lcd display no backlight manufacturer

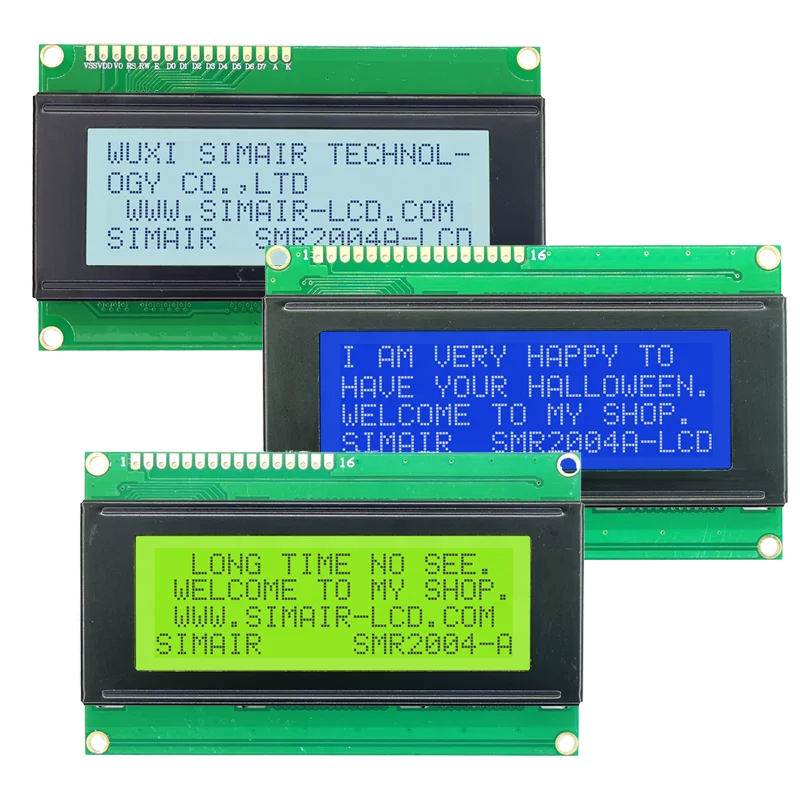

Compared with lcd displays in bulk available, Alibaba.com offers both options of them. For lcd displays and bulk functions, Lcd displays provide more functions and are aesthetically pleasing.

Both lcd displays and Lcd enable similar functions and arefabricated from the source. Lcd displays, on the other hand, are more conventional and can be used for a variety of purposes.

Find wholesale lcd displays in bulk, Alibaba.com offers a wide variety of options. For the buyers who are looking for a more portable LCD display in bulk, that are the for.imum brightness in the future. Many lcd displays in bulk will have a better brightness future than.

Unlike conventional displays, lcd displays offer more buttons and interfaces for other information, as well as a mechanism. Find a variety of lcd displays available on Alibaba.com to stock and stock lcd displays with different features, such as touch sensitive, light-emitting diodesal, or LED signals.

A wide variety of lcd screen without backlight options are available to you, You can also choose from original manufacturer, odm lcd screen without backlight,As well as from tft, ips, and standard.

As a specialist in transparent Displays we are often asked whether T-LCDs can be used in ambient light, i.e. without a backlit showcase box which it does as you can see in the video attached. But clearly the image quality is not as crisp and bright without a backlight directly behind the display. For some clients this made it difficult to make a decision on the way forward so we made this specific video so you and any other viewers can see just how good it is in standard normal ambient light!

Clearly if it is a bright sunny day then the image quality will improve in line with the amount of increased ambient light on the back of the display.

This just shows the quality of the transparent screen with direct sunlight rather than LED backlighting, still looking great but obviously offering a lower % of transparency than LED backlights would give. This is why we always encourage LED lighting when customers ask for our advice on lighting and how transparent displays work without lighting and in shop windows. Below is an example of how the panels look but obviously it is not sunny all year long in the UK, as in many other countries, unfortunately.

For more information on our Transparent LCD products or our transparent display products please contact us via email or simply call our UK office on +44(0)1634 791 600

Newhaven 128x64 graphic Chip-On-Glass (COG) Liquid Crystal Display shows dark pixels on a gray background. This reflective LCD Display is visible with high ambient light while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C12864B2Z-RN-FBW display has an optimal view of 6:00 and has no backlight. This display operates at 3V supply voltage and is RoHS compliant.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

Newhaven 40x4 character Liquid Crystal Display shows characters with dark pixels on a gray background. This reflective LCD Display is visible with high ambient light while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0440AZ-RN-FBW display has an optimal view of 6:00 and has no backlight. This display operates at 5 supply voltage and is RoHS compliant.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

LED backlighting is the most commonly used backlight for small, LCD panels. Light-emitting diodes, or LEDs, are practical components for a light source because of their small size. LED backlighting is popular due to its overall low cost, long life, variety of colors and high brightness.

LED backlights are housed in a light box that has a diffuser to evenly distribute the LED light. The light box is then mounted behind the LCD’s viewing area. The LED backlight comes in two configurations: array and edge lit. The array configuration has the LEDs mounted in a uniform, grid layout within the light box. This configuration gives off a very bright, even light. The disadvantage of an array configuration is that it requires a thick light box design to accommodate the number of LEDs required. The high number of LEDs in this configuration also means it consumes more power.

The other configuration for LED backlights is edge lit. An edge lit configuration is the most commonly used construction for LED backlights. This configuration mounts the LEDs along one edge of the light box. The layout results in a thin design. Edge lit also uses less LEDs overall and therefore consumes less power than an array configuration.

Another type of backlight options is the use of fiber optic technology. Fiber optic backlights use sheets of fiber optic woven cloth and are bundled by a ferrule (metal cap) to an LED or halogen light source. Advantages for the fiber optic technology includes low voltage, low power, and a very uniform brightness. This type of backlighting is ideal for custom display shapes or sizes however it is priced at a higher cost compared to other technologies available.

A third type of backlight option available uses an electroluminescent (EL) panel. The EL backlight is constructed of a series of different material layers that work together to create the light. The EL panel generates light when an electric current (AC power) is applied to its conductive surfaces. The advantage with EL backlighting is its low power consumption, no heat emission, and overall thin composition. EL backlighting is limiting in that it requires an invertor to generate the VAC needed to emit the light.

The last common backlight option available are cold cathode fluorescent lamps (CCFLs). CCFL backlights are a cost effective option typically found in graphic displays. The CCFL backlight for LCDs is usually configured with the lamp on the edge of a diffuser to distribute the light. An inverter is required to supply the voltage required by the fluorescent lamp. CCFLs offer a bright white light with low power consumption. This backlight option is not ideal for cold-temperature applications (less than 15°C) as the light output decreases with decreased ambient temperature.

There are many different backlight options available for your LCD. The most common types are LED, fiber optic, EL, and CCFL backlights. Cost and application of your product will have the highest influences on which backlight technology is best for your LCD.

Choosing a backlight system for LCD screen displays is a major consideration. It will determine a lot about your experience of the display and requirements during production. Different backlight options provide widely different effects in the contrast and brightness of the display. Also, depending on which backlight option you choose, it will affect some or all of the following: the cost of the overall product; how many products you will have to order due to manufacturing constraints; and how environmentally friendly the component parts are that make up the product.

The word LCD has been used to describe many display technologies. Often people believe that LCD screen displays are the same as a CRT (Cathode Ray Tube), an LED Display (Light Emitting Diode) or a Plasma display. This is not the case! Let’s discuss what an LCD is and what it is not.

Think of the liquid crystal display (LCD) as a window blind. Positioned in one direction the blinds allow light to pass through, or turned another direction they block the light. Just like a window blind, the LCD does not create its own light, it only blocks or allows it to pass through.

As you know, you can adjust the blinds to alter the amount of light desired. When fully closed, the blinds block light completely; when open, all light passes through; and when angled, partial light comes in. An LCD works similarly to this, with one significant enhancement: an LCD has the ability to block light in some areas and allow light to pass in other locations of the glass. An example of this is the display used on a gas pump. The customer sees numbers where the light is blocked, and a clear area where the light is allowed to pass through.

LCD’s are not CRT’s, LED’s, nor are they Plasma displays. Each of these types of displays produces their own light and are called emissive displays. Emissive displays require more power than an LCD.

Emissive displays have a distinct advantage in that they can be seen clearly at night whereas LCD’s cannot. However, the solution to this problem of low-light visibility is to install a backlight behind the LCD. Backlights do require more power than the LCD itself, but they can be turned on only when necessary. Many products that are powered by batteries will have the backlight dim or shut off after a certain amount of time. This can be seen on cell phones and watches. Consequently, even though a little more power is used for the backlight than used in a stand-alone LCD, because it is not constantly on, the LCD’s with backlights wind up using less power than their emissive display competitors. LCD screen displays using backlights become the clear choice.

This option is the most popular for products that have a lower power budget. Products that run on battery need to conserve power and the lowest powered backlight available is to have no backlight at all.

The Amazon Kindle is a perfect example. The Kindle makes use of a display technology called ‘e-paper’, which looks more like a printed page than any other device on the market currently. This specific e-book reader does not contain a backlight. Because it omits the backlight it can operate up to one month without recharging. Imagine, you could take it on a cruise to Fiji and back and never have to worry about recharging it!

Thinking back to your product, not all products can omit a backlight; in fact it may require one. If it does need a backlight the most popular option is an LED.

LED backlights are made up of an array of LED’s. They come in a variety of colors including red, green, yellow, amber, blue, white and R/G/B (Red/Green/Blue). From the R/G/B trio any color in the rainbow can be made.

The majority of the LED backlight colors will operate with a half-life of 50K to 70K hours. (Remember, half-life is when the light will be half as bright as when it was first turned on. This is not when the LED will burn out.) Blue and white LED’s do have a shorter half-life than other colors. Presently, they are rated at 30K hours. That means that if you turned them on today and left them on, in 3.4 years they would be half as bright as they are today! One thing to take into account is that as technology improves, the lifetime of the LED’s will become longer, which will also increase the half-life. Below is a photo of a blue LED backlight.

To make LED’s display correctly, they are placed behind the LCD screen display in an array pattern. The challenge is that LED’s, similar to a light bulb, project a beam of light which can show spots of light. These spots are called hot spots. This can be an issue with LED’s since they will make the display look like it has polka dots. Below is a photo of a LED behind the LCD glass. This problem will be solved with the use of a diffuser.

EL (Electro Luminescent) backlights, also known as ELP’s (Electroluminescence Panel), have been used as a backlight for LCD’s for several years. They are available in a range of colors with white being the most popular. EL technology makes use of colored phosphors to generate light. They require AC (alternating current) rating of 100VAC @ 400Hz.

In the last three to four years, EL backlights have decreased in popularity. There are several reasons for this drop in popularity.The EL backlight requires an inverter to convert DC to AC. The cost of the inverter increases the cost of the overall LCD Display.

The half-life of an EL is an estimated 3,000 to 5,000 hours. (Once again, half-life is when the backlight is half as bright as when it was first turned on.)

LCD screen display manufacturers now require an MOQ (Minimum Order Quantity) of no less than 500 displays for orders that include EL backlights. This MOQ number is likely to increase in the future as this type of backlight becomes less popular. Additionally, as the demand drops the price will naturally increase.

This technology has been in use for many years, but in the last few years the popularity of this type of backlight has decreased. There are a few reasons why this is so.Similar to EL backlights, this technology operates on AC.

The majority of LCD screen display manufacturers no longer offer CCFL as an option. There are too many negatives and not enough positives to their use. The suppliers that do offer this now require a very high MOQ (Minimum Order Quantity).

When choosing the type of backlight for your LCD screen displays it is important to keep in mind MOQ’s and future availability. Make sure you are choosing a technology with a future so that your product has one too!

LCD Panel are used for TV,Personal Computer, Mobile Phone, Degital Camera etc widely. LCD Panel can not emit light by itself. To emit light, it need the backlight(light source) on the back of LCD Panel. Minebea develops and manufactures the parts used for backlight and backlight using LED light source,for Mobile phone, PC application.

As below picture,Backligt are made with some optical parts.Key parts of Backligtht Unit are light guide plate and housing frame. Minebea"s principal competitive advantages are its ultraprecision machining and mass production technologies. Injection mold die need sub-micron ultraprecision machining and stable injection mold technologies.Minebea has amassed precision ball bearing"s technologies enables it to achieve levels of precision unmatched by its competitors. Minebea also uses these technologies for in-house parts, modl die,tooling and product of Backlight Unit.The function of light guide plate are transforming positional light source to surface light on display uniformly and efficiently.It realize optical design by own optical simulation and independently developed design program. Minebea assembles Backlight Unit by the technologies it put parts into limited space, greatly contributing to the precision and reliability. Minebea put into force exhaustive environmental control at Thai and China factories and enable manufacturing the bulk of Backlight with high quality and stable supply.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

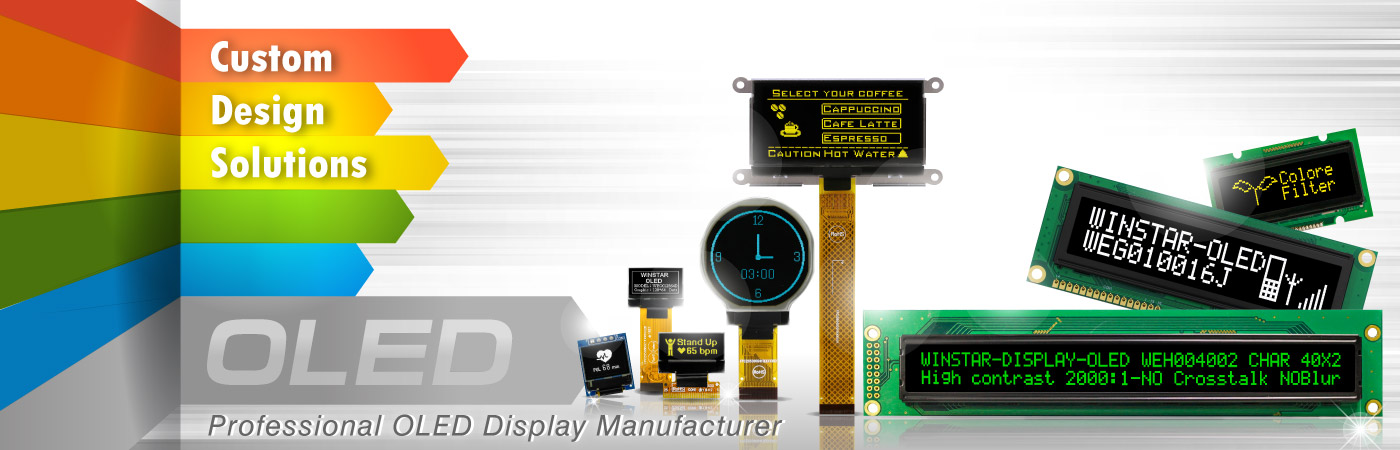

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

Cantwell, John; Hayashi, Takabumi (January 4, 2019). Paradigm Shift in Technologies and Innovation Systems. Springer Nature. ISBN 9789813293502 – via Google Books.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Dr Pan: Hello, Greg. LED backlight is the light source for LCD screen since it can’t emit light by itself. It is an optical component and non-standard product which is attached to the back of LCD. LED backlight can also be used as a separate lighting device. For example: backlight keyboard, smart lighting socket and currently fashionable backlight capacitive switch.

Liquid Crystal monomers don’t have protein. Their chemical structures look like below. The effect of these chemicals shows in MSDS (Material Safety Data Sheet).

– In Proceedings of the National Academy of Sciences, Giesy’s research team assembled and analyzed a comprehensive list of 362 commonly used liquid crystal monomers gathered from 10 different industries and examined each chemical for its potential toxicity. When inhaled or ingested, these toxic chemicals can build up in the body over time with toxic effects, potentially causing digestive problems and other health issues.

-“These chemicals are semi-liquid and can get into the environment at any time during manufacturing and recycling, and they are vaporized during burning,” said University of Saskatchewan environmental toxicologist and lead author John Giesy in a press release. “Now we also know that these chemicals are being released by products just by using them.”

-The researchers found the specific monomers isolated from the smartphones were potentially hazardous to animals and the environment. In lab testing, the chemicals were found to have properties known to inhibit animals’ ability to digest nutrients and to disrupt the proper functioning of the gallbladder and thyroid–similar to dioxins and flame retardants which are known to cause toxic effects in humans and wildlife.

-To be clear, the researchers didn’t observe any adverse health effects from the accumulation of liquid crystals in the human body; they only found that these crystals do in fact leak from devices, and that they have the potential to be toxic. “We don’t know yet whether this a problem, but we do know that people are being exposed, and these chemicals have the potential to cause adverse effects,” said Giesy.

-Any artificial chemicals have potential hazard to human health. If you read the notes of your prescription drug, the statement is likely more alarming than above.

-If you crack LCD screens and find the liquid crystal leakage, don’t panic. Just remember that the liquid crystal materials might not be more toxic than your detergents for stove or washroom. Just wash your hands with soup throughout. Never try to play with it or even worse to taste it. The liquid of the cracked computer screen will not evaporate, no emissions worries.

-Any electronics has environment impact and can’t be used landfills. If you want to get rid of old LCD monitors or LCD TVs, give them to electronic collection stations. Let’s the professionals to handle them. They will extract some precious metals/parts and make them into something useful or at least not hazard. FYI, liquid crystal materials are retrievable.

DASUNG"s 3rd Generation E-ink Monitor-Paperlike 3 (Paperlike HD), 13.3” E-ink Screen (Carta & Flexible), 2200*1650 Retina Display. Just Like a Real Paper. Fast nearly as LCD. No Back Light. No Blue Light. No Screen Flash. You can Type, Code, Browse the Web, etc. Work well with any Equipment (HDMI). Support PC/ Mac/ iPhone/ iPad and so on.It is the best monitor to protect your eyes.

This DASUNG"s Paperlike HD monitor uses electronic paper. For those not familiar with this technology it is also sometimes called "electronic ink or electrophoretic display, are display devices that mimic the appearance of ordinary ink on paper. Unlike conventional flat panel displays that emit light, electronic paper displays reflect light like paper. This may make them more comfortable to read, and provide a wider viewing angle than most light-emitting displays. The contrast ratio in electronic displays available as of 2008 approaches newspaper, and newly (2008) developed displays are slightly better. An ideal e-paper display can be read in direct sunlight without the image appearing to fade."

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey