advantages of touch screen monitors made in china

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

As is known to all, in the past 40 years, China has made remarkable achievements in its industry. With the establishment and improvement of a modern industrial system with complete categories, China has long been the world’s largest manufacturing country.

This is mainly because China has a large population, about the same as the rest of the developed world put together, but it has not yet developed to the point where services account for a large proportion. Because China has a large population and a large number of employed people, labor is cheaper than in other countries. Foreign enterprises can take advantage of China’s labor force by putting their products into production in China, which not only increases the employment rate of Chinese people but also saves a lot of costs in the production of products. Therefore, made in China is so popular.

A guy on Quora mentions that”If you import a lot of raw Material from broad, it will cost a lot of money, but China has a very special weapon: infrastructure. Since the demand for products (mostly commodities) drives demand for raw material, that drives demand for infrastructure to route these raw materials effectively and cheaply. Unlike India, China has that infrastructure and system, and so raw material can flow in large batches and routed effectively to minimize cost.”

It is also true that in the eyes of foreign companies, Chinese products in almost any field can be produced. China’s development in the production field in recent years is very comprehensive, including raw materials, production, logistics, trade, and other supporting industrial chains, which can be said to be very complete. Therefore, foreign enterprises can find a complete industrial chain in a very short time when they come to China, so the reputation of Chinese manufacturing is also very good.

When it comes to cheap Labour, it is much cheaper in south-east Asia than in China. But why is China so popular? This involves the quality of the product. The reason why the labor force in many countries in southeast Asia is cheap is mainly that the economic level of these countries is not high, so no matter the production technology or technological level is inferior to China. To ensure the quality of their products, foreign companies naturally prefer to choose China.

In terms of product production efficiency, China is hard to compare with many other countries. According to relevant data, domestic product manufacturing efficiency is the highest in the world. On the one hand, this is because China’s factories have more comprehensive equipment and a high level of science and technology, which can shorten the production cycle of products. On the other hand, it is because of the high quality of Chinese workers, strong learning ability, and developed transportation, which also speeds up the operation of all aspects of product production.

In order to export more products to other parts of the world, the Chinese government has only a VAT system and only taxes value-added services. As a result, production costs are much cheaper than in other countries. On the other hand, the United States and some other developed countries do not impose low import tariffs on Chinese goods.

It is believed that with the continuous development of Chinese manufacturing and science and technology, made-in-china manufactures will become more popular in the future.

Touchscreen technologies have improved immensely over the past decade. They offer a host of benefits for businesses that require building directories and wayfinding assistance, and that want to provide information or self-service options for employees, guests, and customers.

With digital directory signage systems, you just need to electronically update the information in the data directory once. Then you can replicate and share the same update with all of the digital signs in your mall.

Best of all, you do not have to walk to a sign display to make any changes and updates! You can make changes and updates or alter what information is displayed right from your desk.

You can customize your digital directories with the types of content relevant to your business or industry by implementing different apps and features. For instance, along the side of a digital wayfinding display, you could feature weather, traffic, local news, or stock reports.

It is easy to add more digital signage throughout your property and tailor each touchscreen directory for specific purposes or functions. For instance, in a multi-practice healthcare facility, you could have one touchscreen in the main lobby area for patients to use to locate their physician’s office.

Within each physician’s office, you could have other video displays/touchscreens on which patients could watch content or utilize various apps while they are waiting to see their doctor. Did you know people perceive wait times to be thirty to fifty percent less than they actually are when there are touchscreens and video displays in use?

You could use apps like headline news, current weather, calendar of events, traffic conditions, social media feeds, and so on to keep people entertained anywhere in your healthcare facility. You could even use a display with various apps outside your pharmacy so people could view it while they waited for their prescriptions.

Touchscreens are very user-friendly, even when that person has a physical disability. For example, a person with arthritis can still easily “tap” the screen while using a wayfinding directory to locate a store, doctor’s office, or another place of business they want to visit. Screen displays can also be adjusted for those with visual impairments, so the text and images are made larger, temporarily, to accommodate this individual.

In popular tourist cities, like New York, Orlando, and Las Vegas, not everyone knows English. You can have tourists from Japan, China, France, Germany, Mexico, Brazil, or some other place where English is not the primary language. By offering multiple languages support, your guests can select the language they want to use while using the digital directory for assistance.

Most people are already familiar with how to use touchscreen technologies because their smartphones and tablet devices are touchscreens. There is only a small learning curve for someone who might not be too familiar with touchscreens. You just tap the screen while looking for the information you require. Some displays can also be configured to allow a person to search using an onscreen keyboard.

Touchscreens are flat-paneled devices, much like today’s televisions. They are lightweight and thin and do not take up much space to install. Even the large digital display kiosks you find in malls take up less space than those bulky square-shaped “old-school” directories. Not to mention, they tend to use less energy compared to conventional back-lit directories.

In addition to wayfinding information, our touchscreen displays can provide a great deal of information that will make your business a welcoming environment for your clients and customers. Our devices are able to display headline news, current local weather, even traffic conditions. The possibilities are nearly endless.

With a traditional directory, people have to look line by line to find the name of the business, office, or retailer they are looking for. Then, once they find it, look at the “map” on the display and scan numerous spaces to find the one they want.

With touchscreen technologies, people are able to accomplish desired tasks by as much as 20% faster. If Search is enabled, they just enter the name of the business and know right away where it is located within the building. They could even be provided with onscreen directions to know which way is the most efficient to get there.

Maintaining conventional directories means cleaning the front and sides of the display to remove fingerprints and smudges. If there are any light bulbs burnt out, you would have to open the display and replace those, too.

Touchscreens will also be touched a lot throughout the day. Getting rid of all those fingerprints and smudges is easy to do with an approved screen cleaner. You just spray it on and wipe with a soft cloth. This is essentially the only “housekeeping” type of maintenance they require once they are installed, other than a quick dusting on the tops and sides.

Touchscreen directories can be used in both indoor and outdoor locations. For outdoor areas, however, special types of hardware may be necessary to protect the display from the elements and help ensure proper operating conditions.

As you can see, there are many benefits your business could gain by using touchscreen technologies and displays. Touchscreens come in all different sizes, from small ones you can use in elevators to huge display panels you can mount to the wall or have installed as their own stand-alone display kiosks.

With the number of apps and customizations currently available, and continuing to expand and grow, there really is no limit to how you could use touchscreen and electronic directories in your business.

Some businesses that are still holding an enclave on technology that is traditional require some convincing to enter the exciting world of touch. In order to address the issues and convince clients to adopt touchscreens, suppliers and sellers can convince them of the advantages of this technology, in the following paragraphs.

No More Keyboards and Mouse KeyboardWith touchscreen devices, you are no longer dependent of other input devices. They allow immediate navigation and accessibility with physical control via touch. It removes the necessity of the traditional keyboard and mouse and gives users a more speedier and efficient way of communicating with computers.

Numerous businesses, including restaurants, hotels, retail stores etc. are operating with small space. They are able to utilize the full potential of Touchscreen Solution devices. Utilizing touch screen monitors instead of other hardware that takes up space is an efficient solution to space in the working environment.

The main advantage of touch screen technology is its simple-to-use interface. It is easy to operate using gloved or ungloved fingers the touch screen technology makes using the system easy and more speedy. When you tap or squeeze the screen brings you to the section you need to tackle. Users quickly become accustomed to the operating system and this eventually leads to an increase in productivity and a higher return on investment.

With the advancement of technology, suppliers of touch screens with experience, provide various touch screens that are immune to dust, water and other pollutants. Cleaning and cleaning touch screen devices much easier. For hotels, restaurants, hospitals, and other healthcare establishments touchscreens can be extremely beneficial.

Nowadays, a number of companies in various industries are using the integrated technology of touch screens, and are making the most of the technology provided by suppliers of touch screens such as A D Metro. The availability of a wide selection of touch screens comprising capacitive and resistive and capacitive, further increases the appeal of this method of operation.

The D Metro stands out from other touchscreen screen manufacturers by offering innovative touch solutions for industrial, medical, commercial and military applications. These touch screen solutions have been built to be seamlessly integrated into control panels, Touch kiosk and monitors, as well as all-in-one PCs as well as mobile devices for computing. A D Metro’s trademarked ULTRA touchscreen made of armored glass is the market’s most durable resistive touchscreen sensor that is suitable for harsh operating environments. Watch the Video on Youtube

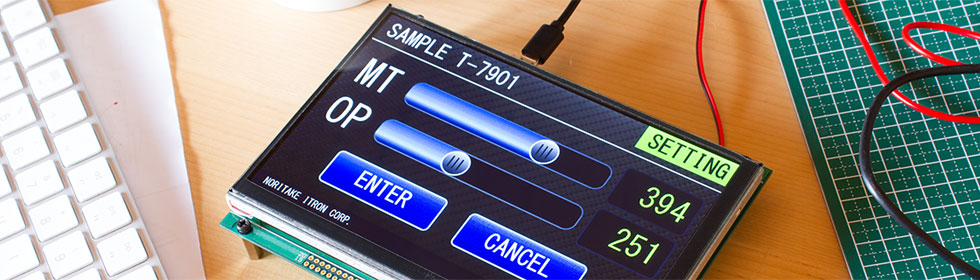

Industrial touch monitors are widely used in laboratories of universities and colleges. It has good anti-interference performance and strong environmental resistance. It can work without hindrance at high and low temperatures. In addition, in recent years, industrial touch monitors are also used in various vending machines, because they have capacitive touch explosion-proof screens, which can ensure the stability of working 24 hours a day. In addition, it is also used in certain applications in workshop control cabinets. Through the application in embedded tablet devices, it is faster and more efficient. Here are some advantages of industrial touch monitors.

Considering the particularity of industrial touch monitors, most of them use industrial driver boards to make them safer and more stable. In the first step, their components usually use industrial-grade components from well-known domestic and foreign brands. The control chip adopts a big-brand industrial-grade display chip, which can ensure the long-term stability of the industrial touch display.

Overall, the best cost-effective industrial touch monitors last longer. It uses withstand voltage design, anti-static design, anti-interference design and anti-magnetic design. Mainboard power management usually uses imported brand chips. It features high reliability, wide operating temperature and low relative humidity requirements.

Industrial touch monitors have been carefully designed, including multi-layer structures, and their image quality should be better. For example, it uses an industrially controlled LED-backlit high-definition LCD screen. Indoor colors are still excellent, making the screen display of industrial touch screens even better.

According to the manufacturer of the industrial touch monitor, it has a strong waterproof ability and fully meets the dustproof and waterproof standards. When it is installed in the control cabinet, it can prevent water droplets and water vapor from splashing into the site and avoid affecting the operation of the equipment. In addition, it has excellent heat dissipation. Many industrial touch displays are made of aluminum alloy, which not only has beautiful appearance and texture, but also improves the heat dissipation performance of the product.

EOTSZ provides you with professional human-computer interaction interfaces in all walks of life. With the service tenet of integrity, rigor, and professionalism, EOTSZ will add splendid factors to your high-tech electronic equipment. For more information about touch monitors, please kindlycontact

As the name suggests, resistive touch LCD screen works on the basis of a pressure applied to LCD screen. A resistive touchscreen consists of several thin layers. The layers comprise of a bottom glass panel that is followed by two resistive circuit layers which are coated with electrically conductive thin metallic layers (e.g. ITO) separated by a slim gap consisting of spacer dots.

When pressure is applied on the screen with a finger or stylus, the outer resistive layer is pushed onto the inner layer. The two metallic conductive layers come into contact, causing a current loop and generating a change in resistance on both vertical and horizontal axis. The change is detected by the sensors located on the screen"s edges which in turn find out the exact location by using the horizontal-vertical coordinates to indicate the touch point.

Minimal production cost- resistive touchscreens are easier to make due to its simple structure and cost less when compared with otherLCD touch technologies.

Activate with any object - as stated above, anything that can apply pressure on resistive touch screen will trigger a touch action and detected by resistive touch sensors. This property makes resistive touch screen the preferred choice in industrial and medical settings, where operators may use gloves on the LCD touch screen.

Less sensitive to stray stimuli - how a touch action is detected by resistive touch screen determines liquid spills/snow or surface contaminants won"t cause the touch screen to react unintentionally. And this is very important for industrial and outdoor environments.

No shattered glass risk - most LCD touch screen technologies use glass as outer touch layer. This is usually not allowed in food and beverage facilities, to avoid shattered glass contamination. Resistive touch screen uses a tough polycarbonate outer layer, which can contain shattered glass in case the LCD screen is cracked.

Resistive touch LCD screens have been used widely for many years. It is a well-proven and trusted solution for building human-machine interface. Here is an example of "How to implement LCD display resistive touch".

Usually, touch screens and LCD displays are produced separately and glued together with air bonding technology. So, there will be an air gap between touch screen and LCD display.

Air bonding is a simpler manufacturing technology with a high yield rate. Double-sided adhesive fixes touch screen and display panel around perimeter. However, there is an air gap between display panel and touch screen, which makes the whole display thicker. Reflected light and dust in air gap make screens less clear, too.

Optical bonding on the other hand, is to glue touch panel onto LCD screen with optical adhesive. Full-fit technology eliminates the air gap between layers. Less reflected light means better display. However, Optical bonding is an expensive technology. Now only a small number of customers with special needs choose this type of touch screen. As more and more end-users demand better LCD display, optical LCD touch screen will become mainstream.

In-Cell refers to embedding touch panel function into liquid crystal pixels, that is, embedding touch sensor function inside LCD screen. Traditional touch panel is no longer necessary. In-cell is an innovation of loading circuits onto liquid crystal. This kind of LCD is much thinner with better readability in sunlight.

On-Cell means embedding touch screen between color filter substrate and polarizer, in other words, equipping sensor on LCD panel. Although manufacture of on-cell screens is easier than In-Cell, there are still thickness and color uneven problems.

OGS technology is to fit touch screen and protective glass together. Inside of protective glass is ITO conductive layer. Coating and lithography are done directly on the glass. This makes touch screen thinner and cheaper. However, protective glass is usually tempered first, then coated, etched, and finally cut. Cutting tempered glass is difficult with low yield rate. Capillary cracks on the edge will weaken the cut glass.

If you have any questions about touch screens, please consult us. Topway with more than 25 years of experience of LCD display, will give you a satisfactory solution.

There are a variety of touch technologies available today, with each working in different ways, such as using infrared light, pressure or even sound waves. However, there are two touchscreen technologies that surpass all others - resistive touch and capacitive touch.

There are advantages to both capacitive and resistive touchscreens, and either can be suited for a variety of applications dependent on specific requirements for your market sector.

Resistive touchscreens use pressure as input. Made up of several layers of flexible plastic and glass, the front layer is scratch resistant plastic and the second layer is (usually) glass. These are both coated with conductive material. When someone applies pressure to the panel, the resistance is measured between the two layers highlighting where the point of contact is on the screen.

Some of the benefits of resistive touch panels include the minimal production cost, flexibility when it comes to touch (gloves and styluses can be used) and its durability – strong resistance to water and dust.

In contrast to resistive touchscreens, capacitive touchscreens use the electrical properties of the human body as input. When touched with a finger, a small electrical charge is drawn to the point of contact, which allows the display to detect where it has received an input. The result is a display that can detect lighter touches and with greater accuracy than with a resistive touchscren.

If you want increased screen contrast and clarity, capacitive touch screens are the preferred option over resistive screens, which have more reflections due to their number of layers. Capacitive screens are also far more sensitive and can work with multi-point inputs, known as ‘multi-touch’. However, because of these advantages, they are sometimes less cost-effective than resistive touch panels.

Although capacitive touchscreen technology was invented long before resistive touchscreens, capacitive technology has seen more rapid evolution in recent years. Thanks to consumer electronics, particularly mobile technology, capacitive touchscreens are swiftly improving in both performance and cost.

At GTK, we find ourselves recommending capacitive touchscreens more regularly than resitive ones. Our customers almost always find capacitive touchscreens more pleasant to work with and appreciate the vibrancy of image that cap touch TFTs can produce. With constant advancements in capacitive sensors, including new fine-tuned sensors that work with heavy duty gloves, if we had to pick just one, it would be the capacitive touchscreen.

A few years ago, a little thing called the “app” altered the way people interact with the electronic systems in their homes. With only a swipe and a tap, smartphone-loving homeowners were in complete charge of everything from thermostats and light switches to complete home automation systems. Convenient? Absolutely. And who can deny the cool factor associated with whipping out a phone while on a date to get the house ready for an impromptu nightcap? With so much hoopla surrounding control apps, it can be easy to forget about one of the most respected user-interfaces available: the dedicated touch screen.

Don’t let this tried-and-true mode of control slip your mind, though. The dedicated touch screen, like the new7- and 10-inch models from Control4, offers a wealth of benefits that no other type of interface can match. The user-interface on a touch screen presents a great deal of information about your house—all in high-resolution quality—from reviewing the current settings of your home’s thermostats and lights, to receiving a status report of electronic door locks and viewing the current weather forecast. With all the pertinent data at your fingertips, organized and laid out in a manner that’s easy to read, the touch screen is arguably the most engaging and intuitive of all user interfaces.

Even as new features get added to a touch screen, like the HD camera, hi-fi speakers and microphone that Control4 recently added to its 7- and 10-inch models, its user-friendliness is never compromised. In fact, with each new function, a touch screen becomes an increasingly more powerful and valuable home control tool.

Touch screens are a fast and responsive user interface that’s always there ready for you to interact with your home. There’s no need to boot up or wait for an app to load. You’re in charge of the electronic system in your house, instantly.

Then there’s the convenience factor. You may not be able to carry a touch screen in your pocket like you can your app-enabled smartphone, but unlike your phone, a touch screen is always right where you left it, never lost between the cushions of your couch. Plus, it’s always powered up and ready to shoot off commands to all the connected devices in your house.

When you’re ready to add automation system to your home or update your existing system, be sure to plan for at least a few touch screens. Positioned in the common areas of your house, like the kitchen, family room and foyer, they’ll give you a quick, easy and reliable way to monitor, manage and control your home environment.

For more information about these sleek and insanely-fast touch screens—including the 10" Tabletop version that was just added to our line-up—get in touch with your dealer or find a Control4 smart home professional near you.

Capacitive touch panels are the more modern and advanced touchscreen option because of their advanced capabilities. They are commonly found in consumer products like smartphones, tablets, appliances, and monitors.

A capacitive touchscreen detects and responds to changes in capacitance caused by the screen"s electrostatic field when the screen"s surface is touched.

Capacitive touchscreen displays allow for touch gestures and respond to multi-touch inputs. You’ll typically be able to enter one to five touch inputs simultaneously, but some capacitive touchscreens can process even more.

Capacitive touchscreens deliver brighter, higher contrast images due to the makeup of their panels. Displays with capacitive touch screens are more durable than resistive touch screens because they are designed with cover glass on their top layer. In fact, all of our capacitive TFT displays have standard 0.7mm thick built-in cover glass and can be further

While the cost is currently higher than resistive touchscreens, capacitive touchscreens are quickly becoming the industry standard in touchscreen technology.

The enhanced responsiveness can be a downside depending on how and where the display is used. For example, a capacitive touchscreen would not easily respond to the user while wearing certain types of gloves. Although capacitive touchscreens don’t respond to inorganic inputs, they can still be accidentally activated by other conductive elements. One of the the most common elements that causes interruptions is water.

Rain, humidity, and condensation on the surface of capacitive touchscreens will often cause accidental inputs and reduced accuracy until the water is removed. This is one of the main reasons why a resistive touchscreen would be chosen over a capacitive touchscreen in certain situations.

Any device that utilizes touch gestures like swiping, pinching, or multi-touch will require a capacitive touchscreen. These features often help make capacitive touchscreen displays more intuitive and user-friendly than resistive touchscreens. Capacitive touchscreens are best suited for applications requiring improved touch responsiveness with better image brightness and contrast.

sense pressure on the display"s top layer and send a signal to the circuit layer to activate the touchscreen functionality. Because they use pressure to activate the touch inputs, resistive touchscreen displays can be used with a stylus, gloves, and other items. Resistive touchscreens are built without cover glass and made of plastic, making them more susceptible to dents and scratches.

"touch event" occurs when these two layers make contact with each other (closing the circuit) by the user"s action of pressing into the soft, semi-flexible top layer. Each layer consists of horizontal and vertical lines (x,y matrix) that detects the exact location of the touch.

The gap or space layer typically consists of air or inert gas and some spacers whose only purpose is to separate the soft top layer from the bottom layer.

Resistive touchscreens are often seen as the less advanced variety of touch panel compared to capacitive touch panels. However, being able to interact with non-organic inputs keeps these touchscreens relevant in specific industries.

Resistive touchscreen displays are less sensitive than capacitive touchscreen displays. This is considered an advantage in some cases and is why they’re chosen for specific applications. Resistive touchscreens will not respond to accidental inputs from the environment, so they won’t be interrupted by things like water spills or lightweight debris landing on the screen.

This type of touchscreen requires more intentional inputs from the user, making them more reliable in rugged and unstable environments. For example, a resistive touchscreen is the perfect solution on a construction site where water or debris might land on the screen. They’re also the best touchscreen display option for situations where the user is wearing gloves.

Resistive touchscreen panels are unfortunately more susceptible to dents and scratches. Their poor visibility in direct sunlight does not make them ideal for outdoor applications. Their inability to respond to multi-touch inputs can be a disadvantage in fast-paced applications requiring such. Because resistive touchscreens rely on the pressure applied to the top layer, they tend to be abused and mishandled, which makes them less durable over time than capacitive touchscreens.

Resistive touchscreen technology is ideal for low-cost applications involving rugged environments, indirect sunlight, and simple touch features. Fewer accidental touch inputs, better resistance to heat and moisture, and the ability to be operated with pretty much anything (stylus, pen, gloves, fingers, etc.) make this touchscreen technology a more reliable solution when user input is crucial.

While it’s clear that capacitive touchscreens are dominating the consumer electronics market, resistive touchscreens still have an advantage in some ways.

If you’re looking for a cost-effective touchscreen that can operate with simple tap inputs in rugged environments, resistive is the way to go. For more advanced and intuitive touchscreen technology with higher quality applications, choose capacitive touchscreens.

Selecting the most suitable type of touch screen for your project can improve device functionality and durability, which can mean a significant increase in customer adoption.

This article highlights the unique advantages and drawbacks of common touch screen technology, to help product design engineers make an informed decision.

Resistive touch is a legacy form of touch screen technology that was broadly popular for many years, but has been replaced by capacitive touch for many applications. Currently, resistive touch has a smaller range of common uses, but can still capably address certain needs.

The core elements of a resistive touch screen are two substrate layers, separated by a gap filled with either air or an inert gas. A flexible film-based substrate is always used for the top layer, while the bottom layers substrate can be either film or glass. A conductive material is applied to the inner-facing sides of the substrate layers, across from the air gap.

When a user applies pressure to the top surface, the film indents and causes the conductive material on the top layer to make an electrical contact with the conductive surface of the bottom layer. This activity creates a difference in voltage that the system registers as a touch. The location of this contact is pinpointed on the X and Y axes, and the touch controller then interprets the action. Because physical force is needed for a resistive touch screen to function, it is similar to a mechanical switch.

Resistive touch screens must be calibrated before they are used to ensure accurate and reliable operation. A user must apply pressure to the four corners of the screen, and sometimes on its center, to calibrate the screen with the rest of the system via a lookup database.

Because resistive touch screens interpret physical pressure as a touch, they are effective in a variety of environments using single touch. Any object capable of applying force to the screen can be used with the same result. For example, in applications where end users wear gloves, resistive touch screens offer reliable single-touch functionality.

Since resistive touch screens area actuated via mechanical force, they continue to function as intended even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens. For example, on single-touch applications within agricultural equipment, boats and underwater machinery.

Besides the functional advantages of resistive touch screens, price is a common reason why OEMs select this option. In projects where cost is a top concern, companies can use this option to realize savings that may not be possible with alternatives.

The configuration of a resistive touch screen removes the possibility of gestures, such as pinching and zooming, or any actions requiring multi-touch functionality. These screens cannot determine the location of a touch if more than one input is present.

In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens were invented before resistive touch screens. However, early iterations of this technology were prone to sensing false touches and creating noise that interfered with other nearby electronics. Due to these limitations, resistive touch screens and other options, like infrared touch screens, dominated the industry.

With more development and refinement of controller ICs, projected capacitive (PCAP) touch screens became the preferred touch technology for a majority of applications. For example, this technology is now commonly used on tablets, laptops and smartphones. Though PCAP stands for “projected capacitive (PCAP) touch”, it’s more commonly referred to as “capacitive touch”.

The foundation of PCAP touch screens is an array of conductors that create an electromagnetic field. As a user touches a PCAP screen, the conductive finger or object pulls or adds charge to that field, changing its strength. A touch controller measures the location of this change and then instructs the system to take a certain action, depending on the type of input received.

For a device with PCAP touch technology to acknowledge an input, users simply need to touch the screen. No physical pressure is required, unlike resistive touch screens.

Another key difference from resistive touch technology is that PCAP screens can accommodate a variety of inputs, with different gestures and more contact points instructing the system to take a variety of actions. PCAP touch can support multi-touch functionality, swipes, pinches, and zoom gestures which aren’t possible with resistive touch screens.

A PCAP touch screen is very similar to a solid state switch, as its mechanism of action requires a change in the electrical field over a control point.

The value that comes with recognizing multiple inputs is a clear and positive differentiator for PCAP touch screens. Users can initiate a variety of commands, providing more functionality in devices where this technology is used. Consider how consumers now expect smartphones, tablets, and interactive laptop screens to support actions requiring two fingers, like pinching and zooming. In more specialized settings, such as multi-player gaming applications, PCAP touch screens can support more than 10 inputs at a single time.

PCAP touch screens do not require initial calibration, offering a simpler experience than resistive touch screens. Additionally, PCAP touch screens are highly accurate even as they support a variety of gestures and subsequent actions by the system.

Since their top layer is usually made of glass, PCAP touch screens offer a high degree of optical transmission and avoid the appearance of haze to users. Additionally, the glass top layerprovides improved durability compared to the film top layer of resistive touch screens – even for the largest sizes of up to 80 inches (and growing).

Operation in environments where a PCAP screen may be exposed to liquids or moisture — including conductive liquids like salt water — is possible through specialized controller algorithms and tuning. PCAP technology has evolved to support medical glove and thick industrial glove operation, as well as passive stylus operation.

PCAP touch screens can be customized with different cover lens materials (soda lime, super glasses, PMMA) based on application specific needs. Cover lenses can be ruggedized with chemical strengthening and substrates that improve impact resistance. This can be especially valuable for public-facing applications, like ATMs, gas pump displays, and industrial applications. Specialized films or coatings – such as AG (anti-glare), AR (anti-reflective), AF (anti-fingerprint) – can be added to the cover lens substrate to improve optical performance.

Unlike resistive touch screens, PCAP touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can’t.

If cost is a top concern for a project, PCAP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

The below table compares the advantages and disadvantages of projected capacitive touch vs resistive touch screens.CharacteristicsPCAP TouchResistive TouchRequires calibrationNoYes

As a leading manufacturer of touch and display products, New Vision Display can help you determine the specific needs of your project and tune your PCAP touchscreen controllers to meet them. Our PRECI-Touch® products are based primarily on PCAP touch technology and can be customized for a variety of applications using a wide range of materials, stacks, and controllers.

Whether your product will be used in a life-saving medical device, the center console of an automobile, or the navigation controls on a yacht – we can deliver an effective solution for your application. To get started on your project, contact our specialists today.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

You do not need to calibrate the image projector before lecturing; with LED lighting technology, IFPDs provide a clear image all the way; and thanks to the IR touchscreen, you can annotate your presentation with almost anything, a dry/wet finger, pen, or stylus.

Commonly, the overlay is a piece of protective glass hemmed in by the IR touch frame, in which Infrared LEDs and photodetectors are embedded. A kind of optical bezel will be inserted between the glass and the frame to fix the frame and transmit infrared light emitted by those LEDs.

Through the optical bezel, IR LEDs emit invisible infrared beams forming grids on the surface of the overlay, Photodetectors are installed across from the LEDs to detect interruptions of beams if touch events on the overlay happen.

There are two rows of IR LEDs, which generate horizontal and vertical invisible IR beams. They form a large beam grid that covers the surface of the overlay. In the meantime, two rows of photoreceptors are installed on the opposite side of the LEDs.

As long as an opaque object touches the surface, it will blot out the light beams. Photoreceptors in both directions (vertical and horizontal) can detect this interruption by that object, finally localize the x and y coordinates, and then send the signal to the processor to respond with relevant action.

To know more details of its structure and workings, you’d better walk into a workshop to learn its assemble process. Most of the time, we do not have that chance, however, regular maintenance work offers you the opportunity to check its components inside.

Better display – without other substance between the LCD and overlay, IR touch screens offer the best light transmission, so they can render more vivid images without color and brightness loss.

Supports multi-touch – with windows and android 9.0 double OS, it can support as many as 40 touchpoints simultaneously. That means it can support up to 4 students interacting together on an IFPD.

Short response time – commonly less than 8ms, IR touch screens localized touch events by detecting light interruption, so they are accurate and quick to respond with actions.

More flexible in customizing screen sizes – by adjusting the numbers of LEDs and photodetectors embedded in the overlay frame, you can fit any custom-made monitor with an infrared touch interface

Clear images – compared with many camera or projector-based systems, equipment with IR touch screens often adopts backlight LED. So, wherever lighting environment they perform in, they can provide clear images to the audience.

No loss of screen display– Since LEDs and sensors are designed to be fixed in the frame that is around the monitor, the screen can display an unrestricted view.

Write with any object – you can write on an IR touch screen with anything, a bare finger, a gloved finger, wet hands, or a pen, as long as it is not transparent.

No calibration – a traditional smart projector board may require regular calibration to display correct pictures, however, devices with IR touchscreen do not need to calibrate the IR LEDs and sensors to guarantee a normal function.

No pressure is required to write – Resistive touch screen technology perceives the writing track by pressure, which can damage the screen after a long time of usage, while IR touch screen technology by detecting light interruption, so you can write freely without having to push hard on the screen.

Of touch screen technologies, infrared and projected capacitive are the top two types that are mostly utilized. However, they are applied to different applications due to the differences between them.

For PCAP touch screens, There is a layer of transparent electrode film that is fixed between the LCD panel and the cover glass, when the human finger touches the screen, the current through that film changes, and the signal of x and y position will be transferred to the computer.

For IR touch screens, the equipment detects the finger’s position by detecting the block of invisible lights from the infrared LEDs that are embedded in the touchscreen frames.

So you will often see a bezel in the IR touchscreen, which is used to transfer the infrared light to the surface of the overlay, while the PCAP touchscreen does not require the bezels.

IR touchscreen can be activated by anything that is not transparent, whereas PCAP types only accept bare fingers, thin surgical gloves, or cotton gloves.

The electrode film in PCAP touchscreens is expensive, especially when it comes to large screens, but for IR ones, when it is applied to large-scale screens, you only need to add a few LEDs and correspondent detectors, apparently, the IR touchscreen solution is more cost-effective in large interactive displays, such as the interactive digital board, which are used for presentation in business meetings.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

Our industrial display touch screen monitors can help your factory personnel and workshops handle complex industrial tasks on intuitive factory grade touch screens. Our wide range of rugged LCD displays with multi-touch and various touch technologies such as resisitive, SAW, optical imaging, projected capacitive and infrared are tough and suitable for virtually any industrial applications. We can help you choose the best touch screen technology and solution that fits best with your needs, and close the gap between your vision and implementation of the digital factory.

Viewsonic"s Touch Screen Solutions helped us simplify the hassle of operating complex machinery in our factory. It really helped us improve our factory line operations and reduced labor input.”

Why buy a portable monitor? For starters, they are becoming a popular way to work on the go. There is an unmistakable benefit to extended screen space when it comes to working on your laptop or even converting a smartphone into a computer. But there are so many other portable monitor uses ranging from one-on-one presentations to improving the readouts on specialized devices.

Learn more about portable monitors below or check out one of ViewSonic’s models. For a high-quality portable display, check out theVG1655or get a touchscreen version with theTD1655.

A portable monitor can be a great addition to either a mobile work solution or a lean desktop setup. They are a great way to extend a laptop screen or scale up a mobile device. With the right features, they can both boost productivity and improve the entertainment experience.

But it’s important to know what you’re getting into to get the right portable display for you. What features do you need? What will you be using it for? There are a lot of questions to answer.

If you’ve already decided to get a portable monitor, you know exactly why you want it. But for anyone still wondering what all the hype is about, there’s a lot to love about portable monitors.

In essence, people want to increase the screen space they have to work with. Use cases range from work and study to gaming and other entertainment. Portable monitors are an easy way to extend a laptop screen or increase the display size for a mobile device. And they are (obviously) a whole lot more portable than a desktop monitor, which makes them a great option for a tech-savvy person who needs more display real estate on the go.

Just like with any device, not all portable monitors are created equal. However, there are certain features that you should absolutely look for when finding the right portable monitor for you.

Size is a major consideration for portable monitors. Many are bigger than standard laptop screens, but it’s important to remember what you’ll be using the second screen for. Is it meant to be a second screen for the kids in the car? Smaller and more portable may work better for you. Are you editing photos or videos away from your desk? Then a big (and higher quality) screen may be what you’re looking for.

Weight is also a consideration if you’re going to be carrying your second screen around with you. A pound or two (or a few hundred grams) may not seem like much until you have to take it on an 8-hour hike to your mountaintop photo shoot.

Screen quality is also going to matter. If all you’re looking to do is watch Netflix or do impromptu one-on-one meetings, then you might not need 4K resolution. If you’re going to be sifting through hundreds of lines of code or editing media, then you’re probably going to want a high-resolution IPS portable monitor.

Orientation control is also very valuable in a portable monitor, especially for photo editing and coding. By turning the monitor from landscape to portrait, you make it easier to see the whole photo you’re working on. Or use it to quickly scan long blocks of code at a glance. There’s even a good chance that your desktop monitor doesn’t have this feature (unless it has good ergonomic design), which could make a portable monitor part of your regular workstation as well.

Connectivity is probably the most important feature. After all, what good is a monitor you can’t plug into your devices? And while it may be helpful to have HDMI or DisplayPort compatibility, the new standard is a USB-C connection. Able to transfer both power and huge amounts of data, a USB-C cable is a must for your portable monitor. Learn more about USB-C and how it compares to other monitor ports.

Touchscreen input is also nice to have (and a common feature in many portable monitors), especially if you plan to use it to supplement creative work or collaborate in small teams. Combined with a digital whiteboarding software, it can become a multi-purpose tool for creating, modifying, and presenting content yourself or as part of a team.

According to the Graziadio Business Review (article here), there are at least three ways increased screen size improve productivity: increased insights into data, more time for primary tasks, and decreased stress levels for better solutions. And while this study looked at monitor size, it’s safe to assume that overall screen size also has a significant impact.

Even if one screen is used as a workspace while the other is used as a communication space, you can save a significant amount of time that was previously wasted on task switching. There are almost certainly diminishing returns on adding more screens, but there is an unmistakable improvement in workflow with more screen real estate.

Even hobbyist photographers find it frustrating previewing photos on their camera’s tiny 2” LCD screens. It simply isn’t an option for professional media creators. A portable monitor connected to a camera, however, lets photographers and videographers check their footage right away on a larger, higher-quality display.

In a firm of 100 to 500 employees, an average of 7 people are involved in most buying decisions. That means either one medium-sized sales meeting or a few very small ones. And nothing is more professional than being prepared. Having your own presentation display – even a smaller one for small meetings – is a total power move.

And if that portable display also includes a touchscreen, it becomes more than a passive display. You and team members can now use it to produce content together or interact with presentations more directly with direct input. It opens up all-new avenues of 1-on-1 communication.

Mobile devices are now an ever-present feature of modern life. However, the tiny touchscreen of a phone or even most tablets can feel terribly inadequate. A portable monitor can give you a full-sized experience from even your smallest devices.

A portable monitor can even make your phone feel more like a computer. With the addition of a Bluetooth keyboard and productivity apps like Google Docs or Microsoft Word, even basic smartphones can become a productivity powerhouse. Some tech companies are even taking it to the next level, like Samsung’s DeX that turns the phone into a fully functioning computer when plugged into a USB-C monitor.

A less productive but equally popular use for portable monitors is entertainment. While we now live in a world where screens are everywhere, something is lost from the experience when watching a movie or playing a game from a tiny mobile device. A portable monitor is a great way to expand a mobile screen for a bit of fun on the go. Perfect for road trips, camping, or even a replacement for in-flight entertainment, a portable monitor is a great way to upgrade mobile viewing experiences.

As screen technology improves, users are expecting clearer displays on their devices. A fuzzy LCD screen just isn’t enough anymore. However, with the right adaptors – and often right out of the box – it’s possible to upgrade everything from medical sensors to cashier’s counters with a portable monitor or touchscreen display.

At the very least, an external portable monitor improves the look of an out-of-date device or beautifies the space. In some contexts – like as a readout on portable medical devices or as part of a mobile wayfinding system – a well-placed portable monitor expansion can save time, money, and even lives.

So why buy a portable monitor? They’re handy for either work or play, and they are pretty versatile devices in a number of specialized tasks. However, even if your needs don’t fall into the typical portable monitor uses, most people would benefit from an additional computer screen. A portable monitor may be a better fit for your lifestyle or workflow than a bulky desktop screen.

If you’re shopping around for a portable monitor, take a look at ViewSonic’s VG1655 for an extra display on the go or the touchscreen TD1655 for a more interactive device.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey