serial graphic lcd module free sample

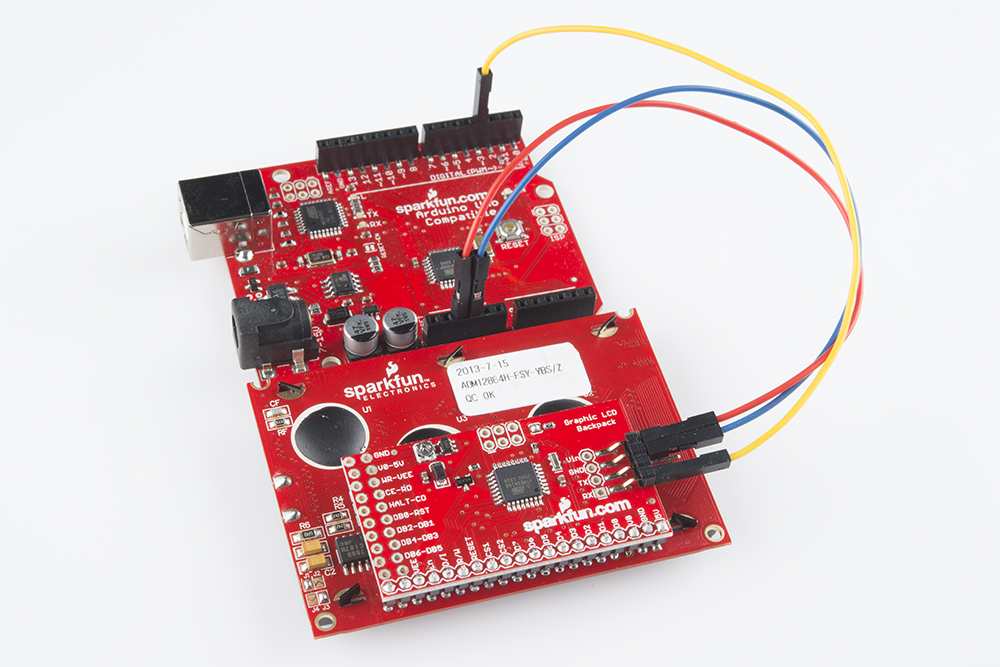

The Graphic Serial LCD Backpack is designed to be controlled by a variety of means. One of which is through a serial terminal. This can be useful if you want to use a personal computer as your control device. You can also send commands to the backpack in real time using the ASCII commands. This is useful for testing the LCD before embedding it into a project. Here is a full list of the ASCII commands.

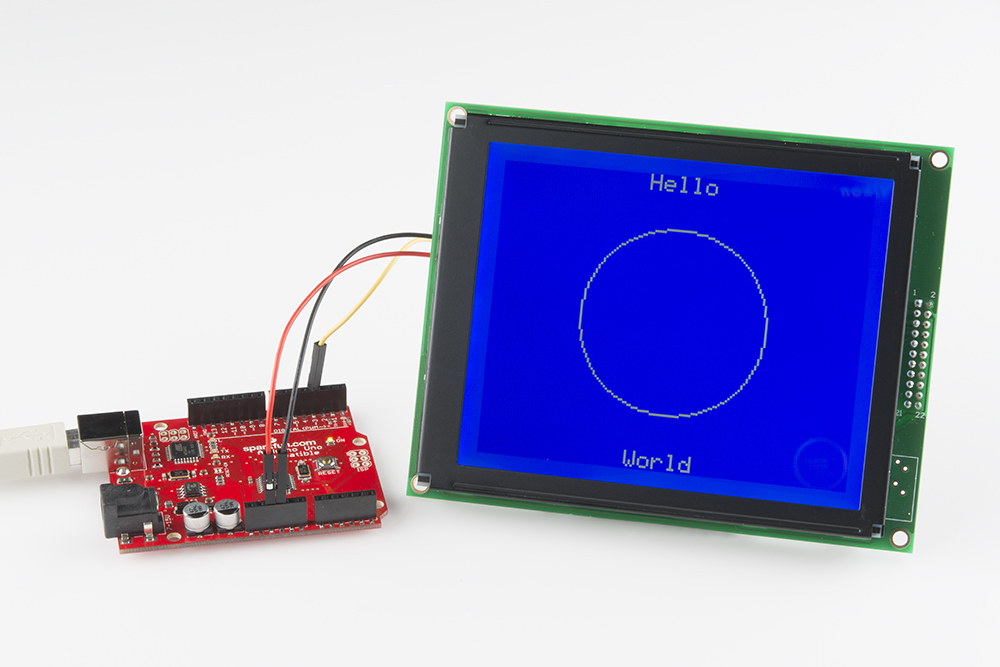

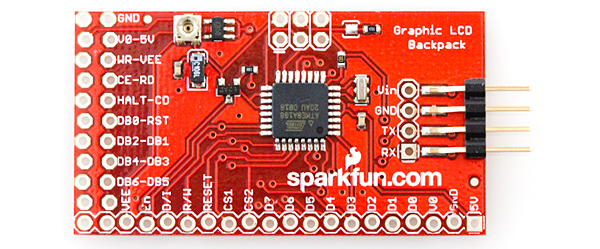

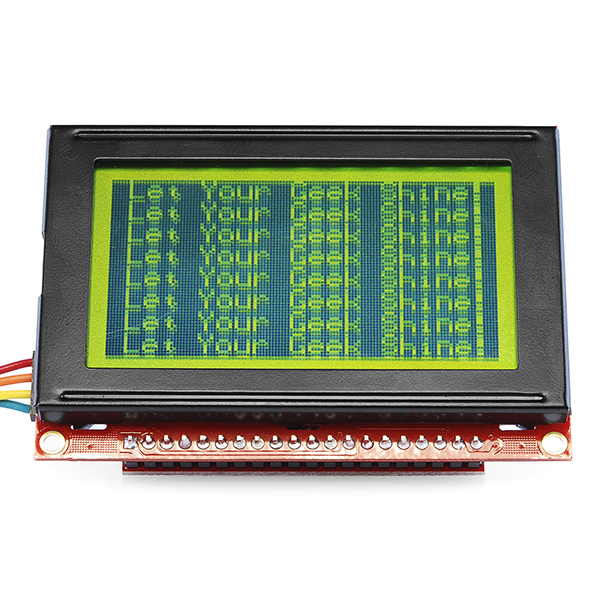

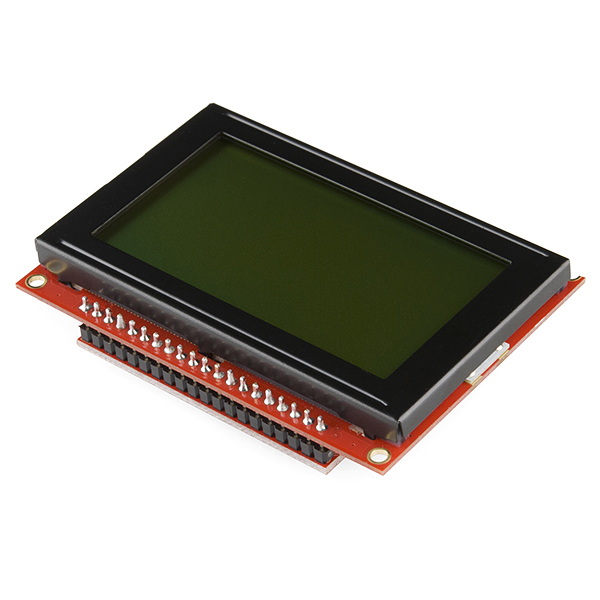

This is the serial backpack for graphic LCDs. The SparkFun Graphic LCD Serial Backpack interfaces to either our 160x128 pixel “Huge” Graphic LCD, or the smaller 128x64 pixel display, and provides a simple serial interface to a full range of controls.

This backpack will allow you to write text, draw lines, circles and boxes, set or reset individual pixels, and erase specific blocks of the display. The backlight and baud rate can also be controlled via serial communication. There’s also a reverse mode that allows the screen to operate blue on white instead of white on blue. Additionally, all source code for the ATMega168 processor is compiled using the free WinAVR compiler and is free for downloading.

In this project, I will show you how to interface a 128X64 Graphical LCD with Arduino UNO. This particular LCD Module is based ST7920 LCD Controller. So, we will first see a little bit about the Graphical LCD Module and its LCD Controller ST7920.

In the previous Arduino project, I have interfaced a Nokia 5110 LCD Module with Arduino. It is also a graphical LCD which can display some basic bitmap images and graphics. But the issue with Nokia 5110 LCD Module is its resolution.

At 84 x 48 pixels, the Nokia 5110 LCD can be used for implementing a menu-based user interface. Due to its small size, the resulting menu will be limited to 3 or 4 items per page.

If we want a bigger display with more real estate to work with, then the obvious choice is to go for the bigger and better 128×64 Graphical LCD Module.

As a demonstration, after making all the hardware connections, I will display a bitmap image on the Graphical LCD Module. If you are interested in implementing a simple 16×2 Alpha-Numeric LCD with Arduino, then check out this tutorial.

At first glance, the 128×64 Graphical LCD Module seems like a bigger brother to the famous 16×2 LCD or 20×4 LCD Modules, with their similar construction and almost similar pin layout.

But there is a significant difference between those two. 16×2 or 20×4 LCDs are essentially character displays. They can only display alpha-numeric characters and some simple custom characters that are confined to a 5×8 matrix.

By using different combinations of pixels, we can basically display characters of various sizes. But the magic doesn’t end there. You can display images and graphics (small animations) as well. In a 128×64 LCD Module, there are 64 rows and 128 columns.

There are several versions of the Graphical LCD in the market. Even though the usage, application and implementations are almost identical, the main difference lies in the internal LCD Controller used to drive the dot matrix display.

Some of the commonly used LCD Controllers are KS0108, SSD1306, ST7920, SH1106, SSD1322, etc. The pin out of the final LCD Module might vary depending on the LCD Controller used. So, please verify the LCD Controller as well as the pin out before making a purchase.

The Graphical LCD Module I purchased consists of ST7920 Controller. It is manufactured by Sitronix and supports three types of bus interfaces i.e., 8-bit mode, 4-bit mode and Serial interface.

If you have used 16×2 LCD Display earlier, then you might be familiar with both 4-bit as well as 8-bit parallel interfaces. The serial interface is something new and we will explore this option in this project.

As I already mentioned, double-check with the manufacturer about the pinout of the Graphical LCD Module. The following table describes the pinout of the 128×64 LCD Module that I have.

Now that we have seen a little bit about the Graphical LCD and its controller ST7920, let us now proceed with interfacing the 128×64 Graphical LCD with Arduino. I will implement a simple circuit to demonstrate how easy it is to interface the LCD and Arduino using very few external components.

In Serial Mode, we need only three pins for the actual data transfer. They are RS, RW and E. RS acts as Chip Select Pin in Serial Communication. RW and E acts as Serial Data IN and Serial CLK pins respectively.

So, connect the RS, RW and E of the LCD to Digital IO pins 10, 11 and 13 of Arduino UNO. Also, in order to select the Serial Interface Mode, the PCB pin must be connected to GND.

The remaining connections are similar to a traditional 16×2 LCD. VCC and GND are connected to 5V and ground of the power supply. VO is connected to the wiper of a 10KΩ POT while the other two terminals of the POT are connected to 5V and GND respectively.

I have used the above “The Office” logo. Remember that the resolution of the 128×64 LCD is, well 128×64 pixels. So, the maximum image size should be 128×64. So, using Microsoft Paint, I have brought down the resolution of the above image to 128×64 pixels and also saved it as Monochrome Bitmap Image.

A simple project for interfacing the 128×64 Graphical LCD with Arduino is implemented here. Instead of displaying plain characters, I have displayed a bitmap image on the LCD to show its capability.

CFAG19232C-TMI-TT Rev.014 should work as a drop in replacement for the CFAG19232C-TMI-TT Rev.011. The only changes to the module effected the LCD bias circuit. Since the module is shipped with fixed (controlled by ST7920) contrast, we do not anticipate any issues migrating to the new revision.

ERC12864FS-1-S7 is 1.4 inch white background with 128x64 monochrome black pixels cog(chip on glass) lcd module,ST7565S controller,compact size,high contrast,wide operating temperature,wide view angle,white led backlight,fstn lcd,fpc connection,optional zif connector and led backlight connector.It supports 6800 8-bit,8080 8-bit parallel and 4-wire serial spi interface.

If we use 14 pins for GLCD, pins left for other tasks = (17-14) = 3. That is impractical for any application. So effectively, we could as well decide not to use 28-pin device for GLCD.

Another issue is that, if your controller is 3.33V, you will have to read the LCD data sheet and make sure that the VIH and VIL are OK for 3.33V inputs.

I was inspired with the 2 wire -- clock and data scheme using 74HC595 very famous to drive character LCD. Please refer to this link (Bill"s version): -

1. Only 2 wires required ( additional 2 wires for 5V and GND). There are 1 wire version as well for LCD interface, but that is more complex. If we extrapolate the trend, we could also achieve 0-wire scheme (say by using bluetooth), but that is even more complex.

Click on the image to see a zoomed version. The 20-pin header is the one that will fit with connector on LCD module. Pleas refer to the LCD module data sheet (bottom of web page) to know the pin description of LCD module.

NMLCD-M12864A-1is glcd 128x64 st7920 controller serial parallel interface graphic lcd module, built-in Chinese character, stn-lcd, yellow green backlight.

Answer: For the segment type LCD module, if you need to modify the outline size or display content, we will start the drawing paper for your checking.

Newhaven 20x2 character Liquid Crystal Display shows characters with dark pixels on a bright yellow/green background when powered on. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0220D3Z-FL-GBW-V3 display has an optimal view of 6:00. This display operates at 5V supply voltage and is RoHS compliant.

The parallel interface typically controls the LCD via 8 data pins and 3 control lines. The control lines used are Enable (E), Register Select (RS), and Read/Write (R/W). RS tells the LCD module if the information being sent is an Instruction or Data. The Enable tells the LCD module that the data or instruction in the register is ready to be interpreted by the LCD Module. Some controllers may have more than one Enable Control Line. The Read/Write tells the module whether to write data or read data from the register.

Serial LCD controllers typically have one Serial Data Line that writes data and cannot read. Normally, a Register Select Line(Sometimes designated A0) is used to tell the controller whether the incoming data is display information or a controller command

SPI, or Serial Peripheral Interface bus, is a synchronous (data is synchronized to the clock) serial data link standard that operates in full duplex mode, which means that devices that can communicate with one another simultaneously. To do this, two data lines are required. With this standard, devices communicate in a master/slave mode, where the master device (host processor) initiates the data and the clock. The LCD module is the (or one of the) peripheral slave device(s) attached to the data bus. Multiple peripherals (display modules and other devices) are addressed on the same serial data bus. However, the LCD module will only listen to the data it sees when the Chip Select line is active (usually low). If the Chip Select line is inactive (usually High), the LCD module listens to the data on the bus, but ignores it. The SDO line is not active when this state occurs. The SPI bus is comprised of four logic signals, two control lines and two data lines and is commonly referred to as SPI (4 wire).

Occasionally, SDI (serial data in) may be called out as MOSI (Master Out Slave In) from Motorola"s original name for these lines and MISO (Master In Slave Out) for SDO. The chip select line may be alternatively labeled SS (Slave-Select), or STE (Slave Transmit Enable). SPI is sometimes referred to as National Semiconductor"s trademark Microwire, which is essentially a predecessor of SPI, which only supports half duplex.

With CS (Chip-Select) the corresponding peripheral device is selected by the LCD Controller. This pin is mostly active-low. In the unselected state the SDO lines are hi-impedance and therefore inactive. The clock line SCL is brought to the device whether it is selected or not. The clock serves as synchronization of the data communication.

The chip select signal CS is optional for a single device system, because you could tie the CS input at the LCD Module low, if the other lines are dedicated to SPI use. This is sometimes called a 3 Wire SPI Interface.

SPI Data transmissions usually involve two shift registers. Most display module applications normally use 8-bit words. However, different size words, such as 12 bit, are also used. By convention, the most significant bit is shifted out of one shift register while the least significant bit is shifted in. The word is then written into memory if the CS (chip-select) is low (active). If not, the data is ignored.

Since the SPI interface protocol is a de facto standard, many variations of the standard protocol are used. For instance, chip manufacturers may use some of the parallel data lines when configuring the IC driver chip for serial communication. chip manufacturers may use some of the parallel data lines when configuring the IC driver chip for serial communication.

I2C uses only two bi-directional lines, Serial Data Line (SDA) and Serial Clock (SCL), which are both typically pulled up with resistors. Typical voltages used are +5 V or +3.3 V. One of the strengths of the I2C interface is that a micro can control multiple devices with just the two I/O pins and software. Because of the I2C design, it is only half-duplex. The interface generally transmits 8-bit words, sending the most significant bit first.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey