4 digit lcd display arduino manufacturer

A wide variety of 4 digit display arduino options are available to you, You can also choose from original manufacturer, odm and agency 4 digit display arduino,As well as from tft, tn, and tab.

Grove - 4-Digit Display module is a 12-pin module. In this module, we utilise a TM1637 to scale down the number of controlling pins to 2. That is to say, it controls both the content and the luminance via only 2 digital pins of Arduino or Seeeduino. For projects that require alpha-numeric display, this can be a nice choice.

The platforms mentioned above as supported is/are an indication of the module"s software or theoritical compatibility. We only provide software library or code examples for Arduino platform in most cases. It is not possible to provide software library / demo code for all possible MCU platforms. Hence, users have to write their own software library.

If we don"t have Grove Base Shield, We also can directly connect Grove-4-Digit Display to Seeeduino as below. We also can plug Grove-4-Digit Display to other Grove digital port.

Step 3. Follow below instructions to select code into Arduino IDE and upload. If you do not know how to upload the code, please check how to upload code. There are 3 examples as below.Clock Display

LCD Display Modules└ LEDs, LCDs & Display Modules└ Electronic Components & Semiconductors└ Electrical Equipment & Supplies└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

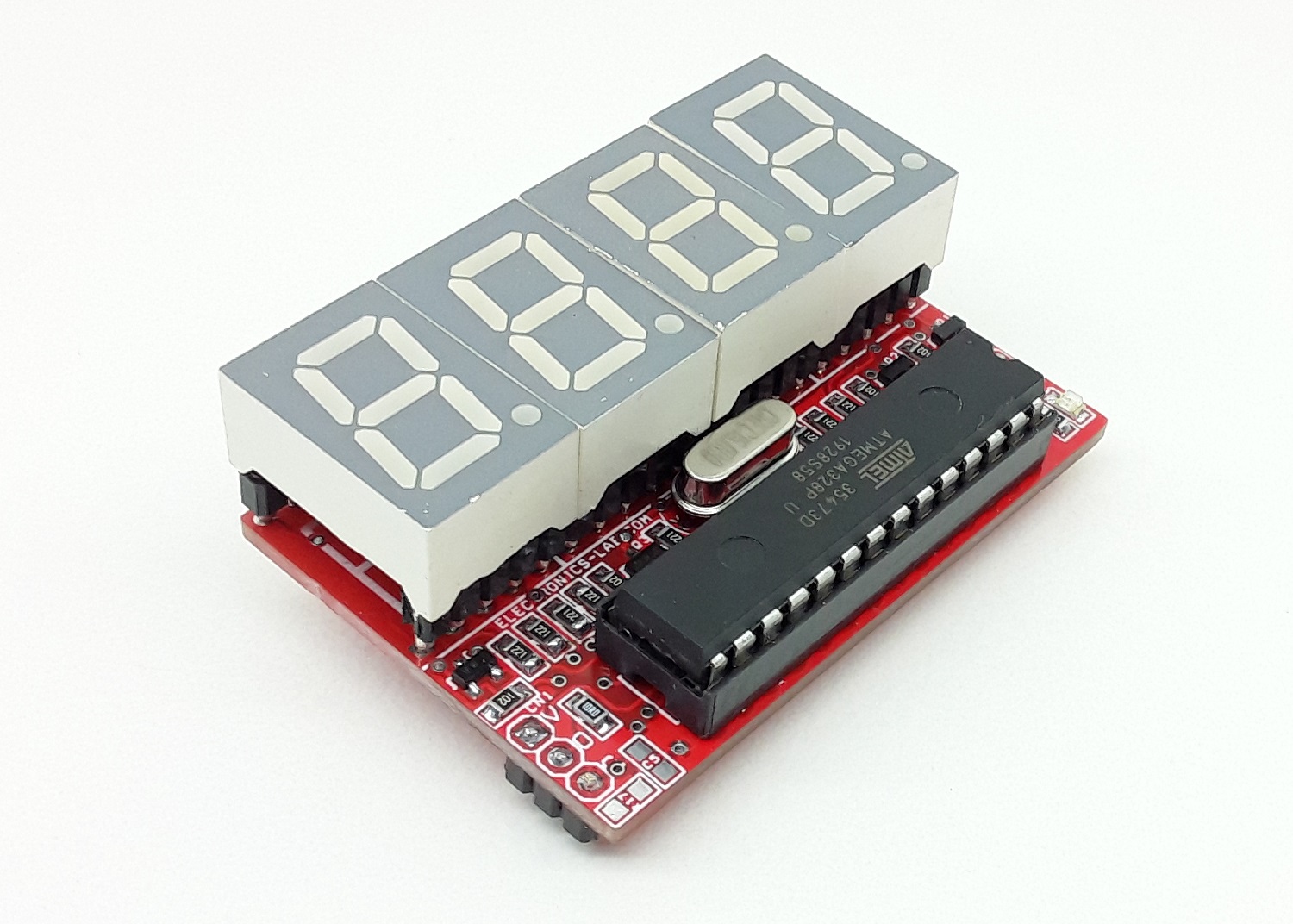

This project will help you to easily develop an Arduino compatible project that requires 4 x -7Segment 0.5″ displays. The project consists of an Atmega328 microcontroller, 4 x BC847 NPN transistors to drive the common cathode displays. All displays are used in multiplexing configurations. The circuit operates with 5V DC and consumes a few milliamps. Arduino code is provided to test the board. The code is pretty simple, it will read 0 to 5V on analog pin A0 and display 0 to 1000 display, basically 0 to 5V mapping to 0-1000. Users may write their own code to read an analog voltage from a sensor or other source and display it on the 4 x 7segment displays.

The Arduino board has a wide variety of compatible displays that you can use in your electronic projects. In most projects, it’s very useful to give the user some sort of feedback from the Arduino.

With the TFT display you can display colorful images or graphics. This module has a resolution of 480 x 320. This module includes the SD card socket and SPI FLASH circuit.

This is a tiny display with just 1 x 0.96 Inch. This display has a black background, and displays characters in white. There are other similar displays that can show the characters in other colors.

So it’s very easy to control the matrix without tons of wiring. Available to make microcontroller control the 4-digit LED segment display via signal interface, greatly saving IO pin resource on microcontroller.

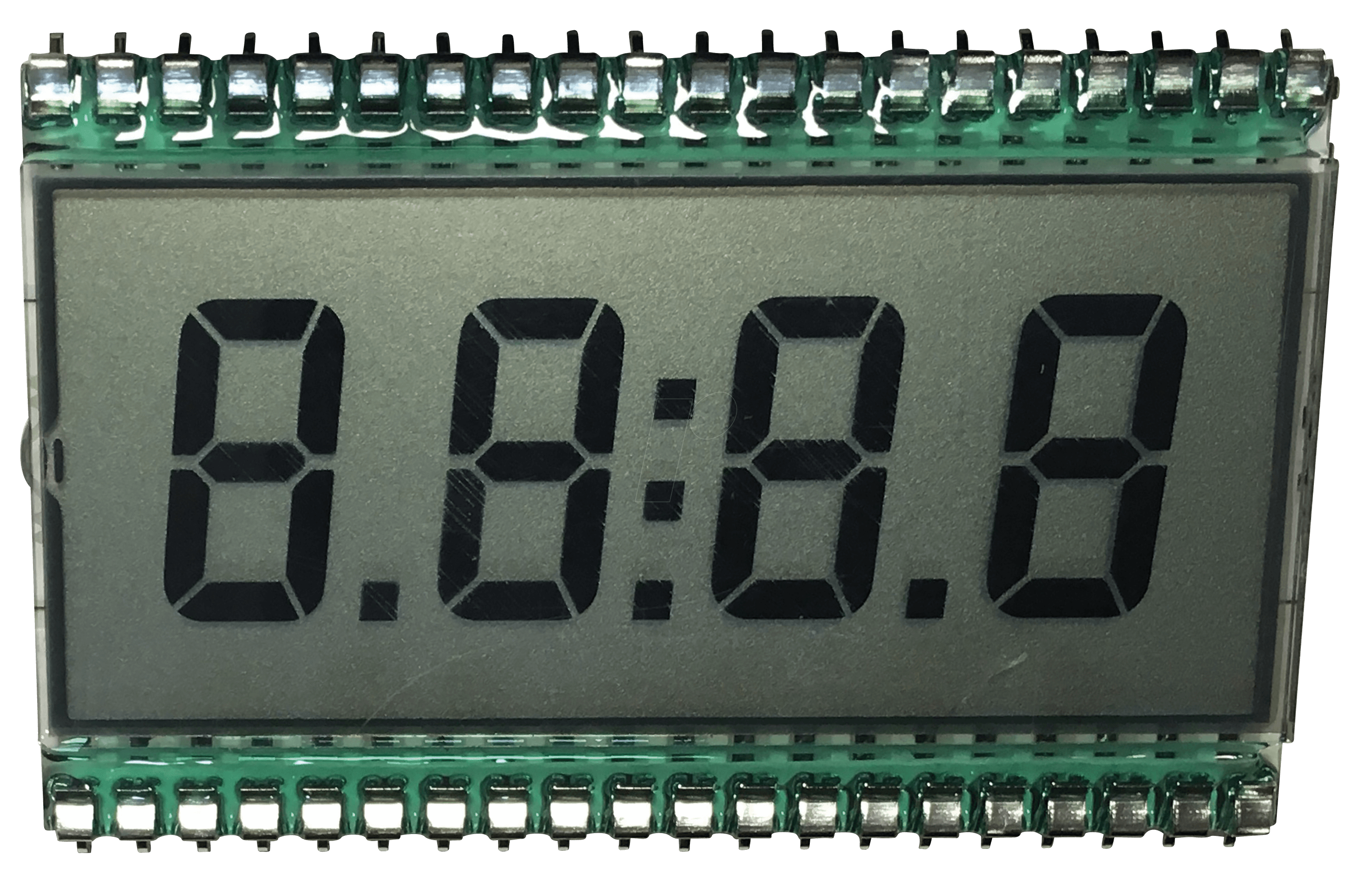

Liquid Crystal displays or LCDs have been used in electronics equipment since the late 1970s. LCD displays have the advantage of consuming very little current And they are ideal for your Arduino projects.

In this article and in the accompanying video I’ll show you how easy it is to add an LCD display to your next Arduino design. I’ll also show you a very popular Arduino Shield that has a keypad which you can use in your projects as well.

Today LCD displays are used in a variety of items from test equipment to televisions. They’re inexpensive and versatile, this makes them ideal for all sorts of designs.

LCD displays do not emit light. Instead they block the passage of light, like little windows which open and shut the let light through. The liquid crystals used inside LCD displays are sandwiched between two layers of polarized material. By changing the orientation of the liquid crystals they allow light to pass or they block the light entirely.

Because transmissive LCD displays (the type we will be using) work by blocking light they require a backlight. Several methods have been used to create back lights including electroluminescent panels and fluorescent tubes. these days the most common form of backlight is an LED, in fact so-called LED televisions are usually just LCD screens with an LED backlight system.

Another type of LCD display, the passive-matrix display, does not require a backlight, it works using reflected light. This type of display is often found in digital watches.

The principles of liquid crystals were discovered in the late 1880s but work on Modern LCD displays did not begin until the mid-1960s. a number of patents were filed in the early 1970s and in 1973 the Sharp Corporation introduced LCD displays for calculators.

The first color LCD displays were developed in the early 1980s but production units were not commonly available until the mid-1990s. By the late 1990s LCD displays were quite common.

A number of LCD displays are available for experimenters. These low-cost monochrome displays are ideal for use with microcontrollers like the Arduino and micro computers like the Raspberry Pi.

These displays are available in a number of different configurations. The part number for the display generally relates to the number of rows and columns in the display.

Common display configurations include 16 x 2, 16 x 4 and 20 x 4. All of these displays are used in a virtually identical fashion the only difference being the number of columns and rows they have.

The LCD1602 display module is a very popular and inexpensive LCD display. It is available in a number of different colors such as blue yellow and green and can easily be connected to an Arduino or Raspberry Pi.

In operation data is sent down the parallel data lines for the display. There are two types of data that can be sent to the display. The first type of data are the ASCII characters which are to be displayed on the display. The other type of data are the control characters that are used to activate the various display functions.

Brightness– This is the input for the brightness control voltage, which varies between 0 and 5 volts to control the display brightness. On some modules this pin is labeled V0.

Because the LCD module uses a parallel data input it requires 8 connections to the host microcontroller for the data alone. Add that to the other control pins and it consumes a lot of connections. On an Arduino Uno half of the I/O pins would be taken up by the display, which can be problematic if you want to use the I/O pins for other input or output devices.

In 4-wire mode the data is sent a half a byte at a time, thus requiring only 4 data connections. The upper half of the data input (D4 to D7) is used while the other pins are not connected to anything.

We will begin our experiments by hooking up the LCD1602 to an Arduino Uno and running a few of the example sketches included with the Arduino IDE. This will allow you to get familiar with the display without needing to write any code.

We need to hookup our LCD display to our Arduino. The display can use any of the Arduino digital I/O pins as it has no special requirements, but if you hook it up as I’ve illustrated here you can run the example sketches without needing to make any modifications.

In addition to the LCD1602 display ands the Arduino Uno you will need a 10K trimpot ot potentiometer, this is used a s a brightness control for the display. You’ll also need a 220 ohm resistor to drop the voltage for the displays LED backlight.

The Arduino IDE includestheLiquidCrystallibraryand this library has a number of example sketches. I’ll go over three of them here but you can also try the other ones.

The sketch starts with a number of credits and a description of the required hardware hookup. You’ll note that this is the same hookup you just performed on your Arduino and LCD module.

We then initialize an object that we call “lcd” using the pinouts of the LCD display. If you decide to hook up your display to different pins then you’ll need to modify this section.

That ends the loop, so we start back at the top of the loop and repeat. The result will be a counter on the second line that counts seconds from the htime the Arduino was last reset.

Load the sketch up to your Arduino and observe your display. If you don’t see anything try adjusting the brightness control that you wired to the display.

The second example we will try isthe Scroll sketch. Scrolling is a useful technique when you can’t get your text to fit on one line of the LCD display.

In the loop the code demonstrates the use of thescrollDisplayLeftandscrollDisplayRightfunctions. As their names imply they move the text in a left or right direction.

Finally the last counter moves the text 16 positions to the left again, which will restore it back to the center of the display. The loop then repeats itself.

Custom characters are useful when you want to display a character that is not part of the standard 127-character ASCII character set. Thi scan be useful for creating custom displays for your project.

A character on the display is formed in a 5 x 8 matrix of blocks so you need to define your custom character within that matrix. To define the character you’ll use thecreateCharfunctionof the LiquidCrystal library. You are limited to defining a maximum of eight characters.

The Custom Character demonstration requires one additional component to be wired to the Arduino, a potentiometer (10K or greater) wired up to deliver a variable voltage to analog input pin A0.

As with the previous sketches we examined this one starts by loading theLiquidCrystallibrary and defining an object calledlcdwith the connection information for the display. It then moves on to define the custom characters.

The last two arrays,amsUpandarmsDowndefine the shape of a little “stickman”, or “stickperson” if you want to be politically correct! This is done to show how we can animate a character on the display.

Finally the setup routine ends by printing a line to the first row of the LCD display. The line makes use of two of the custom characters, the “heart” and the “smiley”.

We begin by reading the value of the voltage on pin A0 using the ArduinoanalogReadfunction. As the Arduino has a 10-bit analog to digital converter this will result in a reading ranging from 0 to 1023.

We then use an Arduinomapfunction to convert this reading into a range from 200 to 1000. This value is then assigned to an integer calleddelayTime, which as its name implies represents a time delay period.

One thing you may have noticed about using the LCD display module with the Arduino is that it consumes a lot of connections. Even in 4-wire mode there are still a total of seven connections made to the Arduino digital I/O pins. As an Arduino Uno has only 14 digital I/O pins that’s half of them used up for the display.

In other cases you would need to resort to using some of the analog pins as digital pins or even moving up to an Arduino Mega which has many more I/O pins.

But there is another solution. Use the I2C bus adapter for the LCD display and connect using I2C. This only consumes two I/O pins and they aren’t even part of the set of digital I/O pins.

The bus has evolved to be used as an ideal method of communicating between microcontrollers, integrated circuits, sensors and micro computers. You can use it to allow multiple Arduinos to talk to each other, to interface numerous sensors and output devices or to facilitate communications between a Raspberry Pi and one or more Arduinos.

In I2C communications there is the concept of Master and Slave devices. There can be multiples of each but there can only be one Master at any given moment. In most Arduino applications one Arduino is designated Master permanently while the other Arduinos and peripherals are the Slaves.

The Master transmits the clock signal which determines how fast the data on the bus is transferred. There are several clock speeds used with the I2C bus. The original design used 100 KHz and 400 KHz clocks. Faster rates of 3.4 MHz and higher are available on some I2C configurations.

The I2C Adapter for the LCD display is a tiny circuit board with 16 male header pins soldered to it. These pins are meant to be connected directly to the 16-pin connection on the LCD1602 display (or onto other displays that use the same connection scheme).

The device also has a 4-pin connector for connection to the I2C bus. In addition there is a small trimpot on the board, this is the LCD display brightness control.

Most Arduino Unos also have some dedicated pins for I2C, these are internally connected to A4 and A5 and are usually located above the 14 digital I/O pins. Some models of the Uno have additional I2C connectors as well.

Note how much easier it is to use the I2C connection, which does not consume any of the Arduino Unos 14 digital I/O pins. Since A4 and A5 are being used for the I2C bus they can’t be used as analog inputs in this configuration.

Load this sketch into your Arduino then open your serial monitor. You’ll see the I2C address of your I2C LCD display adapter. You can then make note of this address and use it in the sketches we’ll be looking at now.

In order to run the subsequent sketches you’ll need to install another library. This is theNewLiquidCrystallibrarywhich, as its name implies, is an improved version of the LiquidCrystal library packaged with your Arduino IDE.

The sketch starts by loading the ArduinoWirelibrary. This is the Arduino library that facilitates communications over I2C and it’s part of your Arduino IDE installation.

On the next line we define the connections to the LCD display module from the I2C Adapter,. Note that these are NOT the connections from the Arduino, they are the connections used by the chip on the adapter itself.

In setup we set the size of the display and then print “Hello world!” on the first line in the first position. After a short delay we print “How are you?” on the second line.

Load the sketch and run it on your Arduino. If you can’t get it to work check out the address and connection information to be sure you have it right.

In this project we will put together a digital temperature and humidity gauge. It’s pretty accurate thanks to the use of a DHT22 temperature and humidity sensor. You could also substitute a cheaper DHT11 sensor but it won’t be as accurate.

As you can see the DHT22 is connected with its output tied to pin 7 of the Arduino. The other two connections are 5 volts and ground. Note that pin 3 of the DHT22 is not used.

This sketch also makes use of theDHTlibrary from Adafruit. We used this library in a previous article, “Using the HC-SR04 Ultrasonic Distance Sensor with Arduino” so you may want to take a look at that one in order to get it installed.

The key thing to note is that this library is dependant upon another Adafruit library, theirUnified Sensorlibrary. Both can be installed using the Library Manager in your Arduino IDE.

The sketch is similar to our demo sketch in that it creates an “lcd” object with the I2C and display connection information. It also defines a couple of parameters for the DHT22 sensor, as well as some floating variables to hold the temperature and humidity values.

Note that this displays the temperature in Celsius. If you want to change this to Fahrenheit its a simple matter of using some math. The formula( temp * 1.8 ) + 32will convert the results to Fahrenheit.

So far we have used the LCD1602 display module for all of our experiments. For our final demonstration we’ll switch to a popular Arduino shield that contains a LCD1602 along with some push buttons.

The LCD Keypad Shield is available from several different manufacturers. The device fits onto an Arduino Uno or an Arduino Mega and simplifies adding an LCD display to your project.

The Reset button is simply connected to the Arduino Reset pin and works just like the Reset button on the Arduino itself. This is common on many shields as the shields physically cover the Reset button.

Instead the buttons are connected to a resistor array that acts as a voltage divider. The entire array is connected to the Arduino’s analog A0 pin. One pin for five push buttons.

Note that the LCD is being used in 4-wire mode. The LCD itself is the same one used on the LCD1602 module, so all of the code for that module will work with the LCD Keypad Shield as well.

Now that you know how the LCD Keypad module works and which Arduino pins it uses all that remains is to install it onto your Arduino and load the demo sketch.

One thing – once the shield is installed on the Arduino you won’t have easy access to the unused I/O pins to connect any sensors or output devices you may want to use (although the demo sketch doesn’t need anything else connected). There are a couple of ways to get around this:

Use a shield that exposes the pins for prototyping before you install the LCD Keypad shield. In the video associated with this article I use a “Screw Shield” that brings all of the Arduino I/O pins out to a series of screw connectors. There are other similar shields. Using one of these shields is the easiest way to work with the LCD Keypad shield, as well as other Arduino shields.

The sketch begins by including theLiquidCrystallibrary. You can use the original one or the one includes with theNewLiquidCrystallibrary. We then set up an object with the LCD connections, note that these are just hard-coded as they won’t change.

Next we define a number of constants, one for each of the push buttons. Note that nothing is defined for the Reset button as it simply mimics the Arduino Reset button, however a constant is defined for the “none” condition.

After that we define a function calledread_LCD_buttons(). This function reads the value on analog port A0 and returns an integer corresponding to the button integers we defined earlier. Note that the function adds approximately 50 to each of the manufacturers specified values to account for intolerances in the resistors in the voltage divider.

We start the loop by placing the cursor 9 spaces over on the second line. We then use themillisfunction to display a counter that counts the time since the Arduino was reset. This is to test the Reset button.

We then call ourread_LCD_buttons()function and use it to display the value of the push button, right before the counter. Then we end the loop and do it again.

Load the code onto the Arduino and run it. You should see the value of each button as you press it, along with a counter that increments each second. If you press Reset the counter should reset itself back to zero.

As you can see LCD displays are pretty simple to use thanks to the availability of some excellent libraries for the Arduino. As these displays are also very inexpensive they will make an ideal addition to many of your Arduino projects.

And finally the LCD Keypad Shield is a convenient method of adding both a display and a simple keypad to your project, no wiring or soldering required.

In this example, we"ll only use a single display. Realize, though, that you could add more displays (or other SPI devices) to the same SPI bus, each requiring only an additional SS pin per device.

The SDI and SCK pins must remain where they are on the Arduino - those are the hardware SPI pins. The SS pin could be moved to any digital pin, as long as it"s changed in the code.

This example works a lot like the serial version. The s7s.print() functions from the previous example are replaced by SPI transfers. Take note that each time an SPI.transfer() occurs, it"s blanketed by two digitalWrite()s to the SS pin. The SS pin must go LOW, to let the display know that usable data is incoming. Once SS goes back to HIGH, the display will know that data is no longer being sent to it.

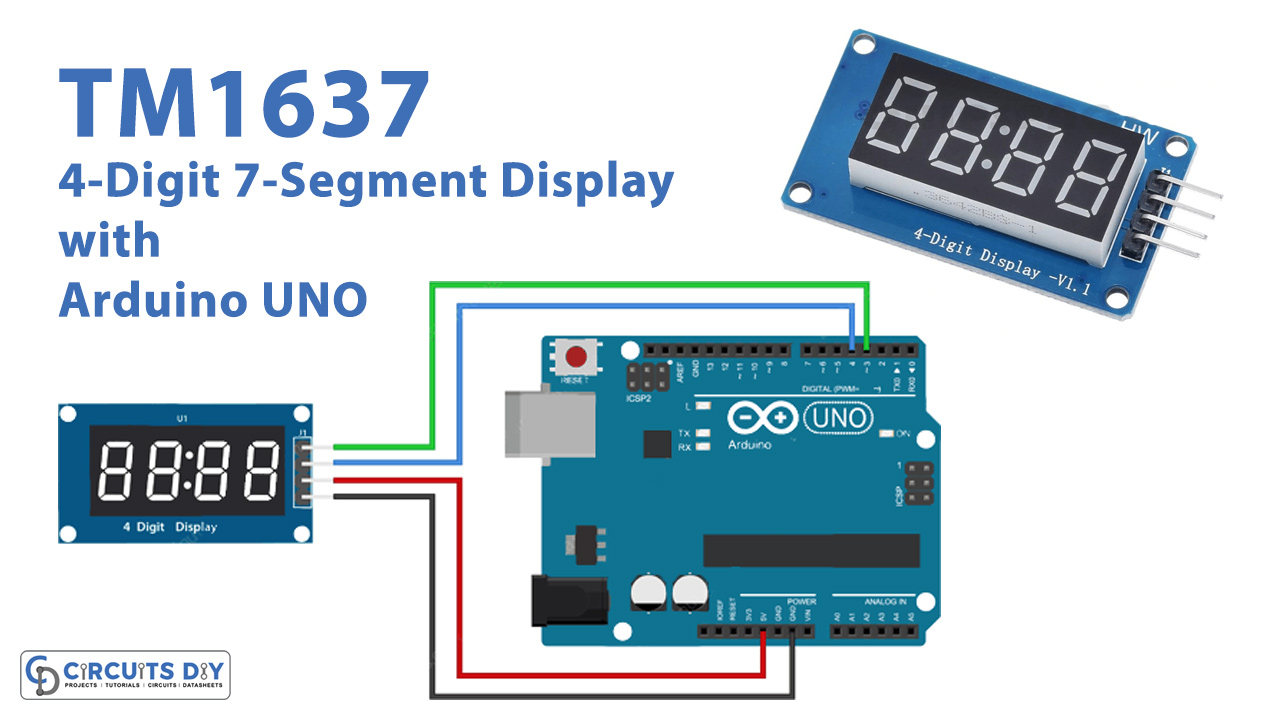

Arduino TM1637 4 Digit 7 Segment Display Module LED Display is a kind of LED (light-emitting diode display) drive control special circuit with keyboard scan interface and it’s internally integrated with MCU digital interface, data latch, LED high pressure drive and keyboard scan.

This product is in DIP20/SOP20 package type with excellent performance and high quality, which is mainly applicable to the display drive of induction cooker, micro-wave oven and small household electrical appliance.

In this tutorial, you will learn how you can control TM1637 4-digit 7-segment displays with Arduino. These displays are fantastic for displaying sensor data, temperature, time, etc.

I have included 3 examples in this tutorial. In the first example, we will look at the basic functions of the TM1637Display library. In the second example, I will show you how you can display the time on a 4-digit display. The last example can be used to create a simple temperature display in combination with the DHT11.

Bare 4-digit 7-segment displays usually require 12 connection pins. That’s quite a lot and doesn’t leave much room for other sensors or modules. Thanks to the TM1637 IC mounted on the back of the display module, this number can be reduced to just four. Two pins are required for the power connections and the other two pins are used to control the segments.

7-segment displays contain 7 (or 8) individually addressable LEDs. The segments are labeled A to G and some displays also have a dot (the 8th LED). Use this image as a reference when setting the individual segments in the code later.

You can buy many different display modules that use a TM1637 IC. The color, size, dots, and connection points can all be different. I don’t have experience with all the different versions of this display but as long as they use the TM1637, the code examples provided below should work.

Connecting the display to an Arduino or other microcontroller is super easy. You only need to connect 4 wires: 2 for power and 2 to transfer the data.

For this tutorial, I connected CLK and DIO to pin 2 and 3 respectively, but you can change this to any of the digital pins you want. You just have to change the pin configuration in the code accordingly.

Avishay Orpaz has written an excellent library for TM1637 displays, the TM1637Display library. This library has several built-in functions that make controlling the display fairly easy.

Next, we create a display object of the type TM1637Display with the defined CLK and DIO pins. Note that I called the display ‘display’, but you can use other names as well like ‘temperature_display’.

The name that you give to the display will be used later to write data to that particular display. You can create and control multiple display objects with different names and connection pins. There currently is no limit in the library.

There are several ways to control the individual segments of the display. Before the setup section of the code, I specified several arrays to set the individual display segments. We will use the function setSegments() later to write them to the display.

The first option is to write hexadecimal numbers to the display for each digit. The hexadecimal 0xff translates to 11111111 in binary, this sets all the segments on (including the dot if your display has one). 0xef for example, translates to 11101111. This would set all the segments on, except for segment E. Note that counting goes from right to left, so 11111111 corresponds to segments (dot)GFEDCBA. You can find a conversion chart for hexadecimal to binary here.

The library has a function built-in that makes setting individual segments a bit easier. See the code snippet below. You can create arrays to spell words. Each segment is separated by a | and digits of the display are separated by a comma.

This function can be used to set the individual segments of the display. The first argument is the array that includes the segment information. The second argument specifies the number of digits to be modified (0-4). If you want to spell dOnE, this would be 4, for a °C symbol, this would be 2. The third argument sets the position from which to print (0 – leftmost, 3 – rightmost). So if you want to print a °C symbol on the third and fourth digit, you would use:

This is probably the function that you will use the most. The first argument is a number that you want to display on the screen. The rest of the arguments are optional.

This function allows you to control the dots of the display. Only the second argument is different from the showNumberDec function. It allows you to set the dots between the individual digits.

This function sets the brightness of the display (as the name suggests). You can specify a brightness level from 0 (lowest brightness) to 7 (highest brightness). The second parameter can be used to turn the display on or off, false means off.

One of the typical uses for a 4-digit 7-segment display is to show the time. By combining the TM1637 with a real time clock module (RTC), you can easily create a 24-hour clock.

The wiring diagram below shows you how you can connect the DS3231 RTC to the Arduino. Note that the TM1637 display is connected in the same way as before.

The following code example can be used to display the time in a 24-hour time format. If your display has a center colon, then this code will make it blink. You can also disable this by removing the last few lines of code.

The code uses the Adafruit RTC library, which you can download here on GitHub. You can also install it via the Library Manager in the Arduino IDE by searching for ‘RTClib’, or click the download button below:

/* Arduino example code to display a 24 hour time format clock on a TM1637 4 digit 7 segment display with a DS32321 RTC. More info: www.www.makerguides.com */

4-Digit 7-segment displays are great for displaying sensor readings like temperature, humidity, voltage or speed. In the following example, I will show you how you can display temperature readings on the TM1637 display.

The example code below can be used to display the temperature readings on the display. It alternates between the temperature in Celius and Fahrenheit, both are shown for 2 seconds.

In this article I have shown you how you can use a TM1637 4-digit 7-segment display with Arduino. We also looked at a clock and thermometer example. I hope you found it useful and informative. If you did, please share it with a friend who also likes electronics and making things!

I really like to use these displays to show sensor readings or things like the speed of a motor. With the TM1637Display library, programming the displays becomes very easy, so there is no reason you shouldn’t incorporate one in your next project.

I would love to know what projects you plan on building (or have already built) with this display. If you have any questions, suggestions, or if you think that things are missing in this tutorial, please leave a comment down below.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey