lcd panel with transistors on the back supplier

Suzhou Unear is a manufacturer which is engaged in the research and development, and manufacture of liquid crystal display (LCD), back light source (LED), liquid crystal display module. There is more than 100 people in the factory, including more than 10 engineering and technical person, 70% of them have experience of working in the field of engineering technology for more than 3 years. It can produce 1.2 million pieces of glass every month. there is nearly 2200 square meters of dust-free workshop. The cleanliness level reaches 1000, some of them can reaches 100. It can fully meet the quality requirements. Products are widely used in the fields of instruments and meters, household appliances, communications equipment, automotive electronics, healthcare, industrial equipment and electronic toys, and other fields. It gains the trust and praise of the broad masses of customers at home and abroad with efficient service and superior quality. Company has been wholeheartedly committed to the research and development and manufacturing of LCD liquid crystal display screen, LED back light. The company has a group of professional and technical person who are specialized in the research and development and manufacturing of LCD liquid crystal display screen, LED back light. Recently we launch the new product such as the FSC, color LCD screen, EBT negative display LCD,PDLC transparent color LCD screen and so on, which has the leading technology in the field of LCD industry.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

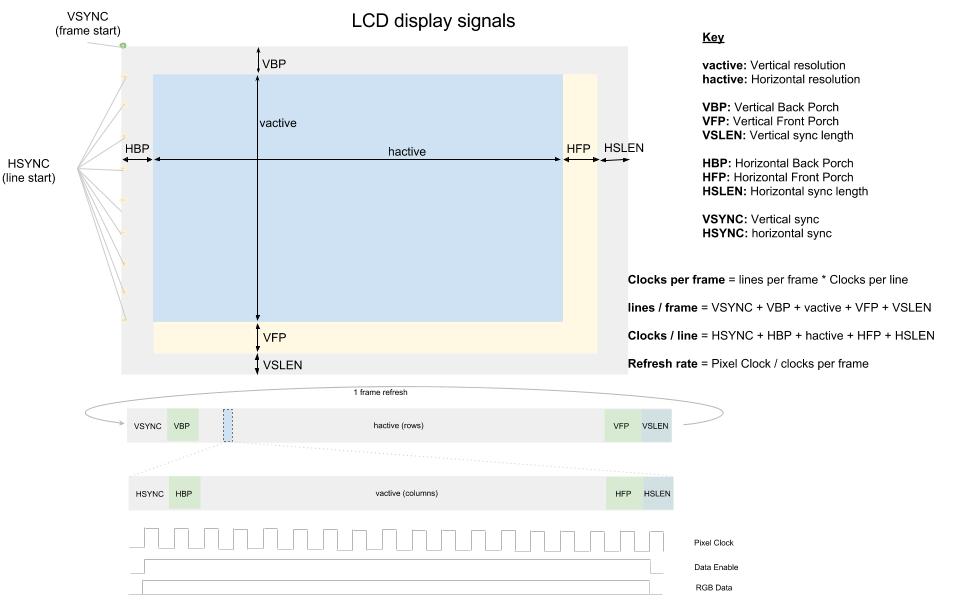

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

1971 – Lechner, F. J. Marlowe, E. O. Nester, and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs

2020 – TFT LCD display technology dominants the display market now. Within the last 20 years, it has wiped out the market of CRT (cathode-ray tube) and Plasma. The only challenges are OLED (organic light-emitting diode)and Micro LED (Maybe, still in lab).

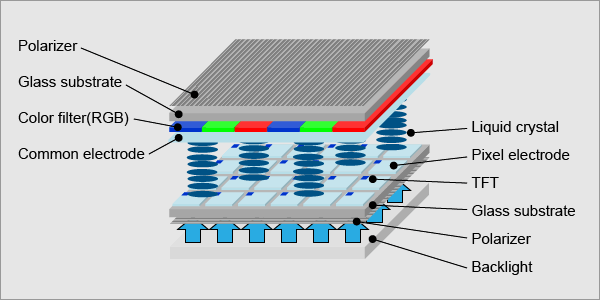

TFT LCD Display (Thin-Film-Transistor Liquid Crystal Display) technology has a sandwich-like structure with liquid crystal material filled between two glass plates. Two polarizer filters, color filters (RGB, red/green/blue) and two alignment layers determine exactly the amount of light is allowed to pass and which colors are created.

Each pixel in an active matrix is paired with a transistor that includes a capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. The TFT layer controls light flow a color filter displays the color and a top layer houses your visible screen.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available.Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available. Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The TFT screen itself can’t emit light like OLED display, it has to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light emitting diodes) to generate their light and therefore utilize less power and require less depth by design.

Thin Film Transistor basics for OEM engineer designers. TFT display modules have been in production for many years and can be seen in products ranging from lap top computers and cell phones to medical equipment. We receive inquires for TFT displays from design engineers for new product designs.

Our technical support staff works with engineers to help narrow down the choices available on TFTs and have narrowed it down to five key options (or thin film transistor basics ) when selecting a color TFT LCD Display.

Color TFT displays have become standardized in the last few years. Although there are a limited number of sizes available, you have other options to consider when locating a source for your color LCD module.

Going back to the thin film transistor basics: Below are five options that a TFT supplier should explore with their customer before recommending a color module for their project.

The first item to decide on is the diagonal size of the TFT display. Color displays are measured in inches along the diagonal. Standard sizes include 1.8”, 2.4”, 3.5”, 7” and on up.

The tooling cost to modify the glass size of the display is very, very expense and can exceed $100K. I recommend choosing a size that is closest to what you need. In other words, you will need to design your project around the size of the display and not the other way around.

The majority of TFT displays now contain a touch panel. TFT touch screen options include resistive, capacitive and a few newer technologies. The two most popular that we offer on our color displays are:

Capacitive touch screen:Capacitive touch screens are more expensive, but allow multiple touches and swiping action. This is very common in cell phones and tablets. The photo below is of a capacitive touch panel installed on a TFT.

Color TFT brightness is a critical component if your product will operate in bright sun light. The more direct the sun light, the more important it is to increase your brightness.

Average nit values for TFT displays range from 200 nits to 1,000 nits. It is possible to modify a TFT display and increase it brightness. This involves a one-time tooling fee. The brighter display will require more power to operate and is a design concern if your product is battery powered.

Monochrome character, graphic and static displays require different input voltages. All the different LCD voltage symbols can be confusing, but believe it or not, there is a system to the madness.

The voltages VCC, VDD, VSS and VEE are used in describing voltages at various common power supply terminals. The differences between these voltages stem from their origins in the transistor circuits they were originally used for.

This LCD voltage terminology originated from the terminals of each type of transistor and their common connections in logic circuits. In other words, VCC is often applied to BJT (Bipolar Junction Transistor) collectors, VEE to BJT emitters, VDD to FET (Field-Effect Transistor) drains and VSS to FET sources. Most CMOS (Complementary metal–oxide–semiconductor) IC data sheets now use VCC and GND to designate the positive and negative supply pins.

In the Pleistocene era (1960’s or earlier), logic was implemented with bipolar transistors. NPN (Negative-Positive-Negative) were used because they were faster. It made sense to call positive supply voltage VCC where the “C” stands for collector. The negative supply was called VEE where “E” stands for emitter.

When FET transistor logic came around a similar naming convention was used, but now positive supply was VDD where “D” stands for drain. The negative supply was called VSS where “S” stands for source. Now that CMOS is the most common logic this makes no sense. The “C” in CMOS is for “complementary” but the naming convention still persists. In practice today VCC/VDD means positive power supply voltage and VEE/VSS is for negative supply or ground.

The convention of VAB means the voltage potential between VA and VB. The convention of using 3 letters was used to show power supply and ground reference voltages as well. In some cases a processor may have both an analog and digital power supply. In this case VCCA/VCCD and VSSA/VSSD are used. Another reason for the 3 letters is in an NPN circuit with a load resister between the collector and VCC. VC would be the collector voltage. In this case VCC is the positive power supply voltage and would be higher than VC.

Note: Most Segment, Character and Graphic displays will operate with a VDD of 5V or 3.3V. It may be possible to drive the display with as little as 3.0V, but the module may not perform very well in colder temperatures. The colder the ambient temperature, the more power is required to drive the segments.

Pin three (3) is Vo and is the difference in voltage between VDD and VSS. This LCD voltage is adjusted to provide the sharpest contrast. The adjustment can be accomplished through a fixed resistor or a variable potentiometer. Many products have firmware that monitor the temperature and automatically adjust the contrast voltage.

In a Liquid Crystal Display (LCD), V0 is used to vary the screen brightness or contrast. Contrast, simply put is the ratio of the light areas to the dark areas in a LCD. This is usually done in a production setting with values which are optimized for most users. Temperature can have an undesirable effect on the display brightness and for this reason a varying resister or potentiometer is used to accommodate the desires of the user.

Below is a data sheet of a 16x2 Character LCD module that shows various recommended driving voltages. The LCD voltage can range from MIN (minimum) to TYP (Typical) to Max (maximum).

If the supplied LCD voltage drops too low, the display is ‘under-driven’ and will produce segments that are ‘grey’. The lower the LCD voltage falls below the acceptable threshold, the lower the contrast will be.

If the LCD is over-driven, you may see ghosting. This is where segments that should not be ‘on’ are gray. They are not as dark as the segments that should be on, but they can be seen and may cause confusion for the end user.

There are times when a customer needs to replace a display that has been discontinued or EOL (End-Of -Life) by their previous LCD supplier. The previous LCD’s pin-outs may be different than Focus’ standard, off-the-shelf display. This is not a large problem to overcome.

Focus Displays will redesign the PCB to match the customer’s old pin out. This will save the customer time and cost so that they will not need to redesign their PCB.

LED backlights are DC (Direct Current) driven and can be supplied from any one of three locations. The most popular is from pins 15 and 16. The second most popular option is to draw power from the ‘A’ and ‘K’ connections on the right side of the PCB.

The third option is to pull power from pins one and two. This is the same location from which the LCD is pulling its power. Focus does not recommend this option and can modify the PCB for the customer to connect the backlight from a different location.

Many LCD Modules will require more than one internal voltage/current. This may make it necessary for the customer to supply the needed inputs. They may need to supply 3V, 5V, 9V, -12V etc.

The solution for this is to integrate a charge pump (or booster circuit) into the LCD circuitry. This solution works in most applications, but if the product will be operating in an intrinsic environment, care must be taken with layout of the circuit board.

Intrinsically-safe LCDs are Liquid Crystal Displays that are designed to operate in conditions where an arc or spark can cause an explosion. In these cases, charge pumps cannot be employed. In fact, the total capacitive value of the display needs to be kept to a minimum.

Focus Display Solutions does not build a display that is labeled ‘Intrinsically safe’ but we do design the LCD to meet the requirements of the engineer. In meeting the design engineer’s requirements, the display may need to contain two or three independent inputs. Focus can redesign the PCB and lay out the traces to allow for these additional inputs.

As we briefly touched on when going over the display technologies, the basic operation of a LCD display is that voltage is applied to the liquid crystal, which either twists or rotates it, allowing polarized light from the backlight through to the different subpixels which provide the red, green, and blue colors. In case you hadn’t noticed yet from all this discussion on color, what most of us are taught in elementary school on what the primary colors are is – while not entirely incorrect – not applicable to displays. Red, green, and blue are the primary colors for emissive (additive) light to give the widest range of color combinations, which is why subpixels are that color. If you were looking at subtractive colors, such as printing on white paper, you"d use cyan, magenta, and yellow.

The basic function of an LCD is to twist an appropriate amount to provide varying levels of light through in order to combine red, green, and blue to make all of the colors you see on your display. To move the liquid crystal, voltage is required, and that voltage is provided through at least one transistor. Since transistors are semiconductors, manufacturers are somewhat limited in what they can use to build the matrix out of, and since you must shine a backlight through it, preferably the transistor will not block all of the backlighting.

Displays leverage a thin-film transistor, or TFT, to provide the matrix of transistors which control all of the subpixels. Traditionally, TFTs were generally made out of amorphous silicon (a-Si) which can be made much thinner than the more traditional crystalline silicon (c-Si) you’d find in an integrated circuit. This allows the backlight to shine through the TFT without being attenuated as drastically as it would be on a c-Si TFT.

While a-Si has served us well for a long, long time, as displays move up in pixel density, the amount of light blocked by the TFT gets to be a higher percentage, since you need more transistors in a given area to control the increased number of pixels. To combat this, manufacturers are developing new TFT materials which provide increased aperture for the backlight.

This is likely to be an ever-expanding list of materials, but materials which provide a higher aperture than a-Si are low-temperature polycrystalline silicon (LTPS) and indium gallium zinc oxide (IGZO). Sharp has been manufacturing IGZO displays for several years now, and LTPS is used in both laptops and smartphones.

Of course, the major reason for the push to these technologies is to improve power efficiency. When you’re powered by a battery, any increases to the efficiency of the display can be dramatic, since the display backlight is often the highest power draw component of a laptop at idle (and laptops like to be idle). As an example, a Surface Book 2 15 with the display set to 100% brightness draws 7.65 W of power at idle. Of that, the display constitutes an amazing 6.22 W, or 81.3% of the power draw. By allowing more light through – via creating a thinner TFT – the net result is a reduction in power required for a backlight, improving its overall efficiency and generally providing a major benefit to a laptop"s battery life.

There’s a lot of confusion here, and a common question you may see is if an IGZO or an IPS display is better, but IGZO is the TFT material, and IPS is the LCD type.

As far as backlighting goes, all modern laptop LCDs require a backlight. Laptops in turn generally rely on white LED backlighting, where the LEDs are located at the edges of the display, and the lighting from those LEDs is shone through a diffuser plate behind the display to provide a uniform backlight. This is most commonly referred to as an edge-lit display.

On larger displays where power draw isn’t as much of a concern, such as televisions, some manufacturers have moved to a full-array backlight, which puts the LEDs directly behind the display. This allows the individual LEDs to be dimmed to provide local dimming, which improves black levels quite dramatically, however it’s unlikely laptops will adopt this due to the extra thickness and power required. On high-end computer monitors, you may find a backlight made up of RGB lighting as well, but for the same reasons, laptops are unlikely to leverage this design.

Backlighting brightness is typically controlled by using pulse-width modulation (PWM). A voltage is applied through a transistor that turns on and off quickly, and depending on how much time is spent in the on versus off position, various average voltage levels are achieved. This is called the duty cycle. A 50% duty cycle will have the voltage on for 50% of the time, and off for 50% of the time, and the average voltage will be half of the maximum.

The downside to PWM is that some people can be susceptible to the flickering that can occur, especially if the PWM frequency is too low. If a manufacturer is trying to save costs, they may utilize a cheaper PWM controller which operates at a frequency that is far too low. This can be more noticeable when the display is dimmed, since the amount of time the backlight is on in the duty cycle is much less. Laptops with a PWM frequency in the low hundreds of Hz can have a noticeable flicker, but quality controllers should operate at frequencies around 10 KHz or so, as to not make it noticeable to the human eye.

A thin-film transistor liquid crystal display, TFT LCD display for short, is a type of LCD display that uses thin-film transistor technology to improve image quality.

TFT LCD displays have many advantages over traditional LCD displays. While traditional LCDs use a single layer of transistors, TFT LCDs use a thin film of transistors. This allows for better image quality, as well as improved response time and lower power consumption. TFT LCDs are also thinner and lighter than traditional LCDs, making them ideal for use in portable devices.

When choosing a TFT LCD, it is important to consider the viewing angle and colour reproduction. While TFT IPS displays offer better image quality, they are also more expensive.

The thin-film transistor array is the layer of transistors that are made of a material such as silicon. The array of transistors is connected to the control circuitry. The control circuitry contains the drivers that control the voltage applied to the transistors.

The colour filter array is the layer of the LCD that contains the colour filters. The colour filters are made of dyes or pigments and are arranged in a specific pattern. The most common patterns are RGB (red, green, blue) and CMYK (cyan, magenta, yellow, black).

When a voltage is applied to the transistor array, the transistors turn on and allow light to pass through. This light is then converted into an image by the colour filter array.

TFT LCDs are used in a wide variety of industries, including consumer electronics, computing, telecommunications, automotive, and medical to name a few. Specifically, they are used in:Computers and laptop computers

The liquid crystal layer is the layer of the LCD that contains the liquid crystals. The liquid crystals are made of materials such as nematic or cholesteric.

The liquid crystals are arranged in a specific pattern. The most common patterns are twist nematic (TN), super twisted nematic (STN), and in-plane switching (IPS). The liquid crystals are aligned with the electric field and are controlled by the voltage applied to the electrodes.

When an electric field is applied, the liquid crystals twist. This twisting allows light of a specific color to pass through. The light is then modulated by the liquid crystal layer.

TFT LCDs use two types of cover glass. Rigid cover glass is made of either soda-lime glass or Gorilla Glass. Flexible cover glass is used in some TFT LCDs, such as those used in mobile phones. The flexible cover glass is more resistant to breakage than rigid cover glass, making it ideal for use in portable devices.

The backlight is the layer of the LCD that emits light. Backlights can be made up of light-emitting diodes (LEDs), an electroluminescent panel (ELP), cold cathode fluorescent lamps (CCFLs), and hot cathode fluorescent lamps (HCFLs), or external electrode fluorescent lamps (EEFLs).

The touchscreen is an optional part of the display module that allows the user to interact with the display. A touchscreen is a layer of glass that is coated with a material that is sensitive to pressure. When the user presses on the touchscreen, the pressure is registered and converted into an electrical signal.

Nauticomp Inc. is a leading provider of industrial LCD displays. Our products are designed for use in a variety of industries, including maritime, aerospace, and military. We offer a wide range of LCDs, including TFT LCDs, OLEDs, and LEDs. Contact us today to learn more about our products and services.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We develop, design, manufacture, and sell displays where it is necessary for the interface that deliver a lot of information at an instant and deliver it to the global market. We create interactive spaces that go beyond the expected, elevate everyday lives, and move people"s hearts. From bases in major cities in Asia, Europe, and North America, we build strong customer relationships by developing products that respond to market needs.

RE:Country of origin; Thin Film Transistor (TFT); Liquid Crystal Display (LCD); TFT/LCD module; PCB; flat panel display computer monitor; marking; outermost container; ultimate purchaser; substantial transformation; Hitachi; Japan; China; HRL 560427; 19 CFR 134.1(a); 134.32(d).

This is in reply to your letter, dated April 8, 2002. In that letter, you requested a ruling on the country of origin marking requirements for TFT- LCD modules assembled in China of Japanese components and imported into the United States to be used to make notebook computer monitors and flat panel desktop computer monitors. Our response follows.

Hitachi will produce finished thin film transistor (TFT)/liquid crystal display (LCD) modules that will be imported into the United States. The two products at issue are: 1) TFT/LCD modules for use with notebook computers; and 2) a Super IPS (In Plane Switching) TFT-LCD module to make flat panel desktop computer monitors.

The Back Light Unit, using a Cold Flourescent Lamp (CFL), which illuminates the screen is assembled in China from Japanese components (sometimes the plastic mold for the back light unit is made in China);

The Back Light Unit is assembled in China. The process includes first adding a reflection sheet to a plastic mold case, the latter sometimes also made in China. Then, the Cold Fluorescent Lamp (CFL) unit, which is made by assembling bushing rubber, the CFL, CFL connector and CFL cable, is affixed to the reflection sheet with a doubled sided adhesive tape. A light guide is also attached to the CFL unit. Then, a diffuser sheet is attached to the top of the light guide. A lens film is then affixed on the diffuser sheet. Another lens film is attached and lastly, a diffuser sheet is placed on top of the lens film.

You state that although the Japanese-origin TFT-LCD Cell is the primary component, the Japanese components are substantially transformed in China when they are assembled into a TFT-LCD module in China. You contend that the components, which include the PCB, Back Light Unit (with CFL), tape, frame, cables, and the TFT-LCD Cell, when assembled result in a different commercial article, that is, a completed TFT-LCD module ready for use to manufacture notebook computer monitors or flat panel desktop computer monitors.

A representative of your company stated by telephone on April 24, 2002, that after importation of the finished TFT-LCD modules into the U.S., your company stores them in a warehouse as part of your company’s inventory. When a customer orders the modules, they are shipped to the customer. Your representative stated that because the imported articles are highly sensitive and fragile, your company does not normally repackage the imported articles. Your company’s customers then incorporate the TFT-LCD modules into a monitor when manufacturing their final computer product. In other words, the modules are not ready to be used as monitors when imported into the U.S. because they lack components such as the frame, power supply, driver, et cetera and must be further processed in the United States.

What are the country of origin marking requirements for finished TFT-LCD modules assembled in China from Japanese components and imported into the United States to be used for manufacturing notebook computer monitors and flat panel desktop computer monitors?

As you are aware, Section 304 of the Tariff Act of 1930, as amended (19 U.S.C. § 1304), provides that unless excepted, every article of foreign origin imported into the United States shall be marked in a conspicuous place as legibly, indelibly, and permanently as the nature of the article (or its container) will permit, in such a manner as to indicate to the ultimate purchaser in the U.S. the English name of the country of origin of the article. 19 CFR part 134 implements the country of origin marking requirements of 19 U.S.C. § 1304.

Section 134.1(d), Customs Regulations (19 CFR § 134.1(d)), provides that the “ultimate purchaser” is generally the last person in the United States who will receive the article in the form in which it was imported. Congressional intent in enacting 19 U.S.C. § 1304 was “that the ultimate purchaser should be able to know by an inspection of the marking on imported goods the country of which the goods is the product. The evident purpose is to mark the goods so that at the time of the purchase the ultimate purchaser may, by knowing where the goods were produced, be able to buy or refuse to buy them, if such marking should influence his will.” United States v. Friedlander & Co., 27 C.C.P.A. 297 at 302; C.A.D. 104 (1940).

Section 134.35(a), Customs Regulations (19 C.F.R. § 134.35(a)), provides that the manufacturer or processor in the U.S. who converts or combines the imported article into a different article having a new name, character or use will be considered the ultimate purchaser of the imported article within the contemplation of 19 U.S.C. § 1304(a), and the article shall be excepted from marking. The outermost containers of the imported articles shall be marked in accord with this part.

Also, 19 C.F.R. § 134.1(d)(1) states that if an imported article will be used in manufacture, the manufacturer may be the “ultimate purchaser” if he subjects the imported article to a process which results in a substantial transformation of the article, even though the process may not result in a new or different article. See also 19 C.F.R. § 134.32(d), which provides for exceptions to marking of imported articles for which the marking of the containers will reasonably indicate the origin of the articles.

An article that consists in whole or in part of materials from more than one country is a product of the last country in which it has been substantially transformed into a new and different article of commerce with a name, character, and use distinct from that of the article or articles from which it was so transformed. See United States v. Gibson-Thomsen, 27 C.C.P.A. 267 (1940); Uniroyal Inc. v. United States, 542 F. Supp. 1026 (Ct. Int’l Trade 1982), aff’d, 702 F.2d 1022 (Fed. Cir. 1983); Koru North America v. U.S., 701 F. Supp. 229 (Ct. Int’l Trade 1988); National Juice Products Ass’n v. United States, 628 F. Supp 978 (Ct. Int’l Trade 1986); Coastal States Marketing Inc. v. United States, 646 F. Supp 255 (Ct. Int’l Trade 1986), aff’d, 818 F.2d 860 (Fed. Cir. 1987); Ferrostaal Metals Corp. v. United States, 664 F. Supp 535 (Ct. Int’l Trade 1987).

In determining whether the combining of parts or materials constitutes a substantial transformation, the issue is the extent of operations performed and whether the parts lose their identity and become an integral part of the new article. Belcrest Linens v. U.S., 6 CIT 204, 573 F. Supp. 1149 (1983), aff’d, 2 Fed. Cir. 105, 741 F.2d 1368 (1984). Assembly operations which are minimal or simple, as opposed to complex or meaningful, will generally not result in a substantial transformation. See C.S.C. 80-111, C.S.D. 85-25, C.S.D. 89-110, C.S.D. 89-118, C.S.D. 90-51, and C.S.D. 90-97. The issue of whether a substantial transformation occurs is determined on a case-by-case basis.

Based on the facts provided, it is our opinion that the assembly of various components used in producing the TFT/LCD module in China, including the Back Light Unit which is made in China from approximately 12 components, effects a substantial transformation of the individual components. The individual components, most of which are made in Japan, lose their identity and become integral part of the new article – TFT/LCD module. The assembly operations are also not minimal or simple. Thus, the TFT/LCD module as imported into the United States qualifies as a product of China and therefore should be marked as such.

Additionally, Customs has addressed the issue of substantial transformation with respect to the production of computer monitors. In Headquarters Ruling Letter (HRL) 560427, dated August 21, 1997; HRL 734966, dated October 18, 1993; HRL 734213, dated February 20, 1992; and HRL 734097, dated November 25, 1991, Customs consistently determined that the assembly of the various components used to produce a computer monitor resulted in a substantial transformation of the component parts.

In HRL 560427, the LCD module was made in Japan and imported into the U.S. The LCD module was then combined with nine other U.S. components to manufacture the final Flat Panel TFT/LCD monitor for personal computers. Customs ruled that the Japanese-origin LCD module was substantially transformed in the U.S. when incorporated into the monitor in the U.S. Similarly, in the instant case, the TFT/LCD module made in China will be incorporated in the United States into flat panel desktop computer monitors and notebook computer monitors manufactured by your customers.

In the instant case, unlike the case in 560247, the importer is not the manufacturer or the processor. However, subject to the terms of 19 C.F.R. § 134.35(a) and 19 C.F.R. § 134.1(d)(1), your company’s customers, who use the imported TFT/LCD modules to produce the flat panel desktop computer monitors and notebook computer monitors in the United States would be considered the ultimate purchasers. Therefore, as in HRL 560247, the imported article in the instant case qualifies for the marking exception provided in 19 C.F.R. § 134.35(a) and 19 C.F.R. § 134.32(d). Consequently, the country of origin marking requirements may be met in the instant case by having the imported articles’ containers (i.e. boxes or other containers that hold the modules) marked with the country of origin, assuming that those containers also reach your customers.

For the foregoing reasons and based on the facts provided, the TFT/LCD modules are products of China and therefore should be so marked. However, because the TFT/LCD modules will be used by your customers to manufacture flat panel desktop computer monitors and notebook computer monitors in the United States, your customers are the ultimate purchasers. Therefore, the marking requirements may be met by marking the containers of the imported articles with their country of origin, assuming that your customers receive the articles in those containers.

A copy of this ruling letter should be attached to the entry documents filed at the time this merchandise is entered. If the documents are filed without a copy, this ruling should be brought to the attention of the Customs officer handling the transaction.

On the back side of the screen you can see one or several labels with numbers. Almost every screen on the market today have manufacturer"s code and screen size included in the model number. You will need the manufacturer part number to find the right replacement screen.

For example a Dell XPS 15 (L502X) has a Dell Part Number of VVR75 or 0VVR75, it has an LCD Part Number: XM5XG and a manufacturer P/N: N156B6 -L0B. The Letter N tells us that the manufacturer is CHI MEI and the 156 that this is a 15.6 inch screen.

Below is a list of LCD screen manufacturers with their abbreviations - if you click on the name (in blue) you will see an example of that manufacturer"s parts label.

LG Display is a large South Korean company and the world"s largest LCD maker, followed by Samsung Electronics. Currently, the two companies together control nearly 50% of the global LCD market. LG Display is headquartered in Seoul, South Korea.

Chi mei Part number start with "N". Some Screens have Revision numbers. Like in this example, the part number is N154I2-L02 followed by revision number indicated by Rev.C1. If you had to search for this particular screen on this site, you should search for "CHI MEI N154I2-L02 Rev. C1".

Toshiba Corporation (manufacturing company, headquartered in Tokyo, Japan Toshiba-made Semiconductors are among the Worldwide Top 20 Semiconductor Sales Leaders. Toshiba is the world"s fifth largest personal computer manufacturer, after Hewlett-Packard and Dell of the U.S., Acer of Taiwan and Lenovo of China and US.

Chungwha Picture Tubes, Ltd. (CPT) is one of Taiwan"s, and the world"s, leading manufacturers of thin-film transistor liquid crystal displays, or TFT-LCDs. Ranked number three in the Taiwan TFT panel market.

Sharp, a Japanese electronics manufacturer, has developed into one of the leading electronics companies in the world. LCD technology continues to be a key part of Sharp"s product range, in both the component and the consumer-applicance sides of the business.

Hyundai Display Technology Inc. (HYDIS) of Ichon, Korea, is an industry leader in the development, sales, marketing and distribution of high-quality LCD, which is a spin-off from HYNIX Semiconductor Inc. Boe Hydis (Formerly Hyundai Displays Korea)

Quanta Display Inc. is a Taiwanese company established in 1999, manufacturing thin film transistor-liquid crystal display panels. It merged with AU Optronics.

AU Optronics is one of the top 3 worldwide manufacturers of thin film transistor liquid crystal display panels (TFT-LCD), and is the largest in Taiwan. AUO provides customers a full range of panel sizes and comprehensive applications, offering TFT-LCD panels in sizes ranging from 1.5 inches to greater than 65 inches.

Let us start with the basics first; refresh the knowledge about TN and LCD displays in general, later we will talk about TFTs (Thin Film Transistors), how they differ from regular monochrome LCD displays. Then we will go on to the ghosting effect, so we will not only discuss the technology behind the construction of the TFT, but also some phenomena, like the ghosting effect, or grayscale inversion, that are important to understand when using an LCD TFT display.

Next, we will look at different technologies of the TFT LCD displays like TN, IPS, VA, and of course about transmissive and transflective LCD displays, because TFT displays also can be transmissive and transflective. In the last part we will talk about backlight.

Let us start with a short review of the most basic liquid crystal cell, which is the TN (twisted nematic) display. On the picture above, we can see that the light can be transmit through the cell or blocked by the liquid crystal cell using voltage. If you want to learn more about monochrome LCD displays and the basics of LCD displays, follow this link.

What is a TFT LCD display and how it is different from a monochrome LCD display? TFT is called an active display. Active, means we have one or more transistors in every cell, in every pixel and in every subpixel. TFT stands for Thin Film Transistor, transistors that are very small and very thin and are built into the pixel, so they are not somewhere outside in a controller, but they are in the pixel itself. For example, in a 55-inch TV set, the TFT display contains millions of transistors in the pixels. We do not see them, because they are very small and hidden, if we zoom in, however, we can see them in every corner of each pixel, like on the picture below.

On the picture above we can see subpixels, that are basic RGB (Red, Green, Blue) colors and a black part, with the transistors and electronic circuits. We just need to know that we have pixels, and subpixels, and each subpixel has transistors. This makes the display active, and thus is called the TFT display. TFT displays are usually color displays, but there are also monochrome TFT displays, that are active, and have transistors, but have no colors. The colors in the TFT LCD display are typically added by color filters on each subpixel. Usually the filters are RGB, but we also have RGBW (Red, Green, Blue, White) LCD displays with added subpixels without the filter (White) to make the display brighter.

What is interesting, the white part of the RGB and RGBW screen will look exactly the same from a distance, because the lights are mixed and generate white light, but when we come closer to the screen, we will not see white light at all.

Going a little bit deeper, into the TFT cell, there is a part inside well known to us from the monochrome LCD display Riverdi University lecture. We have a cell, liquid crystal, polarizers, an ITO (Indium Tin Oxide) layer for the electrodes, and additionally an electronic circuit. Usually, the electronic circuit consists of one transistor and some capacitors to sustain the pixel state when we switch the pixel OFF and ON. In a TFT LCD display the pixels are much more complicated because apart from building the liquid crystal part, we also need to build an electronic part.

That is why TFT LCD display technologies are very expensive to manufacture. If you are familiar with electronics, you know that the transistor is a kind of switch, and it allows us to switch the pixel ON and OFF. Because it is built into the pixel itself, it can be done very quickly and be very well controlled. We can control the exact state of every pixel not only the ON and OFF states, but also all the states in between. We can switch the light of the cells ON and OFF in several steps. Usually for TFT LCD displays it will be 8-bit steps per color, so we have 256 steps of brightness for every color, and every subpixel. Because we have three subpixels, we have a 24-bit color range, that means over 16 million combinations, we can, at least theoretically, show on our TFT LCD display over 16 million distinct colors using RGB pixels.

Now that we know how the TFT LCD display works, we can now learn some practical things one of which is LCD TFT ghosting. We know how the image is created, but what happens when we have the image on the screen for a prolonged time, and how to prevent it. In LCD displays we have something called LCD ghosting. We do not see it very often, but in some displays this phenomenon still exists.

If some elements of the picture i.e., your company logo is in the same place of the screen for a long period of time, for couple of weeks, months or a year, the crystals will memorize the state and later, when we change the image, we may see some ghosting of those elements. It really depends on many conditions like temperature and even the screen image that we display on the screen for longer periods of time. When you build your application, you can use some techniques to avoid it, like very rapid contrast change and of course to avoid the positioning the same image in the same position for a longer time.

You may have seen this phenomenon already as it is common in every display technology, and even companies like Apple put information on their websites, that users may encounter this phenomenon and how to fix it. It is called image ghosting or image persistence, and even Retina displays are not free of it.

Another issue present in TFT displays, especially TN LCD displays, is grayscale inversion. This is a phenomenon that changes the colors of the screen according to the viewing angle, and it is only one-sided. When buying a TFT LCD display, first we need to check what kind of technology it is. If it is an IPS display, like the Riverdi IPS display line, then we do not need to worry about the grayscale inversion because all the viewing angles will be the same and all of them will be very high, like 80, 85, or 89 degrees. But if you buy a more common or older display technology type, like the TN (twisted nematic) display, you need to think where it will be used, because one viewing angle will be out. It may be sometimes confusing, and you need to be careful as most factories define viewing direction of the screen and mistake this with the greyscale inversion side.

On the picture above, you can see further explanation of the grayscale inversion from Wikipedia. It says that some early panels and also nowadays TN displays, have grayscale inversion not necessary up-down, but it can be any angle, you need to check in the datasheet. The reason technologies like IPS (In-Plane Switching), used in the latest Riverdi displays, or VA, were developed, was to avoid this phenomenon. Also, we do not want to brag, but the Wikipedia definition references our website.

We know already that TN (twisted nematic) displays, suffer from grayscale inversion, which means the display has one viewing side, where the image color suddenly changes. It is tricky, and you need to be careful. On the picture above there is a part of the LCD TFT specification of a TN (twisted nematic) display, that has grayscale inversion, and if we go to this table, we can see the viewing angles. They are defined at 70, 70, 60 and 70 degrees, that is the maximum viewing angle, at which the user can see the image. Normally we may think that 70 degrees is better, so we will choose left and right side to be 70 degrees, and then up and down, and if we do not know the grayscale inversion phenomena, we may put our user on the bottom side which is also 70 degrees. The viewing direction will be then like a 6 o’clock direction, so we call it a 6 o’clock display. But you need to be careful! Looking at the specification, we can see that this display was defined as a 12 o’clock display, so it is best for it to be seen from a 12 o’clock direction. But we can find that the 12 o’clock has a lower viewing angle – 60 degrees. What does it mean? It means that on this side there will be no grayscale inversion. If we go to 40, 50, 60 degrees and even a little bit more, probably we will still see the image properly. Maybe with lower contrast, but the colors will not change. If we go from the bottom, from a 6 o’clock direction where we have the grayscale inversion, after 70 degrees or lower we will see a sudden color change, and of course this is something we want to avoid.

To summarize, when you buy older technology like TN and displays, which are still very popular, and Riverdi is selling them as well, you need to be careful where you put your display. If it is a handheld device, you will see the display from the bottom, but if you put it on a wall, you will see the display from the top, so you need to define it during the design phase, because later it is usually impossible or expensive to change the direction.

We will talk now about the other TFT technologies, that allow us to have wider viewing angles and more vivid colors. The most basic technology for monochrome and TFT LCD displays is twisted nematic (TN). As we already know, this kind of displays have a problem with grayscale inversion. On one side we have a higher retardation and will not get a clear image. That is why we have other technologies like VA (Vertical Alignment), where the liquid crystal is differently organized, and another variation of the TFT technology – IPS which is In-Plane Switching. The VA and IPS LCD displays do not have a problem with the viewing angles, you can see a clear image from all sides.

Nowadays all TV sets, tablets and of course mobile phones are IPS or VA. You can turn them around and see the image clear from all sides. But, for monitor applications the TN technology is still widely used, because the monitor usually is in front of you and most of the time you look directly at it, from top, left or right side, but very rarely from the bottom, so the grayscale inversion viewing angle can be placed there. This technology still is very practical because it is affordable and has some advantages for gamers because it is very fast.

Apart from the different organization of the liquid crystals, we also organize subpixels a little bit differently in a VA and IPS LCD displays. When we look closer at the TN display, we will just see the subpixels with color filters. If we look at the VA or IPS display they will have subpixels of subpixels. The subpixels are divided into smaller parts. In this way we can achieve even wider viewing angles and better colors for the user, but of course, it is more complicated and more expensive to do.

The picture above presents the TN display and grayscale inversion. For IPS or VA technology there is no such effect. The picture will be the same from all the sides we look so these technologies are popular where we need wide viewing angles, and TN is popular where we don’t need that, like in monitors. Other advantages of IPS LCD displays are they give accurate colors, and wide viewing angles. What is also important in practice, in our projects, is that the IPS LCD displays are less susceptible to mechanical force. When we apply mechanical force to the screen, and have an optically bonded touch screen, we push the display as well as squeeze the cells. When we have a TN display, every push on the cell changes the image suddenly, with the IPS LCD displays with in-plane switching, different liquid crystals organization, this effect is lesser. It is not completely removed but it is much less distinct. That is another reason IPS displays are very popular for smartphones, tablets, when we have the touchscreens usually optically bonded.

If we wanted to talk about disadvantages, there is a question mark over it, as some of them may be true, some of them do not rely on real cases, what kind of display, what kind of technology is it. Sometimes the IPS displays can have higher power consumption than others, in many cases however, not. They can be more expensive, but not necessarily. The new IPS panels can cost like TN panels, but IPS panels definitely have a longer response time. Again, it is not a rule, you can make IPS panels that are very fast, faster than TN panels, but if you want the fastest possible display, probably the TN panel will be the fastest. That is why the TN technology is still popular on the gaming market. Of course, you can find a lot of discussions on the internet, which technology is better, but it really depends on what you want to achieve.

Now, let us look at the backlight types. As we see here, on the picture above, we have four distinct types of backlight possible. The most common, 95 or 99 per cent of the TFT LCD displays on the market are the transmissive LCD display type, where we need the backlight from the back. If you remember from our Monochrome LCD Displays lecture, for transmissive LCD displays you need the backlight to be always on. If you switch the backlight off, you will not see anything. The same as for monochrome LCD displays, but less popular for TFT displays, we have the transflective LCD display type. They are not popular because usually for transflective TFT displays, the colors lack in brightness, and the displays are not very practical to use. You can see the screen, but the application is limited. Some transflective LCD displays are used by military, in applications where power consumption is paramount; where you can switch the backlight off and you agree to have lower image quality but still see the image. Power consumption and saving energy is most important in some kind of applications and you can use transflective LCD displays there. The reflective type of LCD disp

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey