lcd panel backlight not working in stock

When an LED backlight doesn;t work, it is a bgi issue. An LCD backlight is a solution to make a LCD readable when there is not enough outside light. The LED backlight is the most common type of backlight used in character, static and mono graphic displays and illuminates the LCD from the side or back of the display. Backlights are used in displays to increase visibility in low light conditions. Most LCD’s that are equipped with a backlight employ a diffuser (similar to a lamp shade) to provide a more even light from the LED’s.

It is not uncommon when designing your product to have the LCD work, but it seems the LED backlight doesn"t work. Chances are the backlight still works, but isincorrectly connected.

LED backlights require Direct Current (DC), which means you must connect the positive of the backlight to the positive supply of your power supply. And the negative of the backlight to the negative supply of your power supply.

Connect one wire of the LED backlight to pin 15 and the other wire to pin 16. Turn on the power. If this does not work, turn off the power and reverse the wires.

Connect one wire of the LED backlight to pin #1 and the other wire to pin #2. Turn on the power. If this does not work, turn off the power and reverse the wires

When possible, we recommend designing your product so that pins 15 and 16 are used for the backlight. It is possible to power the backlight with pins 1 and 2, but this is the supply voltage for the LCD and we do not recommend this.

If, after reading this article and trying the steps outlined, you still find your LED backlight doesn"t work, call us. We"d be pleased to help. FocusLCDs.com carries standard LCDs in stock and in many cases can ship the same day. Call us today for help at 480-503-4295

Most likely the inverter cable shorted in the hinge and blowed the logic board"s microfuse that protects the inverter circuitry. I"ve been able to find the microfuse location on the 1197Ghz, 1.2Ghz and on one of the two 1.33Ghz revision models. Look at the left of the inverter socket on the logic board, the microfuse has letters TH written on it. Use a multimeter and check the continuity. If there"s no continuity then the fuse is blown. Bridging the microfuse with a wire should restore the power to the inverter socket then to the inverter board and the backlight if nothing else is damaged on the logic board.

Most hardware operates at voltages between 1.8 V - 5.2 V. However, the backlight circuit operates at about 15 - 20 V. At this higher voltage, the backlight components are more prone to damage when a short circuit occurs. The high voltage backlight circuit is also prone to corrosion from water damage.

The backlight diode - Like the backlight filters, the backlight diode is a fragile component. In cases where a backlight filter is particularly burned up, you’ll often find that the diode has failed as well. Diode failure in the absence of filter damage is rare, but it can happen.

The most common cause of a self-induced short occurs from working on the device with the battery still connected. Even when the screen is dark, there is voltage in the backlight circuit. A slipped pair of tweezers or misalignment of the LCD connector can short the backlight circuit to ground. Avoid self-induced shorts by always disconnecting the battery before working on a device.

Another cause of backlight shorts is faulty assembly procedures. During device fabrication, these solder joints are protected by piece of black tape—however, during the screen refurbishing process some manufacturers neglect to replace the tape, apply it misaligned, or fail to apply it securely. As a result, the screen initially works during testing—but once the metal LCD shield is installed, the exposed solder joints touch the grounded frame, shorting the backlight circuit.

Backlight shorts can occur when the latch for the ZIF connector securing the LCD flex is missing. The LCD flex slides out an angle and the high voltage backlight pin contacts the ground pin, causing a short circuit.

Water damage is a frequent source of backlight problems. Water will corrode the LCD connector pin/pad junction, which breaks the electrical path to the connector and can damage the filter.

Backlight circuit failure can also occur from damage to the electrical traces on the circuit board. If the electrical traces buried in the board are inadvertently severed—for example, from trying to fasten the board with too large a screw—the backlight circuit will not conduct power to the backlight LEDs.

To diagnose whether your device is “dead” or just has a malfunctioning screen, try connecting it to your computer. If the computer recognizes the device, then the problem probably resides with the LCD screen or backlight circuit.

The good news is that nearly all backlight failures are repairable. Once the damaged component is identified it can simply be replaced. Follow this Samsung Television Backlight Replacement guide for more details.

This content is almost entirely sourced from Reed Danis and his iPhone/iPad Backlight Troubleshooting page. Users were finding this content when searching for TV related backlight issues so we repurposed it for TV.

The 17" Dell LCD monitor I found was no exception. When I first plugged it in, it would cycle power on and off continuously, with a notable burning smell. Further inspection revealed a fried power transistor. When i replaced it, the monitor stayed on, but the backlight would flicker on and off, then finally shut off after a few seconds..

For the panel light filters, there should be some diffusing paper/plastic behind the LCD, 3 sheets (one clear, one reflective, one translucent white), and then a large Plexiglass-like filter. I removed the Plexiglass and everything behind it, only keeping the 3 thin paper-like sheets behind the LCD. Shining a light behind the LCD resulted in an even white glow

4) Relocate the boards from the LCD panel to the CRT shell, mount LCD panel, and connect everything up. For mounting everything I drilled holes and used zip ties.

The LCD frame was smaller than the CRT"s. I just cut out some cardboard to fill in the gaps to block out the light for now. I know, it looks ugly. Later, I"ll make a better looking frame.

This would be great for building a cheap MAME arcade cabinet... dead LCD"s are easily found for super cheap... and you"d have lots of room behind it to mount your light source.

One thing to be very careful with is the tube in the CRT. If one does not know how to disarm it properly, it can implode then explode. Very dangerous. There is a proper way to "air a CRT", but you have to know how to do it.0

This is so ghetto. lol No offense. Great idea! I guess you could use any box with heat ventilation to keep the bulb cool and not light up the whole room.0

I don"t mean to be a spolisport, but... why? The whole point of an LCD monitor is that it is thin and saves on desk space. You just made it as big as a CRT monitor, out of a CRT monitor. Why not just use the CRT monitor instead?

One functioning screen is better than two dead ones. CCFL bulbs bought from a reputable place can cost upwards of $70. I"m going to try to wire an LED array to get a screen of mine working. If that doesn"t work, I may do this. SO MUCH potential in a dead screen.0

I wonder what would happen if you had a plexiglass panel and drilled holes on the edges. then in those holes you place superbright white leds, then on one side of the panel you put a tinfoil sheet. would that make an even light? because the leds arnt facing the screen. you could also sand down the frotn of the panel to make it less clear0

Great idea ! For a better illumination try to use fluorescent bulbs ( the old ones like tubes) and in front of them put a laminating foil unheated. This is a mate surface and it will make the light to distribute uniformly. The led solution is not good because the led is omnidirectional, and you will see the spot where the led is.

Nice one. I May be able to get hold of an LCD with dead back light. I wasn"t too sure about how to go about reviving it. May try using supa-bright LEDS for back light and some sort of diffuser.0

i only have the sme thing as same as the finish one aove,but when i turned on the power seems like nothings happened,i know there somethin i didnt door something wrong i did please advice thanksMore CommentsPost Comment

Ever had your TV showing nothing but a black screen even if the audio was working? Unfortunately, that’s a common issue with low/middle-end LCD/LED TVs these days… Even more frustrating, this issue often comes from a rather tiny and cheap component that can be easily replaced. Most common issues are:

The first step into repair is to find the root cause of the issue. As backlight failure is a very common issue, this is the first thing to test. To do so, the easiest way is to power on your screen, put a flashlight very close to it and check if you can see the image through. The image would be very dark, like turning the brightness of the screen very very low.

That implies disassembling the TV to access the backlight which is between the LCD screen in the front and the boards in the rear. In my case, with a Samsung F5000, I had to process as follows:

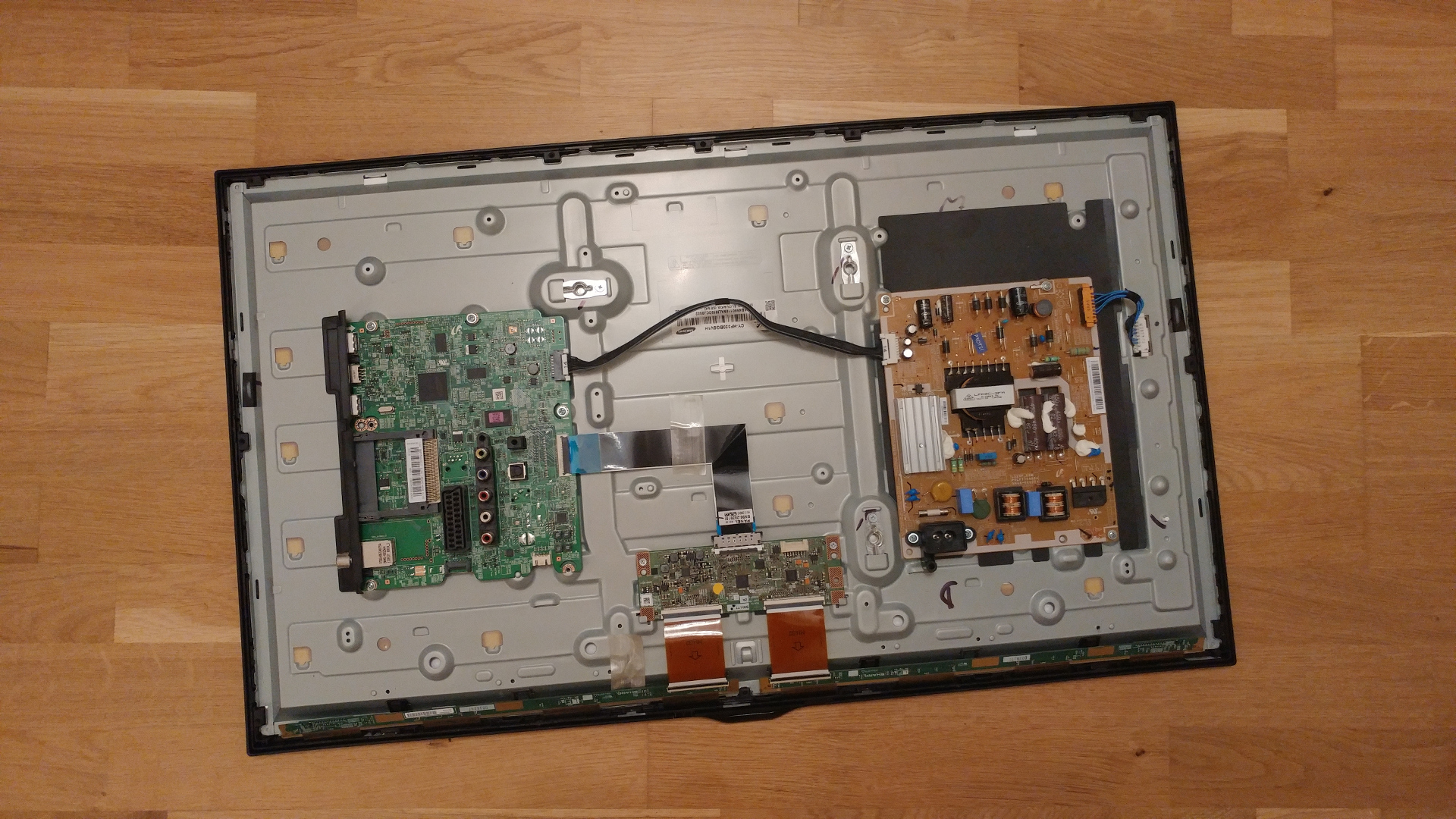

First we have to remove the back housing to reveal the boards (from left to right: main board, T-CON, power supply) and disconnect the LCD panel from the T-CON board.

Note: Older TVs have neon tubes for backlight, which is thicker and less exposed to this kind of failure. LED backlight is the most common thing these days, but do not mistake an LED TV with an OLED TV. The first one is a classic LCD panel with a LED backlight, whereas the second is an OLED panel that doesn’t need any backlight as it is integrated in each pixels (making the spare parts much more expensive by the way).

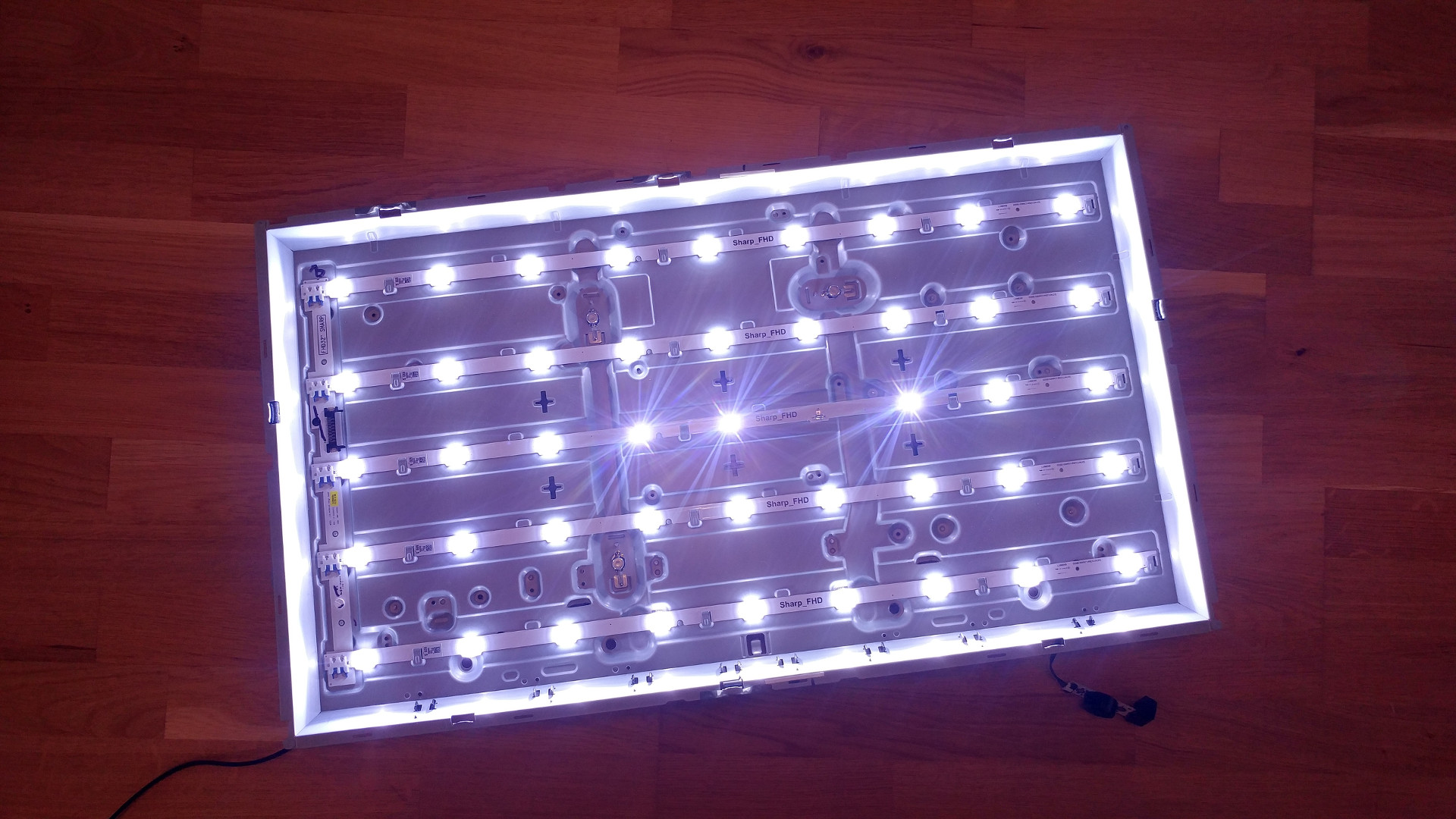

As we can see, the backlight system is made of 5 LED strips. First thing to do is look for burnt LEDs. Most LED backlight systems have strips set in series, meaning that if one of the them fails, all the system goes dark…

One LED like those ones typically needs between 2.5-3.6v input voltage to light up. By looking up this model online, I found out that the ones used on those strips need 3.6v; so as there are 9 LEDs per strip: 3.6 x 9 = 32.4v input voltage required to light a single strip. That’s the maximum voltage we do NOT want to exceed, otherwise LEDs could be damaged during testing.

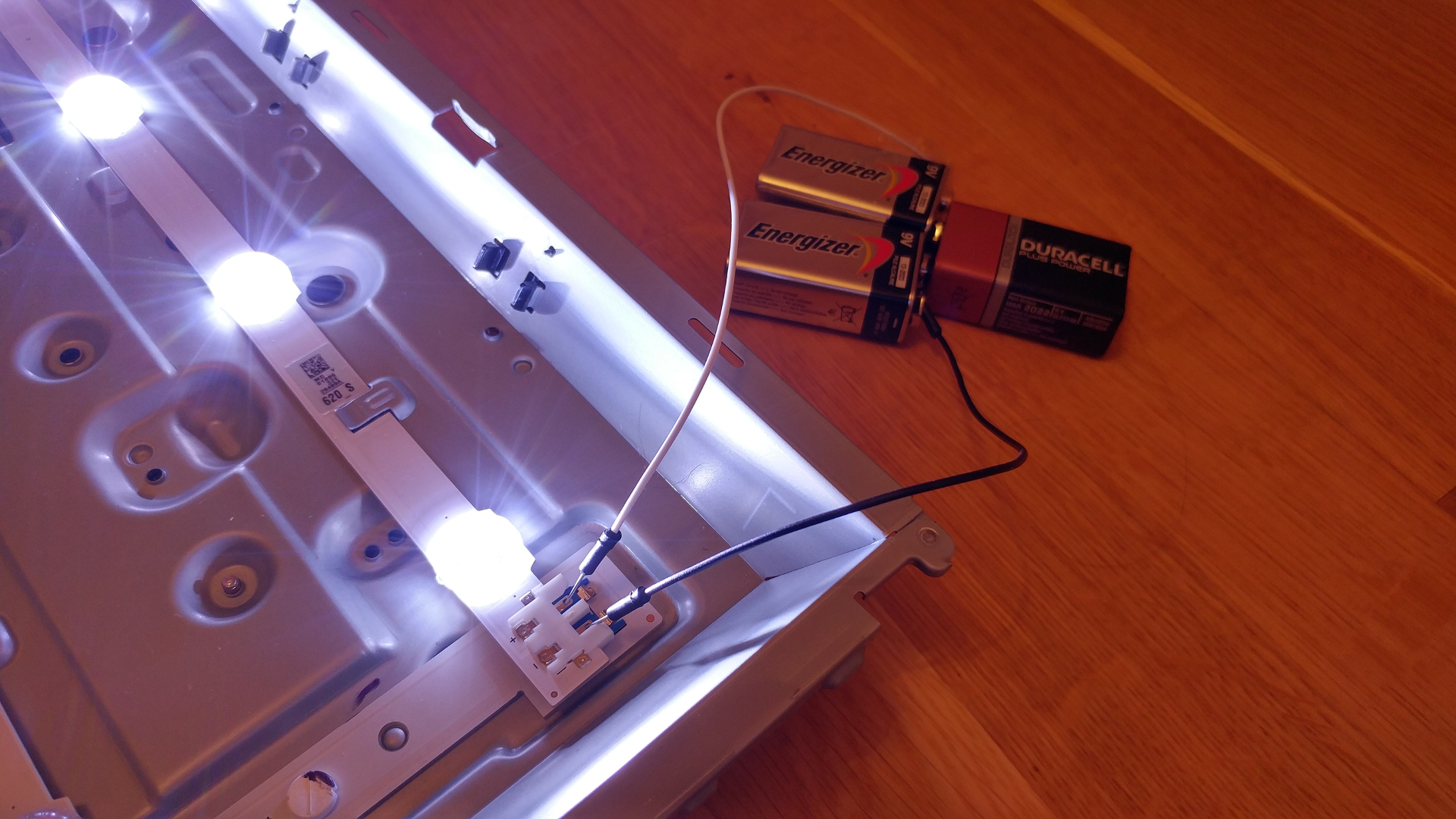

So, I took 3 9v batteries that were laying in a drawer, put them in series to make a virtual 27v battery (3 x 9v). It’s less then the optimal 32.4v required but not that much lower, it might be able to light the strip a bit so we can identify which is not working. Here is a look at the set-up:

Now we simply have to test each strips individually to see if they light up or not. For each that doesn’t completly, it will mean it has at least one defective LED.

After repeating this operation on all strips, I found only 1 defective LED, the same we thought looked burnt when we first had a look at the backlight (3rd strip from the top, 6th LED from the left). For a better understanding at what a burnt LED looks like here are 2 pictures of a burnt one and an OK one. Mind the roasted color compared to the regular one.

For starters I’ll go with the third one, just to make sure there is no other issues with the TV, but afterwards it’s better to replace the LED with a new one, otherwise you might notice a darker spot on the image.

We manufacture and stock backlight assemblies for many Innolux LCD panels. We produce premium quality replacements to extend the life of your flat panel screen devices. If you do not see your panel model listed here, please contact us to learn about our cost effective design and manufacturing process. Simply mail us a sample of the backlight you are looking to replace, and we can recreate and supply you with what you need to meet you needs.

Laptops, computer screens, tablets, notebooks. Is your display not lighting up? Maybe it is getting dim or even starting to have a reddish or pinkish hue, maybe it has completely gone dark. The good news: you need a new CCFL backlight lamp and we have them. We stock LCD backlight bulbs for most LCDs. The backlight repair is actually easier than you think, and once you replace the CCFL lamp in your LCD you have essentially restored your LCD display to new condition, as bright and vibrant as it was the first day you got it. And best of all, one less old LCD panel in a landfill somewhere! Call us today, we are here to help (402) 330-2222.

Nearly every piece of Industrial equipment now made has an LCD control panel of some sort. Expensive equipment like CNC machines, heavy machinery, industrial control panels, medial and military displays, sewing machines, food processing equipment, you name it! What they also have in common is they are all heavily used and the LCD displays eventually fail. The equipment manufacturers charge exorbitant amounts for new displays, but the fact is all that is needed is new CCFL backlights. Install a new CCFL lamp assembly and your critical piece of equipment is back on line.

ATMs, amusement displays such as casino gaming, video games, juke boxes, and kiosks- these LCD displays are notorious for failure due to the 24 hour high demand usage. Again, a new CCFL lamp, and they are back up and running like new. CCFL Warehouse supplies CCFL backlights to many of the largest LCD display repair companies in the world. Our high-quality CCFL lamps are trusted for ultra long life in these demanding environments. If you do not find the exact CCFL lamp that you need on our website, drop us an email or give us a call, we will make it for you.

There is a reason all of the most respected LCD repair facilities in the country, both big and small, purchase their CCFL Backlight lamps from us, quite simply our expertise in the area of LCD backlights is simply unparalleled. Not only do we stock more cold cathode fluorescent lamps than any other company, produce the highest quality lamps, offer exceptional pricing, but we are here to help!

Quite simply, we are the experts in CCFL lamps and LCD backlighting, that is all we do and anything we can do to help you in your repair efforts we are more than happy to accommodate.

CCFLwarehouse.com is the single largest CCFL backlight supplier in North America. We specialize in CCFL lamps, producing the highest quality lamps available and stocking them in high volumes so that they are available for our customer when they need them. Our lamps are used all over the world by a wide range of clients, some just looking to get their laptop back up and running and others who operate some of the largest repair facilities in the world. Whatever your backlight repair needs, we can help.

Our CCFL lamps are designed specifically for repairs of LCD panels made by many of largest LCD panel manufacturers in the world such as: AU Optronics (AUO), Samsung, Sanyo, LG, Innolux, Torisan, Sharp, Che Mei, Chunghwa, NEC, Mitsubishi, Toshiba, Boe Hydis, Hitachi, Fujitsu, HannStar and many more.

In addition we stock LCD backlights specific for the repair of laptop and notebook computers and desktop monitors. Our CCFL lamps are used to repair LCD panels in all major computer brands such as; Acer, Asus, Gateway, Dell, Hewlett Packard (HP), Compaq, Lenova, Apple, Sony, BenQ, Alien Ware, Sager, Quanta, Clevo, and many more.

NOTE: When SupportAssist does not show up in the search results, go to the SupportAssist for PCs and tablets page for information about downloading and installing SupportAssist.

If the issue persists on the other monitor it may be due to the video card (GPU) or video settings and not the monitor, go to the step Verify display or video issue in Windows Safe Mode. Else go to the next step.

Performance issues may occur if there is any type of damage that is caused to the display cables or the LCD screen. LCD screen may show that symptoms like LCD screen stops working, work intermittently, color mismatch, flickering, display horizontal or vertical lines if there is damage to the display cables or the LCD screen.

If you do notice a physical damage, contact Dell Technical Support to learn more about repair options that are available in your region. If there is no damage, go to the next step.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry image, horizontal or vertical lines, color fade, it is a good practice to isolate the monitor by running a diagnostic test on the Dell monitor.

NOTE: Self-test feature check (SFTC) helps check if the Dell monitor is working normally as a stand-alone device. To check for screen abnormalities such as flickering, distortion, clarity issues, fuzzy or blurry image, horizontal or vertical lines, color fade, and so on, run the integrated self-test (BIST) or integrated diagnostic (BID) test.

NOTE: In certain Dell monitors, the integrated self-test (BIST) or integrated diagnostics (BID) can be run only when one or more video cables are unplugged and the Dell monitor is in self-test mode.

NOTE: Connect the USB upstream cable from your Dell touch-capable monitor to a working USB port on the computer. This is essential for the touch feature to work.

If the diagnostic tests on the Dell monitor and video card (GPU) passed, it is most definitely an issue that is related to software that is installed on your computer. If the above troubleshooting steps did not resolve the issue, to restore your computer to factory defaults as a last resort.

Note: If your MacBook Pro has any damage which impairs the service, that issue will need to be repaired first. In some cases, there may be a cost associated with the repair.

I replaced the backlight in my ThinkPad last year some time and it"s still going strong. It"s really not that hard, just be VERY careful to take note of where everything comes apart so you can put it all back together in the right way again.

And go to extra lengths to make sure you do not have dust between the glass when reassembling! That is the only mistake I made, and now there are flecks of schmutz on my screen which I cannot get off, because they aren"t really ON it, but IN it!

I had thought my laptop was dead beyond rescue. Especially when a local repair shop told me they don"t do monitors because it"s not worth it. But it was relatively quick, easy (though intricate) and saved FAR more money than the mere $15.00 I spent to repair it. Honestly I"m not sure why repair shops DON"T do this, as it would be a procedure on which they could have a pretty high profit-margin. Whatever...

I am very new to RPi and hardware add-ons. However I purchased a Adafruit RGB 16x2 LCD screen (with buttons) just for fun to poke around. I followed the tutorial here as thoroughly as possible.

However upon testing the screen displayed nothing! So I thought hmm, maybe it"s not working. But then I just tried turning the contrast up and lo and behold I could barely see some text on the screen like I expected to see. The only problem is that the backlight is not working and I have no idea where to start looking for the issue.

Since it affects the backlighting only is there any specific soldering point I should check? I would assume the top right and where the LCD goes in the top middle are where I should start?

Edit: And yes, I did run the software. Hence how I noticed by turning the contrast up, I was barely able to see the text the software put out. Backlight is just off. :/

According to the provided photo, I believe that the backlighting pins are at the right end of the LCD"s pins row (traces to three resistors on the top right side.

there are not so many solder points that checking them all out is unworkable, and any solder point affecting the I/O expander chip might take it enough out of order, to also prevent turning on the backlight.

Also, make sure your resistors are 220 Ohm, not 220K!I used the provided resistors in the kit. I would assume they gave me the right ones. I"ll check up on all the solder points though, unsure how bad they need to be in order to short something though!

the right side of each resistor should have a low voltage on it for the backlight to turn on, as this LCD seems to have three colored LED"s I"m a bit surprised none o them turn on! Pin 15 of the LCD should have the full VCC on it (5V).

Looking further at the assembly, I forgot to mention this is a Blue&White LCD, I guess I got confused by the product number printed on the package as it leads to http://www.adafruit.com/products/1109

edit2: Nevermind, that"s what I get for not reading source thoroughly. It was attempting to use a color I apparently don"t have, and because of that the screen turns off. Thanks anyway! Now to fix the up button which I believe I didn"t seat properly.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey