lcd panel production 2018 brands

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.wisechip.com.tw. "WiseChip History – WiseChip Semiconductor Inc". www.wisechip.com.tw. Archived from the original on 2018-02-17. Retrieved 2018-02-17.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

BOE Technology Group, the Chinese electronic components producer, is expected to be the leader in producing LCD display panels in the coming years, with a forecast capacity share of 24 percent by 2022. China is the country that has the largest LCD capacity, with a 56 percent share in 2020.Read moreLCD panel production capacity share from 2016 to 2022, by manufacturerCharacteristicBOEChina StarInnoluxAUOLGDHKCCEC PandaSharpSDCOther-----------

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2022, by manufacturer [Graph]. In Statista. Retrieved December 16, 2022, from https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. "LCD panel production capacity share from 2016 to 2022, by manufacturer." Chart. June 8, 2020. Statista. Accessed December 16, 2022. https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. (2020). LCD panel production capacity share from 2016 to 2022, by manufacturer. Statista. Statista Inc.. Accessed: December 16, 2022. https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2022, by Manufacturer." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC, LCD panel production capacity share from 2016 to 2022, by manufacturer Statista, https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/ (last visited December 16, 2022)

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved December 16, 2022, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed December 16, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: December 16, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited December 16, 2022)

(January 23, 2019) – Global shipments of large thin-film transistor (TFT) liquid crystal display (LCD) panels rose again in 2018 despite concerns of over-supply in the market. In particular, area shipments increased by 10.6 percent to 197.9 million square meters compared to the previous year, driven by TV and monitor panels, according to

Fierce price competition in large 65- and 75-inch display panels was ignited as Chinese panel maker BOE started the mass production of the panels in 2018 at its B9 10.5-generation facility. “With BOE operating the 10.5-generation line, panel makers have become more aggressive on pricing since early 2018 to digest their capacity,” said

Rising demand for gaming-PC and professional-purpose monitors boosted shipments of high-end, large panels. “Some panel makers have allocated more monitor panels to the fab, replacing existing TV panels, to make up for poor performance of that business,” Wu said.

Demand for other applications, which include public, automotive and industrial displays, recorded the highest growth rates of 17.5 percent by area and 28.6 percent by unit. “Panel makers view these applications as a new cash cow that can compensate for the sharp price erosion in main panels for TVs, monitors and notebook PCs,” Wu said.

LG Display led the area shipments of large display panels, with a 21 percent share in 2018, followed by BOE (17 percent) and Samsung Display (16 percent). BOE boasted the largest unit-shipment share of 23 percent, followed by LG Display (20 percent) and Innolux (17 percent), according to the

Large TFT LCD panel shipment growth is expected to continue in 2019. The preliminary forecast for unit shipments of three major products indicates that panel makers will continue to focus on the monitor and notebook PC panel businesses, increasing shipments by 5.3 percent and 6.6 percent, respectively, over the year, while shipments of TV panels are forecast to grow just 2.6 percent.

In 2019, three new 10.5-generation fabs – ChinaStar’s T6, BOE’s second fab and Foxconn/Sharp’s Guangzhou line – are expected to start mass production. All of them are assigned to manufacture TV panels, further boosting TV panel supply. “As the TV panel business is predicted to remain tough, panel makers, who enjoyed relatively better outcomes with monitor and notebook PC panels in 2018, will likely focus on the IT panel businesses,” Wu said.

IHS Markit provides information about the entire range of large display panels shipped worldwide and regionally, including monthly and quarterly revenues and shipments by display area, application, size and aspect ratio for each supplier.

As one of the main application markets of small and medium-sized panels, LCD display panel manufacturers never stop competing in the automotive panel display market. Especially with the development of 5G, unmanned driving, and new energy vehicles, the update and iteration of display panel technology are accelerating.

From the perspective of the automotive panel display market and research and development, a-si, TFT-LCD, LTPS, AMOLED, and Mini/Micro LED are the main technologies of vehicle display panels at the present stage. Among them, a-si and TFT-LCD markets are weakening, LTPS is on the rise, AMOLED is rising strongly, Mini/Micro LED is A forward-looking technology reserve, appearing in various exhibitions at high frequency.

Auto display panels shipped 1.615 million units in 2018, up 9.4 percent from a year earlier, according to IHS Markit.IHS notes that the global automotive LCD display panel market is entering a period of slow growth but intense competition.

But car displays panel will grow at a compound annual rate of 7 percent from 2017 to 2025, compared with weak demand for smartphones that will be hard to reverse. Demand for display panels for car and public displays, smartwatches, and OLED TVs is expected to grow faster than other applications.

Panel makers have added more screens for cars in recent years, either to expand revenue growth or to smooth out the shortcomings of smartphone panels.

In terms of vehicle LCD display panel shipments in 2018, JDI, LGD, tianma, au optronics, and qunchuang optronics are the top five global enterprises in terms of vehicle display panel shipments, with market shares of 16.9%, 12.8%, 12.4%, 12.1%, and 11.0% respectively.

JDI and LGD are the dominant vehicle panels for LTPS. With the help of the two companies, LTPS gradually occupied A certain market share of the vehicle display panel after a-si. The advantages of LTPS are ultra-thin, lightweight, low power consumption, colorful and clearer, and the OLED panels are derived from LTPS.

According to the new display of high tech, JDI has laid out the LTPS in 2015 and made the LTPS plan for mass production for vehicle display. With its technical advantages and mass production level, JDI’s vehicle display panel business revenue exceeded 100 billion yen for * times in 2017.JDI’s automotive panel revenue plans to expand to 160 billion yen by 2020, said Holger Gerkens, JDI’s executive officer for automotive panels.

Au optronics is a late adopter of the LTPS, but its LTPS products were introduced to the full range of automotive panels in 2018. Its products are said to achieve color saturation up to NTSC * and can be switched between high-resolution images and traditional mirror mode depending on driving requirements. As au optronics Kunshan 6 generation LTPS panel factory capacity is full, it is expected that the proportion of LTPS vehicle panels is expected to increase.

Mainland panel manufacturers, TCL group subsidiary huaxing optoelectronics have expanded production of the sixth generation of LTPS display panel technology, and the product positioning includes the application of automotive display.

OLED panel has higher response speed, lower energy consumption, flexible display, non-breakable, no dead Angle and other characteristics, in the industry, its performance is conducive to improve driving safety, very suitable for the vehicle display panel market. UBI Research expects OLED to account for 10% of the vehicle display market by 2020.

Mainland manufacturers boe and vechino have both expanded production of AMOLED, and their AMOLED panels have been applied in-vehicle display, breaking the gap in technology and application in the domestic market. According to related reports, boe’s AMOLED panel is also equipped with Mini LED, in-cell, and other technologies.

Vercino AMOLED is still in its initial stage, but there is already A certain scale of the AMOLED production line, and in April this year, transparent a-pillar MVS were mass-produced to solve the problem of driving blind area.

JDI also said that it will take advantage of JOLED printed OLED technology to strengthen the development of new product technology and gradually expand the sales of vehicle panels.

From the application side, OLED display panels are currently mainly used in high-end automobile brands and new energy vehicles, occupying a limited market share. However, some industry insiders believe that OLED is expected to become the mainstream of automotive display, with technology and mass production advantages of the panel factory revenue prospects are considerable.

In addition, with the Mini/Micro LED technology increasingly mature, two technologies have become the panel factory forward-looking technology layout focus.

The car display panel is a niche market. When many enterprises develop Mini/Micro LED, they often regard car display as one of the main application scenarios. However, the Mini/Micro LED in the vehicle display market has not yet entered the commercial stage.

In the future, the vehicle LCD display panel will blossom, especially under the assistance of 5G and self-driving cars, the vehicle display technology will advance towards high specifications.

[Introduction]: This paper analyzes the competitive pattern of the panel display industry from both supply and demand sides. On the supply side, the optimization of the industry competition pattern by accelerating the withdrawal of Samsung’s production capacity is deeply discussed. Demand-side focuses on tracking global sales data and industry inventory changes.

Since April 2020, the display device sector rose 4.81%, ranking 11th in the electronic subsectors, 3.39 percentage points behind the SW electronic sector, 0.65 percentage points ahead of the Shanghai and Shenzhen 300 Index. Of the top two domestic panel display companies, TCL Technology is up 11.35 percent in April and BOE is up 4.85 percent.

Specific to the panel display plate, we still do the analysis from both ends of supply and demand: supply-side: February operating rate is insufficient, especially panel display module segment grain rate is not good, limited capacity to boost the panel display price. Since March, effective progress has been made in the prevention and control of the epidemic in China. Except for some production lines in Wuhan that have been delayed, other domestic panels show that the production lines have returned to normal. In South Korea, Samsung announced recently that it would accelerate its withdrawal from all LCD production lines. This round of output withdrawal exceeded market expectations both in terms of pace and amplitude. We will make a detailed analysis of it in Chapter 2.

Demand-side: We believe that people spend more time at home under the epidemic situation, and TV, as an important facility for family entertainment, has strong demand resilience. In our preliminary report, we have interpreted the pick-up trend of domestic TV market demand in February, which also showed a good performance in March. At present, the online market in China maintains a year-on-year growth of about 30% every week, while the offline market is still weak, but its proportion has been greatly reduced. At present, people are more concerned about the impact of the epidemic overseas. According to the research of Cinda Electronics Industry Chain, in the first week, after Italy was closed down, local TV sales dropped by about 45% from the previous week. In addition, Media Markt, Europe’s largest offline consumer electronics chain, also closed in mid-March, which will affect terminal sales to some extent, and panel display prices will continue to be under pressure in April and May. However, we believe that as the epidemic is brought under control, overseas market demand is expected to return to the pace of China’s recovery.

From a price perspective, the panel shows that prices have risen every month through March since the bottom of December 19 reversed. However, according to AVC’s price bulletin of TV panel display in early April, the price of TV panel display in April will decrease slightly, and the price of 32 “, 39.5 “, 43 “, 50 “and 55” panels will all decrease by 1 USD.65 “panel shows price down $2; The 75 “panel shows the price down by $3.The specific reasons have been described above, along with the domestic panel display production line stalling rate recovery, supply-side capacity release; The epidemic spread rapidly in Europe and the United States, sports events were postponed, local blockades were gradually rolled out, and the demand side declined to a certain extent.

Looking ahead to Q2, we think prices will remain under pressure in May, but prices are expected to pick up in June as Samsung’s capacity is being taken out and the outbreak is under control overseas. At the same time, from the perspective of channel inventory, the current all-channel inventory, including the inventory of all panel display factories, has fallen to a historical low. The industry as a whole has more flexibility to cope with market uncertainties. At the same time, low inventory is also the next epidemic warming panel show price foreshadowing.

In terms of valuation level, due to the low concentration and fierce competition in the panel display industry in the past ten years, the performance of sector companies is cyclical to a certain extent. Therefore, PE, PB, and other methods should be comprehensively adopted for valuation. On the other hand, the domestic panel shows that the leading companies in the past years have sustained large-scale capital investment, high depreciation, and a long period of poor profitability, leading to the inflated TTM PE in the first half of 2014 to 2017. Therefore, we will display the valuation level of the sector mainly through the PB-band analysis panel in this paper.

In 2017, due to the combined impact of panel display price rise and OLED production, the valuation of the plate continued to expand, with the highest PB reaching 2.8 times. Then, with the price falling, the panel shows that PB bottomed out at the end of January 2019 at only 1.11 times. From the end of 2019 to February, the panel shows that rising prices have driven PB all the way up, the peak PB reached 2.23 times. Since entering March, affected by the epidemic, in the short term panel prices under pressure, the valuation of the plate once again fell back to 1.62 times. In April, the epidemic situation in the epidemic country was gradually under control, and the valuation of the sector rebounded to 1.68 times.

We believe the sector is still at the bottom of the stage as Samsung accelerates its exit from LCD capacity and industry inventories remain low. Therefore, once the overseas epidemic is under control and the domestic demand picks up, the panel shows that prices will rise sharply. In addition, the plate will also benefit from Ultra HD drive in the long term. Panel display plate medium – and long-term growth logic is still clear. Coupled with the optimization of the competitive pattern, industry volatility will be greatly weakened. The current plate PB compared to the historical high has sufficient space, optimistic about the plate leading company’s investment value.

Revenue at Innolux and AU Optronics has been sluggish for several months and improved in March. Since the third quarter of 2017, Innolux’s monthly revenue growth has been negative, while AU Optronics has only experienced revenue growth in a very few months.AU Optronics recorded a record low revenue in January and increased in February and March. Innolux’s revenue returned to growth in March after falling to its lowest in recent years in February. However, because the panel display manufacturers in Taiwan have not put in new production capacity for many years, the production process of the existing production line is relatively backward, and the competitiveness is not strong.

On March 31, Samsung Display China officially sent a notice to customers, deciding to terminate the supply of all LCD products by the end of 2020.LGD had earlier announced that it would close its local LCDTV panel display production by the end of this year. In the following, we will analyze the impact of the accelerated introduction of the Korean factory on the supply pattern of the panel display industry from the perspective of the supply side.

The early market on the panel display plate is controversial, mainly worried about the exit of Korean manufacturers, such as LCD display panel price rise, or will slow down the pace of capacity exit as in 17 years. And we believe that this round of LCD panel prices and 2017 prices are essentially different, the LCD production capacity of South Korean manufacturers exit is an established strategy, will not be transferred because of price warming. Investigating the reasons, we believe that there are mainly the following three factors driving:

(1) Under the localization, scale effect, and aggregation effect, the Chinese panel leader has lower cost and stronger profitability than the Japanese and Korean manufacturers. In terms of cost structure, according to IHS data, material cost accounts for 70% of the cost displayed by the LCD panel, while depreciation accounts for 17%, so the material cost has a significant impact on it. At present, the upstream LCD, polarizer, PCB, mold, and key target material line of the mainland panel display manufacturers are fully imported into the domestic, effectively reducing the material cost. In addition, at the beginning of the factory, manufacturers not only consider the upstream glass and polarizer factory but also consider the synergy between the downstream complete machine factory, so as to reduce the labor cost, transportation cost, etc., forming a certain industrial clustering effect. The growing volume of shipments also makes the economies of scale increasingly obvious. In the long run, the profit gap between the South Korean plant and the mainland plant will become even wider.

(2) The 7 and 8 generation production lines of the Korean plant cannot adapt to the increasing demand for TV in average size. Traditionally, the 8 generation line can only cut the 32 “, 46 “, and 60” panel displays. In order to cut the other size panel displays economically and effectively, the panel display factory has made small adjustments to the 8 generation line size, so there are the 8.5, 8.6, 8.6+, and 8.7 generation lines. But from the cutting scheme, 55 inches and above the size of the panel display only part of the generation can support, and the production efficiency is low, hindering the development of large size TV. Driven by the strong demand for large-size TV, the panel display generation line is also constantly breaking through. In 2018, BOE put into operation the world’s first 10.5 generation line, the Hefei B9 plant, with a designed capacity of 120K/ month. The birth of the 10.5 generation line is epoch-making. It solves the cutting problem of large-size panel displays and lays the foundation for the outbreak of large-size TV. From the cutting method, one 10.5 generation line panel display can effectively cut 18 43 inches, 8 65 inches, 6 75 inches panel display, and can be more efficient in hybrid mode cutting, with half of the panel display 65 inches, the other half of the panel display 75 inches, the yield is also guaranteed. Currently, there are a total of five 10.5 generation lines in the world, including two for domestic panel display companies BOE and Huaxing Optoelectronics. Sharp has a 10.5 generation line in Guangzhou, which is mainly used to produce its own TV. Korean manufacturers do not have the 10.5 generation line. In the context of the increasing size of the TV, Korean manufacturers are obviously at a disadvantage in competitiveness.

(3) As the large-size OLED panel display technology has become increasingly mature, Samsung and LGD hope to transfer production to large-size OLED with better profit prospects as soon as possible. Apart from the price factor, the reason why South Korean manufacturers are exiting LCD production is more because the large-size OLED panel display technology is becoming mature, and Samsung and LGD hope to switch to large-size OLED production as soon as possible, which has better profit prospects. At present, there are three major large-scale OLED solutions including WOLED, QD OLED, and printed OLED, while there is only WOLED with a mass production line at present.

According to statistics, shipments of OLED TVs totaled 2.8 million in 2018 and increased to 3.5 million in 2019, up 25 percent year on year. But it accounted for only 1.58% of global shipments. The capacity gap has greatly limited the volume of OLED TV.LG alone consumes about 47% of the world’s OLED TV panel display capacity, thanks to its own capacity. Other manufacturers can only purchase at a high price. According to the industry chain survey, the current price of a 65-inch OLED panel is around $800-900, while the price of the same size LCD panel is currently only $171.There is a significant price difference between the two.

Samsung and LGD began to shut down LCD production lines in Q3 last year, leading to the recovery of the panel display sector. Entering 2020, the two major South Korean plants have announced further capacity withdrawal planning. In the following section, we will focus on its capacity exit plan and compare it with the original plan. It can be seen that the pace and magnitude of Samsung’s exit this round is much higher than the market expectation:

(1) LGD: LGD currently has three large LCD production lines of P7, P8, and P9 in China, with a designed capacity of 230K, 240K, and 90K respectively. At the CES exhibition at the beginning of this year, the company announced that IT would shut down all TV panel display production capacity in South Korea in 2020, mainly P7 and P8 lines, while P9 is not included in the exit plan because IT supplies IT panel display for Apple.

According to our latest industry chain survey, by the end of Q1 in 2020, P7 production capacity remains 140K; P8 has 100K of capacity left.P7 is expected to shut down by the end of the year, and P8 will shut down all TV production capacity at the end of the year, but there is still 40KIT production capacity to continue.

(2) Samsung: At present, Samsung has L8-1, L8-2, and L7-2 large-size LCD production lines in South Korea, with designed production capacities of 200K, 150K, and 160K respectively. At the same time in Suzhou has a 70K capacity of 8 generation line.

Samsung had planned to retire all L8-1 and L8-2 capacity by the end of 2021, while L7-2 would retain 50K of IT capacity. This time, it is planned to withdraw all production capacity by the end of 2020, among which the production line in South Korea will be converted to Qdoled, and the production line in Suzhou will be sold.

This round of capacity withdrawal of South Korean plants began in June 2019. Based on the global total production capacity in June 2019, Samsung will withdraw 1,386,900 square meters of production capacity in 2019-2020, equivalent to 9.69% of the global production capacity, according to the previous two-year withdrawal expectation. In 2021, 697,200 square meters of production capacity will be withdrawn, which is equivalent to 4.87% of the global production capacity, and a total of 14.56% will be withdrawn in three years. After the implementation of the new plan, Samsung will eliminate 2.422 million square meters of production capacity by the end of 2020, equivalent to 16.92 percent of the global capacity. This round of production plans from the pace and range are far beyond the market expectations.

Global shipments of TV panel displays totaled 281 million in 2019, down 1.06 percent year on year, according to Insight. In fact, TV panel display shipments have been stable since 2015 at between 250 and 300 million units. At the same time, from the perspective of the structure of sales volume, the period from 2005 to 2010 was the period when the size of China’s TV market grew substantially. Third-world sales also leveled off in 2014. We believe that the sales volume of the TV market has stabilized and there is no big fluctuation. The impact of the epidemic on the overall demand may be more optimistic than the market expectation.

In contrast to the change in volume, we believe that the core driver of the growth in TV panel display demand is actually the increase in TV size. According to the data statistics of Group Intelligence Consulting, the average size of TV panel display in 2014 was 0.47 square meters, equivalent to the size of 41 inches screen. In 2019, the average TV panel size is 0.58 square meters, which is about the size of a 46-inch screen. From 2014 to 2019, the average CAGR of TV panel display size is 4.18%. Meanwhile, the shipment of TV in 2019 also increased compared with that in 2014. Therefore, from 2014 to 2019, the compound growth rate of the total area demand for TV panel displays is 6.37%.

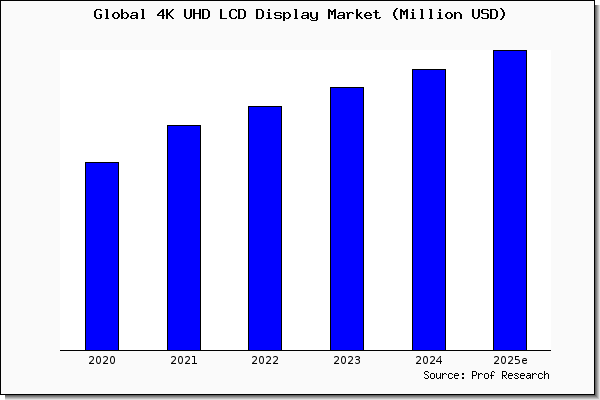

It is assumed that 4K screen and 8K screen will accelerate the penetration and gradually become mainstream products in the next 2-3 years. The pace of screen size increase will accelerate. We have learned through industry chain research that the average size growth rate of TV will increase to 6-8% in 2020. Driven by the growth of the average size, the demand area of global TV panel displays is expected to grow even if TV sales decline, and the upward trend of industry demand remains unchanged.

Meanwhile, the global LCDTV panel display demand will increase significantly in 2021, driven by the recovery of terminal demand and the continued growth of the average TV size. In 2021, the whole year panel display will be in a short supply situation, the mainland panel shows that both males will enjoy the price elasticity.

This paper analyzes the competition pattern of the panel display industry from both supply and demand sides. On the supply side, the optimization of the industry competition pattern by accelerating the withdrawal of Samsung’s production capacity is deeply discussed. Demand-side focuses on tracking global sales data and industry inventory changes. Overall, we believe that the current epidemic has a certain impact on demand, and the panel shows that prices may be under short-term pressure in April or May. But as Samsung’s exit from LCD capacity accelerates, industry inventories remain low. So once the overseas epidemic is contained and domestic demand picks up, the panel suggests prices will surge. We are firmly optimistic about the A-share panel display plate investment value, maintain the industry “optimistic” rating. Suggested attention: BOE A, TCL Technology.

At present, markets such as large-screen TVs are still inseparable from LCD panels. Several Chinese panel manufacturers have surpassed Samsung and LG to become the main LCD panel manufacturers in recent years. Korean companies are no longer able to compete. Samsung will stop the production of LCD panels half a year ahead of schedule. Samsung used to be the largest LCD panel manufacturer, but in recent years, Chinese companies such as BOE and CSOT have rapidly expanded their market shares. Samsung and LG have continued to retreat, making BOE surpass LGD in 2018. As of now, BOE is now the world’s largest manufacturer of LCD panels.

Samsung originally planned to stop the production of LCD panels by the end of 2020. However, the LCD panel market started to increase prices in the past year or so. This made Samsung’s LCD factory continue to operate for another two years. However, the company originally plans to exit the market at the end of 2022. Nevertheless, the LCD panel market has changed since the end of last year. The price has been falling significantly and it is now on a free fall. By January this year, the average price of a 32 -inch panel was only $ 38, a 64% drop relative to January last year.

This situation is making Samsung rethink its initial exit plans. The South Korean manufacturing giant is now planning to withdraw from LCD panel production half a year ahead of schedule. It will stop production in June this year. Samsung Display, a subsidiary of Samsung Electronics, will turn to higher-end QD quantum dot panels. The LCD panels that the company needs will turn to procurement.

According to information released by Samsung Electronics, the company’s three major suppliers of LCD panels are BOE, Huaxing Optoelectronics, and AUO, all of which are Chinese companies. The first two are local companies, and they are the first and second-largest suppliers of LCD.

Due to high demand in South Kore, Samsung Display had to extend its production of Liquid Crystal Display (LCD) panels for TVs and monitors in South Korea. Its exit from the LCD market will give the company room to concentrate on more advanced technologies.

Samsung’s delay in closing the LCD panel plant will increase the production area and there is the risk of material shortages. Thus, the dipping price of LCD panels gives the company all the reasons it needs to quit the market.

As a Zhongguancun enterprise, BOE has always adhered to technology-driven innovation. According to statistics, BOE"s 2018 shipments of LCD TV panels exceeded that of,LG Display Co, one of the world"s biggest manufacturers of display panels used in smartphones and televisions, ranking first in the world that year.

"The display shipments of BOE increased by 24 percent year-on-year in 2018, and its dispatch area increased by 45 percent year-on-year, which is the highest growth among the top five panel makers in the world," According to Sigmaintell Consulting analysts, who added that BOE achieved remarkable results in 2018: the world"s first 10.5 generation TFT-LCD mass production line was put into operation, and its TV panel production capacity increased by over 40 percent.

Meanwhile, BOE"s product structure continues to optimize production of large TV displays. Screens of 55, 65 and 75 inches increased sharply, and BOE"s market share of 75-inch TV displays tops in the world.

Global shipments of LCD TV panels in the first quarter of 2018 [Photo provided to chinadaily.com.cn]BOE accelerated its technology upgrading and achieved a new breakthrough in liquid crystal display technology in 2018. By applying megapixel partitioning technology, BOE 4K display achieved a 100,000-level ultra-high dynamic contrast ratio, with a color depth up to 12bits, so that the LCD display perfectly shows the ultra high definition display effect.

Recently, the US patent service agency IFI Claims released the 2018 US statistics report on patent authorization. BOE"s global ranking had jumped to 17th, with patents granted in America reaching 1,634, an increase of 16 percent. BOE is now the fastest-growing company among the TOP 20 enterprises listed by IFI Claims.

The 2018 US statistics report on patent authorization released by IFI Claims. [Source: IFI CLAIMS official website]Innovation is the only path on which companies can survive and succeed. Since its founding, BOE has always maintained its respect for technology and innovation and has ranked first in the industry for patent applications for consecutive years.

In 2018, BOE added 9,958 new patent applications, 90 percent of them invention patents and 38 percent overseas patents covering the United States, Europe, Japan, South Korea and other countries and regions. The total number of patents held by the company exceeds 70,000.

The "4317 full-spine flat-panel detector" is the world"s first and largest flat-panel detector for full-body scanning. It takes a one-time shot to obtain a complete human spine image, which avoids the patient"s exposure to accumulated X-ray doses and greatly reduces radiation damage.

Over a decade ago, due to the lack of core technologies in the field of semiconductor displays, China"s electronic information industry was shrouded in the shadow of the "lack of LCD screens", and was even unable to independently manufacture a complete LCD TV.

Acquisition of Hyundai Electronics" LCD panel businesses gave Chinese semiconductor companies a chance to break through technological limitations. [Photo provided to chinadaily.com.cn]A group of semiconductor companies like BOE seized the opportunity to acquire Hyundai Electronics" LCD panel businesses. After digesting, absorbing and re-innovating, the companies mastered liquid crystal display technology and ended the dependence on imports in the Chinese semiconductor and display industries.

With a market share of over 20%, Samsung has been the world’s largest TV manufacturer since 2006. It was the first TV company to launch a fully HD LED TV in 2010 at the Consumer Electronics Show (CES), Las Vegas. Samsung also accounts for almost 50% of total 75-inch TV sales worldwide. Samsung’s LCD display technology, QLED, uses quantum dots to enhance colors, enabling the viewer to see minute details on extremely bright or dark scenes. With increasing demand for large-screen TVs, the company is strengthening its QLED TV portfolio by incorporating additional features such as HDR 2000 and a 4K Q Engine, which optimizes high-resolution content for screens larger than 65 inches.

TCL is one of the fastest growing TV manufacturers offering 2K LED TVs, UHD Android TVs, UHD Smart TVs, FHD/HD Smart TVs, and FHD/HD Slim Led TVs at low prices. Companies such as Alcatel and Samsung have outsourced the manufacturing of some models of LCD television to TCL because of its strategic location to lower the production costs. To spread their brand name, TCL have partnered with many companies in the fields of sports, entertainment, music and technology. The company uses TCL Wide Color Gamut technology to deliver the purest LED backlight, which in turn helps to improve display performance and the vividness of the picture. Moreover, TCL brand TVs come equipped with built-in Chromecast that allows users to cast videos or games directly to their TVs.

Panasonic is one of the best TV brands in the world, leading the evolution of televisions from colorization and digitization to flat panels and higher resolutions. The company is focusing on the research and development of visual image processing technologies to provide end-to-end ultra HD solutions. The company has incorporated its technology and extensive knowledge of TV manufacturing into its Studio Color HCX2 Processor to deliver detailed HDR pictures in bright and dark areas in its latest 4K OLED television series.

While there are many different manufacturers of LCD monitors, the panels themselves are actually only manufactured by a relatively small selection of companies. The three main manufacturers tend to be Samsung, AU Optronics and LG.Display (previously LG.Philips), but there are also a range of other companies like Innolux and CPT which are used widely in the market. Below is a database of all the current panel modules manufactured in each size. These show the module number along with important information including panel technology and a detailed spec. This should provide a detailed list of panels used, and can give you some insight into what is used in any given LCD display.

Note:These are taken from manufacturer product documentation and panel resource websites. Specs are up to date to the best of our knowledge, and new panels will be added as and when they are produced. Where gaps are present, the detail is unknown or not listed in documentation. The colour depth specs are taken from the manufacturer, and so where they specify FRC and 8-bit etc, this is their listing. Absence of such in the table below does not necessarily mean they aren’t using FRC etc, just that this is how the manufacturer lists the spec on their site.

LCD panel interfaces have changed over the years as resolutions have moved from 640×480 to 3840×2160. The following outlines the common ones that we support with our LCD controllers and cable kits. They cover most of the large size and higher resolution LCD panels on the market:

LVDS: LVDS was introduced in the late 1990’s and enabled connection for higher resolution panels with the benefit of reducing EMI. The LVDS interface is supported by most Digital View LCD controllers and covers panel resolutions from 640×480 to 3840×2160 though newer formats are replacing it for higher resolutions. It remains very popular for HD type resolutions, ie up to around 1920×1200. Most LCD panel manufacturers have LCD panels supporting LVDS, including AUO, BOE, Innolux, JDI, Kyocera, LG, Mitsubishi, Sharp, Tianma. LVDS is Low Voltage Differential Switching.

V-by-One: Increasingly common on 4K resolution panels typically 55″ and larger though I did find a 32″ 1920×1080 panel and 28″ 3840×2160 panel listed as in production. A benefit of V-by-One compared to LVDS is the reduction in cables for high resolution signal support and reduced EMI. LCD panel brands using V-by-One include AUO, BOE, Innolux, LG, Samsung, Sharp. I thought of V-by-One as replacing LVDS but apparently it was developed to replace FPD-Link.

eDP: First introduced in 2008 it is widely adopted by LCD panels used in laptops and similar devices. We are also now seeing it being used in higher resolution and brightness LCD panels but still typically smaller sizes, ie 30″ or smaller. Digital View LCD controller models supporting eDP include SVX-4096, SVX-2560, SVH-1920v2 and the new DD-1920-HDMI-EDPT. Brands using it include AUO, BOE, Innolux, LG, Panasonic, Samsung, Sharp, Tianma.

TTL: Supported by the ALR-1400v2 and HLR-1400v2 controllers this was the common panel interface when Digital View was founded in 1995. VGA (640×480) to XGA (1024×768) resolutions were mainstream at that time. Still used in commercial and industrial display applications AUO, Innolux, Kyocera, Mitsubishi, Samsung, Sharp, Tianma have LCD panels in production with resolutions such as 640×480, 800×480, 800×600, 1024×768. The name TTL is short for Transistor-Transistor Logic.

FPD-Link: The original low voltage differential switching signal but not to be confused with the LVDS interface on many panels as described above. It is now often used in the automotive market and currently up to FPD-Link III. It is not currently supported by any Digital View’s standard controller models though we are looking at it as a custom development option.

BOE, China’s largest display company, was listed as a major panel supplier in Samsung Electronics’ business report. BOE has filled the vacancy created by Samsung Display’s phased reduction of large LCD panels for TVs.

The business report, which was registered with the Financial Supervisory Service’s electronic disclosure system, listed three major display panel suppliers for the company"s consumer electronics (CE) sector in 2021 -- BOE and CSOT of China and AUO of Taiwan. BOE was newly added as a major supplier. BOE surpassed LG Display in 2018 to become the world’s No. 1 LCD manufacturer.

Samsung Display decided in early 2021 to stop producing large LCD panels beginning from 2022. The decision was made to speed up its transition to next-generation QD-OLED panels as the profitability of the LCD business fell significantly due to a price war with Chinese companies.

It stopped the operation of L7 at Asan Campus in South Chungcheong Province, which had produced large LCD panels, in March 2021. An 8th-generation LCD production line at the Suzhou plant in China was sold in April 2021. However, it is still operating some of its large LCD production facilities at Asan Campus at the request of Samsung Electronics. Samsung Display is considering shutting down these facilities within June 2022.

Industry insiders say that Samsung Display"s withdrawal from the LCD business has weakened Samsung Electronics" bargaining power in negotiations with Chinese vendors.

Samsung Electronics’ price burden for TV panels has nearly doubled over the past year. The Samsung Electronics business report says that the company spent 10,582.3 billion won on purchasing display panels in 2021. This was an increase of 94.2 percent from the previous year (5,448.3 billion won). The main factor behind the increase is a rise in LCD panel prices. Samsung Electronics explained that prices of TV panels rose about 39 percent on year in 2021.

Industry insiders say one solution is to accelerate a shift to OLED-based TVs. Chinese panel makers are investing aggressively to develop large OLED panel technologies, but they have not yet reached the volume production stage.

Samsung Electronics is negotiating with Samsung Display and LG Display over the release of OLED TVs. LG Display is the only company that mass produces large OLED panels. It can produce 10 million TV panels annually. Samsung Display started mass production of large OLED panels at the end of 2021. The two Korean OLED panel makers adopt white (W) and blue (B) light sources, respectively.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey