arduino lcd panel mount free sample

I"m looking for an enclosure for a project that will include one of the 2x8 character LCDs from seeedstudio and should have an IR panel and battery enclosure.

but accoring to the datasheet, the internal dimension is 60mm wide and according to seeedstudio, the LCD is 58mm wide. I"m worried I"ll have trouble fitting the LCD because it"s cutting too close, or in the best case the aesthetics will suffer because the display will be too far off center (it doesn"t look centered on its own PCB).

I"m working with a similar sized LCD but it"s going behind a panel rather than in a box. I am lucky that I can make my own cutout and fit the LCD into it. I"m not real sure how I"m going to protect the LCD though - it will be exposed to the elements.

oh, by the way, I have one of the Seeed modules in my hand and I would say the LCD face is pretty well centered on the board. It"s not EXACT but no more than a couple of mm further from the backlight end of the board than the connector end.

I have the seeedstudio LCD too. It was my original request that he stock them ;). I"m thinking a few mm off will look pretty crappy in the box though.

What trouble are you having getting it to work? It"s working for me, but I had to modify the time delays in the arduino liquidcystal library (the problem was with the library, not the display). I had a horribly frustrating time where it would work once in a while, but 95% of the time would never initialize.

What trouble are you having getting it to work? It"s working for me, but I had to modify the time delays in the arduino liquidcystal library (the problem was with the library, not the display). I had a horribly frustrating time where it would work once in a while, but 95% of the time would never initialize.

I would get either blank or sometimes the black character boxes showing (I now know) that it was getting power. This was the first LCD module I bought and I had not yet learned about the liquidcrystal library so i was working just from the datasheet. The problem could have been my wiring or my code. I have it out now and I"ll try it again. What timing did you have to change?

In terms of centering, I just don"t believe I could detect the offset, maybe mine is not quite the same. How are you going to make the cutout for the LCD and attach it?

I decided to try mounting my prototype yesterday and found it doesn"t work anymore. There"s probably a short somewhere or a wire fell off. It semi-worked once of the 30-40 times I tested it. This hobby is frustrating at times. It was built on perf board with isolated holes, so it"s a big mess of spaghetti wiring so it"s probably easier to start again with a PCB now that I had the hardware working.

it looks better now since ive taped the sides but it was impossible to cut a perfect rectangle witha dremel, nor a box cutter, so i had to sand and sand, and, ofcourse, i over sanded and ended up with huge, awkward gaps between the sides of the lcd screen and the box...

it looks better now since ive taped the sides but it was impossible to cut a perfect rectangle witha dremel, nor a box cutter, so i had to sand and sand, and, ofcourse, i over sanded and ended up with huge, awkward gaps between the sides of the lcd screen and the box...

exactly what I"ve been worrying about. I foolishly expected there would be readily available plastic/chrome bezels that would fit neatly around stock-sized LCDs, no luck yet though.

I got a couple of sample boxes like the one below from pactec. They have a wide variety on their web site. In this case the end is separate but probably too small for the LCD and the sides of the cases just leave you with the same issue of cutting your own hole and finishing it.

If waterproofing/dustproofing is not important, you can just sandwich your project (PCB, LCD etc) between 2 sheets of acrylic, with long screws and spacers.

That one looks good except for the lack of an IR panel. The data sheet for it though has no information on the size of the opening or the PCB dimensions. Also, my local supplier and digikey doesn"t stock it. Mouser seems to with a minimum order of 289 units. It also seems to be double the price of the hammond unit, though that"s not a problem (assuming it has all the hardware in the datasheet listed under different part numbers).

I"m still surprised that there aren"t more readily available LCD mounting options. In my case I need something really weatherproof because I"m mounting on an exposed motorcycle surface but I haven"t see anything that would help finish off a project.

I think it is amazing that there isn"t already on the market a simpe palstic box with rectangular holes the size of the screens on LCD"s, which are all pretty standard.

Mike, I don"t think there is a single standard. I have three 16x2 LCD panels and all require different size cutouts. My 16x1 and 16x4 panels are different sizes again.

bill: There are some nice looking options there, though the ones with IR panels are a bit thinner which makes it harder to fit components. The main issue I seem to have is finding a source, I"m shocked that digi-key doesn"t seem to carry them. I have almost no local sources for electronics parts, but Hammond boxes seem to be one of the few things I can get locally.

I"ve seen the same need to provide enclosures for Arduino, and other DIY projects, and have started working on a couple of things. They are a few months off, so don"t really solve any problems now, but I"m trying to get a couple of manufacturers to work with me on a more modular enclosure design that would work better for the type of projects that Arduino, and other hobby projects seem to need.

Mounting frame for rear panel mounting of 2004 (20x4) LCD displays. Display mounts to frame with two 4-40 x 1/4" screws. Holes need to be tapped before mounting. Remaining two mounts have locating posts. All posts reinforced with fillets for strength. Frame members connect with filleted curves. Panel mounting is 4x #6 thru holes. Allows mounting with I2C daughter card.

Тhis time I will present you a simple way to control 16x2 LCD Display via Windows PC software. For this purpose, we use an Arduino microcontroller, which in this case has the function of an interface between the Display and the USB port of the Computer. Also the LCD display can be controlled directly through the LPT port, but nowadays that port is no longer used and has been replaced by USB.

- Arduino microcontroller, and LCD display which are connected according to the given schematic diagram, and it is powered directly from the USB port.

I mounted the device in a box from a previous project, and is a stand-alone device that can be placed on top of the computer case or somewhere else. Оtherwise the original idea was to mount the LCD screen to the plastic of 5.25-Inch drive bay and be an integral part of the PC.

First, we unpack the.zip archive into a specific folder. Then the LCDT.dll matrix orbital driver should be placed in the "displays" folder. This is actually a driver for the 16x2 LCD display. You can download these archives at the link below. Next, we start the program and select the LCD display plugin, then we set the startup parameters according to the port occupied by the Arduino microcontroller. Now the simplest option is to enter some text in these fields which actually represent the two rows of the LCD display. If we have connected everything exactly according to the instructions, when we press the apply button, the written text should appear on the LCD display. Lcd Smartier has built in support for many systems statistics (i.e. cpu load, network utilization, free disk space, Winamp integration, BBC World News, Email details, game stats, and many more. It is also possible to integrate several different plugins that can be downloaded from the official site and forums. As for the Arduino, the given code should be uploaded, but I should mention that the code is compiled with the LiquidCrystal-1.0.0 Library which you can also download from the link below. LCD Smartie also has support for the popular Winamp player software.

The uLCD-144G2 display module is compact and cost effective and features a 1.44” LCD TFT screen, which is the smallest LCD TFT module available from 4D Systems. Driven by the GOLDELOX processor, the uLCD-144G2 is the perfect compact display solution for any application requiring a small embedded screen.

The module is an elegant combination of a 1.44” TFT LCD screen, along with a modest but comprehensive collection of I/O Features. These include a micro-SD card connector, two general purpose input/output pins (GPIO"s) with Dallas 1-Wire Support, Analog Input and sound generation capability, along with serial communications.

This module works with at least the LiquidCrystal I2C and LiquidCrystal_PCF8574 libraries available in the Arduino library manager. Address 0x3F worked for me since the A0, A1, and A2 jumpers are not shorted.

Google for LCM1602 and you will find many pages that mention the board - including the pinouts stated above and sample programs using the Arduino library.

I liked the idea of the 4-wire interface, but I was disappointed that no documentation was available for this part. However after a night of hacking I got it to work with my Arduino Uno. I thought Id pass along the following information to spare others the trouble.

On the software side, you have to download and install a new LiquidCrystal_I2C library for Arduino, which has the capability to talk to the LCD display over the I2C bus. Heres a link to the library. Follow the example code for the DFRobot board, which turns out to have the same configuration as this LCD, and it should fire right up for you. The LCD has white characters on a backlit blue background, and looked great.

An Arduino Uno shield-style display module which comprises a graphic LCD mounted on a carrier board. This module is specifically designed to simply presses onto a controller with the Arduino Uno form factor, making it easy to begin designing with this display.

So you want to set up your LCD module with your Arduino – but jeeze! What to do with all those pins? Which ones go where? Are there anything things to look out for when buying or setting up a new LCD Module?

Notice some verbiage as we talk about LCDs, you will keep seeing the two words “LCD Module”. This is because, when you buy LCD screens – you are more than likely going to buy it as a “plug-and-play” module.

The LCD screen itself is a subcomponent of the module, which includes other components and circuitry that make interfacing with the LCD screen far more accessible.

Let’s cut to the chase – the MOST important thing you need to ensure when you are buying your LCD is that is compatible with Hitachi HD44780 driver. Let me say that bigger:

But don’t worry. This driver is so common it is pretty much the standard. If you can’t find any documentation to support whether or not the LCD you want to buy will work, then check the pin out. Does it have 16 pins? If the answer is yes, you should feel pretty comfortable that it is compatible.

So why do we need an LCD that is compatible with the Hitachi HD44780 driver? It’s because the LiquidCrystal Library that we will be using to control the LCD from the Arduino uses the driver as its standard. The functions in the library won’t necessarily work on other types of LCD screens.

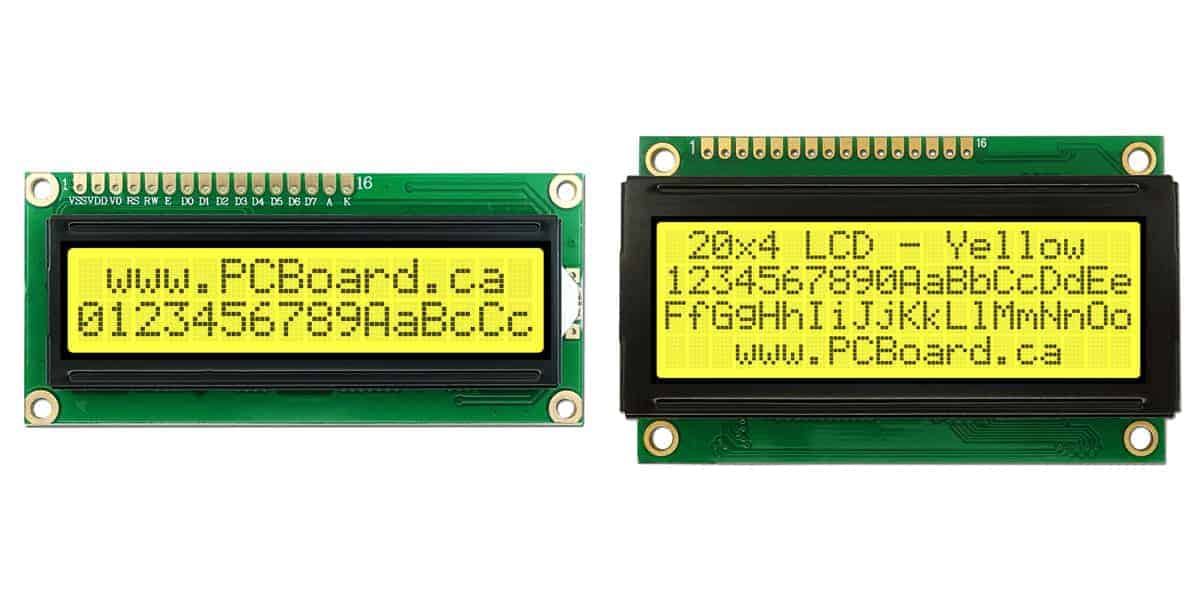

LCDs can also come in different colors – so you don’t have to go for the standard martian green. Plus, they can have backlights to help make the characters to stand out better in different light settings.

The LCD you buy will have 16 pads where you will hook up wires or headers to connect to your Arduino, but many manufactures have made modules that also have a second set of 16 pins that are simply duplicates of the first.

The one I use in this video tutorial series has a set of 16 pads at the top of the LCD and 16 pads at the bottom. What this provides for is more flexibility in where you can connect your wires to control the LCD.

For example, if you plan on mounting your LCD panel in some type of enclosure, maybe the bottom pins would be more accessible. You can also use some pads on the top and some on the bottom – since they connect to the same thing on the LCD module the top and bottom pins are interchangeable.

You may also consider soldering on pin headers to the module. These make connecting your LCD to a breadboard for prototyping about a million times easier. You may not be able to find a 16 pin header, but they are made to be clipped to your desired length.

The final thing I would mention is to check the pin numbering on the PCB. The LCD module I bought only had the numbers 1 and 16 on the far sides of each of the pads. This made it a little confusing when trying to figure out which wire to hook where.

Luckily for us the Arduino website has a great pin layout for us to follow – but I wanted to make one that was step by step – so follow the pictures below and you should be golden.

This is a very popular LCD Keypad shield for Arduino and other variants. It includes a 2x16 LCD display and 6 momentary push buttons. Pins 4, 5, 6, 7, 8, 9 and 10 are used to interface with the LCD. Just one Analog Pin 0 is used to read the five pushbuttons. The LCD shield supports contrast adjustment and back-lit on/off functions. It also exposes five analog pins with DFRobot color code for easy analog sensor plugging and display. The on board LED indicates power on.

This lcd arduino shield has 5 keys — select, up, right, down and left which allow you move through menus and make selections straight from one board attached to yourArduino project without requiring a massive tower of shields.

The used LCD pins are not exposed on top side of the board leaving only the unused ones. This way, conflict with LCD pins on top of the board will not happen anymore. This design includes a APC / Bluetooth v3 socket to enable you data transmission with your robot.

Do you want to detect when a person passes by? Whether it is outside your apartment or your room or even in the next cubicle, you can now wirelessly detect if someone passes by which will sound a voice message and display a message on an LCD screen. This will use the Arduino microcontroller and XBee radio. After all, Arduino and XBee are best friends in the electrical engineering world! Why else would an XBee shield exist?

This project uses the Arduino software, known as the IDE, in order to program the Arduino Uno microcontroller. You can download it for free from the Arduino website software section at http://www.arduino.cc/en/Main/Software. There are many versions, so be sure to download the correct one. A basic guide to how to use it can be found at http://arduino.cc/en/Guide/HomePage.

Attach the potentiometer to the breadboard next to the LCD screen. There are three pins: two terminals (the ends) and a wiper pin (the middle). Connect one terminal of the potentiometer to power and the other to ground (it doesn’t matter which). Connect the wiper (the center pin) to the LCD pin 3.

*when uploading the program to the Arduino board, make sure you switch the TX (connected to pin 1 on Arduino) on the XBee off. This can be done on the XBee shield.*

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

It has 16 pins and the first one from left to right is the Groundpin. The second pin is the VCCwhich we connect the 5 volts pin on the Arduino Board. Next is the Vo pin on which we can attach a potentiometer for controlling the contrast of the display.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

I hope you enjoyed this tutorial and learned something new. Feel free to ask any question in the comments section below and don’t forget to check out my full collection of 30+ Arduino Projects.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey