lcd modules low temperature quotation

At low temperatures, the liquid crystal fluid maintains its viscosity, allowing the IC to refresh the data logic without any latency in the response time. At the high extreme of the operating temperature spectrum, the polarizer and adhesive materials are able to withstand the heat without warping the film and damaging the optical performance of the LCD module.

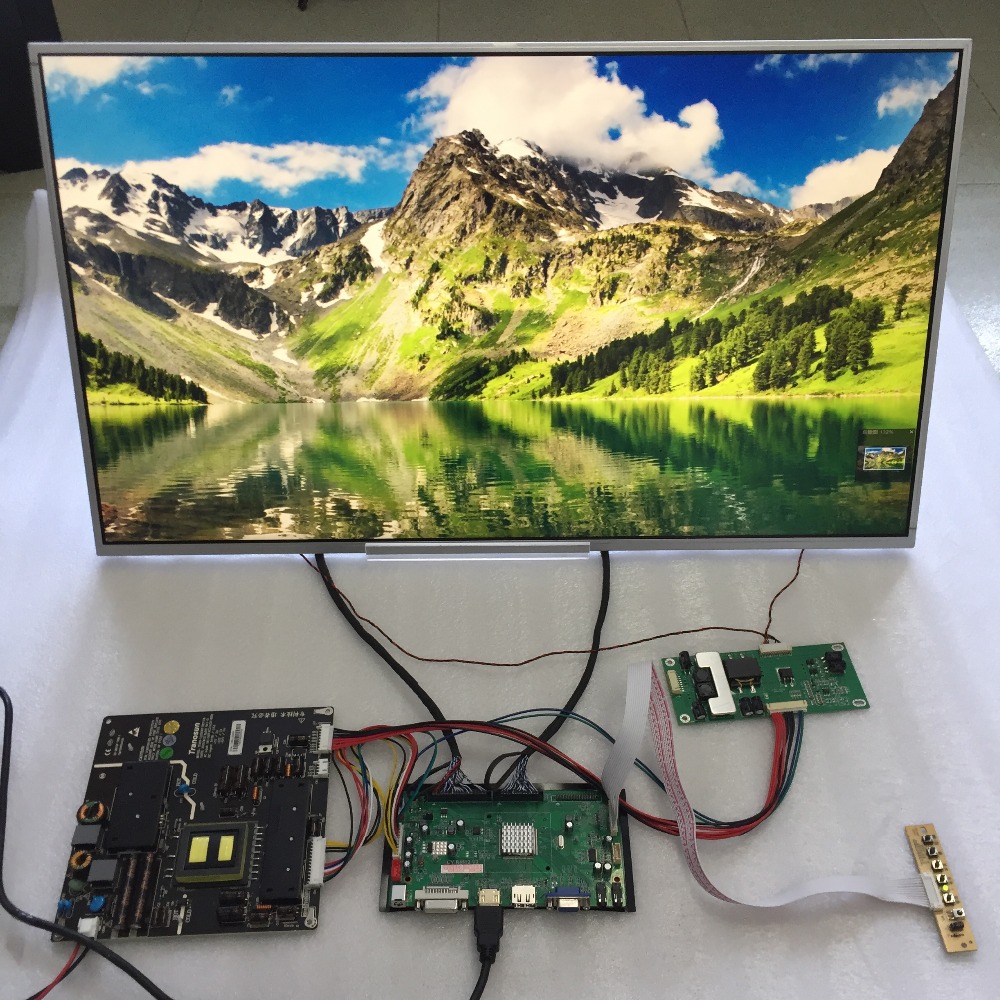

In addition to meeting the stringent quality requirements to withstand high temperature and humidity exposure, our displays also support “smart management” features, in form of a visual interface designed to help control the overall PV or EV application.

Are you tired of squinting at a fuzzy, low-quality screen that strains your eyes and makes you want to hurl your computer across the room? Fear not, my friends, because we have the solution to all of your screen-related woes: the LCD screen! But not just any LCD screen, oh no. We"re talking about the top 5 must-have features for an LCD screen that will revolutionize your viewing experience. Buckle up and get ready to feast your eyes on some seriously impressive technology.

LCD panel is an advanced glass product that has precise and specific orientation processing. If the panel is under tremendous pressure, the orientation of the panel may be disturbed and it is very difficult to return to the original state. If it is dropped on a floor or hit on a hard object, it is very easy to be cracked or broken.

b. When glass LCD panel is installed in the enclosure, you must be careful and not put excess pressure on the glass with your fingers. Otherwise, it may shorten the using time of LCD screen because of the mistaken operation.

d. You should be careful when you touch the polarizer film because it is very tender and susceptible to be damage. You should remove the protective film which protects the polarizer film before you install the LCD panel.

a. It should avoid being stored in a hot and humid conditions. If it is going to be stored for a long time, it should be stored at a temperature between 15 ℃ to 35 ℃ and humidity less than 65%.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

The first step is to select temperature sensors that can be affixed to the display while being small enough to fit within a restricted envelope. Thermistors, thermocouples, or RTDs are all options to consider since they represent relatively low-cost and high-reliability ways to measure the display’s surface temperature. These types of sensors also provide an electrical output that can be calibrated for the desired temperature range.

The next step is to determine the number of temperature sensors and their approximate location on the display. It’s recommended that a minimum of two temperature sensors be used to control the heater. By using multiple sensors, this provides the circuit redundancy and allows for a weighted average of the temperature measurement to mitigate non-uniform heating. Depending on the temperature sensors location, and the thermal mass of the materials involved, the control loop can be optimized to properly control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Insulating materials, air gaps, or other means can be incorporated in the design to manage the way heat travels throughout your system on the way toward an eventual “steady state” condition. During development, prototypes can be built with numerous temperature sensors to map the heat transfer, allowing for the optimal placement of temperature sensors, an adequately sized heater, and a properly controlled feedback loop.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

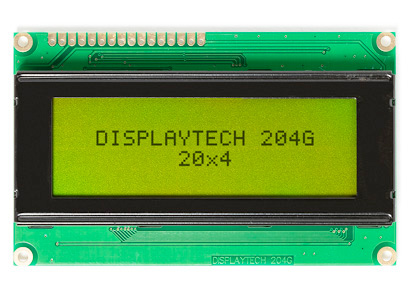

The Displaytech 204G series is a lineup of 20x4 character LCD modules. These modules have a 98x60 mm outer dimension with 77x25.2 mm viewing area on the display. The 204G 20x4 LCD displays are available in STN or FSTN LCD modes with or without an LED backlight. The backlight color options include yellow green, white, blue, pure green, or amber color. Get a free quote direct from Displaytech for a 20x4 character LCD display from the 204G series.

Character LCD Displays (aka Alphanumeric) are one of the most common display technologies available and for that reason we hold inventory for samples and prototypes in our Chandler, Arizona location.

Our team of LCD specialists can assist you in selecting the best options so that your design is able to meet your needs and at a cost that is within your budget. Call today with any questions.

One reason for the popularity of Character LCD displays is that they are equipped with a controller/driver chip containing a built in character (or font) table.

The table holds preloaded letters, numbers, and punctuation for each language. The font table allows the designer to request any character by addressing (selecting) the number of that character. In other words, the letter capital ‘T’ may be assigned the number 31 and the “&” symbol could be assigned number 141. This eliminates the work required to create each charter from scratch and reduces the amount of time necessary to program the LCD module.

The LCD you choose for your new design sets the perceived value of your product. Think about it: The first thing your customer looks at when they are deciding whether to purchase your product, is the LCD display. If it looks good, then your product looks good.

The opposite of a negative mode is positive mode where the background is a lighter color such as yellow/green or grey and the characters/icons/segments are a darker color like black or dark blue.

Negative mode displays must have a backlight on all the time to be readable. The challenge is that the LED backlight will draw/drain 10 times more power than the LCD without a backlight. So, if this is a battery application, it is best to stick with a positive mode.

Positive mode displays are readable without a backlight if there is enough ambient light. The LCD without a backlight will draw around 1uA. LED backlights can draw as little as 15mA up to 75mA or more depending on the number and brightness of the LEDs.

The first question to answer is ‘what size of LCD?’ The larger the display the more information that can be displayed and the larger the characters can be. We recommend you choose one of the standard sizes on this page to reduce cost and lead time. Focus Display Solutions (aka FocusLCDs) carries many of the industry standard sizes in inventory and may be able to ship the same day.

Character LCD Displays are built in standard configurations such as 8×1, 20×2 and 40×4. The two numbers identify the number of characters in each row and then the number of rows. An example of this is a 20×2 which means there are 20 characters in each row and there are two rows. This will provide you a total of 40 characters. The more characters there are on the display, the more drivers are required to drive the LCD. The controller and drivers are included with the LCD.

Note: It is possible to program the software to scroll your letters and numbers across the screen, allowing you to choose a smaller sized LCD and still display all your information.

It is possible to custom build a unique combination such as a 12×2 or a 16×8. This would be considered a custom LCD and would require a one-time tooling cost and possibly a higher MOQ. Go to our

Character LCD modules are available in two temperature ranges, Normal (for indoor use) and Extended (for outdoor use). The outdoor version will continue to operate down to -30C. The cost difference between normal and wide (extended) temperature range is 5% to 7% higher for the extended versions. In most cases, if cost is not critical, we recommend that you incorporate the wider temperature version.

There are three types of backlights available for a character LCD module: No backlight; LED; or EL backlight. Before introducing the various backlight options, it is helpful to cover two terms that are common for backlights: NITs and half-life.

Engineers designing a battery powered product may request a character module with no backlight since the backlight draws more than ten times (10x) the power required for the LCD alone. The goal with a battery powered product is to conserve power and extend the life-time of the battery.

If the product needs to be readable in the dark or low light conditions, then it will be necessary to attach a backlight of one type or another. The best way to conserve power is to keep the amount of time the backlight is on to a minimum. Turn off the backlight as soon as the user no longer needs it. This is a common practice in cell phones. The backlight turns off a few seconds after the number is dialed or the phone is answered. The person using the phone will continue to talk, but the display will be dark.

DC Current – LEDs are driven by DC (Direct Current), which is the same type of power required for the character LCD logic voltage. Also, batteries supply DC which makes it easy to integrate the LED backlight with a battery. EL backlights require an AC (Alternating Current) to operate. The AC signal needs to be generated by an inverter. The added inverter increases the cost of the display and produces electrical noise that can interfere with neighboring circuits.

Dimmable – LED backlights are easily dimmable; the user can adjust the brightness by reducing the driving current supplied to the LED. The ability to dim the backlight allows the user of your product to select different brightness levels. An example would of this might be a higher brightness while plugged into an outlet, and a dimmer brightness if battery driven. This is a common practice for cell phones. The backlight will be at full brightness for the first few seconds and then dimmed for the next few seconds. Note: Cell phones use OLED or

Character LCDs that include an EL (ElectroLuminescent) backlight are not as common and their popularity is decreasing. EL backlights are AC driven which requires an inverter to be supplied by the customer or attached to the LCD. Their half-life is rated at 3K hours which makes this a poor choice for products where the backlight will be on all the time. Their MOQ (Minimum Order Quantities) have increased in the last few years. At this time there is a 500 piece MOQ.

There are some key advantages to EL backlights. They are very thin, around one to two millimeters in thickness. And they provide a very even flow of light. We carry inventory on a few EL character displays, but the majority of the character displays we sell are LED.

There are several possible combinations of background colors. The most common color options are yellow/green; green/grey; blue/white; black/white; and RGB (Red/Green/Blue).

A character LCD is constructed by placing the nematic fluid between two layers of ITO (Indium tin oxide) glass. The function of the fluid is to either block or allow light to pass through.

A TN (Twisted Nematic) monochrome LCDs is the lowest cost option. TN does not provide a very sharp contrast and has a smaller viewing angle then STN or FSTN. A smaller viewing angle means the display is readable if you look directly at it, but if you rotate it more than 40 degrees in either direction, the characters will be difficult to read.

An advantage of TN is faster response time than STN and FSTN and its ability to operate at lower temperatures. We recommend this fluid for applications that will operate at extremely low temperatures.

STN (Super Twisted Nematic) fluid is the most popular option. It provides a sharper contrast and a wider viewing angle than TN. Below is a photo of a STN 16 x2 character display.

FSTN monochrome character LCD displays are assembled by taking the STN fluid and adding a film or retardation coating to the glass. This produces a sharper contrast than STN. FSTN is more popular on higher end products such as medical applications. Below is a photo of a FSTN 16×2 monochrome LCD

There are three types of polarizers: Reflective; Transflective; and Transmissive. The correct polarizer is determined by the various lighting conditions your character LCD display will operate in.

The job of the polarizer is to allow some light to pass through and some of the light to be reflected. Depending on where your display will be operating, will decide which polarizer to choose. There is no cost difference between the three polarizers. Below is a quick summary:

A reflective polarizer cannot be used with a LED backlight or EL backlight since it will not allow any of the light to pass through, but it is possible to use with a LED edge-lit or side-lit display. An advantage of an edge-lit display is that it is thinner than a LED backlight, but not as thin as a display equipped with an EL backlight.

V Logic is the voltage used to drive an LCD and draws very little current, somewhere around 1mA or less. Character displays can be driven with a VL at 3.3V or 5V.

V LED is the voltage used to drive the LED backlight only. This can be 3.3V or 5V. LED backlights can draw up to ten times (10X) the amount of current of just the LCD alone (VLCD). If your product is a battery application, the backlight should be turned off when not in use. Or build in a sensor that only turns it on in the dark.

Is it possible to drive the LCD and the LED backlight from the same connection, but not recommended since interference from the LED backlight could affect the performance of the LCD.

3.3V is popular for battery applications since it can be driven by two ‘AA’ batteries. The downside is their performance suffers in colder temperatures and may require a heater to continue operation.

Choose a 5V if your product will operate in colder temperatures and you have unlimited power. In other words, if your product is plugged into a wall or car battery and there is no concern for battery drain.

A key advantage of character LCDs over multicolor technology such as TFT (Thin Film Transistor) and OLED (Organic Light Emitting Diodes) it their low thirst for current.

When the ambient temperature of the display drops too low, the display’s performance suffers. The colder the fluid in the display, the slower the response. At some point, the display freezes up and the characters no longer change.

As long as the temperature doesn’t drop too low, there will be no damage to the display, and it will return to normal operation when the temperature rises.

This is a transparent film that lays across the top layer of the ITO glass. It provides an even flow of heat and is the most effective heating solution. However, it is also the most expensive heating solution.

This is a much more affordable solution. A small PCB (Printed Circuit Board) is attached to the back of the LCD. The board is populated with several quarter watt resistors in series that generate heat. This option draws a great deal of power. In fact, it draws more than most LED backlights.

Believe it or not, LEDs do generate heat, but nothing close to resistors or heater film. In some cases, it is enough to give the display a little extra warmth to keep it operating when the temperature drops below its threshold.

Nothing saves heat and power like insulation. Putting your LCD into something that breaks the wind and holds in the heat, will save your batteries. Many times, a protected display will continue to operate even when the temperature drops far below the threshold. This should always be the first step taken when worrying about display functionality at low temperatures. Once your product is insulated, the heat producing options noted above can be implemented.

There are three fluid types used in character LCDs: TN, STN and FSTN. TN operates the best at colder temperatures and offers a faster response time. TN does not provide the wide viewing range found in STN and FSTN, but is sufficient for most industrial uses.

The five most common types of LCD technology are: Segment, Character, Graphic, TFT and OLED. Character and Segment are the least likely options to be discontinued. They have been around for many years and are still very popular.

Used to read or write the data being transferred between the LCD and the microprocessor. Tie this to ground if you only plan to write data for one-way communications.

DB 0. Most character LCDs have eight (8) data bits for faster transfer. But can operate on just four (4) data bits if you are running low on I/O (In/Outs) pins.

Positive connection of the LED backlight or side lit. The voltage could range from 5V or 3.3V. Not all character LCDs contain a LED backlight. In this case, the two pins are no connect.

Polarity is an issue with LED backlights, since they are DC (Direct Current). That means positive must connect to positive. Half of the character LCDs have pin 15 as positive and 16 as ground. The other half are reversed. If you need the polarity reversed, there is a jumper on the back of the PCB to switch polarity.

Our lead time on standard Character LCD displays – that are not in stock – range from five to seven weeks. This rapid lead time is due to the fact that we do not ship LCD’s via boat, but FedEx Air. By shipping via FedEx Air, we receive the LCD glass within four to five days after it is completed, compared to shipping by boat which can add several additional weeks to your lead time.

Available options include: background color, backlight type, operating temperature range, driving voltage and other possible choices. These are modifications that do not require a tooling fee.

The cost to design and tool up a custom replacement LCD is much less than the cost associated with retooling a case or having to redesign the customer’s PCB to accept a different LCD. The customer may also need the exact display to repair units that are in the field.

This custom character design allows the customer to avoid any redesign cost or delays in the manufacturing of their product and to offer replacement displays for products that had been in the field for over ten years.

Character LCD displays are built in standard sizes and configurations. This makes the process of locating an equivalent LCD a simple process, but it is critical to make sure that the replacement display is a drop -in equivalent to your current display. It may not be possible to build a 100% equivalent product without some modifications.

If your current LCD supplier has discontinued your display, Focus Display Solutions (aka Focus LCDs) has the ability to cross it over to an equivalent display and in many cases Fed Ex/UPS a sample to you the same day.

Note: when you begin ordering LCD displays from Focus, we will supply you with the data sheet. If you purchase the display, you should own the data sheet.

Providing us the full part number of the LCD allows us to determine not only the size of the display, but also the type of construction such as COB (Chip on Board) or COG (Chip on Glass), number of characters, backlight option, operating temperature range, background and backlight colors, viewing angle, backlight and LCD logic voltage, and in most cases the controller driver used.

With the part number, we will attempt to locate a full data sheet with enough details allowing us to quote a replacement for your discontinued display. If we cannot locate a data sheet, we will ask if your previous supplier had provided one to you.

If we are unable to locate the data sheet of your current LCD, we will request a data sheet. If possible, please forward over the data sheet or a link to the data sheet. If your LCD supplier is no longer in business or they will not provide you the data sheet, the next option is a photo of the display.

Note: when you begin ordering LCD displays from Focus, we will supply you with the data sheet. If you purchase the display, you should own the data sheet.

The liquid crystal display (LCD) technology has been used in several electronic products over the years. There are more reasons for LCDs to be more endearing than CRTs.

The Local Temperature Display can be used with all Sensaphone 2.8k type temperature sensors. This provides an at-a-glance reading of the current temperature as well as the minimum and maximum temperatures. The display is ideal for any location where onsite staff need a quick, convenient visual reading of the sensor, saving them the time of checking the monitoring system"s data.

When the temperature falls out of the programmed high and low limits, the display triggers an audible alarm, immediately alerting onsite staff of a potential problem. This alarm is in addition to the alerts that the Sensaphone monitoring system sends to designated personnel when temperatures fall out of range.

This new display can operate in a wide temperature range -30 to +85 deg C (-22 to +185 deg. F) without any adverse effects. This is perfect for refrigeration and heating applications.

The GTWQ043C3B00PWA is based on Noritake VFD command sets. It has a combination of Noritake’s GU3000 ASCII-based text commands, full color image commands, and scalable-font compatibility. The module can work with a wide range of low and high-end micro-controllers using industry standard serial interfaces (Async., I2C, SPI, and USB).

At 2.2" diagonal, this transflective display is big enough to get all the information across. Plus, it"s readable in most lighting environments, from indoor light to direct sunlight. If you"re looking for a display that can be read in low-light situations, check out the backlight version of this display. This display has a 128x64 monochrome array, plus a row of addressed icons along the top edge of the display.

Products»All Products»Power & UPS»Batteries & Ultracapacitors»Standard DC-DC Power»Smart DC-DC Power»Smart Battery Chargers»Galvanically Isolated Power Supplies»24V Output Supplies»Ultracapacitor Chargers»Adjustable Output Power Supplies»Universal Chargers»Uninterruptible Power Supplies»Embedded Boards»I/O & Communication»Embedded CAN bus Modules»Embedded Ethernet Switches»Embedded Digital IO Modules»Embedded Analog IO Modules»Embedded Serial IO Modules»PCIe Mini Cards»Embedded Power Supplies»Standard Embedded Power»Smart Embedded Power»PC/104 Power Supplies»Embedded UPS Modules»Embedded Motherboards»PC/104 Motherboards»ETX Motherboards»COM Express Motherboards»EPIC Motherboards»EBX Motherboards»Mini-ITX Motherboards»Micro-ATX Motherboards»Industrial ATX Motherboards»Embedded GPS Modules»GPS Receiver Modules»Embedded GPS Antennas»CPU Boards & SBC»PC/104 SBC»EPIC SBC»ETX SBC»EBX SBC»Mini-ITX SBC»ARM CPU Modules»Micro-ATX SBC»Embedded ATX SBC»Com Express SBC»Embedded Ultracapacitor Modules»Embedded Battery Modules»Embedded Video Cards»Systems»Fanless Box PC»Wide Temperature»Industrial Automation Computers»Rugged Vehicle Computers»Railway Computers»Vehicle Tracking Systems»Industrial Rackmount Computers»Wide Temperature Systems»Digital Displays»Marine Monitors»Rugged LCD Displays»Wide Temperature LCD Displays»Waterproof LCD Panels»Advertising LCD Displays»Stretched Bar LCD»Sunlight Readable LCD Displays»Public Transportation LCD Displays»Railway LCD Displays»Outdoor LCD Displays»High Brightness LCD Displays»Extended Temperature LCD Displays»Industrial Monitors»Panel Computing»Marine Panel PC»Infotainment Panel PC»Wide Temperature Panel PC»HMI Panel PC»Modular Panel PC»Mobile Computing»Rugged Tablets»Rugged Windows Tablets»Rugged Android Tablets»Rugged PDA»Antennas»GPS Antennas»External GPS Antennas»Passive GPS Antennas»Active GPS Antennas»Marine GPS Antennas»Internal GPS Antennas»GNSS Antennas»GLONASS Antennas»Multi-Band Antennas»GPS-GLONASS Antennas»Iridium Antennas»GPS & RF Signal Distribution»GPS Amplifiers»Low Noise Amplifiers»GPS Receivers»Marine GPS Receivers»GPS Attenuators»GPS Combiners»GPS Splitters»Active GPS Splitters»Military GPS Splitters»Rackmount GPS Splitters»Passive GPS Splitters»Repeaters»GPS Repeaters»GLONASS Repeaters»GPS Filters»Enclosures & Chassis»PC/104 Chassis»Rugged Mini-ITX Cases»EPIC Enclosures»EBX Enclosures»Memory & Storage»Memory»Flash Storage»Industrial SSD»SATA Disk On Modules»Industrial Micro SD Cards»Industrial SD Cards»Industrial CompactFlash Cards»Sensors»Industrial Networking»Manufactured by Tri-M»Power & UPS»Standard Power Supplies»HE104: 60 Watt»HE104-DX: 60 Watt»HE104-75W: 75 Watt»HE104+DX: 108 Watt»HE-HP: 100 Watt»Smart Power Supplies (PowerOS)»HESC-SERD: 60 Watt»HESC104+: 108 Watt»HPS3512: 203 Watt»HPSP-XYZ: 240W Programmable»V12SC-SER[-UPS]»TPS1000: 35 Watt, 42 Watt»TPSi1075: 75 Watt, Isolated»TPSi1085: 85 Watt, Isolated»HPSC104-SER: 160 Watt»HESC104: 60 Watt»TPS1035»TPC1000»HPS3524»Smart UPS (PowerOS)»TUP1000: Ultracapacitor UPS»V5SC-SER-UPS: NiMh Battery UPS»UltraUPS»V12SC-SER[-UPS]»Ultra Capacitor Packs»TBP4xxx»Battery Backup Packs»BAT-NiMh45»BAT104-NiMh»BAT104-NiCd»BAT-SLA(25/45)»UltraUPS»Heavy Duty Transient Stopper»CPU Modules»I/O & Communication»Input / Output»IO104-60IN: PC104 I/O Board»IR104 PC/104 Relay Module»Communication»TCB1000 PC/104 Com Board»FlexCom104-GPS»Enclosures»VersaTainer: PC104 & EBX»CanTainer: PC104»FlexTainer: EPIC, MITX, EBX»GPS & Networking»GPS & Networking Boards»FlexCom104-GPS»Antennas»Mighty Mouse: Small GPS Antenna»Micro Mouse: Micro GPS Antenna»Big Brother»Re-Radiators»Super-Radiator»Xtreme-Radiator»Vehicle GPS Repeater»Complete System Solutions»HECS1000 System»UltraUPS Complete Backup Solution»Support Products & Accessories»PC104-T AC Termination Modules»Extract104»TS-I2C Temperature Sensor»DA104»VSX-2812 Video Modules»ISA104X1»Postcode104»Legacy Products»Distributed by Tri-M»Diamond Systems»Single Board Computers»Aurora PC/104 SBC»Helios PC/104 SBC»Neptune EPIC SBC»Pluto ETX SBC»Hercules III EBX SBC»IEI»IEI Mobile»MicroMax Computer Intelligence»San Jose Technology (SANAV)»GNSS Repeaters»RK-306»RK-106»Innodisk»GPS Networking»Litemax»Spanpixel»Durapixel»Navpixel»Aaeon Electronics»Systems»Fanless Embedded Computers»Entry-Level Box PC»ICOP Technology»ICOP-2811»VDX2-6554»VEX-6254»VSX-2812S»86Duino Enjoy Desktop 3D Printer»MPLSelector Guides»Power Selector Guide»Backup Power SelectorServices»Conformal Coating»HumiSeal 1B31»Laser Engraving & EtchingTri-M Rugged»PowerOS»Mining Applications»Mining Application Story»Rail & ITS Applications»Automation & Manufacturing»Mil-Aero Defence & Aerospace»Aerospace Application StorySupportAbout Us»About Us»Privacy PolicywebstoreTriple Programmable PSUQuote Request

ASI-T-240DA10SMN/AQ is a 2.4 inch high brightness TFT with a resolution of 240 x 320, SPI & MCU interface, IPS all-angle view and with a brightness of 1000 Nits; viewable in direct sunlight. It also features an extra wide operating temperatures of -30 to +80C; perfect for extreme environmental applications.

ASI-T-350EA10SRN/A is a 3.5 inch TFT with a resolution of 320 x 240, SPI & RGB interface and with a high brightness of 1,000 Nits and wide temperature range of -30 - +85 C.

ASI-T-430FA2F6/AY is a 4.3 inch IPS TFT with a resolution of 480 x 272, RGB interface, a brightness of 220 nits, wide operating temperature and a capacitive touch panel.

ASI-T-430MA10FN/A is a 4.3 inch TFT with a resolution of 800 x 480, IPS all view, RGB interface, a brightness of 1000 Nits with an ultra wide temperature operating and storage range.

ASI-T-430MA8F6/A is a 4.3 inch TFT with a resolution of 800 x 480, IPS all view, RGB interface, a brightness of 850 Nits, capacitive touch panel with an ultra wide temperature operating and storage range.

ASI-T-700MAKFN/A is an industrial grade, high reliability, 7 inch TFT with a resolution of 800 x 480, 24-bit RGB interface, wide temperature range, IPS all view and with a high brightness of 1000 Nits; viewable in direct sunlight.

ASI-T-10251248AKLN/D is a 10.25 inch wide TFT, with a resolution of 1280 x 480, LVDS interface, IPS all view, with wide temperature operation and storage and a high brightness of 1,000 Nits.

ASI-T-1040GA6TN/D is a 10.4 inch wide TFT, with a wide operating temperature and a resolution of 640 x 480, All View display, RGB interface and a brightness of 500 Nits.

ASI-T-1040HB4LN/D is a 10.4 inch wide TFT, with a wide operating temperature and a resolution of 800 x 600, LVDS interface and a brightness of 400 Nits.

ASI-T-1210HB4LN/D is a 12.1 inch wide TFT, with a wide operating temperature, a resolution of 800 x 600, all view display, LVDS interface and a brightness of 450 Nits.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey