lcd panel price trend 2020 pricelist

Prices for all TV panel sizes fluctuated and are forecast to fluctuate between 2020 and 2022. The period from March 2020 to July 2021 saw the biggest price increases, when a 65" UHD panel cost between 171 and 288 U.S. dollars. In the fourth quarter of 2021, such prices fell and are expected to drop to an even lower amount by March 2022.Read moreLCD TV panel prices worldwide from January 2020 to March 2022, by size(in U.S. dollars)Characteristic32" HD43" FHD49"/50" UHD55" UHD65" UHD------

DSCC. (January 10, 2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph]. In Statista. Retrieved December 15, 2022, from https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars)." Chart. January 10, 2022. Statista. Accessed December 15, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. (2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars). Statista. Statista Inc.. Accessed: December 15, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "Lcd Tv Panel Prices Worldwide from January 2020 to March 2022, by Size (in U.S. Dollars)." Statista, Statista Inc., 10 Jan 2022, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC, LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) Statista, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/ (last visited December 15, 2022)

In September, area prices for all screen sizes up to 65” fell in a range from $92 to $106 per square meter, with the 65” area price tied with 32” for the lowest in the industry at $92 per square meter. The largest screen size in our survey, 75” panels, continues to have a premium but that premium has eroded steadily. In June 2022, a 75” panel was priced at $144 per square meter, a $41 or 40% premium over the 32” area price. By September, the 75” premium over 32” had dropped to $27 and 29%. While prices for 65” and smaller panels increased in October, 75” prices stayed flat, and we expect that pattern to continue through Q4 and Q1.

Throughout the many cycles in the industry, we have seen that the most commoditized screen size is 32”, because this screen size can be efficiently produced on every Gen size fab from Gen 6 through Gen 10.5. Thus, when prices go down, 32” prices go down fastest, but when prices increase, the 32” price increase fastest as well. This was true in October as 32” prices increased by $2 or 7% for the month; the area price increased from $92 per square meter in September to $99 in October.

The next chart shows our estimates of cash costs vs. panel prices for large TV panels. While 55” panels have been below cash costs for most of the year, 65” prices reached cash costs in Q2 and for the first time 75” panel prices fell below cash costs in Q3. We expect that 55” and 65” panel prices will increase in Q4 and Q1 2023 but will remain slightly below cash costs.

LCD TV panel prices reached all-time lows in August but they continue to decline in September, and we continue to forecast that the industry will have an “L-shaped” recovery in the fourth quarter. In other words, no recovery at all until 2023; the only question is how low prices will go before they flatten out. The ‘perfect storm’ of a continued oversupply, near-universally weak demand and excessive inventory throughout the supply chain has combined, and every screen size of TV panel has reached an all-time low price. Although fab utilization slowed sharply starting in July, we do not see any signal to suggest that prices can increase any time soon.

THANK YOU FOR VISITING ENERGYTREND (HEREINAFTER REFERRED TO AS "THE WEBSITE"). THE WEBSITE, OWNED AND OPERATED BY TRENDFORCE CORP. (HEREINAFTER REFERRED TO AS "TRENDFORCE"), WILL COLLECT, HANDLE, AND USE PRIVATE USER DATA IN ACCORDANCE WITH THE PERSONAL INFORMATION PROTECTION LAW (HEREINAFTER "PERSONAL INFORMATION LAW") AND THE WEBSITE"S PRIVACY POLICY. THE WEBSITE AIMS TO RESPECT AND PROTECT ALL USERS" ONLINE PRIVACY RIGHTS. IN ORDER TO UNDERSTAND AS WELL AS PROTECT YOUR RIGHTS, PLEASE READ THE FOLLOWING TERMS CAREFULLY:

1.1. THE POLICY COVERS THE HANDLING OF THE PRIVATE INFORMATION EACH USER SHARES WITH TRENDFORCE WHILE VISITING OUR WEBSITES. IF A DIFFERENT PRIVATE POLICY HAS BEEN REFERED TO FOR SPECIFIC TRENDFORCE WEBSITES AND SERVICES, THAT POLICY WILL REPLACE OR SUPPLEMENT THE PRIVACY POLICY MENTIONED IN THIS DOCUMENT. THIS POLICY ALSO COVERS INDIVIDUALS LEGALLY RESIDING IN OR ORGANIZATIONS LEGALLY BASED IN MEMBER COUNTRIES OF THE EUROPEAN UNION (EU) AND ARE SUBJECTED TO EU GENERAL DATA PROTECTION REGULATION (GDPR) WITH REGARD TO PROVISION OF SERVICES AND PERSONAL DATA PROTECTION.

1.2. THIS POLICY IS NOT APPLICABLE TO EITHER COMPANIES OTHER THAN TRENDFORCE AND ITS SUBSIDIARIES OR PERSONNEL NOT EMPLOYED OR AUTHORIZED BY TRENDFORCE AND ITS SUBSIDIARIES.

2.4. THE WEBSITE COLLECTS TRANSACTION DATA BETWEEN YOU AND TRENDFORCE AND FROM RELEVANT BUSINESS PARTNERS. THESE INCLUDE SPECIFIC PRODUCTS AND SERVICES THAT ARE DIRECTLY OBTAINED FROM THE WEBSITE.

b. THIS WEBSITE WILL NOTIFY YOU ON MATTERS RELATED TO YOUR PERSONAL DATA BY EMAIL, OR TRENDFORCE CORP. WILL NOTIFY YOU BY OTHER MEANS (SUCH AS VIA TELEPHONE). CLIENTS ARE FULLY RESPONSIBLE FOR PROVIDING AN UPDATED, VALID, AND DELIVERABLE EMAIL ADDRESS THAT CAN RECEIVE NOTIFICATION EMAILS FROM TRENDFORCE CORP.

EXCEPT AS OTHERWISE EXPRESSEDLY PROVIDED BY GDPR OR ORDERED BY THE LAWS OF A COMPETENT JURISDICTION, CLIENTS CAN USE CUSTOMER EMAILServiceGDPR@energytrend.comTO CONTACT THIS WEBSITE TO EXERCISE THEIR RIGHTS PERTAINING TO THEIR ACCOUNT USER NAMES, ACCOUNT USER DATA, SESSION COOKIES, AND OTHER FORMS OF ACCOUNT DATA RECORDS. THESE RIGHTS INCLUDE RIGHT TO ACCESS, RIGHT TO RECTIFICATION, RIGHT TO BE FORGOTTEN/DATA ERASURE, RIGHT TO RESTRICTION OF PROCESSING, RIGHT OF DATA PORTABILITY, RIGHT TO OBJECT, AND ETC. TO EXERCISE THESE RIGHTS, A CLIENT MUST INCLUDE LEGALLY VALID AND VERIFICABLE PROOFS OF PERSONAL IDENITIFICATION ALONG WITH HIS/HER REQUEST. FURTHEMORE, THE CLIENT ISSUING THE REQUEST TO EXERCISE THESE RIGHTS MUST HAVE FUFILLED VARIOUS LEGAL OBLIGATIONS ON HIS/HER PART BEFOREHAND. AFTERWARDS, TRENDFORCE WILL FULFILL THE CLIENTS’ REQUEST/PROVIDE RESOLUTIONS WITHIN REASONABLE TIME AND EFFORT.

It may seem odd in the face of stalled economies and stalled AV projects, but the costs of LCD display products are on the rise, according to a report from Digital Supply Chain Consulting, or DSCC.

Demand for LCD products remains strong , says DSCC, at the same time as shortages are deepening for glass substrates and driver integrated circuits. Announcements by the Korean panel makers that they will maintain production of LCDs and delay their planned shutdown of LCD lines has not prevented prices from continuing to rise.

I assume, but absolutely don’t know for sure, that panel pricing that affects the much larger consumer market must have a similar impact on commercial displays, or what researchers seem to term public information displays.

Panel prices increased more than 20% for selected TV sizes in Q3 2020 compared to Q2, and by 27% in Q4 2020 compared to Q3, we now expect that average LCD TV panel prices in Q1 2021 will increase by another 12%.

The first chart shows our latest TV panel price update, with prices increasing across the board from a low in May 2020 to an expected peak in May/June of this year. Last month’s update predicted a peak in February/March. However, our forecast for the peak has been increased and pushed out after AGC reported a major accident at a glass plant in Korea and amid continuing problems with driver IC shortages.

The inflection point for this cycle, the month of the most significant M/M price increases, was passed in September 2020, and the price increases have been slowing down each month since then, but the January increase averaged 4.1%. Prices in February 2021 have reached levels last seen exactly three years ago in February 2018.

Prices increased in Q4 for all sizes of TV panels, with massive percentage increases in sizes from 32” to 55” ranging from 28% to 38%. Prices for 65” and 75” increased at a slower rate, by 19% and 8% respectively, as capacity has continued to increase on those sizes with Gen 10.5 expansions.

Prices for every size of TV panel will increase in Q1 at a slower rate, ranging from 5% for 75” to 16% for 43”, and we now expect that prices will continue to increase in Q2, with the increases ranging from 3% to 6% on a Q/Q basis. We now expect that prices will peak in Q2 and will start to decline in Q3, but the situation remains fluid.

All that said, LCD panels are way less costly, way lighter and slimmer, and generally look way better than the ones being used 10 years ago, so prices is a relative problem.

LCD panel prices have risen for 4 months in a row because of your home gaming? Since this year, the whole LCD panel market has smoked. Whether after the outbreak of the epidemic, LCD panel market prices rose for four months, or the panel giants in Japan and South Korea successively sold production lines, or the Chinese mainland listed companies frequently integrated acquisition, investment, and plant construction, all make the industry full of interesting.

LCD panel prices are already a fact. Since May this year, LCD panel prices have risen for four months in a row, making the whole industry chain dynamic. Why are LCD panels going up in price in a volatile 2020? The key factor lies in the imbalance between supply and demand.

For larger sizes, overseas stocks remained strong, with prices for 65 inches and 75 inches rising $10 on average to $200 and $305 respectively in September.

The price of LCDS for large-size TVs of 70 inches or more hasn’t budged much. In addition, LTPS screens and AMOLED screens used in high-end phones have seen little or no increase in price.

As for October, LCD panel price increases are expected to moderate. The data shows that in October 32 inches or 2 dollars; Gains of 39.5 to 43 inches will shrink to $3;55 inches will fall back below $10; The 65-inch gain will narrow to $5.

During the epidemic, people stayed at home and had no way to go out for entertainment. They relied on TV sets, PCS, and game consoles for entertainment. After the resumption of economic work and production, the market of traditional home appliances picked up rapidly, and LCD production capacity was quickly digested.

However, due to the shutdown of most factories lasting 1-2 months during the epidemic period, LCD panel production capacity was limited, leading to insufficient production capacity in the face of the market outbreak, which eventually led to the market shortage and price increase for 4 consecutive months.

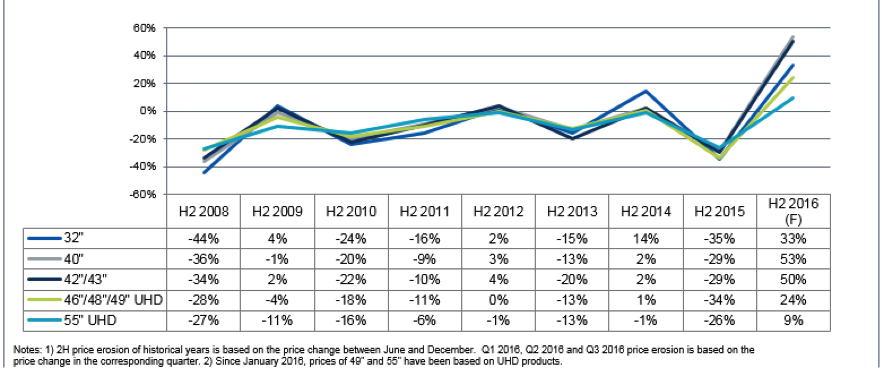

In fact, the last round of price rise of LCD panels was from 2016 to 2017, and its overall market price has continued to fall since 2018. Even in 2019, individual types have fallen below the material cost, and the whole industry has experienced a general operating loss. As a result, LCD makers have been looking for ways to improve margins since last year.

A return to a reasonable price range is the most talked about topic among panel makers in 2019, according to one practitioner. Some manufacturers for the serious loss of the product made the decision to reduce production or even stop production; Some manufacturers planned to raise the price, but due to the epidemic in 2020, the downstream demand was temporarily suppressed and the price increase was postponed. After the outbreak was contained in April, LCD prices began to rise in mid-to-late May.

This kind of price correction is in line with the law of industrial development. Only with reasonable profit space can the whole industry be stimulated to move forward.

In fact, the market price of LCD panels continued to decline in 2018-2019 because of the accelerated rise of China’s LCD industry and the influx of a large number of local manufacturers, which doubled the global LCD panel production capacity within a few years, but there was no suitable application market to absorb it. The result of excess capacity is oversupply, ultimately making LCD panel prices remain depressed.

Against this background, combined with the impact of the epidemic in 2020, the operating burden of LCD companies in Japan and South Korea has been further aggravated, and it is difficult to make profits in the production of LCD panels, so they have to announce the withdrawal of LCD business.

business in June 2022. In August, Sharp bought JDI Baishan, a plant in Ishikawa prefecture that makes liquid crystal display panels for smartphones. In early September, Samsung Display sold a majority stake in its SUZHOU LCD production plant to Starlight Electronics Technology, a unit of TCL Technology Group. LGD has not only pulled out of some of its production capacity but has announced that it will close its local production line in 2020. According to DSCC, a consultancy, the share of LCD production capacity in South Korea alone will fall from 19% to 7% between 2020 and 2021.

It is worth mentioning that in industry analysis, in view of the fact that Korean companies are good at using “dig through old bonus – selling high price – the development of new technology” the cycle of development mode, another 2020 out of the LCD production capacity, the main reason may be: taking the advantage of China’s expanding aggressively LCD manufacturers, Korean companies will own LCD panel production line hot sell, eliminating capacity liquid to extract its final value, and turning to the more profitable advantage of a new generation of display technologies, such as thinner, color display better OLED, etc. Samsung, for example, has captured more than 80% of the OLED market with its first-mover advantage.

From the perspective of production capacity, the launch of LCD tracks by major manufacturers in Japan and South Korea must reduce some production capacity in the short term, which to some extent induces market price fluctuations. In the long run, some of the Japanese and Korean LCD production capacity has been bought by Chinese manufacturers, coupled with frequent investment in recent years, the overall capacity is sure to recover as before, or even more than before. But now it will take time to expand the production layout, which more or less will cause supply imbalance, the industry needs to be cautious.

The LCD panel industry started in the United States and then gradually moved to Japan, South Korea, China, and Taiwan. At present, the proportion of production capacity in The Chinese mainland has reached 52% in 2020, and there are leading LCD panel products in China represented by BOE, Huxing Optoelectronics. Meanwhile, the production capacity layout of BOE, Huike, Huxing Optoelectronics, and other manufacturers has been basically completed, making industrial integration a necessity.

On the one hand, South Korean enterprises out of the LCD track, the domestic factory horse enclosure, plant expansion action. While LCDs may not sell as well as “upstart” flexible screens, respondents believe they are still strong enough in the traditional home appliance market to warrant continued investment. Zhao Bin, general manager of TCL Huaxing Development Center, has said publicly that the next-generation display technology will be mature in four to five years, but the commercialization of products may not take place until a decade later. “LCD will still be the mainstream in this decade,” he said.

On the other hand, there is no risk of neck jam in China’s LCD panel industry, which is generally controllable. In mainland China, there will be 21 production lines capable of producing 32-inch or larger LCD panels by 2021, accounting for about two-thirds of the global total. In terms of the proportion of production capacity, the Chinese mainland accounted for 42% of the global LCD panel in 2019, 51% this year, and will continue to climb to 63% next year.

Of course, building factories and expanding production cannot be accomplished overnight. In the process of production capacity recovery, it is predicted that there will be several price fluctuations, and the cost may be passed on to the downstream LCD panel manufacturers or consumers when the price rises greatly, which requires continuous attention.

One of the reasons Samsung decided to make the leap to OLED was because the price of LCD panels was going up so much., that it was worth betting on a technology that offers better quality and for the same money. But it seems that things are changing.

And it is that, in recent years the cost of LCD panels skyrocketed due to the production problems caused by the coronavirus, plus a notable increase in demand (people are at home, so the consumption of televisions increases). But the market is merciless, and has begun to regulate itself.

According to Display Supply Chain Consulting (DSCC), a renowned market research firm in the industry, the expected price of LCD TV panels this month was $ 38 for a 32-inch HD model. This is a 56.8% drop compared to June of last year at $ 88.

During this same period,43-inch Full HD panels have gone from $ 139 to $ 70, 50-inch UHD panels have gone from $ 196 to $ 91, 55-inch from $ 225 to $ 112, and 65-inch 4K panels have gone from costing $ 285 to “only” $ 186.

This makes it clear that the upward trend that began in May 2020, when COVID-19 began to spread globally, has ended. Component shortages, as well as increased demand, sent prices skyrocketing.

This impacted the user, sincethe price of this type of television increased significantly. And it was a turning point for Samsung, which saw how it had to stop its own LCD panel production as it could not compete with so many Chinese rivals. And this has been the reason why it has decided to take the leap and present its QD-OLED technology.

It should be noted that, as the DSCC has indicated in its report “In the fourth quarter of last year, the price fell the most compared to the previous quarter in the history of the flat panel display industry.This can translate into a very possible reduction in the price of LCD televisions, but that does not mean that it is the path that firms such as LG and Samsung will follow. Nothing is further from reality.

Samsung Display, which is estimated to account for around 4% of LCD TV panels in total sales, is also considering a plan to withdraw from business.. Samsung Display responded to a conference call in the third quarter of last year and said: “In a situation where prices for LCD panels are falling rapidly, we are internally reviewing whether to produce additional LCDs. ‘

The two Korean giants know that they cannot compete with Chinese companies that make LCD panels at lower prices. than the Samsung and LG factories. So they have decided to focus their efforts on OLED technology.

Kim Dong-won, a researcher at KB Securities, said: “Samsung’s new entry into the OLED TV market is an opportunity to expand and popularize the OLED ecosystem, and it will shake up the global market for supply and strategic partnership between the two. companies will expand from large LCD screens to OLED screens. ‘

LG is the only supplier of this type of panel, to the point that Samsung has preferred to give its arm to twist against its great rival and become LG’s largest customer, which makes it clear that the future of both brands is to be understood. And that Samsung is less and less interested in LCD technology.

Large-area flat panel display prices increased by over 50% in 2020 due to increased demand from consumers, according to Omdia"s latest OLED and LCD Supply Demand & Equipment Tracker.

A combination of tight capacity for thin film transistor display screens, along with material and component supply bottlenecks, is fueling a panel shortfall, which is increasing demand further, as set manufacturers buy more panels to fulfill demand in 2021, according to a press release on the Omdia tracker results. In the second half of 2021, TFT supply/demand is forecast to trend above 10% almost reaching similar glut levels to 2019.

A string of accidents has created a historically tight glass market and caused an unusual industry average price increase of several percentage points, according to the press release. The lack of investment in polarizers and base films in 2019 caught the industry off guard when demand turned around in 2020. Aside from these three main components, many other materials are also in tight supply, which is affecting makers in different ways, supporting inflationary price trends.

"Although multiple caveats remain about how both supply and demand will trend over the coming months, the modeled glut level is a leading indicator that the next cycle is now on its way, which implies falling prices, utilization and profitability," Charles Annis, practice leader for display manufacturing, technology and cost at Omdia, said in the press release. "Industry players should consider the implications when planning business strategies for the next two years."

A rapid increase in liquid crystal display (LCD) panel prices has sharply narrowed the price gap between LCD panels and organic light-emitting diode (OLED) displays – the latter showing a downward trend due to increased supply. LCD panel prices have been climbing steeply since the first half of last year and rose to their highest level in almost four years this month, with Chinese manufacturers keeping LCD panel supply under control to shore up prices. By contrast, LG Display Co., the world"s largest OLED TV panel maker, has been ramping up OLED production to accelerate its penetration into the TV market.

According to market researcher Omdia on Apr. 19, the average price of the industry-standard 55-inch OLED panel dropped to $510 in the first quarter of this year, compared to $200 for LCD panels. Year on year, OLED panel prices declined 8.1% on average, whereas LCD panel prices spiked 73.9%. As a result, the price gap between the two has narrowed to $310 from $440.

Since the beginning of this month, LCD panel prices increased further to hit $206 on average, their highest level in three years and 10 months. It marked the first time for the average LCD panel price to top $200 since July 2017.

"TV makers have a shortage of LCD panel supplies, with their inventory falling to 60% of normal levels," said KB Securities analyst Kim Dong-won. "They will also continue to suffer supply shortages of other major components such as glass substrates and ICs (integrated circuits) through the second half of this year."

Since South Korean panel makers led by Samsung Display Co. and LG Display pulled out of the low-margin TV LCD market from the second half of last year, Chinese manufacturers led by BOE and CSOT have filled the void. They had rapidly expanded their presence in the LCD market, flooding the market with cheaper products such as 10th-generation panels measuring 2,900mm in width and 3,100mm in length. Chinese manufacturers are now scaling back on LCD panel production to bolster margins.

In the OLED market, by contrast, LG Display has been stepping up supply. Since its Guangzhou plant started operation in the second half of last year, LG"s glass substrate production for OLED panels has more than doubled to 130,000 units a month from 60,000 units. That led to the price cut of OLED TV panels.

Thanks to the reduced price gap with LCD panels, Omdia forecasts that global shipments of OLED TVs will climb to 5.80 million units this year, up 59% from 3.65 million in 2020.

LG Display plans to boost its OLED TV panel shipments to as many as 8 million units this year from 4.5 million units in 2020. Based on its shipment goal, analysts expect global OLED TV sales in 2021 to double from last year"s number, with more than a 10% share in global TV sales.

Demand for large-sized OLED panels is expected to be around 7.2 million units this year, but this will increase to 10 million units in 2023 and 12 million units in 2024, Yi said at an online conference on Friday.

LG Display is currently the sole supplier of large-sized OLED panels. Its current production capacity for the panels is around 10 million units a year. It has production lines in Paju, South Korea and Guangzhou, China.

Yi said LG Display may commence expansion of its capacity earlier than scheduled in light of this possibility. Last January, LG said it plans to start spending in expanding its Gen 10.5 (2940x3370mm) OLED production line in 2023. Yi expects LG Display to start investing no later than next year as it will take time to reach the production yield rate in a Gen 10.5 line, since the Gen 10.5 will be the 1st of its kind. Yi demand forecast is based on those from LG Electronics, Sony and other of LGD’s OLED panel customers.

Should the reports be true that Samsung Electronics will procure large-sized OLED panels from LG Display, the shortage would be pushed up by a year, he noted. In this scenario, LG Display will need to start expanding its capacity this year. The UBI Research CEO said that 1.8m large-sized OLED panels were shipped in Q221, an 186% Y/Y and a 13% increase sequentially.

The National Association of REALTORS® reported that home price growth remained strong for the second quarter of 2022. Prices continued to rise, with 80% of the markets showing double-digit home price appreciation. National median prices rose 14.2% year over year to $413,500, rising above $400,000 for the first time.

Here is a look at the metro areas with the most substantial price growth in the second quarter of 2022, as well as a look at the yearly change in median existing single-family home prices among the top five highest and lowest growth metro areas of the second quarter of 2022.

The top five single-family metro areas with the highest home price appreciation in Q2 2022 were Fayetteville-Springdale-Rogers, AR-MO; Lakeland-Winter Haven, FL; Naples-Immokalee-Marco Island, FL; North Port-Sarasota-Bradenton, FL; and Myrtle Beach-Conway-North Myrtle Beach, SC-NC.

The bottom five single-family metro areas with the slowest home price appreciation in Q2 2022 were Bismark, ND; Davenport-Moline-Rock Island, IA-IL; Fond du Lac, WI; Pittsfield, MA; and Trenton, NJ.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey