lcd panel connector repair manufacturer

2. #Confirm whether there is 12V input, if not, confirm whether the connector is OK, and confirm the resistance value of 12V voltage to earth; If conn. NG, change conn.; If 12V is short-circuited to the ground, disconnect FP1 to determine the short-circuiting circuit.

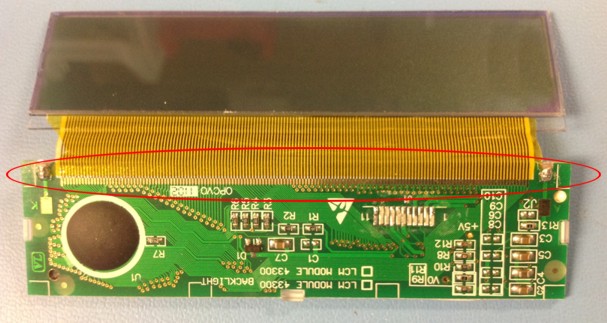

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

3. #Disassemble the backlight, confirm whether there is a short circuit with broken skin on the lamp strip, whether the plug of the lamp strip is fully integrated with the socket, whether the pin is aslant/off, whether the connector is off, and whether the LED bead is black and injured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Heat, vibration and 20+ years of aging causes significant wear on the factory LCD connector. Spring terminals weaken, wires break and oxidation pits the surface of the terminals. Eventually the contacts become open and LCD operation becomes intermittent, or the LCD stops working entirely

What exactly is short in the market? Your iPhone’s screen is one solid unit made up of several elements that are fused together with OCA (optically clear adhesive). The exterior glass, the digitizer panel (touch sensor), the polarizer and LCD panel. The LCD panel is the key component that is in short supply. Originally Apple had 3 manufacturers to produce LCD panels (LG, Sharp and Toshiba). Apple’s authorized manufacturers have the exclusive technology to produce LCD panels. Other Chinese manufacturers can copy the glass, digitizer, polarizers, OCA, flex cables, backlights, frames and everything except for the main component of the LCD assembly.

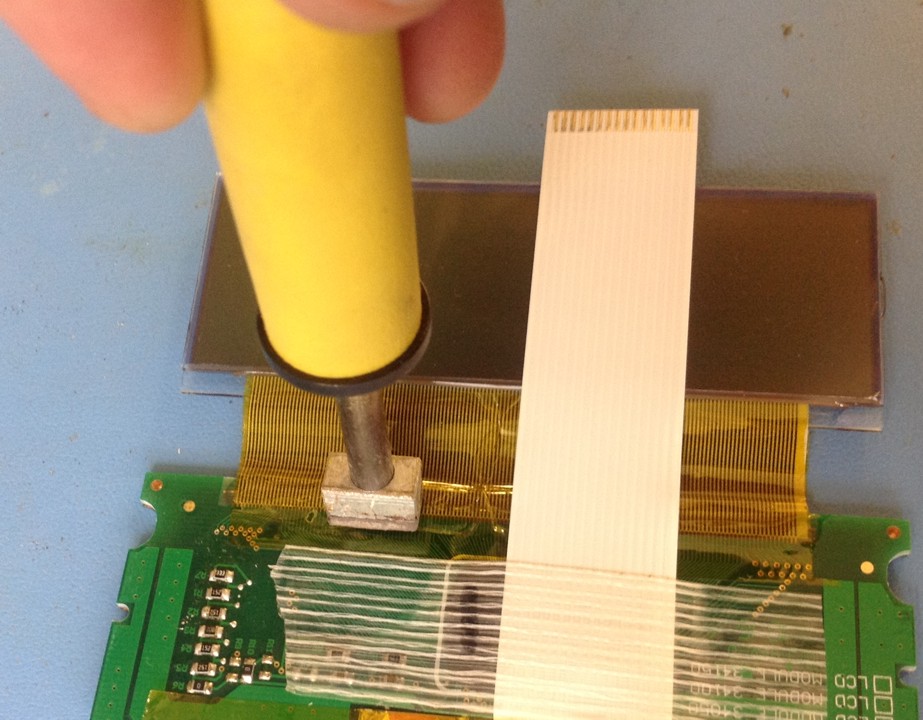

How were we getting these parts before? A big leak in Apple’s supply chain. The iPhone 5, 5S and 5C all share most of the same raw components including the LCD panel, the only difference is the flex cable and plastic frame. Independent factories in China can produce these components and can manufacture any 5 series assembly from an LCD panel. Shown on the left is a pulse pressing machine, used to connect the flex cable to the LCD. We use one of these to repair LCDs with damaged flex cables.

So what’s happening?A few things, first Apple has cut off LG and Toshiba, making Sharp their exclusive supplier for iPhone LCD panels and implemented very tight security. Secondly, they have had Foxconn destroy stockpiles of series 5 LCD panels to reduce the parts and material leakage to factories that re-engineer them for the independent repair industry. Along with this strategy, Apple has instructed Foxconn to reduce series 6 materials leakage from their manufacturing centers. Lastly, Apple is working aggressively with US Customs to seize inbound parts.

How long is this shortage going to last? In short,we have no idea. At the time of this writing, LCD prices have been steadily rising for 6 months and replacement iPhone 6S LCDs cost twice what Apple charges for their repair service. Apple does not intend to compete with independent repair shops, instead they are squeezing the profit out of the industry. LCD refurbishing may help shops cut cost but without new LCD panels entering the system it won’t last long.

What does this mean for the independent repair community?Apple is the only repair operation that is immune. Even the Chinese LCD refurbishing plants used by the large chain repair companies are running out of LCDs. Continually rising costs may push out the big chains but with lower overhead and clever problem-solving, the owner-operated shops stand a fighting chance.

What can we do?Apple has done everything in their power to protect their repair monopoly. When there’s only one repair shop around, prices and wait time goes up and quality goes down. Apple has every incentive to eliminate the parts market. Don’t let them. Check out the Right to Repair Bill.

Try using laptop screen cable repair found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use laptop screen cable repair to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All laptop screen cable repair are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for laptop screen cable repair at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for laptop screen cable repair on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

For example: for Dell U2415 monitor the factory installed display panel is 24.0" LM240WUA-SSA1 manufactured by LG Display, which supports 1920(RGB)×1200 (WUXGA) display and has WLED backlight incorporated (no LED driver is present in the panel). The signal interface is LVDS (2 ch, 8-bit), a single 30-pins connector. There are other matching panels made by LG, Samsung, AUO and possibly others (abundantly available from 3rd party resellers), but the most important is that the mainboard LVDS connector signals mapping do match the LVDS panel specifications - as found in the panel datasheet.

buy a used display panel, or a used monitor with similar size and resolution (checking first the monitor model specifications / resolution / backlight type / panel make, model, datasheet).

The replacement job will require disassembly, and one should carefully observe the steps in the video tutorials other users have created and posted on Internet. Or even better, leave it to a licensed repairer or somebody who has proven practical experience and knows how to avoid risk of electrical shock, ESD damage to the electronic components or the display panel - and can offer warranty for their work. Pay extra care with the cables connecting the mainboard to the display (LVDS, LED backlight and menu button board) as they can be easily damaged when removing the mainboard.

I am an IT guy who discovered repairing electronics by need - when looking to fix the hardware related problems I encountered with monitors, laptops, computers, networking, printing, audio-video and so.

I found that working with resources disposed for recycling is a very efficient way to learn, and solve many problems without big expenses. I agree that the cost of repair at specialized centres could bear a high cost - considering that fixing requires time, experience and somehow be lucrative. But younger generations tend to break technological barriers easier, and with the help of readily available information consumers can solve problems themselves when manufacturers can"t.

Getting your laptop screen repaired is no easy task. Not everyone can do it, and the good ones are expensive. Not only that, you will have to leave your laptop with the person repairing it and work off a different machine for the time being.

However, there are certain things you need to keep in mind. If your laptop is under warranty, it is best to get it repaired by the manufacturer. But if you are looking for an all-in-one tech solution for your laptop, then come to Gophermods.

Now comes the question, why are some laptop screen repairs excessively expensive? Why are some laptop screen repairs $179, and some quoted at $500? Why is there such a massive difference in prices? It’s just a simple laptop screen, right?

Well, not really; it is not just a simple laptop screen. Different laptops have different types of screens, and the cost depends on the parts of the screen. Here we have you a list of reasons that can make the repairs of your laptop screen excessively expensive.

For example, if there were custom parts for every car, then their repairs would have been expensive too. Just like that, not all parts fit every model of the laptop screens, and certain specs differ from one manufacturer to manufacturer. This is what makes screen repair problematic. All other things in the laptop are usually standardized except the screen.

There are two most commonly used screens by the masses – LEDs and LCDs. Some might think they are the same, but that is not at all true. Both LED and LCD are two different quality displays.

There is a saying that all LED screens can be LCD screens. While not all LCD screens can be LED screens, both displays work with liquid crystals to create an image, but the main difference is the backlight. A normal LCD uses a fluorescent backlight, but an LED display uses light-emitting diodes for backlight.

LED screens have better picture quality in comparison with LCD screens. So the parts and products used in LED screens are much more expensive than LCD parts, which can make the repair cost of LED screens a little higher.

Higher costs involved with LED screens may make people shy away from getting them repaired, but it is a must if it affects the functioning of your laptop.

If your laptop has a touchscreen, you should take extra care of it. Touchscreen displays are great for people who are in graphic design or someone looking for tactile functionality. Otherwise, there is very little utility in a touchscreen, and just an excessive cost when it comes to repair.

Because touchscreen displays use better and high technology parts, they tend to be more expensive than the standard displays and cause higher repair expenses. They are easier to use and give you tangible results just with your fingers and have been growing in popularity in recent times. They make your workflow faster and save time. They might come in at a higher cost, but you cannot put a price on the boost that they give to your efficiency.

Today we have multiple types available in the market, and laminated glossy glass display is one of them. Since it has more layers, it provides more safety and better quality screen resolution. It’s made of three different types of layers: Display panel

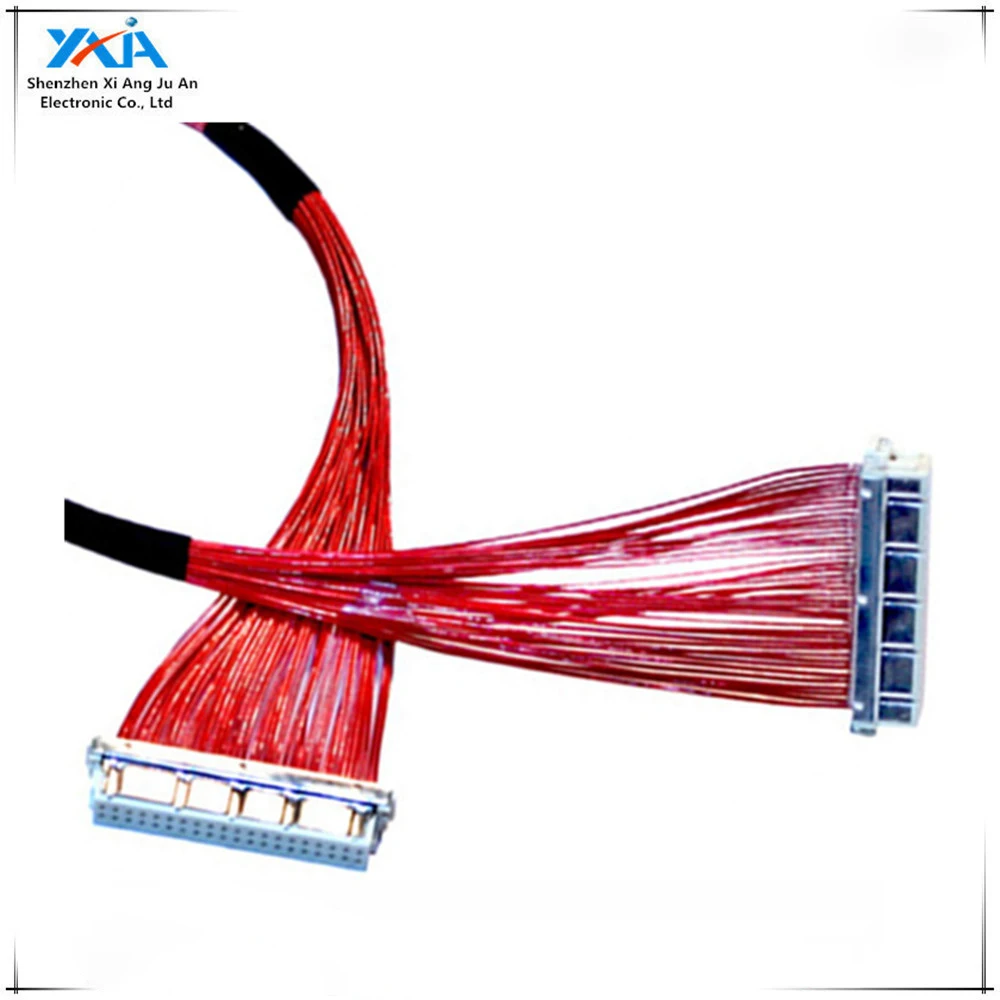

Price increase of small components, like flex cables, connectors, digitizers, bezels, etc., can also add to the high repair cost of the laptop screens. So, if there is an increase in the cost of small, important parts, it will only end up raising the repair costs.

In the world of laptop displays, “spot repairs” do not exist. This is the main reason why laptop screen repairs are so expensive. In most cases, the whole screen is replaced, and a new unit is put in place.

Since 4k, ultra HD (UHD) or high refresh rate displays are of much better quality and made with high technology parts, it only adds to the repair cost.

Increased rate of manual labor, meaning if there is an increase in hourly wage, then it’s safe to say the repair cost will also be high. It will depend on how many hours have been spent on the repair.

If your laptop screen is not working, come to us at Gophermods, and we will be more than happy to work on it. Our experts have years of experience in working on laptop screens and will repair yours too in no time.

In Union Repair store, we grade our iPhone screen into 5 different types of quality on the basis of different material assembled. The following is the full details of each condition.

It is with widely accept major complaint replacements for original parts, which keeps a right balance between price and quality. It has sustainable supplying chain in China, and all the components of the screen are copy quality. Typically, the LCD screen is from several different factories, the most popular 4 on China market are JK,AUO, LongTeng, and ShenChao. By comparing the brightness and sharpness of the LCD, we found JK is the best quality among them and the second best is AUO. No doubt, the other components on the screen are all copy.

It is better than After Market Basic cause it comes with original laminated flexes and the LCD panel. Other components like touch panel, frame(hot pressed), backlight, polarize lens, and OCA is all copy from different factories.

The core components (like LCD and flexes) is 100% original pulled from used iPhone while the frame and touch panel is copy. The touch panel and frame come together with cold pressed glue and assembled together with the LCD by the capable third-party factory which keeps its excellent quality.

It is 100% original from Apple-authorized factories like Toshiba, Sharp, and LG. We get this kind of screen from the first level dealer. The touch panel of the screen is oleophobic coated which prevents from fingerprints when using your iPhone. And starting with iPhone 7g, the backlight from different authorized factories comes with a different code. Backlight from Sharp has the code begins with DKH/CON, from Toshiba begins with C11/F7C/FZQ, from LG begins with DTP/C3F.

HP recommends that you only order parts from an authorized HP repair parts dealer. Parts ordered from third-party companies might not perform as expected and might cause additional

![]()

Every LCD screen eventually fails, usually due to the backlight behind the screens. That is why we have a backlight solution for every LCD screen on the market. Plazmo currently has the single largest global stock of drop-in CCFL and LED backlight assemblies.

Each of our assemblies comes complete with a pre-wired harness, OEM connector plug, silicone end caps and an optional metal rail. Nearly every LCD screen has a unique model design and we have developed the molds and manufacturing specifically to fit more than 200,000 LCD screen models in use today.

Plazmo also has robust manufacturing capabilities and specializes in perfectly replicating OEM backlight assemblies. Using our LED and CCFL backlight assemblies, we pass on savings to our customers while helping keep their LCD screens running smoothly.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey