circuits of the chips are provided in their datasheets, so it is unnecessary to go into the details of them here.

The 7-inch TFT-LCD has a resolution of pixels and supports the 24-bit for three RGB colors. The interface of the 60-pin TFT-LCD can be categorized into data interface, control interface, bias voltage interface, and gamma correction interface.

The data interface supports the parallel data transmitting of 18-bit (6 bits per channel) for three RGB colors. Thus, a range of colors can be generated. The control interface consists of a “horizontal synchronization” which indicates the start of every scan line, a “vertical synchronization” which indicates the start of a new field, and a “pixel clock.” This part is controlled by the graphics display controller which is integrated in the MB91F599. We just need to connect the pins of the LCD to those of the microcontroller correspondingly.

Bias voltages are used to drive the liquid crystal molecules in an alternating form. The compact LCD bias IC TPS65150 provides all bias voltages required by the 7-inch TFT-LCD. The detailed circuit is also provided in the datasheet of TPS65150.

The greatest effect of gamma on the representations of colors is a change in overall brightness. Almost every LCD monitor has an intensity to voltage response curve which is not a linear function. So if the LCD receives a message that a certain pixel should have certain intensity, it will actually display a pixel which has intensity not equal to the certain one. Then the brightness of the picture will be affected. Therefore, gamma correction is needed. Several approaches to gamma correction are discussed in [20–22]. For this specific 7-inch LCD, only the producer knows the relationship between the voltage sent to the LCD and the intensity it produces. The signal can be corrected according to the datasheet of the LCD before it gets to the monitor. According to the datasheet, ten gamma correction voltages are needed. These voltages can be got from a resistive subdivision circuit.

For this instrument, the LED indicators, the backlight, and the chord alarm need to be supplied with a voltage of +12 V; the CAN transceiver, the EEPROM, and the buttons need to be supplied with a voltage of +5 V; the video buffer circuit, the external FLASH, and the data interface of the LCD need to be supplied with a voltage of +3.3 V. Besides, the microcontroller needs to be supplied with voltages of +5 V and +3.3 V simultaneously. Figure 8 offers a detailed block diagram of the power supply for the automobile instrument.

The main task for the program is to calculate the driving parameters of the vehicle and display them on the TFT-LCD. The calculation is triggered by the input signals via the sampling circuits or the CAN bus. The main program flow chart of the system is shown in Figure 10.

The design scheme of a TFT-LCD based automobile instrument is carried out form aspects of both the hardware and the main program flow chart. The MB91F599 simplifies the peripheral circuits with its rich on-chip resources and shows high performance in real-time data processing. The automobile instrument is capable of displaying the velocity of the vehicle, the engine speed, the cooling water temperature, the oil pressure, the fuel volume, the air pressure, and other information on the TFT-LCD, which contributes a lot to driving safety and satisfies drivers’ aesthetics. Besides, the rearview video makes the parking and backing easier and safer for the driver. Moreover, the CAN bus interface and TFT-LCD make it easier for the upgrading of the instrument without changing the hardware, thus saving the cost.

※Price Increase NotificationThe TFT glass cell makers such as Tianma,Hanstar,BOE,Innolux has reduced or stopped the production of small and medium-sized tft glass cell from August-2020 due to the low profit and focus on the size of LCD TV,Tablet PC and Smart Phone .It results the glass cell price in the market is extremely high,and the same situation happens in IC industry.We deeply regret that rapidly rising costs for glass cell and controller IC necessitate our raising the price of tft display.We have made every attempt to avoid the increase, we could accept no profit from the beginning,but the price is going up frequently ,we"re now losing a lot of money. We have no choice if we want to survive. There is no certain answer for when the price would go back to the normal.We guess it will take at least 6 months until these glass cell and semiconductor manufacturing companies recover the production schedule. (Mar-03-2021)

ER-TFT023-1 is 320x240 dots 2.3" color tft lcd module display with ILI9342 controller,optional 4-wire resistive touch panel and optional capacitive touch panel ,superior display quality,super wide viewing angle and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO ARM and Raspberry PI.It can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports 8080 8-bit,9-bit,16-bit,18-bit parallel,3-wire,4-wire serial spi interface. FPC with zif connector is easily to assemble or remove.Lanscape mode is also available.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".Here is the link for 2.3"TFT Shield with Libraries, Examples.Schematic Diagram for Arduino Due,Mega 2560 and Uno.For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and Development Kit at the bottom of this page.

I was searching for some stuff how to retrofit a navigation system into e39 540i which originally came with a business radio unit. I went to a scrap yard and came across an e39 530i 2002 with MK III navigation system. Anyway it looked like someone before me was trying to pull it out of the car but gave up for some reason. I took the challenge and I"ve managed to pull the wire loom from the car with LCD display, radio unit BM 53, amplifier Alpine. The only thing I"m missing is a GPS module. Unfortunately someone cut the plugs off the LCD unit and now I"m struggling to connect the cut ends of wires together. I saw the diagrams for the connectors in this post but it doesn"t help me with my issue. I was hoping someone can help me.

Also I didn"t know much about retrofitting a MKIII system before removing it from a wrecked car so now I"m wondering how big of a job it is to connect it to the existing wiring in my e39. Any help would be greatly appreciated.

As an option, you can order this TFT pre-assembled onto a breakout/carrier board. The board allows easy prototyping through its 0.1" headers. You can also include the carrier board in your end product to simplify construction and assembly. The carrier board contains a constant-current switching LED driver. The PCB is sized to fit neatly within the outline of the display, with a total weight of 51 grams.

This kit consists of a CFAF240320B1-032T-TS TFT LCD module mounted on a carrier board. The carrier board supports a current driver for the LED backlight of the display. It is available under Additional Options on the website page for CFAF240320B1-032T-TS.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey