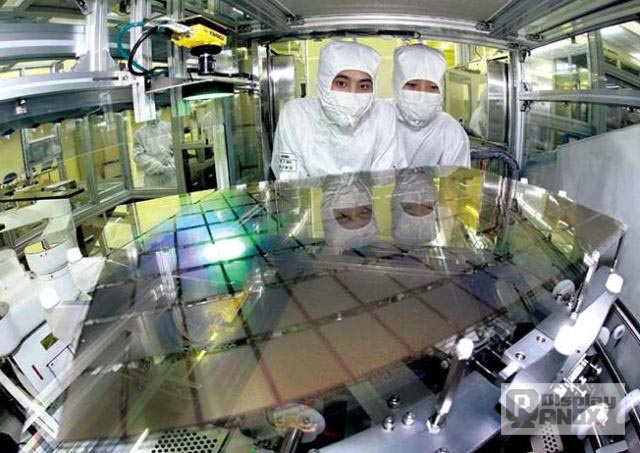

lg lcd panel manufacturer factory

LG Display Co., a major South Korean display maker, is expected to stop producing liquid-crystal display panels for TV by the end of this year at the earliest, industry sources said Monday, amid falling profitability and fierce competition from Chinese rivals.

The company said in a regulatory filing last week that it was reviewing an end of production at its LCD TV panel factory in Paju, north of Seoul, without specifying the exact date of production suspension.

The panel maker has been scaling down its loss-making LCD TV panel business, with a goal of discontinuing domestic production as early as possible. It has also said it will reduce production in China in a phased manner.

Demand was falling at an "unprecedented level" both for LCD and premium organic light-emitting diode panels, the company said during an earnings call in October, after years of pandemic-driven strong growth for personal IT devices.

Facing mounting challenges, the company has been trying to turn its business around by putting more resources in LCD panels for IT products and high-margin OLED business and expanding its high-value make-to-order business.

Kim Yang-jae, an analyst at Daol Investment & Securities, forecast OLED panels will make up for more than 60 percent of LG Display"s revenue by 2023, up from less than 40 percent in 2021.

LG Display"s fourth-quarter operating profit is forecast to be around 515.9 billion won, according to an estimate by Yonhap Infomax, the financial news and information arm of Yonhap News Agency.

Samsung Display, Samsung Electronics" display unit, had scaled down its LCD TV panel business since mid-2010 and completely stopped production in June.

LG Display (Korean: LG 디스플레이) is one of the world"s largest manufacturers and supplier of thin-film transistor liquid crystal display (TFT-LCD) panels, OLEDs and flexible displays. LG Display is headquartered in Seoul, South Korea, and currently operates nine fabrication facilities and seven back-end assembly facilities in Korea, China, Poland and Mexico.

LG Display was originally formed as a joint venture by the Korean electronics company LG Electronics and the Dutch company Philips in 1999 to manufacture active matrix liquid crystal displays (LCDs) and was formerly known as LG.Philips LCD, but Philips sold off all its shares in late 2008.joint venture, called LG.Philips Displays, dedicated to manufacturing cathode ray tubes, deflection yokes, and related materials such as glass and phosphors.

On 12 December 2008, LG.Philips LCD announced its plan to change its corporate name to LG Display upon receiving approval at the company"s annual general meeting of shareholders on 29 February. The company claimed the name change reflects the company"s business scope expansion and business model diversification, the change in corporate governance following the reduction of Philips" equity stake, and LG"s commitment to enhanced responsible management.

LG Display became an independent company in July 2004 when it was concurrently listed on the New York Stock Exchange (NYSE: LPL) and the South Korean Stock Exchange (KRX: 034220).

They are one of the main licensed manufacturers of the more color-accurate IPS panels used by Dell, NEC, ASUS, Apple (including iMacs, iPads, iPhones, iPod Touches) and others, which were developed by Hitachi.

In December 2010, the EU fined LG Display €215 million for its part in an LCD price fixing scheme.Chimei Innolux, AU Optronics, Chunghwa Picture Tubes Ltd., and HannStar Display Corp.

This followed the 2008 case in the US, when LG Display Co., Chunghwa Picture Tubes and Sharp Corp., agreed to plead guilty and pay $585 million in criminal finesliquid crystal display panels.

LG Display would pay $400 million, the second-highest criminal fine that the US Justice Department antitrust division had ever imposed. Chunghwa would pay $65 million for conspiring with LG Display and other unnamed companies and Sharp would pay $120 million, according to the department.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

LG Display will also continue to manufacture LCD panels for TVs at its facility in Guangzhou, China. However, their production capacity will be reduced by 40% than before __ from 210,000 Gen 8.5 substrates per month to 120,000. The facility has two factory lines __ GP1 and GP2.

In the more recent decades, LG Electronics has steadily established a few factories in other countries and places such as New Zealand, Australia, Asian nations, and American countries as well. Some of their Korean plants even migrated to these nations too.

LG opened a new factory in Hai Phong, Vietnam, back in 2015 for the purpose of producing smartphones. In April 2021, however, just 6 years after the LG factory was established, the company decided to discontinue the production of its mobile phones.

It was announced afterward that the Hai Phong plant has been refocusing on the production of household appliances and other electronics since LG Vietnam manufactures led TVs from the start.

LG has factories in China, notably in the industrial city of Guangzhou, China. They produce TVs, smartphones, air conditioners, and other LG products. Production of liquid crystal displays seems to be more of the focus in this plant, as it was listed to be under LG Display.

In 2021, it was reported that LG Display was expanding its production capacity of OLED displays used for their top-tier TVs in the Guangzhou factories due to cheaper labor and materials.

LG Electronics exports up to 10% of their total component production in LG India. One of the TV products initially sold for the Indian market was the ‘mosquito-repelling television,’ which uses ultrasonic waves that causes mosquitoes to avoid the area.

LG factories in LG Indonesia are the longest-running factories for the company, established way back in 1990. Recently, before the COVID-19 pandemic, two factories in Gumi, South Korea[1]are gradually moving production to Indonesia.

These LG Korean plants were migrated as a strategy to better respond to the consumer demands in Southeast Asia and Australia. OLED displays and Ultra HD TVs will be the primary focus of these two production lines.

LG established LG TV factories in Ruza, which manufacture TVs at an estimated 1 million TV units annually. While the facility ships LG products to Eastern European countries, it does face tight competition with Polish LG facilities.

Furthermore, plans are already in place to establish a multi-million EUR plant in Wroclaw, Poland, with LG intent on making it the biggest battery plant in the world. Suffice to say, LG TV factories won’t be leaving Poland anytime soon.

We have LG Russia and Poland for the European market, but what about the USA? In Mexico, LG manufactures TVs for the North American market through its TV factory in Reynosa.

To cope with the demand for LG TVs in the US, South America, and Latin America, Mexico LG reportedly increased its TV production capacity in the country last 2019.

There are industry overlaps in Mexico, the strongest industry being electronic production, which greatly benefits the appliance manufacturing sector. It was reported that more brands are establishing factories in Mexico along with LG.

Their entire range of LED TVs is highly commended for their excellent picture quality. Chinese TV manufacturers are also emulating their TV production.

Chinese brands like TCL and Hisense are producing TVs with high specifications and large screens like LG does. Given their long history in manufacturing televisions and the revenue growth, this has contributed to the company, one thing is clear: an LG TV is built to last.

Among the world famous brands, the screen of South Korea"s samsung and LG is known to be produced and sold by themselves.Display screens of other niche brands, and those brands capable of self-production and self-marketing, also have an unassailable position in their own segments, facing various brands.For buyers, how to find suitable suppliers from these LCD panel manufacturers?

The world-renowned LCD panel production line is mainly controlled by several enterprises: au optronics in Taiwan;Chi mei electronics in Taiwan, China;Sharp, Japan;South Korea samsung, South Korea LG;Philips;Boe, etc.These companies supply the world"s main demand for liquid crystal displays.

LG Display is currently the world"s first LCD panel manufacturer. It is affiliated to LG group and headquartered in Seoul, South Korea.Its subsidiaries are: LG electronics, LG display, GS caltex, LG chemistry, LG life and health, etc., covering the fields of chemical energy, electronics and appliances, communication and service.LG Display"s customers include Apple, HP, DELL, SONY, Toshiba, PHILIPS, Lenovo, Acer and other world-class consumer electronics manufacturers.LG"s manufacturing base in China is in nanjing, shenyang.

Innolux is a tft-lcd panel manufacturing company founded by foxconn technology group in 2003.The factory is located in longhua foxconn technology park in shenzhen.Innolux has a strong display technology research and development team, coupled with foxconn"s strong manufacturing capacity, to effectively play the vertical integration benefits, to improve the level of the world plane display industry will have a pointer contribution.In March 2010, it merged with chi mei electronics and tong bao optoelectronics.

Au optronics, formerly known as acer technology, was founded in August 1996. It was renamed au optronics after the merger of au optronics and united optronics in 2001.Au optronics is the world"s first tft-lcd design, manufacturing and development company to be publicly listed on the New York stock exchange (NYSE).

Au optronics is the first manufacturer in the world to obtain ISO50001 energy management system certification and ISO14045 product system certification for ecological benefit assessment. Au optronics has been included in the dow Jones world sustainability index in 2010/2011 and 2011/2012, setting an important milestone for the industry.

Boe, founded in April 1993, is the largest display panel manufacturer in China and a provider of Internet of things technology, products and services.At present, boe has reached the world"s first place in the field of notebook LCD, flat LCD and mobile LCD. With its success in joining the apple supply chain, boe will become the world"s top three LCD panel manufacturers in the near future.

Sharp is known as "the father of LCD panel".Since its founding in 1912, sharp corporation has been developing the world"s first calculator and liquid crystal display, represented by the live pencil, which is the name of the company. At the same time, sharp corporation has been actively expanding new fields, contributing to the improvement of human living standards and social progress.Sharp is already owned by foxconn.

The company has set up tft-lcd key materials and technology national engineering laboratory, national enterprise technology center, post-doctoral mobile workstation, and undertakes national development and reform commission, ministry of science and technology, ministry of industry and information technology and other major national special projects.The company"s strong technology and scientific research capabilities become the cornerstone of the company"s sustainable development.

LG Display has started mass-production at its second OLED panel production plant, the company announced Thursday. The new plant, located in Guangzhou, China, has the capacity to initially produce 60,000 OLED sheets a month, which combined with LG’s existing plant in Paju, South Korea means that LG Display’s total OLED production capacity has almost doubled to 130,000 sheets monthly.

According to LG, the panels produced at its new plant will be used to create displays ranging in size from 48 to 77-inches. They’re for TVs, in other words. LG Display is a major supplier of OLED panels for TVs across the industry. 19 brands, including LG, Vizio, Sony, Panasonic, Hisense, Bang & Olufsen, and Toshiba, use LG Display OLED panels in their TVs according to FlatPanelsHD.

The opening of LG Display’s new plant comes as it and competitor Samsung Display are shifting their attention away from LCD panels, which the majority of TVs currently use. LG Display announced earlier this year that it is ending production of LCD TV panels in South Korea, Reutersreports, while Samsung Display said it was ending LCD display production in South Korea and China.

LG Display’s CEO, James Hoyoung Jeong, said he hoped the new plant will “enable more rapid adoption of OLED displays in the market.” He called large OLED displays an “essential growth engine” for LG Display. LG Display says that production capacity could increased to 90,000 sheets a month in the future at the new factory.

By 2021, LG Display has said it wants OLED panels to make up 50 percent of its revenue, up from around 30 percent in 2018, according to Reuters. Samsung Display, meanwhile, is pinning its hopes on quantum dot, with ZDNet reporting that its future QD displays will incorporate an OLED panel rather than the LCD layer used by its existing displays.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAscensionAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia-HercegovinaBotswanaBrazilBritish Indian Ocean TerritoryBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, Dem Rep ofCook IslandsCosta RicaCroatiaCubaCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEast TimorEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IsHondurasHungaryIcelandIndiaIndonesiaIranIraqIrelandIsraelItalyIvory CoastJamaicaJapan 曰本JordanKazakhstanKenyaKirgizstanKiribatiKosovoKuwaitLaosLatviaLebanonLeeward IslesLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedonia, FYRMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Fed States ofMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestinePanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandPolandPortugalPuerto RicoQatarReunionRomaniaRussiaRwandaST MartinSaint HelenaSaint Kitts and NevisSaint LuciaSaint Vincent and GrenadinesSamoaSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth GeorgiaSpainSri LankaSudanSurinameSwazilandSwedenSwitzerlandSyriaTaiwanTajikistanTanzaniaThailandTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUS Minor Outlying IsUgandaUkraineUnited Arab EmiratesUnited KingdomUruguayUzbekistanVanuatuVenezuelaVietnamVirgin Islands, BritishVirgin Islands, USWallis and FutunaYemenZambiaZimbabwe

LG Display saw a decrease in panel shipments in the fourth quarter due to worsening macroeconomic conditions, as set makers’ inventory adjustments further impacted demand in the high-end product sector which had been solid.

The company recorded a quarter-on-quarter increase in revenues by 8% thanks to increased panel shipments for mobile devices, while reporting an operating loss due to a continuous decline in mid-sized panel prices and a high-intensity action plan of utilization adjustment to decrease inventory.

Panels for TVs accounted for 25% of revenues in the fourth quarter, while panels for IT devices including monitors, laptops and tablet PCs accounted for 34%, panels for mobile and other devices accounted for 34%, and those for automobiles accounted for 7%.

LG Display will make all-out efforts to improve the financial structure by strengthening its operations focusing on market-to-order business in response to market volatility and economic uncertainty.

With respect to the market-to-order business which now accounts for 30% of its revenue, LG Display will expand its share in revenue by over 40% in 2023 and 50% in 2024 to establish a stable profit structure resilient to market conditions. In addition, the company will further strengthen its position in the automotive display sector and continue to lead the mid-sized OLED market including tablet PCs, as the rise in smartphone panel shipments in the second half of 2023 is expected to add positive fuel to its efforts to enhance its market-to-order business.

After the company’s decision to end its LCD TV panel production in Korea, LG Display"s large-sized OLED business was evaluated by an external institution and divided into separate cash-generating unit in accordance with related accounting standards and objective procedures. The company’s large-sized OLED business was reflected KRW 1,331 billion as asset impairment loss after calculated by an external institution, causing the net loss to expand. Considering it occurred only in the financial statement without actually affecting business operations, it is in turn expected to remove possible uncertainties in the company’s businesses in the future.

For its large-sized OLED business, LG Display will further strengthen its profit structure by improving competitiveness in products and costs while concentrating continuously on qualitative growth. In addition, the company will make efforts to enhance its market position by further improving its fundamental competitiveness with its OLED technology, as well as expanding its market-creating business with high growth potential such as Transparent and Gaming OLED panels.

LG Display will also secure financial soundness by minimizing its investment such as investing only in essential and market-to-order businesses, while maintaining its inventory at the minimum level and flexibly adjusting production accordingly.

“Our preemptive move to reduce the company’s inventory in the fourth quarter is expected to improve our performance down the road, and the quarterly result is also expected to improve as we continue to intensely reduce our costs,” said Sung-hyun Kim, CFO and Senior Vice President at LG Display.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

LG Display, a major Korean display maker, is expected to stop producing liquid-crystal display (LCD) panels for TVs by the end of this year at the earliest, industry sources said Monday, amid falling profitability and fierce competition from Chinese rivals.

The company said in a regulatory filing last week that it was reviewing an end of production at its LCD TV panel factory in Paju, Gyeonggi, without specifying the exact date of production suspension.

The panel maker has been scaling down its loss-making LCD TV panel business, with a goal of discontinuing domestic production as early as possible. It has also said it will reduce production in China in a phased manner.

Demand was falling at an "unprecedented level" both for LCD and premium organic light-emitting diode (OLED) panels, the company said during an earnings call in October, after years of pandemic-driven strong growth for personal IT devices.

Facing mounting challenges, the company has been trying to turn its business around by putting more resources in LCD panels for IT products and high-margin OLED business and expanding its high-value make-to-order business.

Kim Yang-jae, an analyst at Daol Investment & Securities, forecast OLED panels will make up for more than 60 percent of LG Display"s revenue by 2023, up from less than 40 percent in 2021.

LG Display"s fourth-quarter operating profit is forecast to be around 515.9 billion won, according to an estimate by Yonhap Infomax, the financial news and information arm of Yonhap News Agency.

Samsung Display, Samsung Electronics" display unit, had scaled down its LCD TV panel business since mid-2010 and completely stopped production in June.

While LG Display isn’t the only manufacturer out there making OLED panels, it’s pretty much the only one that counts when it comes to the size and quality of OLED panels required for today’s TV sets. Reports have recently emerged from multiple sources, though, suggesting that another display manufacturer, BoE, is preparing to start making OLED panels big enough for TV use too.

The well connected people at market research company Display Supply Chain Consultants confirmed on the back of the Display Week showing that BoE really does seem intent on making such large panels on a commercial basis. Assuming that their information is correct (it usually is), it doesn’t require much of a mental leap to think that such a move would spell good news for OLED-loving consumers. After all, more panel suppliers means more competition, which usually in turn means cheaper prices and more innovation.

For starters, don’t forget that BoE’s 95-inch OLED prototype really was a very high-end affair. Its combination of a huge screen and native 8K rather than 4K resolution was joined by a native 120Hz refresh rate, coverage of around 99% of the DCI-P3 colour range, and pretty high peak brightness of 800 nits – the sort of specifications that consumers can currently expect to spend tens of thousands of pounds to secure. LG’s latest ‘mere’ 88-inch native 8K OLED model, for instance, the OLED88Z2, costs a cool £25,000 / $25,000 / AU$60,000 at the time of writing. Even if BoE manages to deliver a king-sized OLED panel cheaply enough to enable TV brands to sell huge OLED TVs for much less than that, it’s safe to say they will still hardly be mainstream propositions.

As OLED-info reports, though, the ‘B5 R&D Line’ in China that BoE is apparently eyeing up for production of its TV-sized panels currently has a very low capacity by today’s panel production standards. It’s certainly not capable of producing anything like the quantities of big-screen OLED panels that a number of LG Display lines can. In fact, its apparent production capacity for large OLEDs appears to be so limited that analysts suspect that BoE likely isn’t even contemplating trying to use it to produce screens for the ‘mass market’, focusing instead purely on the high-end niche.

Actually, if some of the ‘chatter’ surrounding the Display Week show is to be believed, BoE might even struggle to move the premium OLED TV dial, at least in the short term, since while the 95-inch RGBW panel BoE showed apparently impressed in some ways, its overall quality supposedly didn’t feel as if it was yet sufficient for a full real-world roll out. Though I should add that I haven’t found anyone sharing specific examples of the sort of issues the BoE panel allegedly suffered with.

It does appear, on the upside, as if the yield rates of usable panels at BoE’s B5 production line are pretty high, at least. The simple reality, though, is that once you delve even a little behind the eye-catching ‘major new manufacturer eyes big-screen OLED production’ headlines, the prospect of a pitched new battle between two makers of TV-sized OLED panels and the hammering of OLED TV prices that might follow doesn’t look set to become a reality any time soon.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey