space engineers change flight seat lcd panel names in stock

The old (legacy) method to calculate the average bar sizes and values should only be used on identical blocks. When averaging blocks with different maximum values the AltCalc keyword should be used. This will change the method of calculation to:

(Like when you had blocks with the names "Thruster #1" and "Thruster #2" and wanted to address them with "Thruster #") In such a case use the IconCount option.

FSD can clone the text content of other displays. These texts can be fixed or could be generated by other scripts (like Automatic LCDs 2 by MMaster or Isy"s Inventory Manager)

LCD Panel, clone:0 position(100,50) fontsize=0.5 TextColor(255,128,0)This would clone the text contend of the first screen of the block "LCD Panel" to the position (x=100 y=50) in an orange color with a font size of 0.5.

This way you can ether reduce the number of LCD Panels needed or greatly enhance the amount of information you can display with a given set of screens/panels.

Caution: There has to be no space between "layoutrate" and the equals sign "="This will set the rate of changes for the screen layouts. (in changes per minute)

You can overide individual LCD/Cockpit screen settings by using a special keyword line starting with "FSD options:" in the Custom Data field of the Programmable block itself.

All keywords for this override options must be in a single line and this line must be located above an optional "ShowStats" line or else the used keywords affect only the LCD panels of the Programmable block.

The same is true for the rate of display layout changesYou can turn the rate up or down. But it due to visual reasons it should remain a fraction of the FpM.

The SeparatorsThese characters are used to separate the "names" part from the "option keyword" part in the Data_sets. Change these at your own risk!!!

The various LCD Panel blocks are a great way to add a human touch to a ship or base by displaying useful images or text. For LCD configuration and usage, see LCD Surface Options.

Note: Some functional blocks, such as Cockpits, Programmable Blocks, Custom Turret Controllers, and Button Panels, have customizable LCD surfaces built in that work the same way as LCD Panel blocks, which are also discussed in detail under LCD Surface Options.

LCD Panels need to be built on a powered grid to work. Without power, they display an "Offline" text. While powered without having a text, image, or script set up, they display "Online".

LCD Panel blocks come in a variety of sizes from tiny to huge (see list below) and are available for large and small grid sizes. Note that LCD Panel blocks all have connections on their backs, and very few also on a second side.

All LCD Panels and LCD surfaces work with the same principle: They are capable of displaying dynamic scripts, or few inbuilt static images accompanied by editable text. Access the ship"s Control Panel Screen to configure LCD Panels or LCD surfaces; or face the LCD Panel block and press "K".

A Text Panel, despite its name, can also display images. On large grid, it is rectangular and does not fully cover the side of a 1x1x1 block. On small grid it is 1x1x1, the smallest possible LCD block in game.

On large grid, you choose the Text Panel when you need something that has rectangular dimensions that make it look like a wall-mounted TV or computer screen. If you want to display images, this one works best with the built-in posters whose names end in "H" or "V" (for horizontal or vertical rotation). On Small grid, you place these tiny display surfaces so you can see them well while seated in a cockpit or control seat, to create a custom display array of flight and status information around you.

Corner LCDs are much smaller display panels that typically hold a few lines of text. They don"t cover the block you place them on and are best suited as signage for doors, passages, or containers. They are less suitable for displaying images, even though it"s possible. If you enable the "Keep aspect ratio" option, the image will take up less than a third of the available space.

These huge Sci-Fi LCD Panels come in sizes of 5x5, 5x3, and 3x3 blocks, and can be built on large grids only. These panels are only available to build if you purchase the "Sparks of the Future" pack DLC.

They work the same as all other LCD Panels, the only difference is that they are very large. In the scenario that comes with the free "Sparks of the Future" update, they are used prominently as advertisement boards on an asteroid station.

This LCD panel can be built on large and small grids. The transparent LCD is basically a 1x1x1 framed window that displays images and text. It is part of the paid "Decorative Blocks Pack #2" DLC.

What is special about them is that if you set the background color to black, this panel becomes a transparent window with a built-in display. In contrast to other LCD Panels it has no solid backside, which makes it ideal to construct transparent cockpit HUDs, or simply as cosmetic decoration.

While configuring an LCD Panel, the GUI covers up the display in-world and you can"t see how the text or images comes out. In the UI Options, you can lower the UI Background opacity to be translucent, so you can watch what you are doing more easily.

Yes, that would indeed be a very good idea. He could also have the cameras on the cockpit screens. There is also a bug that causes the cockpit lcd screens not to turn off if there is no power. Otherwise it is true that the cockpit screens are really not very used.

Yes, that would indeed be a very good idea. He could also have the cameras on the cockpit screens. There is also a bug that causes the cockpit lcd screens not to turn off if there is no power. Otherwise it is true that the cockpit screens are really not very used.

The controls from the LCD"s terminal window can be mostly directly copied, with one addition: a drop down menu to pick which LCD you want to edit! Bottom-left, Bottom-center, etc, since those should be fully customizable in number and names (linked to a material present in the cockpit model)

The controls from the LCD"s terminal window can be mostly directly copied, with one addition: a drop down menu to pick which LCD you want to edit! Bottom-left, Bottom-center, etc, since those should be fully customizable in number and names (linked to a material present in the cockpit model)

How about having some sort of G menu for the lcds, where you would for example drag down Large Cargo Container 3 and select "Display Volume/Damage/Power"? Feels like it would be simpler and faster to assign stuff to your lcds this way. This way might be more intuitive for new players, rather than having them be standard LCD"s requiring enabled programming. On the other hand, it would be good to also have that feature, so you can assign scripts to the LCD if you want.

How about having some sort of G menu for the lcds, where you would for example drag down Large Cargo Container 3 and select "Display Volume/Damage/Power"? Feels like it would be simpler and faster to assign stuff to your lcds this way. This way might be more intuitive for new players, rather than having them be standard LCD"s requiring enabled programming. On the other hand, it would be good to also have that feature, so you can assign scripts to the LCD if you want.

For me, there is no more important thing than LCDs in cockpits. I have 2273 hours in SE and if you reject this project I will uninstall the game. The game does not make sense with dead displays in cockpits. There is a super mod, which the cockpit becomes functional: https://steamcommunity.com/sharedfiles/filedetails/?id=1430180943. Why not add it to the basic version of the game?

For me, there is no more important thing than LCDs in cockpits. I have 2273 hours in SE and if you reject this project I will uninstall the game. The game does not make sense with dead displays in cockpits. There is a super mod, which the cockpit becomes functional: https://steamcommunity.com/sharedfiles/filedetails/?id=1430180943. Why not add it to the basic version of the game?

Btw, can we write text on LCDs using different colors? For e.g. I would like to display msg if I got damaged blocks in blinking red, rest of the lines simply in white etc.

Btw, can we write text on LCDs using different colors? For e.g. I would like to display msg if I got damaged blocks in blinking red, rest of the lines simply in white etc.

Sometimes I design vehicles that have LCDs outside the cockpit. But I immediately give up such ideas. For me, the entire interface should be transferred into the cockpit the moment I board it. I do not understand the technical problem, why all indicators could not be on the dashboard of the cockpit? I"m tired of playing game with mods all the time, just because the game lacks something as elemental as the dashboard indicators. So, if they reject the project of adding lcd to the cockpit, I will uninstall the game. And this is the game I played the longest in my life (well, except for the Civilization series). And I will consider it as a personal failure - devoting a lot of time to an unfinished game. Because without functional cockpits this game is unfinished.

Sometimes I design vehicles that have LCDs outside the cockpit. But I immediately give up such ideas. For me, the entire interface should be transferred into the cockpit the moment I board it. I do not understand the technical problem, why all indicators could not be on the dashboard of the cockpit? I"m tired of playing game with mods all the time, just because the game lacks something as elemental as the dashboard indicators. So, if they reject the project of adding lcd to the cockpit, I will uninstall the game. And this is the game I played the longest in my life (well, except for the Civilization series). And I will consider it as a personal failure - devoting a lot of time to an unfinished game. Because without functional cockpits this game is unfinished.

Just not completing this game is not bad. Provided that this does not apply to functional cockpits. If they do not make active indicators and / or lcds in cockpits, all the rest of the improvements will not make sense. At least for me. I have been waiting for it from the very beginning. And it was always obvious to me that if there are cockpits in the game and have modeled displays and other buttons, it"s only a matter of time until they become functional. If that does not happen, I will feel cheated.

Just not completing this game is not bad. Provided that this does not apply to functional cockpits. If they do not make active indicators and / or lcds in cockpits, all the rest of the improvements will not make sense. At least for me. I have been waiting for it from the very beginning. And it was always obvious to me that if there are cockpits in the game and have modeled displays and other buttons, it"s only a matter of time until they become functional. If that does not happen, I will feel cheated.

One more thing. This game is an engineering game, it means that it is about building various constructions, including space ships, bases, vehicles, etc. But building is not an end in itself, it is built in order to finally wonder if everything works like we assumed. And to check it you need various indicators. While designing my vehicles, I focus mainly on their functionality - the indicators are necessary for me. I want to see if I have an open hatch, a detached lander, how far I have a distance to the connector when docking, or to the surface of the planet during landing, etc .. I use scripts, displays and always some cockpit mod for that. Whenever I start a new world in SE, I decide to play without mods, but I never succeed. Always missing these indicators in the cockpit and end up installing mod. So for me, KSH"s decision whether or not the displays will be in cockpits, means whether I will continue playing in SE or not.

One more thing. This game is an engineering game, it means that it is about building various constructions, including space ships, bases, vehicles, etc. But building is not an end in itself, it is built in order to finally wonder if everything works like we assumed. And to check it you need various indicators. While designing my vehicles, I focus mainly on their functionality - the indicators are necessary for me. I want to see if I have an open hatch, a detached lander, how far I have a distance to the connector when docking, or to the surface of the planet during landing, etc .. I use scripts, displays and always some cockpit mod for that. Whenever I start a new world in SE, I decide to play without mods, but I never succeed. Always missing these indicators in the cockpit and end up installing mod. So for me, KSH"s decision whether or not the displays will be in cockpits, means whether I will continue playing in SE or not.

Thx for clarifying I understood now that it is personally very important to you and your arguments are totally valid! I also would like to have them. However let me try to help you to feel less disappointed (I will barely succeed doing so, lol - giving the fact that you have played 10x times more than me in SE), what if u think to this problem this way: engineering is always about overcoming limitations, solving problems, so what if you are looking to the lack of cockpit lcd-s just as a limitation you need to solve somehow for now. (And hopefully they will add it to vanilla in the future). I admit I am speaking easily, b/c my worlds probably are not that advanced therefore perhaps I feel lack of cockpit lcd-s less severely.

Thx for clarifying I understood now that it is personally very important to you and your arguments are totally valid! I also would like to have them. However let me try to help you to feel less disappointed (I will barely succeed doing so, lol - giving the fact that you have played 10x times more than me in SE), what if u think to this problem this way: engineering is always about overcoming limitations, solving problems, so what if you are looking to the lack of cockpit lcd-s just as a limitation you need to solve somehow for now. (And hopefully they will add it to vanilla in the future). I admit I am speaking easily, b/c my worlds probably are not that advanced therefore perhaps I feel lack of cockpit lcd-s less severely.

The bright blue screen looks like a bad placeholder, it’s nice to put something useful there. I would almost prefer a selection of relevant widgets to select from for the display, but that would be “yet another thing to add”. For now I think just LCD would make everyone happy despite needing program script to make useful output to it.

The bright blue screen looks like a bad placeholder, it’s nice to put something useful there. I would almost prefer a selection of relevant widgets to select from for the display, but that would be “yet another thing to add”. For now I think just LCD would make everyone happy despite needing program script to make useful output to it.

However, I would prefer a more functional flight seat to appear in the game. I would like it to have all the necessary indicators and 3 displays, just like in this cockpit mod. One display is not enough. It annoys me that in every vehicle I have to set up huge screens that block the view from the cabin. I would like the pilot"s seat and all cockpits (small and large grid) to have the same functionality. Ideally it would be if the entire HUD moved from the helmet to the pilot"s seat or the cockpit.

However, I would prefer a more functional flight seat to appear in the game. I would like it to have all the necessary indicators and 3 displays, just like in this cockpit mod. One display is not enough. It annoys me that in every vehicle I have to set up huge screens that block the view from the cabin. I would like the pilot"s seat and all cockpits (small and large grid) to have the same functionality. Ideally it would be if the entire HUD moved from the helmet to the pilot"s seat or the cockpit.

And one more thing. It occurred to me that the second pilot"s seat with a large screen is completely unnecessary in the game. I would exchange it for a control console with indicators and screens, but without a seat. You set the console in front of an ordinary chair (which is already in the game) and you have all the indicators and screens you need. Such a set: cockpits, pilot"s seat and console of indicators (+ an ordinary chair) were a set, thanks to which you can build a fully functional vehicle of any kind. Cockpits for small grid ships and small large grid units. Pilot"s seat for medium large grid vehicles. Armchair and console for the largest units.

Such is my dream. That"s how I see it in the perfect version of Space Engineers. I do not need anything else to start a game without mods for the first time in my life.

And one more thing. It occurred to me that the second pilot"s seat with a large screen is completely unnecessary in the game. I would exchange it for a control console with indicators and screens, but without a seat. You set the console in front of an ordinary chair (which is already in the game) and you have all the indicators and screens you need. Such a set: cockpits, pilot"s seat and console of indicators (+ an ordinary chair) were a set, thanks to which you can build a fully functional vehicle of any kind. Cockpits for small grid ships and small large grid units. Pilot"s seat for medium large grid vehicles. Armchair and console for the largest units.

Such is my dream. That"s how I see it in the perfect version of Space Engineers. I do not need anything else to start a game without mods for the first time in my life.

Remember guys: I need (I think, not just me) cockpits and dashboards with indicators and at least two screens. The best in three versions: cockpit, pilot"s seat and control console (without seat). As I wrote above.

Remember guys: I need (I think, not just me) cockpits and dashboards with indicators and at least two screens. The best in three versions: cockpit, pilot"s seat and control console (without seat). As I wrote above.

Petr, I wonder: would it be possible to add cockpit-specific keybindings, for example using the numerical arrow keys and enter (by default)? If the cockpits had LCDs, and we had some option to react to cockpit-related keyboard inputs in the programmable block, that would open incredibly wide possibilities to implement all sorts of interactive functionalities for cockpits.

Petr, I wonder: would it be possible to add cockpit-specific keybindings, for example using the numerical arrow keys and enter (by default)? If the cockpits had LCDs, and we had some option to react to cockpit-related keyboard inputs in the programmable block, that would open incredibly wide possibilities to implement all sorts of interactive functionalities for cockpits.

VCZ modular cockpit, in the steam workshop. Cockpit with parts that include working LCDs, programmable blocks & timers, cargo, H2/O2 storage and generator. That and MMasters Automatic LCDs are absolute must-haves for me - stuff that should absolutely be stock.

VCZ modular cockpit, in the steam workshop. Cockpit with parts that include working LCDs, programmable blocks & timers, cargo, H2/O2 storage and generator. That and MMasters Automatic LCDs are absolute must-haves for me - stuff that should absolutely be stock.

Actions: these are all available actions for block with their names in game, so if you want to increase broadcast radius for antenna, you need to execute IncreaseRadius action for block.

All terminal blocks have terminal actions and properties. Sub-interfaces share their parent interface"s terminal actions and properties. Therefore, as IMyTerminalBlock has OnOff action, all blocks also have it. To save space, any content a parent interface has will NOT be listed in the sub-interfaces.

Space Engineers is a sandbox game about engineering, construction, exploration and survival in space and on planets. You can build space ships, space stations, planetary outposts of various sizes and uses, pilot ships and travel through space to explore planets.

Space Engineers: Warfare 2 “Broadside” pack includes Warfare Ion Thruster, Warfare Reactor, Warfare Hangar Door variants, Warfare Rocket Launcher, Warfare Gatling Gun, Searchlight, Bridge Windows, Passenger bench, Light panel, Helm, Warfare Battery, Heat vent, Sliding Hatch Door, Woodland Camo Armor Skin, Shark mouth helmet skin, “Rock paper scissors” emotes, “Salute” Emote

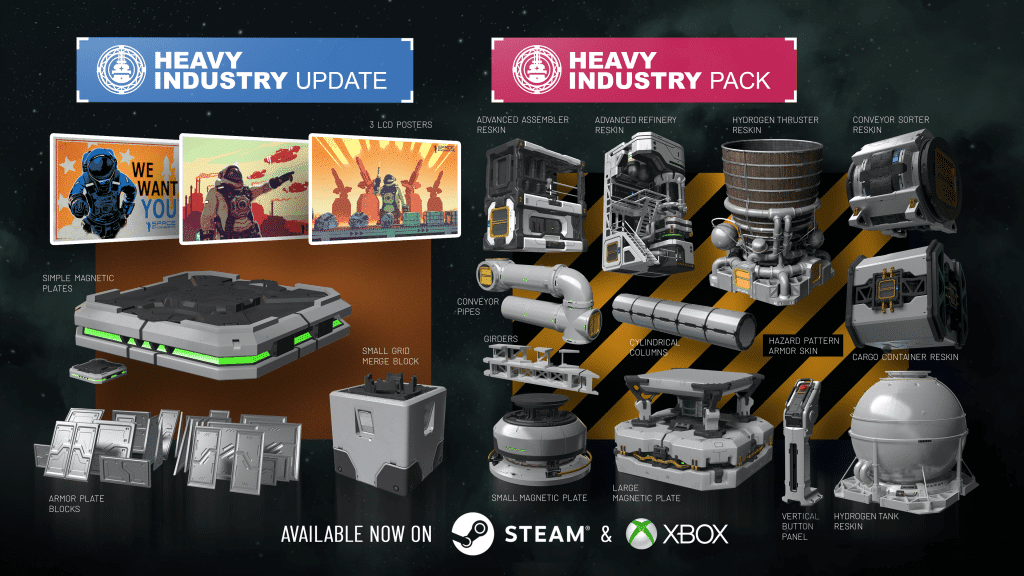

Space Engineers “Heavy Industry” pack includes Large Magnetic plate, Beam Blocks, Industrial conveyor pipes, Cylindrical Column, Vertical button panel, Large Hydrogen Tank Reskin, Large Cargo Container Reskin, Industrial Refinery, Industrial Assembler, Industrial Hydrogen Thrusters and Hazard pattern armor skin.

Space Engineers “Warfare 1: Field Engineer” pack includes Fire Cover Block, Half window Block, Weapon Rack Block, Five new passage blocks, Embrasure Block, Two new Emotes and the Assault Suit skin.

Space Engineers “Wasteland” pack includes Off road wheels, Exhaust pipes, Buggy cockpit, 2 View port blocks, Barred Window, Offset Light, Offset Spotlight, 3 Storage Shelves, Concrete Armor Skin, Dust Armor Skin, Rust 2 Armor Skin, Retro future Armor Skin, Scavenger Character skin, and 2 new character emotes.

The Space Engineers - Sparks of the Future includes the Sci-Fi LCD, the Neon Tubes, the Sci-Fi Ion Thrusters, the Sci-Fi Atmospheric Thrusters, the Sci-Fi Interior Wall, the Bar Counter, the Sci-Fi Control Panel, the Sci-Fi 1-Button Panel, the Sci-Fi 4-Button Panel, the Sci-Fi Sliding Door, the Sci-Fi Armor Skin, the 2 Neon Armor Skins, the 8 new character emotes.

The Space Engineers - Frostbite includes: the Frostbite Scenario, the Antenna Dish, the Dead Engineers, the Gate, the Offset door, the Frozen Armor Skin, the I"m Cold Emote, the Check Wrist Emote and the LCD Posters.

The Space Engineers - Decorative Pack #2 includes the Dispenser, the Jukebox, the Lab equipment, the Shower, the Window walls, the Medical station, the Transparent LCD, the Grated catwalks, the Grated stairs and half stairs, the Railings, the Rotating Light and the Freight.

The Space Engineers - Economy Deluxe Pack includes the Miner suit, the Soldier suit, the Disco armor skin, the Silver armor skin, the Glamour armor skin, fourteen Safe zone skins, thirty two Faction icons, the Vending machine and the ATM machine.

The Space Engineers - Style Pack includes four character skins, four character emotes and four armor skins. The character and armor skins, as well as the emotes included in the Style Pack, do not bring new functionality and game mechanics to Space Engineers; they are purely decorative and provide an extra layer of entertainment for players.

The Space Engineers - Decorative Pack #1 includes the decorative blocks, which can be used for various decorations of your spaceships, vehicles and space stations.

Virgin Galactic is a spaceflight company founded by Richard Branson and the Virgin Group conglomerate which retains an 11.9% stake through Virgin Investments Limited.California, and operates from New Mexico. The company is developing commercial spacecraft and aims to provide suborbital spaceflights to space tourists. Virgin Galactic"s suborbital spacecraft are air launched from beneath a carrier airplane known as White Knight Two. Virgin Galactic‘s maiden spaceflight occurred in 2018 with its VSS Unity spaceship.October 2014 crash of VSS Enterprise.

On 13 December 2018, VSS Unity achieved the project"s first suborbital space flight, VSS Unity VP-03, with two pilots, reaching an altitude of 82.7 kilometres (51.4 mi), and officially entering outer space by U.S. standards.VSS Unity VF-01, with a member of the team floating within the cabin during a spaceflight that reached 89.9 kilometres (55.9 mi).

On 11 July 2021, the company founder Richard Branson and three other employees rode on a flight as passengers, marking the first time a spaceflight company founder has travelled on his own ship into outer space (according to the NASA definition of outer space beginning at 50 miles above the Earth).

The Spaceship Company (TSC) was founded by Richard Branson through Virgin Group (which owned 70%) and Burt Rutan through Scaled Composites (which owned 30%) to build commercial spaceships and launch aircraft for space travel. From the time of TSC"s formation in 2005, the launch customer was Virgin Galactic, which contracted to purchase five SpaceShipTwos and two WhiteKnightTwosNorthrop Grumman acquired Scaled Composites, Virgin Galactic acquired the remaining 30% of The Spaceship Company.

After a claimed investment by Virgin Group of US$100 million,sovereign wealth fund of Abu Dhabi, Aabar Investments group, acquired a 31.8% stake in Virgin Galactic for US$280 million, receiving exclusive regional rights to launch tourism and scientific research space flights from the United Arab Emirates capital.US$110 million to develop a program to launch small satellites into low Earth orbit, raising their equity share to 37.8%.Google about the injection of capital to fund both development and operations.

On Monday 28 October 2019, Virgin Galactic listed into the New York Stock Exchange, trading under the ticker symbol "SPCE", the first publicly traded space tourism company (i.e., company whose primary business is space tourism). The company raised $450 million through a SPAC merger listing, and company’s market value after listing was more than $2.4 billion. At the time, the company claimed to have over 600 customer reservations representing approximately $80 million in total collected deposits and more than $120 million in “potential revenue.”

The spacecraft initially called SpaceShipTwo is planned to achieve a suborbital journey with a short period of weightlessness. Carried to about 16 kilometers, or 52,000 ft, underneath a carrier aircraft, White Knight II, after separation the vehicle would continue to over 100 km (the Kármán line, a common definition of where "space" begins). The time from liftoff of the White Knight booster carrying SpaceShipTwo until the touchdown of the spacecraft after the suborbital flight would be about 2.5 hours. The suborbital flight itself would be only a small fraction of that time, with weightlessness lasting approximately 6 minutes.

In July 2007, three Scaled Composites employees were killed and three critically injured at the Mojave spaceport while testing components of the rocket motor for SpaceShipTwo. An explosion occurred during a cold fire test, which involved nitrous oxide flowing through fuel injectors. The procedure had been expected to be safe.

Just a year later, in July 2008, Richard Branson predicted the maiden space voyage would take place within 18 months.Spaceport America "within two years."The Guardian: "We’ve changed dramatically as a company. When I joined in 2010 we were mostly a marketing organisation. Right now we can design, build, test, and fly a rocket motor all by ourselves and all in Mojave, which I don’t think is done anywhere else on the planet".

In addition to the suborbital passenger business, Virgin Galactic intended to market SpaceShipTwo for suborbital space science missions and market White Knight Two for "small satellite" launch services. It had planned to initiate RFPs for the satellite business in early 2010, but flights had not materialized as of 2014.

On 14 May 2013, Richard Branson stated on Virgin Radio Dubai"s Kris Fade Morning Show that he would be aboard the first public flight of SpaceShipTwo, which had again been rescheduled, this time to December 25, 2013.The Observer at the time of her 90th birthday in July 2014, Branson"s mother, Eve, told reporter Elizabeth Day of her intention of going to space herself. Asked when that might be, she replied: "I think it’s the end of the year", adding after a pause, "It’s always "the end of the year" ".

In September 2014, Richard Branson described the intended date for the first commercial flight as February or March 2015; by the time of this announcement, a new plastic-based fuel had yet to be ignited in-flight.Federal Aviation Administration licence to carry passengers, the craft needs to complete test missions at full speed and 62-mile height. Following the announcement of further delays, UK newspaper Tom Bower, author of Branson: The Man behind the Mask, told the Sunday Times: "They spent 10 years trying to perfect one engine and failed. They are now trying to use a different engine and get into space in six months. It"s just not feasible."

At 10:51 PST 31 October 2014, the fourth rocket-powered test flight of the company"s first SpaceShipTwo craft, VSS Enterprise, ended in disaster, as it broke apart in mid-air, with the debris falling into the Mojave desert in California, shortly after being released from the mothership. Initial reports attributed the loss to an unidentified "in-flight anomaly".Michael Alsbury was killed and 43-year-old pilot Peter Siebold was seriously injured.

U.S. National Transportation Safety Board Chairman Christopher Hart said on 2 November 2014 that investigators had determined SpaceShipTwo"s tail system was supposed to have been released for deployment as the craft was traveling about 1.4 times the speed of sound; instead, the tail section began pivoting when the vehicle was flying at Mach 1. "I"m not stating that this is the cause of the mishap. We have months and months of investigation to determine what the cause was." Asked if pilot error was a possible factor, Hart said: "We are looking at all of these issues to determine what was the root cause of this mishap." He noted that it was also unclear how the tail mechanism began to rotate once it was unlocked, since that maneuver requires a separate pilot command that was never given, and whether the craft"s position in the air and its speed somehow enabled the tail section to swing free on its own.

At a hearing in Washington D.C. on 28 July 2015,FAA oversight and a potentially anxious co-pilot without recent flight experience as important factors in the 2014 crash. They determined that the co-pilot, who died in the accident, prematurely unlocked a movable tail section some ten seconds after SpaceShip Two fired its rocket engine and was breaking the sound barrier, resulting in the craft"s breaking apart. But the Board also found that the Scaled Composites unit of Northrop Grumman, which designed and flew the prototype space tourism vehicle, did not properly prepare for potential human slip-ups by providing a fail-safe system that could have guarded against such premature deployment. “A single-point human failure has to be anticipated,” board member Robert Sumwalt said. Instead, Scaled Composites “put all their eggs in the basket of the pilots doing it correctly.”

NTSB Chairman Christopher Hart emphasized that consideration of human factors, which was not emphasized in the design, safety assessment, and operation of SpaceShipTwo"s feather system, is critical to safe human spaceflight to mitigate the potential consequences of human error. “Manned commercial spaceflight is a new frontier, with many unknown risks and hazards. In such an environment, safety margins around known hazards must be rigorously established and, where possible, expanded. For commercial spaceflight to successfully mature, we must meticulously seek out and mitigate known hazards, as a prerequisite to identifying and mitigating new hazards.”

While Virgin has been pursuing the development of a smallsat launch vehicle since 2012, the company began in 2015 to make the smallsat launch business a larger part of Virgin"s core business plan, as the Virgin human spaceflight program has experienced multiple delays.Virgin Orbit in 2017.

Following the crash of VSS Enterprise, the replacement SpaceShipTwo named VSS Unity was rolled out on 19 February 2016.Unity completed its first flight, a successful glide test, in December 2016. The glide lasted ten minutes.Unity had gone considerably higher and faster in its testing program than had its predecessor.Unity reached a height of 82.7 km (51.4 miles) above the Earth at speeds close to three times the speed of sound. The two pilots, Mark "Forger" Stucky and Frederick "CJ" Sturckow earned commercial astronaut wings from the US government for the accomplishment.

After transfer to Spaceport America in New Mexico in February 2020, a couple of 15 km altitude test flights were carried out. Due to a surge in the number of Covid-19 cases in New Mexico, Virgin Galactic had to postpone a key test flight of its spacecraft in November 2020,Michael Masucci and the four passengers were Richard Branson, Beth Moses, Colin Bennett and Sirisha Bandla.FAA grounded Virgin Galactic"s space planes before allowing a resumption of flights after some changes to procedures including reserving a larger volume of airspace.

On 14 October 2021, Virgin Galactic announced that an upgrade program for Unity and Eve would begin, delaying future commercial flights to mid 2022. This followed material analysis that required further analysis.

The first Spaceship III, VSS Imagine, was rolled out on 30 March 2021 and it was indicated there is ground testing to do before glide test flights should commence not earlier than Summer 2021.

On 17 December 2003—on the 100th anniversary of the Wright brothers first powered flight of an aircraft—SpaceShipOne, piloted by Brian Binnie on Flight 11P, made its first rocket-powered flight and became the first privately built craft to achieve supersonic flight.: 8

All of the flights of SpaceShipOne were from the Mojave Airport Civilian Flight Test Center. Flights were numbered, starting with flight 01 on May 20, 2003. One or two letters are appended to the number to indicate the type of mission. An appended C indicates that the flight was a captive carry, G indicates an unpowered glide, and P indicates a powered flight. If the actual flight differs in category from the intended flight, two letters are appended: the first indicating the intended mission and the second the mission actually performed.

Virgin Galactic and the Virgin Group are collaborating with Boom Technology in order to create a new supersonic passenger transporter as a successor to the Concorde. This new supersonic plane would fly at Mach 2.2 (similar to Concorde) for a 3-hour trans-Atlantic flight (half of standard), projected to cost $2,500–10,000 per seat (half of Concorde) for a load of 45 passengers (the Concorde held 100). It is anticipated that with the accumulation of knowledge since the design of Concorde, the new plane would be safer and cheaper with better fuel economy, operating costs, and aerodynamics. Boom would collaborate with Virgin"s The Spaceship Company for design, engineering, and flight-test support, and manufacturing.

The initial model would be the Boom Technology XB-1 "Baby Boom" Supersonic Demonstrator 1/3-size prototype. It would be capable of trans-Pacific flight, LA-to-Sydney in 6.75 hours, traveling at 2,335 km/h (1,451 mph). XB-1 would be equipped with General Electric J85 engines, Honeywell avionics, with composite structures fabricated by Blue Force using TenCate Advanced Composites carbon fibre products. First flight is scheduled for 2021.

On 24 January 2019, Virgin Galactic announced a partnership with Under Armour for the fabrication of space suits for passengers and pilots of SpaceShipTwo. Under Armour will also create uniforms for Virgin Galactic employees working at Spaceport America. The full range known as the UA | VG (Under Armour | Virgin Galactic) built with UA"s new Intelliknit fabric was revealed later this year, ahead of Richard Branson"s inaugural commercial flight.

David Mackay, former RAF test pilot, was named chief pilot for Virgin Galactic in 2011Mike Moses replaced Steve Isakowitz as president; Isakowitz moved to Aerospace Corp. to become president and CEO; Moses was promoted from VP Operations, and was once a NASA flight director and shuttle integration manager.

The White Knight Two is a special aeroplane built as the mother ship and launch-platform for the spacecraft SpaceShipTwo and the uncrewed launch vehicle LauncherOne. The mothership is a large fixed-wing aircraft with two hulls linked together by a central wing. Two aircraft are planned – VMS EveVMS Spirit of Steve Fossett.Unity to a launch altitude of 44,000 feet.

Virgin Galactic plans to have generation 2 motherships ready for 2025, for the next-generation Delta-class spaceplanes. It partnered with Boeing"s Aurora Flight Sciences to design and build the next generation of mothership.

Richard Branson unveiled the rocket plane on 7 December 2009, announcing that, after testing, the plane would carry fare-paying passengers ticketed for short duration journeys just above the atmosphere. Virgin Group would initially launch from a base in New Mexico before extending operations around the globe. Built from lightweight carbon-composite materials and powered by a hybrid rocket motor, SS2 is based on the Ansari X Prize-winning SpaceShipOne concept – a rocket plane that is lifted initially by a carrier aircraft before independent launch. SS1 became the world"s first private spaceship with a series of high-altitude flights in 2004.

Its successor is twice as large, measuring 18 m (60 ft) in length; whereas SpaceShipOne could carry a single pilot and two passengers, SS2 will have a crew of two and room for six passengers. By August 2013, 640 customers had signed up for a flight,

SpaceShipTwo was designed to fly to a height of 110 km,boundary of space (100 km) and lengthening the experience of weightlessness for its passengers. The spacecraft would reach a top speed of 4000 km/h (2485 mph). On 23 May 2014, Virgin Galactic announced that they had abandoned use of the Sierra Nevada Corporation (SNC) nitrous-oxide-rubber motor for SpaceShipTwo;Dream Chaser space shuttle.

In honor of the science-fiction series Enterprise. To reenter the atmosphere, SpaceShipTwo folds its wings up and then returns them to their original position for an unpowered descent flight back onto the runway. The craft has a very limited cross-range capability, and until other planned spaceports are built worldwide, it has to land in the area where it started. Further spaceports are planned in Abu Dhabi and elsewhere, with the intention that the spaceline will have a worldwide availability and commodity in the future.

There have been a series of delays to the SS2 flight test vehicle becoming operational, amidst repeated assurances from Virgin Galactic marketing that operational flights were only a year or two out. The Wall Street Journal reported in November 2014 that there has been "tension between Mr. Branson’s upbeat projections and the persistent hurdles that challenged the company’s hundreds of technical experts."

In 2008 it was announced that test launches for its fleet of two White Knight Two mother ships and five or more SpaceShipTwo tourist suborbital spacecraft would take place from the Mojave Spaceport, where Scaled Composites was constructing the spacecraft.Spaceport America in New Mexico, saw the contract awarded to URS and Foster + Partners architects.Spaceport SwedenRAF Lossiemouth in Scotland.

While the original plan called for flight operations to transfer from the California desert to the new spaceport upon completion of the spaceport,SpaceShipTwo. In October 2010, the 3,000 m (10,000 ft) runway at Spaceport America was opened, with SpaceShipTwo "VSS Enterprise" shipped to the site carried underneath the fuselage of Virgin Galactic"s Mother Ship Eve.

LauncherOne was publicly announced in July 2012. It was intended to launch "smallsat" payloads of 200 kilograms (440 lb) into Earth orbit. Several commercial customers initially contracted for launches, including GeoOptics, Skybox Imaging, Spaceflight Services, and Planetary Resources. Both Surrey Satellite Technology and Sierra Nevada Space Systems began developing satellite buses "optimized to the design of LauncherOne".

Virgin Galactic is not the only corporation pursuing suborbital spacecraft for tourism. Blue Origin is developing suborbital flights with its New Shepard spacecraft. Although initially more secretiveKarman line and landed in 2015

On 16 September 2014, SpaceX and Boeing were awarded contracts as part of NASA"s CCtCap program to develop their Crew Dragon and CST-100 Starliner spacecraft, respectively. Both are capsule designs to bring crew to orbit, a different commercial market than that addressed by Virgin Galactic.

Now-defunct XCOR Aerospace had also worked on rocket-powered aircraft during many of the years that Virgin Galactic had; XCOR"s Lynx suborbital vehicle was under development for more than a decade, and its predecessor, the XCOR EZ-Rocket experimental rocket powered airplane did actually take flight, but the company closed its doors in 2017.

On 11 July 2021 Virgin Galactic became the first spaceflight company to independently launch a founder of the company into space, using the 50-mile (80 km) high US definition of space, having flown founder Richard Branson above the 50-mile (80 km) mark on flight Unity 22VSS Unity, enabling Branson, three other employee passengers and the two pilots to experience approximately three minutes of weightlessness above Earth’s atmosphere. The entire flight lasted approximately one hour, taking off and landing at Spaceport America facility near Truth or Consequences, New Mexico.

This flight had originally been scheduled to occur later in the summer; however, shortly after the announcement of competitor Blue Origin"s plans to fly Amazon founder Jeff Bezos into space on 20 July 2021, the Virgin Galactic flight was rescheduled to occur on 11 July 2021. Virgin Galactic has been certified by the FAA to provide commercial spaceflight travel,US$450,000 per person.

The SpaceShipTwo vehicles (like VSS Unity) are designed for 8 people, 6 passengers and 2 pilots, so whether this flight was fully-crewed is debatable. But it is true that at the time of this flight, only 6 seats (4 passengers, 2 pilots) were installed in VSS Unity, so in this sense this flight was fully-crewed.

The claim of being the first spaceflight company to independently launch a civilian into space on a suborbital flight using the 50-mile (80 km) high definition of space can be disputed as this had been done already in 2004, (see SpaceShipOne, which actually reached the 100 km (62 mi) Kármán line level). If it is meant that Virgin Galactic was the first to launch a civilian non-pilot into space on a suborbital flight, this was done already in 2019 with Beth Moses. Furthermore, because of Mr. Branson"s affiliation with Virgin Galactic, it is impossible to distinquish whether his flight was done as a private person for amusement, also as a space tourist, or as a company employee on company time and company pay (also whether Branson was advertising/marketing the company, and thus was working during the flight in the capacity of company officer for the company, and was not a space tourist at all); this latter case (working during the flight) would have been a similar situation as Beth Moses or the pilots that flew Virgin Galactic"s prior spaceflights were in their respective spaceflights. So it is not clear whether Mr. Branson"s flight can be considered the first space tourist flight into suborbital space either; and if it cannot, then the flight is not a "first" as many people, including the above-mentioned Beth Moses, have made a spaceflight because of their work without being an astronaut, some even an orbital flight, and as Ms. Moses was in a similar situation as Mr. Branson (working for Virgin Galactic, flying suborbitally in the passenger cabin, i.e. not as a pilot) it is very hard to see in which way the 11 July 2021 flight, and especially Mr. Branson"s role in it, constituted a "first of something in space" (as most of the "firsts of something in space" would have been accomplished prior to the 2021 Branson flight, for example by the 2019 Moses flight). However, as an exception to the previous statement that the 11 July 2021 flight and Mr. Branson"s participation in it did not achieve any "firsts in space", let it be said that it is true that the 11 July 2021 flight was the first time more than 3 people flew suborbitally on a (USAF/NASA) spaceflight and the first time more than 1 passenger (i.e. non-pilot) flew on a suborbital (USAF/NASA) spaceflight, and Mr. Branson was the first founder of a spaceflight company to fly to (USAF/NASA) space on his own company"s craft, all the above using the USAF/NASA definition of space as above 50 miles. Furthermore, all of the above concerns only suborbital spaceflights (above 50 miles) as there have been numerous orbital space flights of various space tourists (civilian, non-pilot, flying for amusement or for work, etc.) over the years and decades, e.g. Dennis Tito in 2001.

This article is about a spacecraft system used by NASA. For space shuttles in general, see spacecraft and spaceplane. For the spaceplane component of the Space Shuttle, see Space Shuttle orbiter.

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program name was Space Transportation System (STS), taken from a 1969 plan for a system of reusable spacecraft where it was the only item funded for development.STS-1) of four orbital test flights occurred in 1981, leading to operational flights (STS-5) beginning in 1982. Five complete Space Shuttle orbiter vehicles were built and flown on a total of 135 missions from 1981 to 2011. They launched from the Kennedy Space Center (KSC) in Florida. Operational missions launched numerous satellites, interplanetary probes, and the Hubble Space Telescope (HST), conducted science experiments in orbit, participated in the Shuttle-Mir program with Russia, and participated in construction and servicing of the International Space Station (ISS). The Space Shuttle fleet"s total mission time was 1,323 days.

Space Shuttle components include the Orbiter Vehicle (OV) with three clustered Rocketdyne RS-25 main engines, a pair of recoverable solid rocket boosters (SRBs), and the expendable external tank (ET) containing liquid hydrogen and liquid oxygen. The Space Shuttle was launched vertically, like a conventional rocket, with the two SRBs operating in parallel with the orbiter"s three main engines, which were fueled from the ET. The SRBs were jettisoned before the vehicle reached orbit, while the main engines continued to operate, and the ET was jettisoned after main engine cutoff and just before orbit insertion, which used the orbiter"s two Orbital Maneuvering System (OMS) engines. At the conclusion of the mission, the orbiter fired its OMS to deorbit and reenter the atmosphere. The orbiter was protected during reentry by its thermal protection system tiles, and it glided as a spaceplane to a runway landing, usually to the Shuttle Landing Facility at KSC, Florida, or to Rogers Dry Lake in Edwards Air Force Base, California. If the landing occurred at Edwards, the orbiter was flown back to the KSC atop the Shuttle Carrier Aircraft (SCA), a specially modified Boeing 747.

The first orbiter, Approach and Landing Tests (ALT), but had no orbital capability. Four fully operational orbiters were initially built: Challenger in 1986 and Columbia in 2003, with a total of 14 astronauts killed. A fifth operational (and sixth in total) orbiter, Challenger. The three surviving operational vehicles were retired from service following Atlantis"s final flight on July 21, 2011. The U.S. relied on the Russian Soyuz spacecraft to transport astronauts to the ISS from the last Shuttle flight until the launch of the Crew Dragon Demo-2 mission in May 2020.

During the 1950s, the United States Air Force proposed using a reusable piloted glider to perform military operations such as reconnaissance, satellite attack, and air-to-ground weapons employment. In the late 1950s, the Air Force began developing the partially reusable X-20 Dyna-Soar. The Air Force collaborated with NASA on the Dyna-Soar and began training six pilots in June 1961. The rising costs of development and the prioritization of Project Gemini led to the cancellation of the Dyna-Soar program in December 1963. In addition to the Dyna-Soar, the Air Force had conducted a study in 1957 to test the feasibility of reusable boosters. This became the basis for the aerospaceplane, a fully reusable spacecraft that was never developed beyond the initial design phase in 1962–1963.: 162–163

Beginning in the early 1950s, NASA and the Air Force collaborated on developing lifting bodies to test aircraft that primarily generated lift from their fuselages instead of wings, and tested the NASA M2-F1, Northrop M2-F2, Northrop M2-F3, Northrop HL-10, Martin Marietta X-24A, and the Martin Marietta X-24B. The program tested aerodynamic characteristics that would later be incorporated in design of the Space Shuttle, including unpowered landing from a high altitude and speed.: 142: 16–18

On September 24, 1966, NASA and the Air Force released a joint study concluding that a new vehicle was required to satisfy their respective future demands and that a partially reusable system would be the most cost-effective solution.: 164 The head of the NASA Office of Manned Space Flight, George Mueller, announced the plan for a reusable shuttle on August 10, 1968. NASA issued a request for proposal (RFP) for designs of the Integrated Launch and Re-entry Vehicle (ILRV), which would later become the Space Shuttle. Rather than award a contract based upon initial proposals, NASA announced a phased approach for the Space Shuttle contracting and development; Phase A was a request for studies completed by competing aerospace companies, Phase B was a competition between two contractors for a specific contract, Phase C involved designing the details of the spacecraft components, and Phase D was the production of the spacecraft.: 19–22

In December 1968, NASA created the Space Shuttle Task Group to determine the optimal design for a reusable spacecraft, and issued study contracts to General Dynamics, Lockheed, McDonnell Douglas, and North American Rockwell. In July 1969, the Space Shuttle Task Group issued a report that determined the Shuttle would support short-duration crewed missions and space station, as well as the capabilities to launch, service, and retrieve satellites. The report also created three classes of a future reusable shuttle: Class I would have a reusable orbiter mounted on expendable boosters, Class II would use multiple expendable rocket engines and a single propellant tank (stage-and-a-half), and Class III would have both a reusable orbiter and a reusable booster. In September 1969, the Space Task Group, under the leadership of Vice President Spiro Agnew, issued a report calling for the development of a space shuttle to bring people and cargo to low Earth orbit (LEO), as well as a space tug for transfers between orbits and the Moon, and a reusable nuclear upper stage for deep space travel.: 163–166

After the release of the Space Shuttle Task Group report, many aerospace engineers favored the Class III, fully reusable design because of perceived savings in hardware costs. Max Faget, a NASA engineer who had worked to design the Mercury capsule, patented a design for a two-stage fully recoverable system with a straight-winged orbiter mounted on a larger straight-winged booster.: 166

After they established the need for a reusable, heavy-lift spacecraft, NASA and the Air Force determined the design requirements of their respective services. The Air Force expected to use the Space Shuttle to launch large satellites, and required it to be capable of lifting 29,000 kg (65,000 lb) to an eastward LEO or 18,000 kg (40,000 lb) into a polar orbit. The satellite designs also required that the Space Shuttle have a 4.6 by 18 m (15 by 60 ft) payload bay. NASA evaluated the F-1 and J-2 engines from the Saturn rockets, and determined that they were insufficient for the requirements of the Space Shuttle; in July 1971, it issued a contract to Rocketdyne to begin development on the RS-25 engine.: 165–170

NASA reviewed 29 potential designs for the Space Shuttle and determined that a design with two side boosters should be used, and the boosters should be reusable to reduce costs.: 167 NASA and the Air Force elected to use solid-propellant boosters because of the lower costs and the ease of refurbishing them for reuse after they landed in the ocean. In January 1972, President Richard Nixon approved the Shuttle, and NASA decided on its final design in March. That August, NASA awarded the contract to build the orbiter to North American Rockwell, the solid-rocket booster contract to Morton Thiokol, and the external tank contract to Martin Marietta.: 170–173

On June 4, 1974, Rockwell began construction on the first orbiter, OV-101, which would later be named Enterprise. Enterprise was designed as a test vehicle, and did not include engines or heat shielding. Construction was completed on September 17, 1976, and Enterprise was moved to the Edwards Air Force Base to begin testing.: 173Main Propulsion Test Article (MPTA)-098, which was a structural truss mounted to the ET with three RS-25 engines attached. It was tested at the National Space Technology Laboratory (NSTL) to ensure that the engines could safely run through the launch profile.: II-163 Rockwell conducted mechanical and thermal stress tests on Structural Test Article (STA)-099 to determine the effects of aerodynamic and thermal stresses during launch and reentry.: I-415

The beginning of the development of the RS-25 Space Shuttle Main Engine was delayed for nine months while Pratt & Whitney challenged the contract that had been issued to Rocketdyne. The first engine was completed in March 1975, after issues with developing the first throttleable, reusable engine. During engine testing, the RS-25 experienced multiple nozzle failures, as well as broken turbine blades. Despite the problems during testing, NASA ordered the nine RS-25 engines needed for its three orbiters under construction in May 1978.: 174–175

NASA experienced significant delays in the development of the Space Shuttle"s thermal protection system. Previous NASA spacecraft had used ablative heat shields, but those could not be reused. NASA chose to use ceramic tiles for thermal protection, as the shuttle could then be constructed of lightweight aluminum, and the tiles could be individually replaced as needed. Construction began on Columbia on March 27, 1975, and it was delivered to the KSC on March 25, 1979.: 175–177 At the time of its arrival at the KSC, Columbia still had 6,000 of its 30,000 tiles remaining to be installed. However, many of the tiles that had been originally installed had to be replaced, requiring two years of installation before Columbia could fly.: 46–48

On January 5, 1979, NASA commissioned a second orbiter. Later that month, Rockwell began converting STA-099 to OV-099, later named Challenger. On January 29, 1979, NASA ordered two additional orbiters, OV-103 and OV-104, which were named Discovery and Atlantis. Construction of OV-105, later named Endeavour, began in February 1982, but NASA decided to limit the Space Shuttle fleet to four orbiters in 1983. After the loss of Challenger, NASA resumed production of Endeavour in September 1987.: 52–53

After it arrived at Edwards AFB, Enterprise underwent flight testing with the Shuttle Carrier Aircraft, a Boeing 747 that had been modified to carry the orbiter. In February 1977, Enterprise began the Approach and Landing Tests (ALT) and underwent captive flights, where it remained attached to the Shuttle Carrier Aircraft for the duration of the flight. On August 12, 1977, Enterprise conducted its first glide test, where it detached from the Shuttle Carrier Aircraft and landed at Edwards AFB.: 173–174 After four additional flights, Enterprise was moved to the Marshall Space Flight Center (MSFC) on March 13, 1978. Enterprise underwent shake tests in the Mated Vertical Ground Vibration Test, where it was attached to an external tank and solid rocket boosters, and underwent vibrations to simulate the stresses of launch. In April 1979, Enterprise was taken to the KSC, where it was attached to an external tank and solid rocket boosters, and moved to LC-39. Once installed at the launch pad, the Space Shuttle was used to verify the proper positioning of launch complex hardware. Enterprise was taken back to California in August 1979, and later served in the development of the SLC-6 at Vandenberg AFB in 1984.: 40–41

On November 24, 1980, Columbia was mated with its external tank and solid-rocket boosters, and was moved to LC-39 on December 29.: III-22 The first Space Shuttle mission, STS-1, would be the first time NASA performed a crewed first-flight of a spacecraft.: III-24 On April 12, 1981, the Space Shuttle launched for the first time, and was piloted by John Young and Robert Crippen. During the two-day mission, Young and Crippen tested equipment on board the shuttle, and found several of the ceramic tiles had fallen off the top side of the Columbia.: 277–278 NASA coordinated with the Air Force to use satellites to image the underside of Columbia, and determined there was no damage.: 335–337 Columbia reentered the atmosphere and landed at Edwards AFB on April 14.: III-24

NASA conducted three additional test flights with Columbia in 1981 and 1982. On July 4, 1982, STS-4, flown by Ken Mattingly and Henry Hartsfield, landed on a concrete runway at Edwards AFB. President Ronald Reagan and his wife Nancy met the crew, and delivered a speech. After STS-4, NASA declared its Space Transportation System (STS) operational.: 178–179

The Space Shuttle was the first operational orbital spacecraft designed for reuse. Each Space Shuttle orbiter was designed for a projected lifespan of 100 launches or ten years of operational life, although this was later extended.: 11 At launch, it consisted of the orbiter, which contained the crew and payload, the external tank (ET), and the two solid rocket boosters (SRBs).: 363

Responsibility for the Shuttle components was spread among multiple NASA field centers. The KSC was responsible for launch, landing, and turnaround operations for equatorial orbits (the only orbit profile actually used in the program). The U.S. Air Force at the Vandenberg Air Force Base was responsible for launch, landing, and turnaround operations for polar orbits (though this was never used). The Johnson Space Center (JSC) served as the central point for all Shuttle operations and the MSFC was responsible for the main engines, external tank, and solid rocket boosters. The John C. Stennis Space Center handled main engine testing, and the Goddard Space Flight Center managed the global tracking network.

The orbiter had design elements and capabilities of both a rocket and an aircraft to allow it to launch vertically and then land as a glider.: 365 Its three-part fuselage provided support for the crew compartment, cargo bay, flight surfaces, and engines. The rear of the orbiter contained the Space Shuttle Main Engines (SSME), which provided thrust during launch, as well as the Orbital Maneuvering System (OMS), which allowed the orbiter to achieve, alter, and exit its orbit once in space. Its double-delta wings were 18 m (60 ft) long, and were swept 81° at the inner leading edge and 45° at the outer leading edge. Each wing had an inboard and outboard elevon to provide flight control during reentry, along with a flap located between the wings, below the engines to control pitch. The orbiter"s vertical stabilizer was swept backwards at 45° and contained a rudder that could split to act as a speed brake.: 382–389 The vertical stabilizer also contained a two-part drag parachute system to slow the orbiter after landing. The orbiter used retractable landing gear with a nose landing gear and two main landing gear, each containing two tires. The main landing gear contained two brake assemblies each, and the nose landing gear contained an electro-hydraulic steering mechanism.: 408–411

The Space Shuttle crew varied per mission. The test flights only had two members each, the commander and pilot, who were both qualified pilots that could fly and land the orbiter. The on-orbit operations, such as experiments, payload deployment, and EVAs, were conducted primarily by the mission specialists who were specifically trained for their intended missions and systems. Early in the Space Shuttle program, NASA flew with payload specialists, who were typically systems specialists who worked for the company paying for the payload"s deployment or operations. The final payload specialist, Gregory B. Jarvis, flew on STS-51-L, and future non-pilots were designated as mission specialists. An astronaut flew as a crewed spaceflight engineer on both STS-51-C and STS-51-J to serve as a military representative for a National Reconnaissance Office payload. A Space Shuttle crew typically had seven astronauts, with STS-61-A flying with eight.: III-21

The crew compartment comprised three decks and was the pressurized, habitable area on all Space Shuttle missions. The flight deck consisted of two seats for the commander and pilot, as well as an additional two to four seats for crew members. The mid-deck was located below the flight deck and was where the galley and crew bunks were set up, as well as three or four crew member seats. The mid-deck contained the airlock, which could support two astronauts on an extravehicular activity (EVA), as well as access to pressurized research modules. An equipment bay was below the mid-deck, which stored environmental control and waste management systems.: 60–62: 365–369

On the first four Shuttle missions, astronauts wore modified U.S. Air Force high-altitude full-pressure suits, which included a full-pressure helmet during ascent and descent. From the fifth flight, STS-5, until the loss of Challenger, the crew wore one-piece light blue nomex flight suits and partial-pressure helmets. After the Challenger disaster, the crew members wore the Launch Entry Suit (LES), a partial-pressure version of the high-altitude pressure suits with a helmet. In 1994, the LES was replaced by the full-pressure Advanced Crew Escape Suit (ACES), which improved the safety of the astronauts in an emergency situation. Columbia originally had modified SR-71 zero-zero ejection seats installed for the ALT and first four missions, but these were disabled after STS-4 and removed after STS-9.: 370–371

The flight deck was the top level of the crew compartment and contained the flight controls for the orbiter. The commander sat in the front left seat, and the pilot sat in the front right seat, with two t

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey