a si active matrix tft lcd quotation

* Product descriptions and part numbers are subject to change, and may not reflect manufacturer product changes. Please check the manufacturer"s website and use the item"s manufacturer part number to find the most up to date product description.

A dynamic analysis of an amorphous silicon (a-Si) Thin-Film-Transistor-Liquid-Crystal-Display (TFT-LCD) pixel is presented using new a-Si TFT model and new Liquid Crystal (LC) capacitance models for SPICE simulators. This analysis is useful to all Active Matrix LCD designers for evaluating and predicting the performance of LCD"s. The a-Si TFT model is developed to simulate important a-Si TFT characteristics such as off-leakage current, threshold voltage shift due to voltage stress and temperature, localized states behavior, and bias- and frequency-dependent gate to-source and gate-to-drain capacitance. In addition, the LC Capacitance model is developed using simplified empirical equations. The modeling procedure is useful to TFT and LCD designers who need to develop their own models. Since our experiments simulate critical TFT-LCD transient effects such as the voltage drop due to gate-to-source capacitance and dynamic off-leakage current, it is possible to accurately characterize TFT-LCD"s in the time domain. The analysis and models are applicable to today"s optical characterizations of Flat-Panel-Displays (FPD"s).

A wide variety of tft active matrix lcd options are available to you, You can also choose from datasheet, tft active matrix lcd,as well as from tft, ips, and lcm tft active matrix lcd,

Microtech Technology Company Limitedestablished in 2001,offers professional design and manufacturing services for hundreds types of Liquid Crytal Display modules and Touch Panels-TN,FSTN,TFT,RTP,CTP.With the advantages of high contrast,fast response time,wide viewable angle and low power consumption,Microtech"s products are widely used in Industrial Equipment,Medical devices,Home Intelligent Devices,Digital cameras,Video Game Devices,Instruments etc.Since its establishment,the management has been following human-oriented strategy and developing reliance among customers.To comply with these beliefs and ISO 9001:2015 standards,Microtech keeps on recruiting capable professionals,adopting advanced technology,developing new products,improving process and enhancing quality.Based on its strong R&D capacity, outstanding product quality and professional service,Microtech has won the high reputation from both mainland and oversea customers,and established long-term strategic partner relationship with them.

Our products are not only satisfy the display individuation requirement of all the mobile phone manufacturing factories in the mainland,but also meet the highly uniformity and reliability requirement to the display effect of module for many famous brands in Europe,American and Asia pacific.In addition,our products which have reached the extent of excellent quality and reliability could be applied in Automotive,Medical,Power station,Transportation,Industrial & Equipment and Office equipment for many famous enterprises in American,France,Italy,Australia,Korea and so on.

Our company have passed theISO 9001 quality system certification and SGS, RoHS, CE certification, to ensure all of our products and services are in international standard.

In order to obtain an excellent quality management team and offer our customers professional & efficient service and satisfied products,We comprehensively carry out Zero Defect quality management,implement ISO9001:2008 standards training and organize the examination /enrollment of quality management personnel national professional qualification.Our Mission "Efficient and timely service is the key to our success.Our success is tied with our client"s success. We are dedicated to provide excellent service to our customer at the most competitive prices." To provide customer a value added LCD product by stringent quality control,comprehensive technical support,and utilization of latest technology.

With our motto "Quality and Services are vital to enterpriess",Microtech aims to produce high quality LCD module to meet the customers" specific needs in all-round way.Meanwhile we seek for continuous service improvement,increase our market share,strengthen our competitiveness,and ultimately,expand our market worldwide!

Color LCD module PS302-04043-00 is composed of the amorphous silicon thin film transistor liquid crystal display (a-Si TFT LCD) panel structure with driver LSIs for driving the TFT (Thin Film Transistor) array and a dual mode backlight. The a-Si TFT LCD panel structure is injected liquid crystal material into a narrow gap between the TFT array glass substrate and a color-filter glass substrate. Color (Red, Green, Blue) data signals from a host system (e.g. signal generator, etc.) are modulated into best form for active matrix system by a signal processing board, and sent to the driver LSIs which drive the individual TFT arrays. The TFT array as an electro-optical switch regulates the amount of transmitted light from the backlight assembly, when it is controlled by data signals. Color images are created by regulating the amount of transmitted light through the TFT array of red, green and blue dots.

![]()

A si TFT active matrix LCD of 7"(diagonal dimensions) with a resolution of 800*3(RGB)*480. Features include white LED backlight and VGA and Video input.The signal interface is parallel RGB(1ch,6-bit) with wide range of display colors of 262K.

Offering you a complete choice of products which include Si TFT Active Matrix LCD, 3.5" Active Matrix LCD Panel, 7" Amorphous Transmissive Tft LCD Screen, 6.7" Amorphous Si TFT Color LCD Module, PQ 3Qi-01 is a 10.1" TFT Liquid Crystal Display and TFT LCD Panel 3.45.

A si TFT active matrix LCD of 7"(diagonal dimensions) with a resolution of 800*3(RGB)*480. Features include white LED backlight and VGA and Video input.The signal interface is parallel RGB(1ch,6-bit) with wide range of display colors of 262K.

It features Transmissive type and back-light with six LEDS(Serial type) with support resolution of n 320xRGBx240 (16.7M Color) which includes 24bit parallel RGB Interface (8bit x 3).

A070VW04_V1 is an amorphous transmissive type TFT (Thin Film Transistor) LCD (Liquid crystal Display). This model is composed of TFT-LCD, driver IC, FPC (flexible printed circuit), and backlight unit.

This color LCD module is composed of amorphous silicon thin film transistor liquid crystal display panel structure with driver LSis for driving the TFT array and a backlight.Color (Red,Green,Blue) data signals from a host system e.g. signal generator are modulated into the best form for active matrix system by signal processing board, and sent to the driver LSIs which drive the individual TFT arrays.

This 10.1” TFT Liquid Crystal Display module supports 1024 x RGB x 600 Wide-SVGA (WSVGA) mode and can display 262,144 colors.This module also supports two low power modes: a transflective mode with lower color and a reflective black and white (64 grayscales) mode. In reflective mode the screens shows higher resolution at 3072 x 600 pixels, in transflective mode the color resolution is 1024 x RGB x 600, while the black/white/grey resolution is 3072 x 600. The converter module for the LED backlight is built in.

3.45“ color TFT-LCD panel. The 3.45“ color TFT-LCD panel is designed for camcorder, digital camera application and other electronic products which require high quality flat panel displays. This module follows RoHS.Added features include High Resolution :230,400 Dots (320 RGB x 240) . Image Reversion: Up/Down and Left/Right.

Active matrix is a type of addressing scheme used in flat panel displays. In this method of switching individual elements (pixels), each pixel is attached to a transistor and capacitor actively maintaining the pixel state while other pixels are being addressed, in contrast with the older passive matrix technology in which each pixel must maintain its state passively, without being driven by circuitry.

Active matrix technology was invented by Bernard J. Lechner at RCA,MOSFETs (metal–oxide–semiconductor field-effect transistors).thin-film transistors (TFTs) by T. Peter Brody, Fang Chen Luo and their team at the Thin-Film Devices department of Westinghouse Electric Corporation in 1974, and the term was introduced into the literature in 1975.

Given an m × n matrix, the number of connectors needed to address the display is m + n (just like in passive matrix technology). Each pixel is attached to a switch-device, which actively maintains the pixel state while other pixels are being addressed, also preventing crosstalk from inadvertently changing the state of an unaddressed pixel. The most common switching devices use TFTs, i.e. a FET based on either the cheaper non-crystalline thin-film silicon (a-Si), polycrystalline silicon (poly-Si), or CdSe semiconductor material.

Another variant is to use diodes or resistors, but neither diodes (e.g. metal insulator metal diodes), nor non-linear voltage dependent resistors (i.e. varistors) are currently used with the latter not yet economical, compared to TFT.

The Macintosh Portable (1989) was perhaps the first consumer laptop to employ an active matrix panel.cathode ray tubes as a consumer display technology, virtually all TVs, computer monitors and smartphone screens that use LCD or OLED technology employ active matrix technology.

Castellano, Joseph A. (2005). Liquid gold : the story of liquid crystal displays and the creation of an industry ([Online-Ausg.] ed.). New Jersey [u.a.]: World Scientific. p. 176. ISBN 978-981-238-956-5.

Brody, T. P.; Luo, Fang Chen; Szepesi, Z. P.; Davies, D. H. (1975). "A 6 x 6-in 20-lpi electroluminescent display panel". IEEE Transactions on Electron Devices. 22 (9): 739. doi:10.1109/T-ED.1975.18214.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

T. Arai, H. Iiyori, Y. Hiromasu, M. Atsumi, S. Ioku, and K. Furuta,“Aluminium-Based Gate Structure for Active Matrix Liquid Crystal Displays,” IBM Journal of research and Development, Vol. 42, No. 3/4, pp. 491–499,1998.

Y.-F. Chen, C.-C. Chen, and K.-H. Chen “Mixed Color Sequential Technique for Reducing Color Breakup and Motion Blur Effects,” IEEE Journal of Display Technology, Vol. 3, No. 4, pp. 377–385, Dec. 2007.

W.C. Elmore, “The Transient Response of Damped Linear Networks with Particular Regard to Wideband Amplifiers,” Journal of Applied Physics, Vol. 19, No. 1, pp. 55–63, 1948.

D. Eliav, E.H.A. Langendijk, S. Swinkels, I. Baruchi, “Suppression of Color Breakup in Color-Sequential Multiple-Primary Projection Displays,” SID Digest, Vol. 36, No. 1, pp. 1510–1513, 2005.

N. Fisekovic, T. Nauta, N.J. Cornelissen, and J. Bruinink, “Improved Motion- Picture Quality of AM-LCDs Using Scanning Backlight,” Proceedings of International Display Workshops, pp. 1637–1640, 2001.

K. Fujimori, Y. Narutaki, and N. Kimura, “High-Transmissive Advanced TFT LCD Technology,” Sharp Technical Journal, No. 4, 2003. (sharpworld.com/corporate/info/rd/index.html).

H. Gleskova and S. Wagner, “DC-Bias Stressing of a-Si:H TFTs Fabricated at 150°C on Polyimide Foil,” IEEE Transactions on Electron Devices, Vol. 48, No. 8, p. 1667, 2001.

W.G. Hawkins, “Polycrystalline-Silicon Device Technology for Large Area Electronics,” IEEE Transactions on Electron Devices, Vol. 33, No. 4, pp. 447–450, 1986.

A. Hepburn, J.M. Marshall, C. Main, M.J. Powell, and C. van Berkel, “Metastable Defects in Amorphous Silicon Thin Film Transistors,” Physical Review Letters, Vol. 56, No. 20, pp. 2215–2218, 1986.

M. Hack and M.S. Shur, “Physicals Models for Amorphous-Silicon Thin Film Transistors and their Implementation in a Circuit Simulation Program,” IEEE Transactions on Electron Devices, Vol. 36, No. 12, pp. 2764–2769, 1989.

J. Hirakata, A. Shingai, Y. Tanaka, K. Ono, and T. Furuhashi, “Super-TFT-LCD for Moving Picture Images with the Blink Backlight System,” SID Digest, Vol. 32, No. 1, pp. 990–993, 2001.

Y. Igarashi, T. Yamamoto, Y. Tanaka, J. Someya, Y. Nakamura, M. Yamakawa, S. Hasegawa, Y. Nishida, and T. Kurita, “Proposal of The Perceptive Parameter Motion Picture Response Time (MPRT),” SID Digest, Vol. 34, No. 1, pp. 1039–1041, 2003.

M.D. Jacunski, M.S. Shur, and M. Hack, “Threshold Voltage, Field Effect Mobility and Gate-to-Channel Capacitance in Polysilicon TFT’s,” IEEE Transactions on Electron Devices, Vol. 43, No. 9, pp. 1433–1440, 1996.

Y. Kuo, “Amorphous Silicon Thin Film Transistors,” Thin Film Transistors: Materials and Processes, Vol. 1: Kluwer Academic Publishers, pp. 186–188, 2004.

M.-D. Ker, C.-K. Deng, and J.-L. Huang, “On-Panel Design Technique of Threshold Voltage Compensation for Output Buffer in LTPS Technology,” SID Digest, Vol. 36, No. 1, pp. 288–291, 2005.

Y. Kanemori, M. Katayama, N. Nakazawa, H. Kato, K. Yano, and Y. Fukuoka, “10.4 in.-Diagonal Color TFT-LCDs without Residual Images,” SID Digest, pp. 408–411, 1990.

K. Karim, A. Nathan, M. Hack, and W. Milne, “Drain Bias Dependence of Threshold Voltage Stability of Amorphous Silicon TFTs,” IEEE Electron Device Letters, Vol. 25, No. 4, pp. 188–190, 2004.

J.P. Krusius, D.P. Seraphim, R.G. Greene, D.S. Skinner, and B. Yost, “Approaches Toward Ultralarge FPDs,” Proceedings of IEEE, Vol. 90, No. 4, pp. 559–580, 2002.

S.-J. Kim, Y.-C. Sung, and O.-K. Kwon, “Pre-Emphasis Driving Method for Large Size and High Resolution TFT-LCDs,” SID Digest, Vol. 34, No. 1, pp. 1354–1357, 2003.

T. Krita, A. Saito, and I. Yuyama, “Consideration on perceived MTF of hold type display for moving images,” Proceedings of International Display Workshops, pp. 823–826, 1998.

S. Kawai, N. Takagi, T. Kodama, K. Asama, and S. Yanagisawa, “Amorphous Silicon Thin-Film Transistor for Liquid Crystal Display Panel,” SID Digest, pp. 42–43, 1982.

F.R. Libsch and S.-C.A. Lien, “Understanding Crosstalk in High-Resolution Color Thin-Transistor Liquid Crystal Displays,” IBM Journal of Research and Development, Vol. 42, pp. 467–479, 1998.

A.G. Lewis, D.D. Lee, and R.H. Bruce “Polysilicon TFT Circuit Design and Performance,” IEEE Journal of Solid-State Circuits, Vol. 27, No. 12, pp. 1833–1842, 1992.

B.-W. Lee, K. Song, D.-J. Park, Y. Yang, U. Min, S. Hong, C. Park, M. Hong, and K. Chung, “Mastering the Moving Image: Refreshing TFT-LCDs at 120 Hz,” SID Digest, Vol. 36, No. 1, pp. 1583–1585, 2005.

Z. Li, S. Venugopal, R. Shringarpure, D.R. Allee, and L.T. Clark, “An Analytical Lifetime Model for Digital a-Si:H Circuits,” SID Digest, Vol. 37, No.1, pp. 270–273, 2006.

M. Miyasaka and J. Stoemenos, “Excimer Laser Annealing of Amorphous and Solid-Phase-Crystallized Silicon Films,” Journal of Applied Physics, Vol. 86, pp. 5556–5565, 1999.

H. Nakagawa, “Current Trends of Flat Panel Displays Viewed from Applications,” Sharp Technical Journal, No. 4, 2003. (http://sharpworld.com/corporate/info/rd/index.html).

K. Ono, Y. Imajo, I. Mori, R. Oke, S. Kato, K. Endo, H. Ishino, and Y. Ooishi, “New IPS Technology Suitable for LCD-TVs,” SID Digest, Vol. 36, No. 1, pp. 1848–1851, 2005.

M.J. Powell, “Charge Trapping Instabilities in Amorphous Silicon-Silicon Nitride Thin Film Transistors,” Applied Physics Letters, Vol. 43, No. 6, pp. 597–599, 1983.

M.J. Powell, C.V. Berkel, and J.R. Hughes, “Time and Temperature Dependence of Instability Mechanisms in Amorphous Silicon Thin-Film Transistors,” Applied Physics Letters, Vol. 54, No. 14, pp. 1323–1325, 1989.

M.J. Powell and S.C. Deane, “Improved Defect-Pool Model for Charged Defects in Amorphous-Silicon,” Physical Review B, Vol. 48, No. 15, pp. 10815–10827, 1993.

K. Suzuki, “Compensative Addressing for Switching Distortion in a-Si TFTLCD,” Proceedings of 7th International Display Research Conference, pp. 107–110, 1987.

K.H. Shin, J.Y. Ahn, K.D. Kim, H.H. Shin, and I.J. Chung, “Acceptable Motion Blur Levels of a LCD TV Based on Human Visual System,” SID Digest, Vol. 37, No. 1, pp. 287–290, 2006.

H. Seetzen, W. Heidrich, W. Stuerzlinger, G. Ward, L.A. Whitehead, M. Trentacoste, A. Gosh, and A. Vorozcovs, “High Dynamic Range Display Systems,” ACM Transactions on Graphics, Vol. 23, pp. 760–768, 2004.

Y.-C. Sung and O.-K. Kwon, “Low-Cost TFT-LCDs with Pre-Emphasis Driving Method for Large-Size and High-Definition TVs,” IEEE Transactions on Consumer Electronics, Vol. 53, No. 4, pp. 1674–1681, 2007.

Y. Son, J. Kim, H. Cho, J. Hong, J. Na, D. Kim, D. Han, J. Hong, Y. Jeon, and G. Cho, “A Column Driver with Low-Power Area-Efficient Push-Pull Buffer Amplifiers for Active-Matrix LCDs,” Proceedings of IEEE International Solid- State Circuits Conference, pp. 142–143, 2007.

T. Shiga, S. Kuwahara, N. Takeo, and S. Mikoshiba, “Adaptive Dimming Technique with Optically Isolated Lamp Groups,” SID Digest, Vol. 36, No. 1, pp. 992–995, 2005.

J.H. Souk and J. Lee, “Recent Picture Quality Enhancement Technology Based on Human Visual Perception in LCD TVs,” IEEE Journal of Display Technology, Vol. 3, No. 4, pp. 371–376, 2007.

J.H. Stessen and J.G.R. vanMourik, “Algorithm for Contrast Reserve, Backlight Dimming, and Backlight Boosting on LCD,” SID Digest, Vol. 37, No. 1, pp. 1249–1252, 2006.

M.S. Shur, H.C. Slade, M.D. Jacunski, A.A. Owusu, and T. Ytterdal, “Spice Models for Amorphous Silicon and Polysilicon Thin Film Transistors,” Journal of Electrochemical Society, Vol. 144, No. 8, pp. 2833–2839, 1997.

E. Takeda, “Simplified Method of Capacitively Coupled Driving for TFTLCD,” Proceedings of 9th International Display Research Conference, pp. 580–583, 1989.

H. Takatsuji, E.G. Colgan, C. Cabral, Jr., and J.M.E. Harper, “Evaluation of Al(Nd)-alloy Films for Application to Thin-Film-Transistor Liquid Crystal Displays,” IBM Journal of Research and Development, Vol. 42, No. 3/4, pp. 501–508, 1998.

C.T. Angelis, C.A. Dimitriaids, M. Miyasaka, F.V. Farmakis, G. Kamarinos, J. Brini, and J. Stoemenos, “Effect of Excimer Laser Annealing on the Structural and Electrical Properties of Polycrystalline Silicon Thin-Film Transistors,” Journal of Applied Physics, Vol. 86, No. 8, pp. 4600–4606, 1999.

W.-C. Tsai, J.-Y. Lai, K.-Y. Tu, H.-T. Lin, and F.-Y. Gan, “A Novel Barrierless Cu Gate for TFT-LCD,” SID Digest, Vol. 37, No. 1, pp. 1181–1184, 2006.

E. Takeda, Y. Nan-no, Y. Mino, A. Otsuka, S. Ishihara, and S. Nagata, “Capacitively Coupled TFT-LCD Driving Method,” SID Digest, Vol. 31, No. 2, pp. 87–94, 1990.

S. Uchikoga, “Future Trend of Flat Panel Displays and Comparison of its Driving Methods,” Proceedings of 18th International Symposium on Power Semiconductor Devices & IC’s, pp. 1–5, 2006.

J.-S. Yoo, “A Novel Polysilicon TFT with Lateral Body Terminal for Driving Circuit Application of AMLCDs,” ITE Technical Report, Vol. 23, No. 67, p. 27, 1999.

Y.-S. Son, H.-H. Son, Y.-S. Kim, H.-S. Oh, and G.-H. Cho, “A Gray-Level Dependent Pre-Emphasis Column Driver with Fast Settling for Active-Matrix LCD Applications,” IEEE Transactions on Circuits and Systems - Part II, pp. 1057–1061, 2007.

Y. Yamada, K. Kimura, and Y. Ishii, “Technology Trend for High Quality Display Image of LC-TV,” Proceedings of International Display Workshops, Vol. 12, No. 1, pp. 227–230, 2005.

T. Yanagisawa, K. Kasahara, and M. Kajimura, “Compensation of the Display Electrode Voltage Distortion,” Proceedings of International Display Research Conference, pp. 192–199, 1986

N. Yamagishi, Y. Tanabe, H. Ishibashi, and H. Yamagami, “Moving Picture Simulations with OCB for Image-Blurring-Free LC TVs,” SID Digest, Vol. 37, No. 2, pp. 1804–1807, 2006.

Z. Yu and H.R. Wu, “Human Visual System Based Objective Digital Video Quality Metrics,” Proceedings of International Conference on Signal Processing, Vol. 2, pp. 1088–1095, 2000.

M.M. Ahmadi, “A New Modeling and Optimization of Gain Boosted Cascode Amplifier for High-Speed and Low-Voltage Applications”, IEEE Transactions on Circuits and Systems - Part II, Vol. 53, No. 3, pp. 169–173, 2006.

B.S. Bae, J.W. Choi, J.H. Oh, and J. Jang, “Level Shifter Embedded in Drive Circuit with Amorphous Silicon TFTs,” IEEE Transactions on Electron Devices, Vol. 3, No. 3, pp. 494–498, 2006.

K. Bult and G. J. G. M. Geelen, “A Fast-Settling CMOS Op Amp for SC Circuits with 90-dB DC Gain,” IEEE Journal of Solid-State Circuits, Vol. 25, No. 6, pp. 1379–1383, 1990.

A. Boni, A. Pierazzi, and D. Vecchi, “LVDS I/O Interface for Gb/s-per-Pin Operation in 0.35-εm CMOS,” IEEE Journal of Solid-State Circuits, Vol. 36, No. 4, pp. 706–711, 2001.

P. C. Chen and J. B. Kuo, “Sub-1V CMOS Large Capacitive-Load Driver Circuit Using Direct Bootstrap Technique for Low-Voltage CMOS VLSI,” Electronics Letters, Vol. 38, No. 6, pp. 265–266, 2002.

H.-J. Chung, S.-W. Lee, and C.-H. Han, “Poly-Si TFT Push-Pull Analogue Buffer for Integrated Data Drivers of Poly-Si TFT-LCDs,” Electronics Letters, Vol. 37, No. 17, pp. 1093–1095, 2001.

Y.Z. Cao, Z.M. Lin, and H.C. Lai, “Single Capacitor Bootstrapped Driver for TFT-LCD Gate Driver Circuit,” Proceedings of IEEE Conference on Electron Devices and Solid-State Circuits, pp. 885–888, 2007.

J. Choi, K. Min and C. Yoo, “High-Speed and Low-Power Analog Source Driver for TFT-LCD using Dynamic Biased Operational Amplifier,” SID Digest, Vol. 38, No. 1, pp. 1647–1650, 2007.

V.M. Da Costa and R.A. Martin, “Amorphous Silicon Shift Register for Addressing Output Drivers,” IEEE Journal of Solid-state Circuits, Vol. 29, No. 5, pp. 596–600, 1994.

S. Di Fazio, F. Pulvirenti, T. Signorelli, C. Lao, S. Pennisi, “Low Quiescent Current High Speed Amplifier for LCD Column Driver”, Proceedings of European Conference on Circuit Theory and Devices, pp. 523–526, 2007.

C.C. Enz and G.C. Temes, “Circuit Techniques for Reducing the Effects of Op-Amp Imperfection: Autozeroing, Correlated Double Sampling, and Chopper Stablilization,” Proceedings of IEEE, Vol. 84, No. 11, pp. 1584–1614, 1996.

S. Edo, M. Wakagi, and S. Komura, “A 2.2” QVGA a-Si TFT LCD with High Reliability Integrated Gate Driver,” SID Digest, Vol. 37, No. 1, pp. 1551–1554, 2006.

J.C. Garcia, J.A. Montiel-Nelson, and S. Nooshabadi, “A Single Capacitor Bootstrapped Power-Efficient CMOS Driver,” Proceedings of IEEE Midwest Symposium on Circuits and Systems, Vol. 1, pp. 287–290, 2005.

J.C. Garcia, J.A. Montiel-Nelson, J. Sosa, and H. Navarro, “A Direct Bootstrapped CMOS Large Capacitive-Load Driver Circuit,” Proceedings of IEEE Design, Automation and Test in Europe Conference and Exhibition, Vol. 1, pp. 680–681, 2004.

M. Hirose, F. Inoue, N. Kabuto, H. Kataoka, and K. Masuda, “5-bit TV Pictures on 3-bit Color TFT-LCDs Using Alternating Dither,” SID Digest, pp. 597–600, 1992.

R. Hogervorst, J.P. Tero, G.H. Eschaizier and J.H. Huisjing, “A Compact Power-Efficient 3V CMOS Rail-to-Rail Input/Output Operational Amplifier for VLSI Cell Libraries,” IEEE Journal of Solid-State Circuits, Vol. 29, No. 12, pp. 1505–1513, 1994.

H.-R. Han, J.-F. Tsai, W.-T. Liao, and W.-C. Wang, “Reliable Integrated s-Si Select Line Driver for 2.2-in. QVGA TFT-LCD,” SID Digest, Vol. 36, No. 1, pp. 946–949, 2005.

T. Itaku, H. Minamizaki, T. Satio, and T. Kuroda, “A 402-Output TFT-LCD Driver IC with Power Control Based on Number of Colors Selected,” IEEE Journal of Solid-State Circuits, Vol. 38, No. 3, pp. 503–510, 2003.

J. Jeon, K.-S. Choo, W.-K. Lee, J.-H. Song, and H.-G. Kim, “Integrated a-Si Gate Driver for TFT-LCD Panel,” SID Digest, Vol. 35, No. 1, pp. 10–13, 2004.

S.H. Jung, J. H. Park, C.W. Han, and M.K. Han, “New Source Follower Type Analog Buffers Using Poly-Si TFTs for Active Matrix Displays,” SID Digest, Vol. 35, No. 1, pp. 1452–1455, 2004.

J.-H. Kim, B.-D. Choi, and O.-K. Kwon, “1-Billion-Color TFT-LCD TV with Full HD Format,” IEEE Transactions on Consumer Electronics, Vol. 51, No. 4, pp. 1042–1050, 2005.

M.-D. Ker, C.-K. Deng, and J.-L. Huang, “On-Panel Output Buffer With Offset Compensation Technique for Data Driver in LTPS Technology,” IEEE Journal of Display Technology, Vol. 2, No. 2, pp. 153–159, 2006.

K. Kawabe and T. Furuhashi, and Y. Tanaka, “New TFT-LCD Driving Method for Improved Moving Picture Quality,” SID Digest, Vol. 32, No. 1, pp. 998–1001, 2001.

T.-S. Kim, B.-I. Park, J.-H. Park, B. Berkeley, and S.-S. Kim, “An Optimized Boost Table Measurement Method for Response Time Acceleration in LCD,” SID Digest, Vol. 35, No. 1, pp. 372–375, 2004.

S. Kim, Y. Son and G. Cho, “Low-Power High-Slew-Rate CMOS Buffer Amplifier for Flat Panel Display Drivers,” Electronics Letters, Vol. 42, No. 4, pp. 214–215, 2006.

A. Kumar, S. Sambandan, K. Sakariya, P. Servati, and A. Nathan, “Amorphous Silicon Shift Registers for Display Drivers,” Journal of Vacuum Science and Technology A, Vol. 22, No. 3, pp. 981–986, 2004.

C.W. Lu, “High-Speed Driving Scheme and Compact High-Speed Low- Power Rail-to-Rail Class-B Buffer Amplifier for LCD Applications,” IEEE Journal of Solid-State Circuits, Vol. 39, No. 11, pp. 1938–1947, 2004.

P.W. Li, M.J. Chin, P.R. Gray, and R. Castello, “A Ratio-Independent Algorithmic Analog-to-Digital Conversion Technique,” IEEE Journal of Solid- State Circuits, Vol. 19, No. 6, pp. 828–836, 1984.

C. Lu and K. Hsu, “A High Speed Low-Power Rail-to-Rail Column Driver for AMLCD Application,” IEEE Journal of Solid-State Circuits, Vol. 39, No. 8, pp. 1313–1320, 2004.

J.C. Lee and J.Y. Jeong, “High Speed, Small Area, Reliable, LTPS TFT-based Level Shifter for System-On-Panel Technology,” Proceedings of IEEE International Conference on Integrated Circuit Design and Technology, pp. 1–4, 2006.

J.H. Lou and J.B. Kuo, “A 1.5V Full-Swing Bootstrapped CMOS Large Capacitive-Load Driver Circuit Suitable for Low-Voltage CMOS VLSI,” IEEE Journal of Solid-State Circuits, Vol. 32, No. 1, pp. 119–121, 1997.

H.C. Lai and Z.M. Lin, “A High-Speed Full Swing CMOS Driver for TFT-LCD Scan-Line Circuit,” Proceedings of TENCON 2007 - IEEE Region 10 International Conference, pp. 1–3, 2007.

K.M. Lim, K.E. Lee, J.S. Yoo, J.-M. Yoon, M.K. Baek, J.-S. Yoo, Y.-S. Jung, J.K.Park, S.-W. Lee, H.C. Kang, C.-D. Kim, and I.-J Chung, “A 3.5 in. QVGA Poly-Si TFT-LCD with Integrated Driver Including New 6-bit DAC,” Solid- State Electronics, Vol. 49, No. 7, pp. 1107–1111, 2005.

C.T. Liu, A. Wang, H.-J. Hong, Y.-J. Hsieh, M.-S. Lai, A. Tsai, T.M. Wang, M.-J. Jou, W.-C. Chang, S.-L. Sui, J.H. Liao, and M.-F. Tien, “Color and Image Enhancement for Large-Size TFT-LCD TVs,” SID Digest, Vol. 36, No. 1, pp. 1730–1733, 2005.

L.C. Fatt, Y.K. Seng, and S.S. Rofail, “Sub-1V Bootstrapped CMOS Driver for Giga-Scale-Integration Era,” Electronics Letters, Vol. 35, No. 5, pp. 392–393, 1999.

R. McCartney, “A Liquid Crystal Display Response Time Compensation Feature Integrated into an LCD Panel Timing Controller,” SID Digest, Vol. 34, No. 1, pp. 1350–1353, 2003.

S. Matsumoto, N. Komiya, M. Okuyama, and K. Hirosawa, “Level Shifter for Use in Active Matrix Display Apparatus,” U.S. Patent #6,801,181 B2, issued 2004.

S.-H. Moon, Y.-S. Lee, M.-C. Lee, B.H. Berkeley, N.-D. Kim, and S.-S. Kim, “Integrated a-Si:H TFT Gate-Driver Circuits on Large-Area TFT-LCDs,” SID Digest, Vol. 38, No. 1, pp. 1478–1481, 2007.

Y. Nakajima, Y. Kida, M. Murase, Y. Toyoshima, and Y. Maki, “Latest Development of “System-on-Glass” with Low Temperature Poly-Si TFT Display,” SID Digest, Vol. 35, No. 1, pp. 864–867, 2004.

Y.I. Park, D.Y. Lee, J.S. Yoo, H.C. Kang, K.M. Lim, C.-D- Kim, and I.-J. Chung, “LTPS PMOS Four-Mask Process for AMLCDs,” SID Digest, Vol. 36, No. 1, pp. 341–343, 2005.

G. Palmisano, G. Palumbo, and S. Pennisi, “Design Procedures for Two–Stage CMOS OTAs: A Tutorial,” Analog Integrated Circuits and Signal Processing, Vol. 27, No. 3, pp. 179–189, 2001.

P. Rombouts, L. Weyten, J. Raman, and S. Audenaert, “Capacitor Mismatch Compensation for the Quasi-Passive Switched-Capacitor DAC,” IEEE Transactions on Circuits and Systems - part I, Vol. 45, No. 1, pp. 68–71, 1998.

Y. Sung, B. Choi and O. Kwon, “Low-Power TFT-LCD Source Driver Using Triple Charge Sharing Method,” Proceedings of International Conference on VLSI and CAD, pp. 317–320, 1999.

M.-S. Shin, J.-W. Choi, Y.-J. Kim, K.-R. Kim, and I. Lee, “Design of Low-Cost 2.2-inch qVGA LTPS TFT-LCD Panel,” SID Digest, Vol. 38, No. 1, pp. 260–263, 2007.

E. Sackinger and W. Guggenbuhl, “A High-Swing High-Impedance MOS Cascode Circuit,” IEEE Journal of Solid-State Circuits, Vol. 25, No. 1, pp. 289–298, 1990.

R.E. Suarez, P.R. Gray, and D.A. Hodges, “All-MOS Charge Redistribution Analog-to-Digital Conversion Techniques - Part II,” IEEE Journal of Solid- State Circuits, Vol. 10, No. 6, pp. 379–385, 1975.

Y.-C- Sung and O.-K. Kwon, “Low-Cost TFT-LCDs with Pre-Emphasis Driving Method for Large-Size and High-Definition TVs,” IEEE Transactions on Consumer Electronics, Vol. 53, No. 4, pp. 1674–1681, 2007.

H.-S. Shim, J.-H. Kim, B.-C. Cho, and O.-K. Kwon, “A New Level Shifter Using Low Temperature Poly-Si TFTs,” International Meeting on Information Display Digest, pp. 117–120, 2003.

K. Sekiya and H. Nakamura, “Overdrive Method for TN-mode LCDs–Recursive System with Capacitance Prediction,” SID Digest, Vol. 32, No. 1, pp. 114–117, 2001.

J. Someya, N. Okuda, H. Yoshii, and M. Yamakawa, “A New LCD-Controller for Improvement of Response Time by Compression FFD,” SID Digest, Vol. 32, No. 1, pp. 1346–1349, 2003.

Y.–C. Sung, S.–M. So, J.–K. Kim, and O.–K. Kwon, “10bit Source Driver with Resistor-Resistor Digital to Analog Converter,” SID Digest, Vol. 36, No. 1, pp. 1099–1101, 2005.

C.S. Tan, W.T. Sun, S.H. Lu, C.H. Kuo, I.T. Chang, S.H. Yeh, C.C. Chen, L. Liu, Y.C. Lin, and C.S. Yang, “A Simple Architecture for Fully Integrated 2.4” Poly-Si TFT-LCD,” SID Digest, Vol. 36, No. 1, pp. 336–339, 2005.

Y. Unekawa, K. Seki-Fukuda, K.Sakaue, T. Nakao, S. Yoshioka, T. Nagamatsu, H. Nakakita, Y. Kaneko, M. Motoyama, Y. Ohba, K. Ise, M. Ono, K. Fujiwara, Y. Miyazawa, T. Kuroda, Y. Kamatani, T. Sakurai, and A. Kanuma, “A 5-Gb/s 8x8 ATM Switch Element CMOS LSI Supporting Five Quality-of-Service Classes with 200-MHz LVDS Interface,” Proceedings of IEEE Solid-State Circuits Conference, pp. 118–119, 1996.

S.-H. Yang, W.-C. Chen, H.-Y. Lin, C.-H. Lee, V. Lai, C.-M. Chiu, H.-C. Wang, and C.-C. Lee, “High Integrated 10.2-inch WVGA LTPS LCD Manufactured by PMOS Process,” SID Digest, Vol. 38, No. 1, pp. 245–248, 2007.

Y.S. Yoo, J.Y. Choi, H. S. Shim, and O. K. Kwon, C “A High Accurate Analog Buffer Circuit Using Low Temperature Poly-Si TFT,” SID Digest, Vol. 35, No. 1, pp. 1460–1463, 2004.

S. Yang, P. Guo, T. Chang, and J. Hong, “A Multi-Phase Charge-Sharing Technique without External Capacitor for Low-Power TFT-LCD Column Drivers,” Proceedings of IEEE International Symposium on Circuits and Systems, Vol. 5, pp. 365–368, 2003.

K. Yamashita, T. Inada, S. Deane, P. Collins, S. Kawata, Y. Onda, M. Yoshiga, J. Hector, and M. Inoue, “a-Si Gate Driver Design for Low Power AMLCD Operation”, Information and Media Technologies, Vol. 2, pp. 1–5, 2007.

S.Y. Yoon, Y.H. Jang, B. Kim, M.D. Chun, H.N. Cho, N.W. Cho, C.Y. Sohn, S.H. Jo, C.-D. Kim and I.-J. Chung, “Highly Stable Integrated Gate Driver Circuit Using a-Si TFT with Dual Pull-Down Structure,” SID Digest, Vol. 36, No. 1, pp. 348–351, 2005.

C. Yoo, D.-J. Kim, and K.-L. Lee, “Threshold Voltage and Mobility Mismatch Compensated Analogue Buffer for Driver-Integrated Poly-Si TFT LCDs,” Electronics Letters, Vol. 41, No. 2, pp. 65–66, 2005.

K.-S. Yeo, J.-G. Ma, and M.-A Do, “Ultra Low Voltage Bootstrapped CMOS Driver for High Performance Applications,” Electronics Letters, Vol. 36, No. 8, pp. 706–708, 2000.

Liquid Crystal Pixels are transmission type pixels with a backlight, meaning that they are not emitting their own light. While there are many types of liquid crystal materials such as smectics, nematics and cholesterics, twisted nematic (TN) display mode is the most advanced and popular. A TN pixel cell consists of two glass substrates coated on their inner surfaces with transparent electrodes and separated by several millimeters from each other. A nematic liquid crystal material fills the space between the two substrates and two polarizers are attached on both sides of the pixel with their polarization axis crossed. The polarizer is a three-layer composite film with a stretched iodine doped polyvinyl alcohol (PVA) polarizing film in the center and two outer films for protecting the PVA film from the ambient. Since the two substrates, each having alignment layer, are oriented with their alignments perpendicular to each other, liquid molecule is twisted initially. In the voltage-off state, the polarizers are oriented perpendicular and the incoming light from a back light source, whose polarity is twisted by the liquid crystal, is transmitted through the output polarizer. When a voltage is applied to the electrodes, the director of the molecules tends to orient themselves parallel to the applied field, since liquid crystal materials have positive dielectric anisotropy. In this situation, the polarization of the light transmitted through liquid crystal is crossed to the output polarizer resulting in the cut off of the light and thus creating a black state for the display pixel. This operation is called normally white mode, while normally black mode can be achieved by changing the polarizers to a parallel orientation. Figure 10 shows the configuration a TN pixel cell in a normally white mode.

The transmission (luminance) versus the applied voltage characteristic is shown in Fig. 11. The shown characteristic is for normal viewing angle and indicates that grayscale levels can be achieved by varying the voltage across the LCD. Unfortunately, the transmission – voltage curve is viewing angle dependent, leading to grayscale errors and color shift in a display when it is viewed from significant angles to the display normal.

The equivalent circuit with the parasitic elements of a pixel cell and a typical TFT-LCD pixel layout are shown in fig. 12. The pixel consists of a switch TFT device, with the gate electrode connected to the row driver lines and the source electrode connected to the column driver lines. Furthermore, a storage capacitor is connected in parallel to the LC pixel capacitance.

The aperture part is the light transparent part and it is designated for the placement of the liquid crystal while the TFT, voltage lines and storage capacitor areas are non-light transparent. The ratio between the transparent portion of a pixel and its surrounding electronics is called aperture ratio or fill factor. Furthermore, in the shown layout design, the storage capacitor is connected to an adjacent row line resulting in the maximization of the aperture ration but the load capacitance of the row lines is, also, increased. The counter electrode of the LC pixel capacitor is the common ITO electrode on the opposite substrate (Den Boer, 2005). For large displays, this configuration is difficult to be used due to the large RC delay time of the row lines. In order to overcome this problem, a common storage bus can be placed in the aperture area which reduces the load capacitance of the row lines, but also reduces the aperture ration of the pixel.

The crosstalk effect is caused due to the column-line video-signal coupling during one frame and a DC component is being added to the AC data voltage. The DC component can not be entirely eliminated for all gray across the entire pixels matrix, resulting to slight difference in the pixel transmittance between the odd and even frames. A solution to this problem is the polarity inversion method. Apart from elimination of the DC component, the influence of the flicker on the display image quality is also eliminated with the use of a polarity inversion method. Four different polarity inversion methods have been widely used. Figure 13 shows the configuration of the four polarity inversion methods. The type of the polarity inversion method has an impact on the power consumption of the display. In the frame inversion method, all the pixels are driven to + Vp polarity in one frame period and then all of them are driven to – Vp polarity during the next frame period. This method is the most power-efficient method. However, this method is sensitive to the flicker and to vertical and horizontal crosstalk, meaning that this method can not be used in high image quality displays.

In the line and column inversion methods, the polarity of the pixels is alternated in the adjacent rows and columns, respectively. The line inversion method is compatible to the Vcom modulation (Den Boer, 2005) while column inversion method is not compatible. Furthermore, the line inversion method consumes more power than the column inversion method because the capacitance of all row busses is charged and discharged every row time. Finally, the column inversion method has better results to the compensation of the flicker.

In the pixel inversion method, the polarity of each pixel is inverted from the polarity of its neighbouring pixels, by a combination of simultaneous row and column inversions. This produces the highest quality images by total elimination of the flicker and crosstalk effect. This method is not compatible with the Vcom modulation and thus it requires high voltage column drivers leading to high power consumption.

A full color LCD display can be generated by incorporating red, green and blue color filters at the pixels. In order to produce the desirable color tone, the pixel is divided into three sub-pixels each one having red, green and blue color filter, respectively. The three sub-pixels have the same dimensions and the proper combination of each color tone; by applying the right voltages to the liquid crystals, the desired pixel emissive colour will be produced. The width of each sub-pixel is three times smaller than the sub-pixel length and when the three sub-pixels are very closely placed in parallel, a square full color pixel is produced. Figure 14 shows a full colour square pixel.

Thin-Film Transistor Liquid Crystal Displays use thin-film transistors to control the voltage applied to the liquid crystal layer at a sub-pixel level. The structure of TFT LCDs consists of a TFT “sandwich” and a BLU (Backlight Unit). A typical configuration is shown in the schematic diagram below.

Firstly, between the back and front polarizers, TFT LCD cells are made with two glass substrates – one for color filters, the other for a TFT array – and a liquid crystal layer sandwiched in between.

Secondly, BLU (Backlight Unit) usually consists of three components: BEF (Brightness Enhancement Film), DBEF (Dual Brightness Enhancement Film), and LGP (Light Guide Plate).

For normally black TFT LCDs, if we follow along a piece of light setting off from its backlight source, it will bea)guided uniformly by LGP;b)reflected and enhanced by BEF and DBEF;c)polarized by the back polarizer;d)polarization changed by twisted LC under the voltage applied by TFT arrays;e)“tinted” red/green/blue by corresponding color filter of the subpixel;f)let through the front polarizer by matched polarization; andg)finally, it will reach the surface and appears in viewer’s eyes.

For normally white panels, processd)will be the opposite – known as the polarization rotation effect, light is twisted in a voltage-off stage and can pass through the front polarizer by default, thus displaying white normally. However, when the voltage applied increases, this polarization rotation effect would be gradually diminished. And the light would not be able to pass through the front polarizer anymore without changing its polarization. In this way, certain pixels will appear in different colors.

Normally black LCDs have higher contrast and wider viewing angles without grayscale inversion phenomenon compared to their normally white relatives. And whether TFT LCDs are normally black or white depends on their LC switching mode:

2Chen, HW., Lee, JH., Lin, BY.et al.Liquid crystal display and organic light-emitting diode display: present status and future perspectives.Light Sci Appl7,17168 (2018).https://doi.org/10.1038/lsa.2017.168

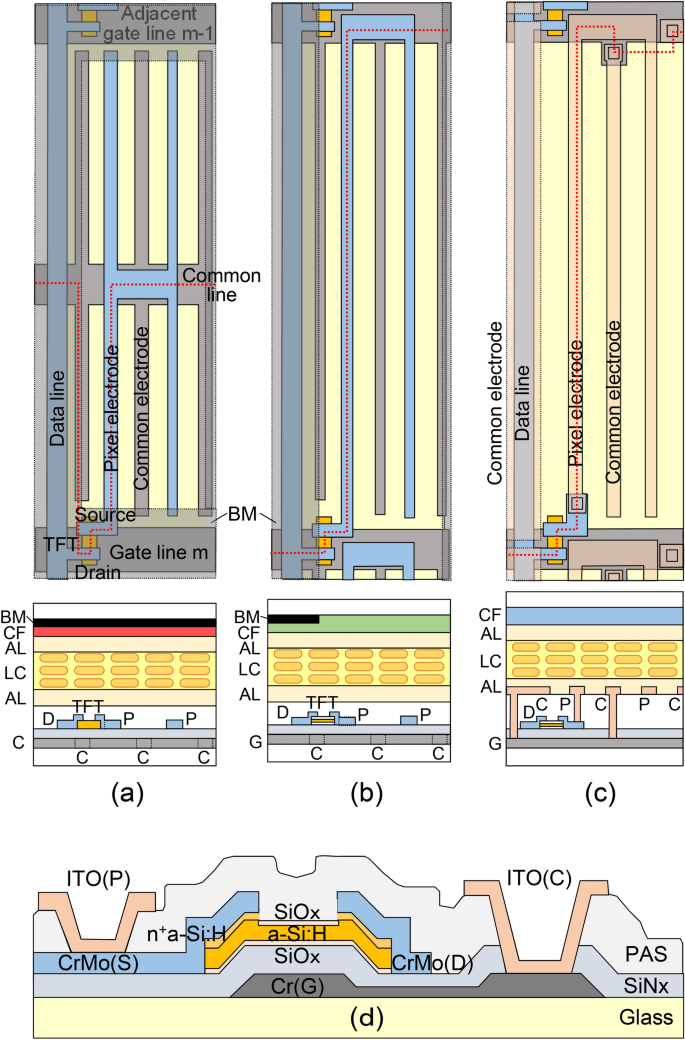

Schematic diagram of the (a) TN mode, (b) VA mode, (c) FFS mode, and (d) IPS mode. *LC orientations shown are under applied voltages. C/F stands for the color filter.

As previously mentioned, TN mode functions with the polarization rotation effect. Under traditional TN/VA display mode, the liquid crystal molecules are vertically arranged, with a relatively narrow visual angle. When an external force is exerted on the screen, the liquid crystal molecular structure will sink in a herringbone pattern to slowly recover – a pattern called vertical alignment. Therefore, an evident “water ripple” usually appears when the display surface is touched and impacts the user experience. In comparison, the VA mode provides higher contrast. And MVA (multi-domain vertical alignment) is an upgraded version of VA with improved viewing angles.

Under IPS mode, the LC directors are horizontally (homogeneously) aligned, which makes them free from ripple effects when made into touch panels. The drawback is lower transmittance, especially for LCs in a “dead zone”close to electrodes.

In an FFS cell, LC molecules rotate in both vertical and horizontal dimensions, enabling excellent viewing angles, high transmittance, low driving voltage/power consumptions, and high contrast ratio.

3 Yang DK, Wu ST.Fundamentals of Liquid Crystal Devices. 2nd edition. New York, USA: John Wiley & Sons. 2014.4 BOE ADSDS Ultra Hard screen Technology, Restoring Real and Beautiful Life. 2020 BOE Technology Group Co., Ltd. Retrieved December 01, 2020, fromhttps://www.boe.com/en/cxkj/boecx/boecxxqy/dynamic/pecbbd751.html

Figures 3a–d show optical and SEM (scanning electron microscopy) images of the fabricated CL and CLSE pixel structures. Each structure has the same pixel size (80 μm × 240 μm) and minimum pattern size (5 μm). As shown in Fig. 3d, the white line patterns are the ITO interdigitated pixel and common electrodes. They are well connected to the source electrode and gate line via through holes, and the common electrodes at both ends cover the underlying data lines to prevent electrical noise from being applied to the LC layer. As will be shown later, this noise shield electrode (SE) is what makes the black matrix above the data line unnecessary

Optical and SEM (scanning electron microscopy) images of fabricated (a, b) CL and (c, d) CLSE pixel structures. The five white line patterns in (d) are the ITO interdigitated pixel and common electrodes. (e) Images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel. (f) The three-black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM) and (g) optical images of pixels without BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines).

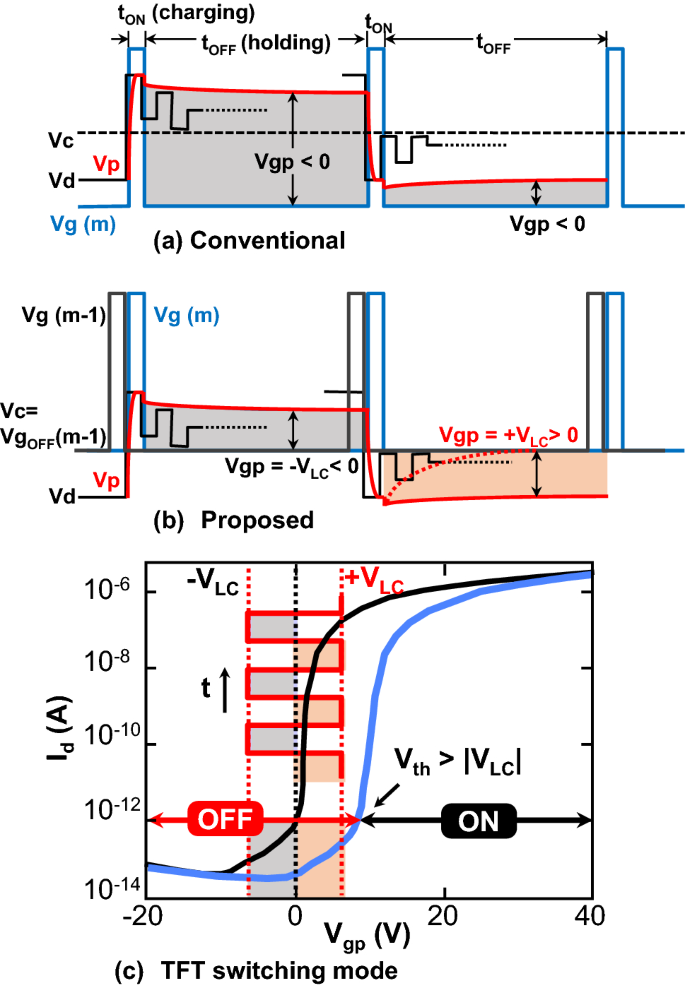

Figure 3e shows images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel fabricated in our laboratory, (f) the three black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM), and (g) optical images of panel areas without the BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines). As can be seen in the image from the normal direction, the brightness and contrast of the display area with the top BM and middle BM patterns are almost the same, but the contrast of the display area without the BM is relatively lower because of the lower darkness level of the LC off pixels indicating “HITACHI”. As shown in Fig. 3g, this is due to light leaking through the aperture between the data line and adjacent common lines. Therefore, in the CL structure, the BM on the drain line is necessary to obtain a high contrast ratio by shielding light leakage. This is the same as in the conventional structure. On the contrary, there is no light leakage along the gate line through the gaps between the gate line and edges of the pixel/common electrodes, as is clearly shown in Fig. 3g. This is a unique advantage of the CL structure because the conventional structure must shield these gaps with the BM to prevent light leakage. The suppression of light leakage along the gate line in the CL structure is due to the driving scheme (see Fig. 2b,a for a comparison with the conventional structure). During the holding period (tOFF) in the conventional structure, regardless of the pixel voltage, Vp (including Vp = 0), nonzero Vgp and Vgc are always applied to keep the TFT off, and these voltages are applied to the LC layer, inducing light leakage as reported in

Figure 4a shows the gate voltage (Vg) dependence of the panel brightness, while the inset shows that of the TFT current (transfer characteristics). The gray curves are for the conventional IPS TFT-LCD with the TFT before enhancement, the common line, and the matrix BM (MBM) shown at the top of Fig. 3f. The blue curves are for the proposed CL structure with the enhanced TFT and the stripe BM (SBM) shown in the middle of Fig. 3f. In this case, enhanced TFT characteristics were obtained by using an MNOS TFT without back-channel oxidation that was enhanced by the BTS process. In both structures, the threshold voltages for panel brightness, defined by extrapolating the straight part of the brightness curves, reflect those of the TFT transfer curves defined as Vg at a drain current of 10−12 A, and they are well matched to be 4 V and 9 V, respectively. The maximum brightness for the CL structure is 137% higher than that for the conventional structure, which is due to the increase in the aperture ratio from 38 to 52% that results from the elimination of the common line and the BM covering the gate line.

(a) Dependence of panel brightness and TFT current on gate voltage for the conventional pixel structure of 38% aperture ratio (AR) with matrix black matrix (MBM) over both drain and gate lines and proposed CL pixel structure of 52% AR with strip black matrix (SBM) over only the drain lines. Transfer characteristics before and after bias temperature stress (BTS) treatment are shown in the inset. (b) Charging and (c) holding characteristics of enhanced TFT of the CL structure with gate as a common line. Vg and Vd in the TFT ON state are 30 V and +/−7 V, respectively.

To estimate the charging and holding characteristics of the MNOS-enhanced TFT in the panel, the gate TFT ON and OFF time dependences of the panel brightness were measured (Fig. 4b,c). The charging characteristics in Fig. 4b are plotted as a function of tON at tOFF = 16.6 ms, Vg = 30 V, and Vd = ± 7 V. The holding characteristics in Fig. 4c are plotted as a function of tOFF at tON = 34 μs. 95.1% charging at tON = 34 μs and 95.3% holding at tOFF = 16.6 ms indicate that the enhanced TFT has sufficient charging and holding performance to drive a standard VGA (640 × 480 pixels) panel (the number of scanning lines is estimated as tOFF/tON = 16.6/0.034 = 488).

To confirm the driving conditions for the CL structure without the BM along the gate line (with the SBM), the tOFF dependence of the contrast ratio (CR) in the CL panel was further investigated as shown in Fig. 5a, where CR is plotted as a function of tOFF for the CL panels with the matrix BM (MBM) and the strip BM (SBM). The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. The SBM and MBM panels keep CR higher than 240 with tOFF

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey