a si active matrix tft lcd supplier

The most common semiconducting layer is made of amorphous silicon (a-Si). a-Si thin film transistor - liquid crystal display (TFT-LCD) has been the dominant technology for the manufacturing of active matrix TFT-LCD for over 20 years. a-Si is a low cost material in abundant supply.

a-Si is a low cost material in abundant supply. However, the electron mobility of a-Si is very low (around 1cm2/Vs) and can’t physically support high refresh rates such as the 240Hz needed for HDTV. Due to their high electron mobility, new materials such as metal oxide (MO) and low temperature polysilicon (LTPS) are now replacing a-Si to manufacture the industry’s two main types of screens: LCD and organic light-emitting diode (OLED) displays.

A wide variety of tft active matrix lcd options are available to you, You can also choose from datasheet, tft active matrix lcd,as well as from tft, ips, and lcm tft active matrix lcd,

* Product descriptions and part numbers are subject to change, and may not reflect manufacturer product changes. Please check the manufacturer"s website and use the item"s manufacturer part number to find the most up to date product description.

* Product descriptions and part numbers are subject to change, and may not reflect manufacturer product changes. Please check the manufacturer"s website and use the item"s manufacturer part number to find the most up to date product description.

Offering you a complete choice of products which include Si TFT Active Matrix LCD, 3.5" Active Matrix LCD Panel, 7" Amorphous Transmissive Tft LCD Screen, 6.7" Amorphous Si TFT Color LCD Module, PQ 3Qi-01 is a 10.1" TFT Liquid Crystal Display and TFT LCD Panel 3.45.

A si TFT active matrix LCD of 7"(diagonal dimensions) with a resolution of 800*3(RGB)*480. Features include white LED backlight and VGA and Video input.The signal interface is parallel RGB(1ch,6-bit) with wide range of display colors of 262K.

It features Transmissive type and back-light with six LEDS(Serial type) with support resolution of n 320xRGBx240 (16.7M Color) which includes 24bit parallel RGB Interface (8bit x 3).

A070VW04_V1 is an amorphous transmissive type TFT (Thin Film Transistor) LCD (Liquid crystal Display). This model is composed of TFT-LCD, driver IC, FPC (flexible printed circuit), and backlight unit.

This color LCD module is composed of amorphous silicon thin film transistor liquid crystal display panel structure with driver LSis for driving the TFT array and a backlight.Color (Red,Green,Blue) data signals from a host system e.g. signal generator are modulated into the best form for active matrix system by signal processing board, and sent to the driver LSIs which drive the individual TFT arrays.

This 10.1” TFT Liquid Crystal Display module supports 1024 x RGB x 600 Wide-SVGA (WSVGA) mode and can display 262,144 colors.This module also supports two low power modes: a transflective mode with lower color and a reflective black and white (64 grayscales) mode. In reflective mode the screens shows higher resolution at 3072 x 600 pixels, in transflective mode the color resolution is 1024 x RGB x 600, while the black/white/grey resolution is 3072 x 600. The converter module for the LED backlight is built in.

3.45“ color TFT-LCD panel. The 3.45“ color TFT-LCD panel is designed for camcorder, digital camera application and other electronic products which require high quality flat panel displays. This module follows RoHS.Added features include High Resolution :230,400 Dots (320 RGB x 240) . Image Reversion: Up/Down and Left/Right.

If you just need a few samples, it`s better to directly on ourAliexpress store, we are 5 stars feedback supplier with 100% Honesty. (The buy link is on the right of the product image)

Different displays have different characteristics, just tell Panox Display your application, and operating environment, Panox Display will suggest a suitable display for you.

But Panox Display is not a school, if customers don`t know the basic knowledge to design circuit board, we suggest using our controller board to drive the display.

First, you need to check whether this display has On-cell or In-cell touch panel, if has, it only needs to add a cover glass on it. If not, it needs an external touch panel.

Because the shape of the cover glass depends on the design of the clients, to avoid infringement of appearance, most of the developers need different customized touch panels.

If you don`t know or don`t want to write a display program on Raspberry Pi, it`s better to get an HDMI controller board from us, and Panox Display will send a config.txt file for reference.

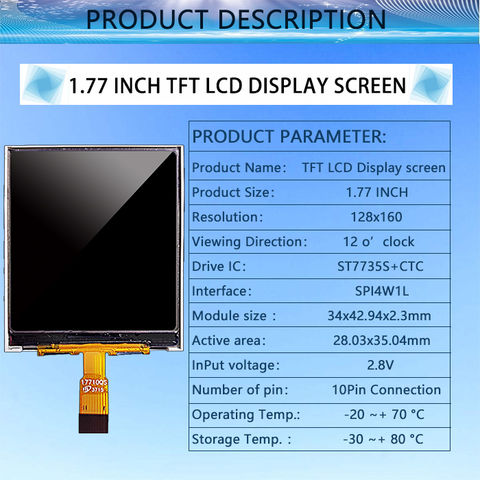

Raystar is a professional TFT (Thin Film Transistor) module manufacturer. There are different models of our TFT active matrix display with various features. Whether you need TFT display with control board, high brightness, wide viewing angle, monochrome, bar type, we have some options for you to choose from. We also offer customization service of backlight and FPC. The available diagonal sizes of our standard TFT display modules are 0.96", 1.77" 2.4", 2.8", 2.84", 3.5", 3.9", 3.97", 4.3", 4.6", 5", 5.2", 5.6", 5.7", 6.2", 7", 8", 8.88", 9",10.1", 10.2", 12.1" and 12.3.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

Color LCD module PS302-04043-00 is composed of the amorphous silicon thin film transistor liquid crystal display (a-Si TFT LCD) panel structure with driver LSIs for driving the TFT (Thin Film Transistor) array and a dual mode backlight. The a-Si TFT LCD panel structure is injected liquid crystal material into a narrow gap between the TFT array glass substrate and a color-filter glass substrate. Color (Red, Green, Blue) data signals from a host system (e.g. signal generator, etc.) are modulated into best form for active matrix system by a signal processing board, and sent to the driver LSIs which drive the individual TFT arrays. The TFT array as an electro-optical switch regulates the amount of transmitted light from the backlight assembly, when it is controlled by data signals. Color images are created by regulating the amount of transmitted light through the TFT array of red, green and blue dots.

TFT Glass has as many TFTs as the number of pixels displayed, while a Color Filter Glass has a color filter that generates color. Liquid crystals move according to the difference in voltage between the Color Filter Glass and the TFT glass. The amount of light supplied by Back Light is determined by the amount of movement of the liquid crystals in such a way as to generate a color.

Medical devices should have high contrast, high resolution, wide viewing angles, and high-quality LCD screen image displays. LCD screens will also be required to have higher brightness when used in operating rooms, emergency rooms, ICUs, and other environments that use high-brightness lighting. A newer design trend is the use of low-voltage differential signal transmission LCD modules to ensure minimal electromagnetic interference to the equipment. The industrial control screens used in medicine are generally those of Mitsubishi and AUO. Industrial control panel stability, high parameters, is the best choice for medical equipment.

Industrial screens are usually used in automatic control equipment, industrial sites, mines, oilfields, test equipment, etc. Most modules used in industrial integrated workstations range from 5.7 inches to 19 inches. The brightness of the LCD screen is usually required to be above 300, wide temperature, 4:3 thick LCD screen, industrial LCD screen, or desktop LCD screen is a better choice.

LCD provides a powerful information management platform for security monitoring. Through the integration of case high incidence areas, key protection units, police road information, monitoring information, police force configuration information, electronic maps, police identification symbols, etc., can achieve full-screen view, multi-screen browsing, touch head operation, and other functions can realize personnel, vehicles and other police resources simulation deployment. This display is also commonly used in industrial LCD screens, stable, high parameters, but in the military screen is usually equipped with a touch screen, do a full paste, to help explosion-proof, brighten.

In an era where many “manufacturers” simply resell touch screens from low-cost suppliers or outsource manufacturing to third parties, Reshine is a true Capacitive touch&Resistive touch display OEM manufacturer with 12 years of experience. Reshine Display (HK) Technology Co., Limited is a branch of Shenzhen Ruixiang Digital Technology Co., Ltd., which is a high-tech enterprise established in 2007, located in Longhua District, Shenzhen.

We are a leading designer and manufacturer of touch screens, and we have rich experiences in medical & industrial & home automation& products supply.Reshine"s mission is to be the most successful touch screen display supplier in the markets it serves.

The company has a total construction area of 4,000 square meters, with a monthly production capacity of 500,000 pieces, a production staff of 150-200 people, 5 R&D engineers, and 15 quality control personnel with 5-10 years of experience in the touch screen industry, The factory has introduced brand touch&display production equipment from the United States, Japan, South Korea, Taiwan, and a hundred-level purification workshop to ensure that the screens meet the requirements of production equipment and environment.

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

The TFT panel is composed of millions of TFT devices and ITO (In TI Oxide, a transparent conductive metal) regions arranged like a matrix, and the so-called Array refers to the region of millions of TFT devices arranged neatly, which is the panel display area. The figure below shows the structure of a TFT pixel.

No matter how the design of TFT display board changes or how the manufacturing process is simplified, its structure must have a TFT device and control liquid crystal region (if the light source is penetration-type LCD, the control liquid crystal region is ITO; but for reflective LCD, the metal with high reflection rate is used, such as Al).

The TFT device is a switch, whose function is to control the number of electrons flowing into the ITO region. When the number of electrons flowing into the ITO region reaches the desired value, the TFT device is turned off. At this time, the entire electrons are kept in the ITO region.

The figure above shows the time changes specified at each pixel point. G1 is continuously selected to be turned on by the driver IC from T1 to TN so that the source-driven IC charges TFT pixels on G1 in the order of D1, D2, and Dn. When TN +1, gATE-driven IC is selected G2 again, and source-driven IC is selected sequentially from D1.

The more vertical the Angle at which the LIQUID crystal stands, the more light will not be guided by the LIQUID crystal. Different liquid crystal standing angles will direct different amounts of light. From the above examples, the larger the angle at which the liquid crystal stands, the weaker the light that can be penetrated. (The direction of the upper and lower polarizer will determine the intensity of penetration, so as long as you understand the Angle of the liquid crystal standing will guide the intensity of light).

Undirected light is absorbed by the upper polarizer. Natural light is polarized in any direction. The function of the polarizer is to filter out most of the light oscillating in different directions and only allow light in a specific direction to pass through.

Many people don’t understand the differences between generations of TFT-LCD plants, but the principle is quite simple. The main difference between generations of plants is in the size of glass substrates, which are products cut from large glass substrates. Newer plants have larger glass substrates that can be cut to increase productivity and reduce costs, or to produce larger panels (such as TFT display LCD TV panels).

The TFT-LCD industry first emerged in Japan in the 1990s, when a process was designed and built in the country. The first-generation glass substrate is about 30 X 40 cm in size, about the size of a full-size magazine, and can be made into a 15-inch panel. By the time Acer Technology (which was later merged with Unioptronics to become AU Optronics) entered the industry in 1996, the technology had advanced to A 3.5 generation plant (G3.5) with glass substrate size of about 60 X 72 cm.Au Optronics has evolved to a sixth-generation factory (G6) process where the G6 glass substrate measures 150 X 185 cm, the size of a double bed. One G6 glass substrate can cut 30 15-inch panels, compared with the G3.5 which can cut 4 panels and G1 which can only cut one 15-inch panel, the production capacity of the sixth generation factory is enlarged, and the relative cost is reduced. In addition, the large size of the G6 glass substrate can be cut into large-sized panels, which can produce eight 32-inch LCD TV panels, increasing the diversity of panel applications. Therefore, the global TFT LCD manufacturers are all invested in the new generation of plant manufacturing technology.

The TRANSISTor-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

– The Array process in the front segment is similar to the semiconductor process, except that thin-film transistors are made on glass rather than silicon wafers.

– The middle Cell is based on the glass substrate of the front segment Array, which is combined with the glass substrate of the color filter, and liquid crystal (LC) is injected between the two glass substrates.

-The rear module assembly process is the production operation of assembling the glass after the Cell process with other components such as backlight plate, circuit, frame, etc.

The luminescence principle is tied to the vapor electroplating organic film between the transparent anode and the metal cathode. The electron and electric hole are injected, and the energy is converted into visible light by the composite between the organic film. And can match different organic materials, emit different colors of light, to achieve the requirements of the full-color display.

The organic light display can be divided into Passive Matrix (PMOLED) and Active Matrix (AMOLED) according to the driving mode. The so-called active driven OLED(AMOLED) can be visualized in the Thin Film Transistor (TFT) as a capacitor that stores signals to provide the ability to visualize the light in a grayscale.

Although the production cost and technical barriers of passive OLED are low, it is limited by the driving mode and the resolution cannot be improved. Therefore, the application product size is limited to about 5″, and the product will be limited to the market of low resolution and small size. For high precision and large picture, the active drive is mainly used. The so-called active drive is capacitive to store the signal, so when the scanning line is swept, the pixel can still maintain its original brightness. In the case of passive drive, only the pixels selected by the scan line are lit. Therefore, in an active-drive mode, OLED does not need to be driven to very high brightness, thus achieving better life performance and high resolution.OLED combined with TFT technology can realize active driving OLED, which can meet the current display market for the smoothness of screen playback, as well as higher and higher resolution requirements, fully display the above superior characteristics of OLED.

The technology to grow The TFT on the glass substrate can be amorphous Silicon (A-SI) manufacturing process and Low-Temperature Poly-Silicon (LTPS). The biggest difference between LTPS TFT and A-SI TFT is the difference between its electrical properties and the complicated manufacturing process. LTPS TFT has a higher carrier mobility rate, which means that TFT can provide more current, but its process is complicated.A-si TFT, on the other hand, although a-Si’s carrier movement rate is not as good as LTPS’s, it has a better competitive advantage in cost due to its simple and mature process.Au Optronics is the only company in the world that has successfully combined OLED with LTPS and A-SI TFT at the same time, making it a leader in active OLED technology.

Polysilicon is a silicon-based material about 0.1 to several um in size, composed of many silicon particles. In the semiconductor manufacturing industry, polysilicon should normally be treated by Low-Pressure Chemical Vapor Deposition. If the annealing process is higher than 900C, this method is known as SPC. Solid Phase Deposition. However, this method does not work in the flat display industry because the maximum temperature of the glass is only 650C. Therefore, LTPS technology is specifically applied to the manufacture of flat displays.

Let me suppose that it belongs to the SPC method. However, compared with traditional SPC, this method can produce polysilicon at low temperatures (about 500~600 C). This is because the thin layer of metal is coated before the formation of crystallization, and the metal composition plays an active role in reducing crystallization.

A method for direct deposition of Poly-film without vapor extraction. The sedimentation temperature may be below 300C. Growth mechanisms contain catalytic cracking reactions of SiH4-H2 mixtures.

This method is currently the most widely used. The Excimer laser is used for heating and melting A-SI. It contains low amounts of hydrogen and recrystallizes to Poly-film.

The LTPS membrane is much more complex than a-SI, yet the LTPS TFT is 100 times more mobile than A-SI TFT. And CMOS program can be carried out directly on a glass substrate. Here are some of the features that p-SI has over A-SI:

2. Vehicle for OLED: High mobility means that the OLED Device can provide a large driving current, so it is more suitable for an active OLED display substrate.

3. Compact module: As part of the drive circuit can be made on the glass substrate, the circuit on the PCB is relatively simple, thus saving the PCB area.

MVA technology not only improves the panel view but also solves most of the problems of gray-scale inversion due to the special arrangement mode of liquid crystals.

LCD screens are backlit to project images through color filters before they are reflected in our eye Windows. This mode of carrying backlit LCD screens, known as “penetrating” LCD screens, consumes most of the power through backlit devices. The brighter the backlight, the brighter it will appear in front of the screen, but the more power it will consume.

The “reflective” architecture USES an external light source to display the image via a reflector, which saves electricity but is harder to see in the absence of an external light source.

“Half penetration and half reflection” is the compromise between the two. The device USES a half mirror instead of the reflector, which can not only pass through the backlight but also use the reflection from the external light source to achieve the effect of saving electricity, increasing brightness, and reducing weight.

Different from the traditional manufacturing process, COG technology directly assumes the drive IC on the glass substrate. The advantages of this technology include:

ODF process is an epoch-making manufacturing method, which is time-consuming, low yield, and difficult to achieve in the past. Such as the production of large panels of TV products, in response to the rapid response of small Gap panels, or advanced high-quality MVA panels, using ODF process technology, the problem can be readily solved.

using the ODF process, we no longer need a vacuum tempering process, LIQUID crystal injection machine, sealing machine, and panel cleaning equipment after sealing.

Generally speaking, in the ODF process, the use efficiency of a LIQUID crystal is more than 95%, but compared with 60% of the traditional process, it can fully save more than 35% of the cost of liquid crystal materials. It can also save water, electricity, gas, and lotion when cleaning sealant and related panels.

The manufacturing process saved is originally the most time-consuming and time-consuming process in the traditional manufacturing process. Moreover, with the trend of large-scale panels, or high-quality panels of small Cell Gap, the time will be longer. Traditionally, Cell processes take at least three days to complete, but ODF processes take less than one day.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey