lcd panel failure reasons for sale

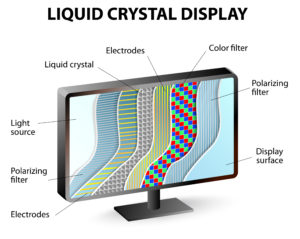

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

With the modern manufacturing process and design, this kind of failure rarely happens. Normally, it is caused by no power. Please check if the battery dead or adapter (power supply) failure or even check if you have plug in firmly or with the wrong power supply. 99% the display will be back on.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

Unfortunately, it is common for some failures to make it through final testing. After the vibration and thermal effects from the shipping process, these defects can be exposed and result in an out of box failure at the assembly line.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

Performing a failure analysis is next. Then, linking that analysis to the customer’s field environment. You’ll need to determine (1) whether the failure is caused by the environment and (2) whether a product improvement can better support the application, or whether there’s a way to limit the environmental extremes.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

Depending on the backlight structure, there will be different results. The failure of the performance may be a point-off, or it may be a backlight with a dark band.

4. #The fault of the product is basically caused by the above reasons. If the appearance is fault-free, the lamp bar can be crossed to confirm whether the phenomenon follows the lamp bar, or the voltage of the lamp bar and the conduction condition between the lamp beads can be measured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

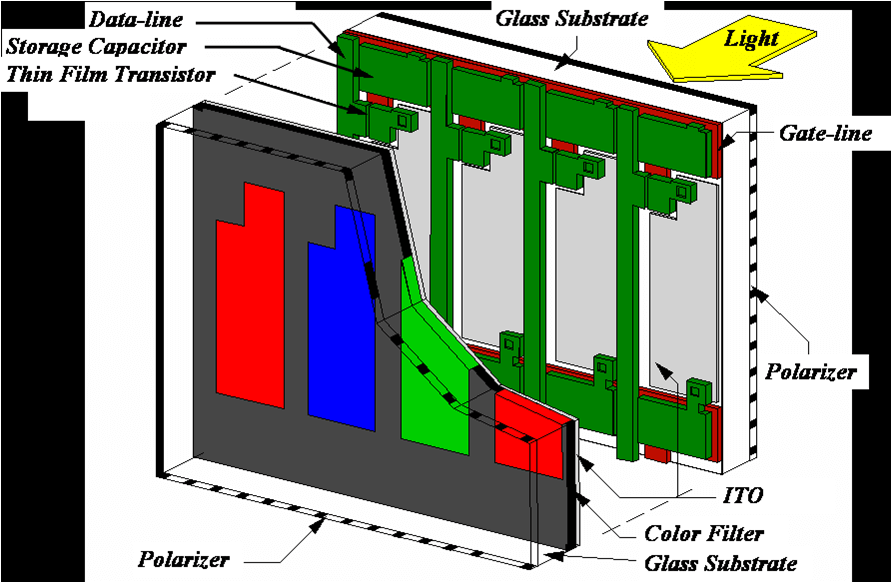

Unlike older cathode ray tube (CRT) displays that scan an electron beam over a phosphor screen to create light, LCD displays are composed of a fixed grid of tricolor pixels that change transparency based on a range of voltage levels provided by the monitor"s controller. Without a voltage the pixel is opaque and blocks the screen"s backlight from transferring through it, and when a full voltage is applied then the pixel allows full transmittance of the backlight. When this is done over the entire pixel grid in patterns, then you see those patterns on the screen.

This pixel-based setup for LCD monitors provides many advantages over CRT displays, but does have potential drawbacks arising from the fact that the image is dependent on millions of independent electrical components as opposed to a single scanning beam, so if faults occur in these components then the display output can be affected. The resulting problems include stuck or dead pixels, as well as a residual image effect.

One of the more common problems with LCD displays is the potential for stuck or broken pixels, where the pixel either does not receive a voltage and remains black, or does not respond to voltage changes and stays at a set luminance level. Sometimes this can happen for individual pixels, suggesting a problem with the pixel itself, or it can happen to groups of pixels, suggesting the possibility of problems with the display"s controller or a defect in a portion of the pixel grid.

LCD monitors can also be affected by another problem called "transient persistence" that is reminiscent of CRT burn-in. Classic burn-in would happen because the phosphor coating on the screen would get depleted by the persistent bombardment of electrons from the CRT, resulting in the inability of those sections of the display to convert the electron beam to visible light. This meant that if you kept a specific pattern showing on the screen then over time it could become a permanent residual image on the display that would show even when the display was turned off. This was a reason why screensavers were developed--to keep the wear on the screen"s phosphor coating as even as possible.

The physical burn-in of displays is no longer an issue now that LCD displays have taken over, but while transient image persistence is not a physical burn of the device, it is an alteration of the pixel response to voltage changes (usually temporary) that prevents pixels from getting as bright as others on the screen.

Similar to CRT burn-in, LCD image persistence generally happens after you have displayed a pattern of intense colors on screen; however, unlike CRT burn-in, LCD persistence can sometimes set in after only a few hours of displaying the image, as opposed to the weeks or even months that it can take for burn to set in on a CRT monitor. Additionally, unlike CRT burn-in, image persistence can often be reversed.

What happens with LCD monitors is the affected pixels have lost their ability to respond to the full range of voltages that the display gives them, resulting in a limited range of colors that can be output. This can happen if the pixel is acting like a capacitor and is retaining a residual charge, or if it is not able to reach the level of luminance that is desired when given a specific voltage. Either way, the pixel is not able to reach its full range of possible intensities.

Unlike stuck or dead pixels that may benefit from having the monitor turned on and off rapidly to produce rapid voltage changes, image persistence will benefit from a lengthy stretching of the pixel"s range. Therefore, instead of using tools like JScreenFix to run random patterns over the affected screen area, you might instead place a pure white window (such as an empty TextEdit window, or what you get using the "White" option in the LCD Repair tool listed above) over the affected area for a few hours or even a few days if necessary. Doing this will force those pixels to be fully on, and over time their intensities may increase to be the same as the surrounding pixels.

Likewise, try turning off the pixels fully by shutting down the display for a long period of time or placing a pure black texture over the affected area (see the LCD Repair tool listed above for this option as well). This will turn the pixels completely off and allow residual voltage in them to drain slowly over time.

So far we have discussed pixel-based problems with LCD displays, but the system"s backlight can also suffer some common problems that include the backlight randomly blinking off, not turning on, or only illuminating part of the screen.

If only the backlight is malfunctioning, then the LCD panel itself should still be working just fine and should be rendering the text and images of your computer"s output. To test for this, use a bright flashlight and shine it on your screen at an angle in an area where you expect images and text to be (such as the Dock or menu bar). On Apple"s laptop systems, you can shine the flashlight through the Apple logo on the back to illuminate the screen on the front and better detect text and images that way.

In a situation where it seems that the screen is on but displays no image, the failure could be the power supply, the motherboard or the inverter (module that supplies current to the backlight).

Contact us to receive a diagnosis and repair. Our laboratory has advanced and innovative equipment to diagnose and repair any issue on PC LCD monitors. Our technicians provide professional and quick high-quality service. Many satisfied customers attested to that by leaving testimonials.

LCD’s do have many replaceable parts and have higher probably of repair than the old CRT box monitors. In Most cases a failed or broken Laptop Screen is worth the repair.

The AC Adapter can be easily tested with a multi-meter. This test is usually 90% conclusive if the AC adapter is good or bad. Also if the LCD has absolutely no power, no power light, no faint display, no reaction at all, the AC Adapter is a likely culprit. A quick multi-meter test can usually be done for free at most repair centers.

This is an internal part that inverts power to the needed amount for the backlight and panel. Inverters fail, and can be easily replaced. Failing inverter symptoms:

The panel itself can fail. The panel contains thousands of tiny pixels all connected by a mesh of thin signal cables. When a panel discolors or fails, the entire panel needs to be removed and replaced. This is less common, and is only sometimes worth the repair. Failing Panel Symptoms:

What if I break my panel? This is rather common on a laptop. Almost always its worth fixing. Usually can purchase a new panel or pull from a parted out laptop.

Other Failures. This can be anything from bad controller board or bad internal cable. These items should be diagnosed by a professional. A simple cable issue can be $5 part. Bad board might be a time to buy a new screen.

In all cases, it might be worthwhile to fix your LCD, especially on a laptop. Although with a few year old desktop LCD, you may consider a replacement, especially if you’re thinking of an upgrade.

Knowing the reasons why liquid-crystal display (LCD) monitors fail will give you the knowledge you need to avoid problems. If your LCD fails, you"ve be able to easily diagnose it and determine an appropriate course of action, whether it be repair or replacement.

Failure of the LCD backlight is a fairly common problem beginning to crop up in LCD technology. If the backlight fails, the monitor will go dark and it will become unusable. Repair of a failed backlight requires expert repair. You can contact your manufacturer for warranty and service information for your LCD panel.

If your LCD screen goes completely black, it may mean that the power supply has failed. If this happens, you can repair it for a moderate fee. The failure may be in the internal power supply inside the monitor, or in the AC adapter power supply cord. This type of failure is repairable for a small to moderate investment in labor and/or parts.

If your LCD monitor fails mysteriously, it may be that some of the capacitors on the internal circuitry have begun to bulge. Bulging in capacitors is caused by the electrolyte inside drying up. This usually occurs in cheaply made capacitors. The good news about this type of failure is that it can be repaired. The individual capacitors can be replaced with fresh ones, which should result in your monitor"s return to normal functionality.

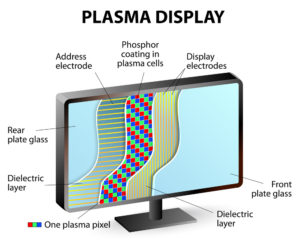

There you have it, the pros and cons of different display types and some of their common failures. Remember, if you suffer a failure of any display type, we are here to help. Be sure to visit us online at gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!

Before we get into specifics about how this would work, it is important to understand that liquid crystal display panels and polarizers utilize organic compounds that are susceptible to high heat and light energy stress. These organic compounds will eventually break down if deployed in high stress environments. One such contributing factor to LCD panel failure is the use of a high energy unfiltered illuminator. The near IR and shorter UV wavelengths not only add excess heat that may overheat the liquid crystal and prevent them from working properly, but they also add UV band energy that is destructive to organic compounds.

Over time the UV and IR will degrade and damage the LCD panel and polarizers to the point that they produce an unacceptably poor performance. In most applications this is observed to be color shift, washed out images and an observable raise in the darkness levels produced by a damaged LCD panel.

In order to help prolong the onset of such damage a set of UV and IR band filters and mirrors can be used to minimize the amount of harmful energy that is conveyed to the LCD panel from the illuminator. In order to determine what combination of filters and mirrors are best for any particular application it is important to know how each material reacts to the various intensities of bandwidths emitted by your chosen illuminator.

Frequently the Illuminators used in LCD systems are gas discharge lamps such as xenon arc lamps and metal halide light sources. A standard hot mirror that reflects energy between 750 and 1200 nm can be used to mitigate the majority of IR energy being conveyed to the LCD panel. In addition a UV blocker can be used to mitigate the damage from energy below 400 nm.

Other thin film coatings and substrates can be utilized to reduce the IR and UV damage to an LCD panel. Any solution must be well researched to minimize concerns so that a sufficient cooling mechanism is planned and allowed for in the application.

Televisions are an expensive purchase and they come with a maximum manufacturer’s warranty of 3 years, which is not enough. Plus, they are delicate and can start to show signs of failure if not properly maintained.

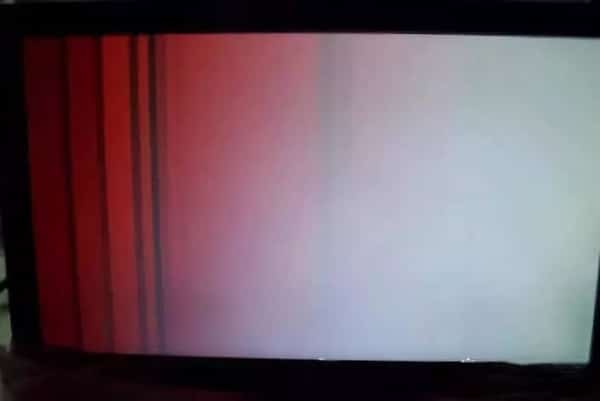

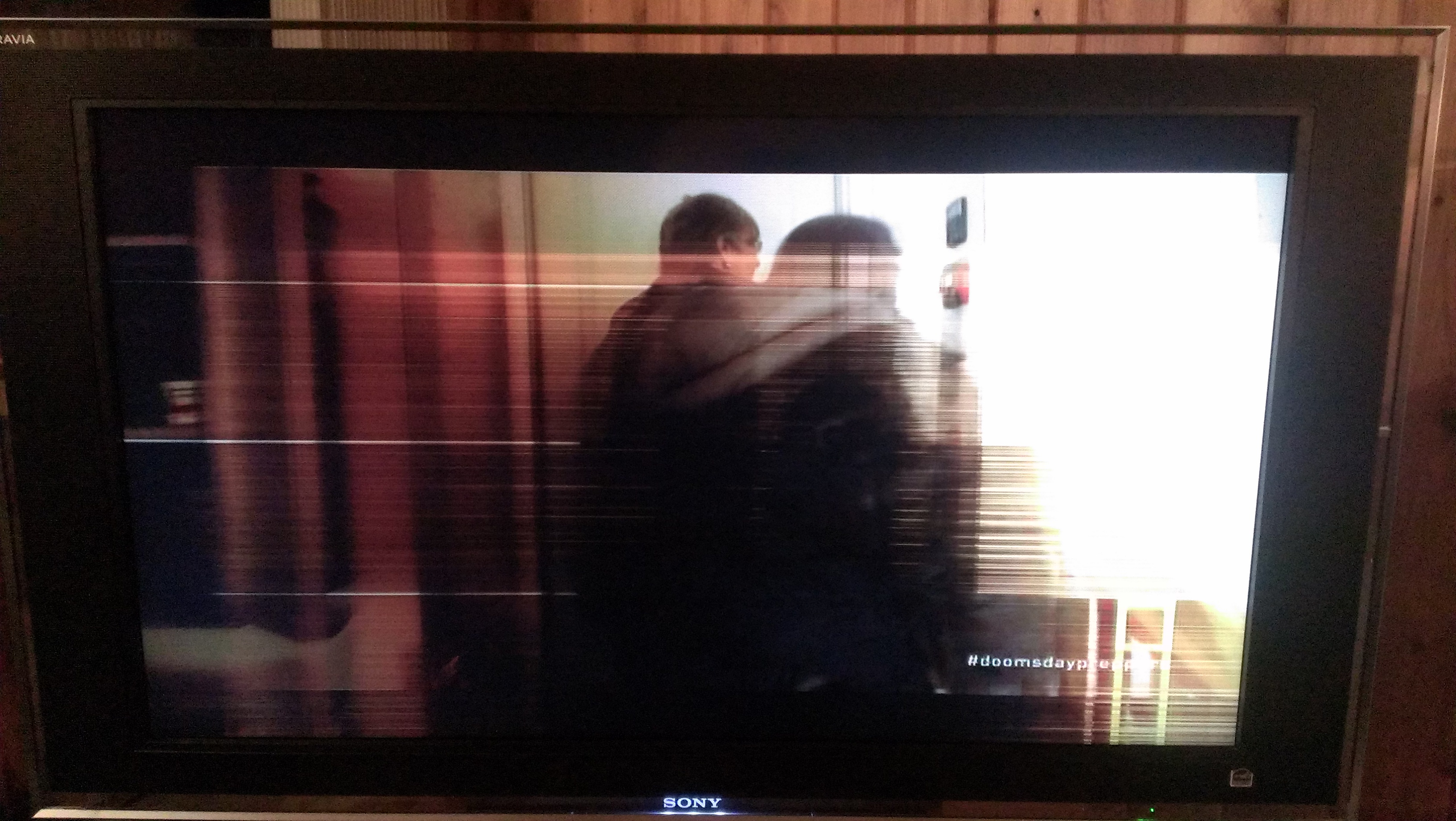

This is a common problem in TVs and is a sign that your TV panel is failing. But before you call an expert to check the TV, you could try following these steps and check if they work:

If it continues to show lines, you may mostly have to get the panel replaced and replacing the panel can be a costly affair, depending on the TV and its model. LED panels range anywhere between Rs 8,000 to Rs 85,000, while LCD panels range between Rs 6,000 to Rs 25,000.

When the TV has speakers that work perfectly fine but it has no picture, there is mostly an issue with the back-lighting system or the power supply board, which will need to be replaced. In the case of an LCD TV, it works with the help of a backlight that is used to illuminate the picture on the screen. When the backlight begins to have problems, the screen turns blank.

To fix this issue, the backlight will have to be replaced by a TV expert. Another possible reason is that the backlight on the LCD TV which has a power inverter has failed. When this happens, you may need to replace the inverter or the capacitor.

There could be several reasons for a flickering TV screen, which is mostly a common issue with LED TVs.One of the major reasons for this is loose or defective cables that result in screen flicker.

Be it a panel issue or a major technical issue with the TV, resolving these problems is a costly affair. It’s best not to ignore any of these signs and call an authorized TV expert before the problem worsens.

I own a Philips 32" PFL 3403 LCD TV. The panel is an MVA from AOU. The TV was purchased during November, 2008. It was all the while connected through a Belkins Surge Protector to the mains. Despite the antiquated panel, I was fond of its picture quality. However, one fine evening in October, 2011, while the TV was on, the colours of the TV suddenly became pale and white, and there was ghosting / clouding of the image. The Philips Service Centre guy said it was a panel problem which cannot be repaired, and asked me to buy a new TV. To have a second opinion, I approached a reputed, independent LCD TV repair centre, to be told the same thing. When I checked online (Consumer Court), I found innumerable cases like mine, where the LCD TV has developed panel problems within three years. Most such complaints in India were related to Samsung LCD / LED TVs, may be due to purely statistical reasons such as the number of TVs sold of the brand. Some were related to Sony LCD TVs. Other brands like LG, Philips (in my case), Toshiba and Panasonic do also figure.

Not to abandon hope, I contacted "Repair & Return" of Bangalore (Repair & Return Technology India Private limited), which claims to have a state-of-art LCD panel repair facility. In turn, I was told that they are a B2B company and not B2C.

1. Why do LCD/LED panels go bad all of a sudden without any apparent reason (even when they are protected through surge suppressors and voltage stabilizers), and without any warning?

3. Repair & Return says they are a B2B firm. Since they are thriving successfully, it means there would be certainly B2C panel repair guys linked up with them. Where to find them?

These steps are as generic as possible, since most LCD displays use a similar design. However, you will need to think carefully about how to take the display apart so you can put it back together, and have it still work!

The images are from Repair ViewSonic VX924 LCD Monitor Blinking Green power Button (youtube). You should watch it through once to get an idea for what it"s like.

The difference between a LED TV and a LCD TV is that they are both LCD TV’s except one has LED stripes and the other has CCFL Backlights- (Florescent Tubes). I used a Philips Magnavox Emerson LG TV when testing these repaird, but they should work on other TV brands that are similar. Before you do any Repair, check to see if you are still under warranty, or are covered by a recall of your TV!!

If your Plasma or LCD/LED or CCFL/LCD TV or monitor has stopped working, or is displaying one of the following symptoms, then it *may* need some new capacitors in the power supply board or a replacement board

If the TV is still locked and will not respond to any commands from the front panel control buttons or the remote control unit, it is apparently locked in a failure or diagnostic mode, and would probably have to be diagnosed and repaired by a reputable TV repair facility. Good luck.

If it is a thin vertical line that appears on certain video resolution/image then it is normal and is indicated in the users manual under troubleshooting. If the line is almost half the screen, it could be a problem with the cable connection between the LCD panel and logic board, or the LCD panel itself. Try reseating the cable first if it’ll solve the problem. I’ve done similar issue in the past. Reseating the cable worked for a couple of months till eventually the LCD panel is the problem. Replacing the LCD panel is quite costly and impractical.

If the lines are there all the time or intermittent but in the same location it is an indication of a bad panel. The panel driver can also be the cause of this symptom.

If the lines/bars are across the OSD Menu, and all the video signal inputs also same result, that means the TV LCD Panel is defective Most of the time this symptom is caused by a bad LCD Panel 95%. You can try refitting LVDS Cable or replacing Main Board capacitors or replacing Main Board—5%

Bad news unfortunately, their are two possible causes for what you have described, one would be a fault with the picture drive pcb ( Power Control Board ), and the other is physical damage to the LCD cell matrix, (screen).

There’s videos on how to fix this. It has to do with putting foam, in between panel frame and screen, which applies pressure to solder joints, which then completes the circuit- Contact my10cents, for better explanation.

Is the OSD menu affected as well? If yes then possibility could be the LCD Panel or the t-con board. Since you have replaced the t-con board then possibility is the LCD panel. There could be also a possibility of mainboard where upgrading the firmware could restore the picture. If the OSD menu is not affected then the LCD panel is good.

If the lines are across the OSD menu then chances is very high the LCD panel is the cause of the problem otherwise it can be due to bad T-con board or even Mainboard. Have you tested on the OSD menu to see if the lines are really across the menu?

White Lines– There are several possibilities that can cause white lines on an lcd screen. One would be high temperature on the logic board. Logic board drives the LCD panel and when it overheats can cause this display problem. One solution would be to clean the vent holes around the TV. One possibility that I have experienced myself servicing is a bloated capacitor on the power supply board. The worst possibility is a defective LCD panel, which is costly to repair, and sometime more practical to buy a new TV set.

There are several problems that could cause this problem. It could be the connection from the T-Con board to the panel, try wiggling these cables around and see if the picture comes up even for a second. The Mainboard or it’s cables are not the issue in my opinion. The isdsue is either going to be a bad capacitor, faulty output from the power supply to the T-Con board, a bad connection from T-Con to panel, or the T Con or the panel itself are faulty.

It could be the connection from the T-Con board to the panel, try wiggling these cables around and see if the picture comes up even for a second. The Mainboard or it’s cables are not the issue in my opinion. This is due to either a bad capacitor, faulty output from the power supply to the T-Con board, a bad connection from T-Con to panel, or the T Con or the panel itself are fault. Also, it’s possible the A/V receiver’s Video On feature was turned off by an electrical surge or something else.Turn the Video feature back to On and suddenly that bad blue screen was gone.

Now we need to know if PSU Board has all the correct output voltages. This means checking the secondary side output voltages of Power Board. Probable causes are the Power Supply, the T-Con board, Main Board or the LCD panel itself has failed.

You will have to go into the TV and check for capacitors or burn marks or cracked solder around the pins–Main board could be IC’s, or regulators–Panel–Disconnect panel and see if your TV stay’s on—

The flashing green light indicates a fault on the power board inside your TV. This will be due to a faulty component like a capacitor or voltage regulator. Faulty electrolytic capacitors on the power board are the most common cause of this problem. These capacitors will often leak and stop working as the TV set gets older,but could also be caused by the Main Board or the inverter board. (LCD TV ONLY) So we will have to take a look inside and maybe do some circuit testing and a visual of your boards-

In a dark room take a flashlight and at an angle shine it on the screen and see if you can see any movement. If you can see movement or see your menu then its backlight failure. If totally black screen with sound then its T-Con board. So if you see movement on a led screen, then it’s your LEDs inside the panel. If on a LCD TV you see movement and lamps are not turning on, replace inverter. If with a LCD TV your lamps turn on, with no picture replace T-Con Board.

Plasma is the most durable in terms of panel failure. LED/LCD is terrible for panel failure. (But every model gets bad apples. Samsung LED/LCD panels die frequently. LG panels are a lot more reliable.) Overall I’d say plasma is more reliable, and even if it fails, in most cases plasma is repairable, LED/LCD is expensive to repair and often difficult to troubleshoot.

A blurry image on a high-definition LCD TV is typically the result of a mismatch between the TVs resolution capabilities and the resolution of the signal that is coming from connected devices, such as a DVD player or satellite TV receiver. Typically, blurry pictures result when a peripheral device connects to the TV through non HD cables and jacks.

With quite a high initial outlay, digital signage is never cheap to install and planning a return on this initial investment is vital before embarking on any digital out of home (Dooh) campaign.One thing that can really scupper the best thought out digital signage strategy is the failure of units once they are installed. Having to replace screens can dramatically alter the running costs of a digital signage campaign and if screen failure becomes a common occurrence, any return on investment may get more and more difficult with each added failure.

Ensuring the devices do not fail and that you get the maximum from the initial investment can drastically increase the chances of getting a ROI and making the entire campaign a success. Here are some of the most common reasons LCD screens and other devices fail in a digital signage campaigns.

Over heating is perhaps the most common cause of LCD and plasma screen failure. So many different components inside a modern LCD screen are vulnerable to excessive heat. Capacitors are the main culprit in an overheating failure and are very susceptible to heat build up as are invertors and many other components.

Preventing overheating is crucial for digital signage systems both indoors and out. Ensuring airflow and somewhere for the heat to disperse such as vents or louvers is essential to prevent overheating and ensuring the unit will continue operating. All digital signage or LCD enclosures should contain fans or other air flow systems to provide this heat dispersal.

Outdoor digital signage can often fail because of a lack of protection from the elements. Waterproof LCD enclosures should be manufactured to a recognised standard such as NEMA 4 or IP54 to ensure protection against rainfall and other hostile elements such as dust.

Consideration also has to be given to cold temperatures. Whilst heat is an electronic devices main enemy, extreme cold can be just as damaging as any internal humidity or condensation can freeze in causing expansion and damage to components. Any outdoor digital signage placed in sub zero temperatures needs some sort of heater system in the signage or LCD enclosure.

LCD flat screen TVs are commonly back–lit by cold cathode fluorescent lamps (CCFL) which are often the cause of failure. Usually CCFL’s go when there is a fault with other components such as the inverter, capacitors or power supply. However, more LCD screens are being produced with back-lit LED systems that not only are far more reliable, they also use a lot less power and produce far less heat.

Sadly, vandalism is a common cause of screen failure and ensuring any public or outdoor digital signage is protected against deliberate attack is important to prevent failure. Shatterproof screens and solid steel LCD enclosures are the best method of defending against such attacks.

Our data shows that LCD inspection in a controlled environment produces more accurate results. Our testing yields significantly higher passing rates than testing in the field. Too often, recoverable LCDs are wrongly deemed unusable. Why?

Field testers often produce false negatives due to connection issues. These failures can be intermittent so the tester is often not identified as the actual root cause.

Our repair capabilities ensure maximum recovery rates. We have the essential resources to make sure that every LCD that can be refurbished, is refurbished.

In our experience, a significant percentage of initial testing failures (once confirmed) can be successfully repaired through ACF bonding of the primary flex ribbons.

LCD Buyer is able to offer payouts (at reduced rates to account for the additional repair costs) for these candidates. This is one more way we get the maximum value for you. Please contact your rep for further details.

It is estimated that there are around one billion personal computers around the world, and with every single desktop computer, there is also a monitor attached to it. Every day, hundreds of computer monitors break down, and if you have a LCD monitor that you bought fairly recently and have questioned why it won"t turn on anymore, it"s most likely a power problem that can be fixed to save you hundreds of dollars. This guide will specialize on the computer monitor model LG L196WTQ-BF, but most monitors will follow similar design and can generally be fixed using the same instructions.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure. Accidental damage is not covered under the standard warranty of the product. Such damage is often the result of a drop or an impact on the LCD screen or any other part of the product which may render the device non-functional. Such types of damage are only covered under an Accidental Damage service offering which is an optional add-on to the basic warranty of the product. Accidental Damage must not be confused with an occasional dead or stuck pixel on the LCD panel. For more information about dead or stuck pixels, see the Dell Display Pixel Guidelines.

The LCD glass on the display is manufactured to rigorous specifications and standards and will not typically crack or break on its own under normal use. In general, cracked, or broken glass is considered accidental damage and is not covered under the standard warranty.

Spots typically occur due to an external force hitting the screen causing damage to the LCD panel"s backlight assembly. While the top layer did not crack or break, the underlying area was compressed and damaged causing this effect.

If your Dell laptop LCD panel has any accidental damage but the laptop is not covered by the Accidental Damage service offering, contact Dell Technical Support for repair options.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey