minimum clock speed needed for lcd tft display manufacturer

Low voltage differential signaling (LVDS, also known as OpenLDI) thin-film transistor (TFT) liquid crystal (LCD) displays typically have a specified resolution and minimum required clock frequency to meet desired resolution. Normally, you will find this information listed in the display data sheet and won’t need to perform any calculations.

However, if you do not yet have access to your display data sheet and only know what resolution you want your system to support, you can estimate what clock frequency you need and determine which serializer/deserializer (SerDes) is appropriate for your application.

%Blanking: The blanking period, or the percentage of time when active video is not being displayed. As shown in Figure 1, it is represented horizontally as horizontal pulse width (HPW), horizontal back porch (HBP) and horizontal front porch (HFP). It is also represented vertically as vertical pulse width (VPW), vertical back porch (VBP) and vertical front porch (VFP).

The values for these blanking parameters are listed in display data sheets. The total blanking period varies from 3% to 39%. If your system uses reduced blanking, then you can estimate %Blanking at 10%. If you are not sure what blanking period your system uses, estimate around 20% and above to be conservative.

Frame rate (or refresh rate):the frequency at which consecutive images (frames) are displayed, and is measured in hertz or frames per second (fps). 60Hz is the most common frame rate, but this value can vary from 24Hz to 70Hz.

Throughput is another metric that you can use to determine whether or not a device will support your desired display resolution. The throughput is the effective payload of video data, and is derived from the required pixel clock frequency and color depth of your system, as shown in Equation 2:

Color depth: For a first-generation SerDes like the SN65LVDS93A, color depth is typically 24-bit red-green-blue (RGB) or 18-bit RGB for single pixel in, single pixel out (SISO) applications, and 48-bit RGB or 36-bit RGB for dual pixel in, dual pixel out (DIDO) applications.

The color depth will determine how many LVDS data lanes your display requires. SerDes serialize data at a rate of 7x the pixel clock frequency on each LVDS data lane. If the color depth is 24-bit RGB, then you will need four LVDS data lanes (there are an additional four bits used for control, which brings the total bit count to 28 bits) and can use a SerDes like the SN65LVDS93A. If the color depth is 18-bit RGB, then you will need three LVDS data lanes (there are an additional 3 bits used for control, which brings the total bit count to 21 bits) and can use a SerDes like the SN74LVDS84A or the SN65LVDS93A.

If the color depth is 48-bit RGB, then you will need eight LVDS data lanes (there are an additional 8 bits used for control, which brings the total bit count to 56 bits) and will need to use a device like the DS90C387 or DS90C189-Q1, which can output as many as eight LVDS data lanes.

When calculating the throughput for DIDO applications, you need to calculate the throughput for the odd pixels and even pixels separately and then add them together. For example, for a 48-bit DIDO application, the total required throughput would be 2 x Pixel Clock x 24.

Since the color depth is 24-bit RGB, you will need four LVDS data lanes. The SN65LVDS93A is a good fit for this application, since it has a pixel clock frequency range of 10MHz to 135MHz. Additionally, the maximum throughput for each LVDS data lane on this device is 135 x 7 = 945Mbps. Because this device has four LVDS data lanes, the total maximum throughput is 945 x 4 = 3780Mbps, which is higher than the minimum required throughput.

So the minimum pixel clock frequency to support a 2048 x 1536 resolution display is 208MHz. However, since this is a 48-bit DIDO application, there are actually two clocks: the frequency is split between them. Each clock must have a frequency of at least 104MHz.

Since the color depth is 48-bit RGB, you will need eight LVDS data lanes. The DS90C387 and DS90C187 are a good fit for this application, since they have a pixel clock frequency range of 32.5MHz to 112MHz (the DS90C387) and 25MHz to 105MHz (the DS90C187) for each channel in DIDO applications. Thus, if you don’t have access to the display data sheet yet, you can still estimate the required pixel clock frequency and throughput to support your desired resolution. If the SerDes does not meet these parameters, data on the display may display incorrectly, or not display at all.

This note will discuss the considerations made when choosing a microcontroller that will work for your display. A few requirements need to be met depending on the display’s features, interface, and size. These can also be determined by the embedded IC in the display. An overview of the considerations when choosing a microcontroller can be seen below. It should be noted that these items are separated for definition but may serve the same purpose and be interconnected in the ecosystem of the controller.

Application and display specific peripheral requirements. I2C, SPI, UART, Parallel, MIPI, LVDS, HDMI etc. Determines pin connections and required architecture of the device.

Flash and RAM memory requirements. Minimum frame buffer memory is dependent on the size andresolution of the display. Location of memory (external or internal) can restrict interface speed and must becompatible with the chosen interface.

Communication speed requirements defined by the interface and intended application. Refresh rateis determined on the size of the display and location of memory. This will indicate which processors arecompatible.

A displays embedded IC can offer resources such as internal RAM, clock generators and power control.This can save resources otherwise needed to be provided externally. Check the datasheet of the display’s ICcontroller for device function specifics.

Availability of resources for programming and debugging the microcontroller. Online resources andexampleprograms to leverage from can a lot of save time. Compatibility with a familiarprogramming environment isadditionally beneficial.

The interface selection is dependent on the intended application of the display. Each display has a different interface or different choices for a connection interface. For smaller displays a 3/4-wire serial interface would be sufficient. For larger display’s with high resolution a faster interface should be chosen. A parallel RGB interface is capable of high-speed data transmission however requires many pin connections. If the intended application for the display is video a MIPI, LVDS or HDMI connection would be a good choice.

The available memory of a microcontroller often becomes a highlighted issue when determining which microcontroller to select. The microcontroller needs a minimum amount of RAM to hold the frame buffer of the display. Even small displays require more RAM than a typical microcontroller possess. To verify that your microcontroller will have enough memory, it is important to calculate the frame buffer.

The minimum RAM required for the frame buffer in this example would then be 768kB. It is important to note that external RAM can be provided for the frame buffer if the microcontroller does not provide it internally. Clocking speed should be verified if using external RAM as the microcontroller cannot access external RAM as quickly. The clock frequency constrained by external RAM sometimes does not meet the minimum requirements of some very high-speed interfaces (ex. DSI-MIPI). Additionally, the display can contain some form of RAM depending on the IC controller inside the display. This can be verified on the specification sheet of the IC.

The speed of the microcontroller is heavily dependent on the interface used in the application. The minimum and maximum of the clock frequency is specified in the datasheet of the display and in the specification sheet of the display’s controller IC. The frame rate is typically around 50-60Hz, which is the median oscillation frequency to refresh the display to maintain an image. The display will often provide an internal high frequency clock that can be initialized to certain frequencies.

It is important to verify in the controller data sheet which resources are provided by the internal IC of the display. Some key information to look for would be: Does the display have sufficient RAM or does this need to be provided? Does the display have an internal oscillator for clock generation for the interface chosen? An additional graphics controller can be used to interface the display with the microcontroller to meet these requirements. Features like these can be utilized to avoid additional cost, space, and memory of your application.

After a brief consideration of intended application and interface of the display you can get some idea of which microcontroller processor and architecture you will need. There are a few different microcontroller processors to choose from. The main choices are ARM, AVR, PIC, and 8051. The difference between them is the bit size of the processor, 8-bit, 16-bit, 32-bit or 64-bit data . The data bit width is the amount of data that can be sent at a time. This determines the speed of data transfer and thus compatible applications and interfaces.

The AVR has an 8-bit processor and is a RISC type microcontroller. This type of processor is compatible with low speed interfaces (SPI, I2C) and smaller displays. A common AVR microcontroller board is the Arduino which has the embedded 8-bit ATMEL RISC processors. These processors are widely popular which provide the benefit of numerous online resources and availability. The Arduino processors (ATmega/SAM3X) are typically available in most microcontroller programming environments. Additionally, Arduino offers 32-bit AVR development boards which function closely to the ARM processors.

The AVR microcontrollers are constrained by the low frequency, internal memory availability and power costs. AVR’s cannot use external program memory but some may allow expansion of external SRAM. These microcontrollers alone would be incompatible for high frequency applications such as video, large displays, or capacitive touch panels.

The ARM microprocessors have a RISC architecture. They offer 32-bit or 64-bit processors and are great options for high speed interfaces (Parallel, LVDS, MIPI, HDMI) and high-resolution displays. Common ARM processors can be found from STMicroelectronics and Raspberry Pi. The most common version of the ARM processors is the “Microcontroller” Arm-M group which include the Cortex-M0 and Cortex-M4 series.

The ARM processors are compatible with most displays and connection interfaces. These microcontrollers have become increasingly popular, so the cost has become comparable between the ARM and the AVR types. These processors provide the speed, but it is recommended to verify the available RAM as these boards vary widely on included features.

The PIC architecture consists of 8, 16, and 32-bit processors developed by Microchip. The PIC 32-bit series of microcontrollers have been geared toward graphical embedded applications and there are a lot of resources online for these devices. There is a huge variety of PIC controllers which make them easily available. These microcontrollers are known for being low cost and are comparable to the ARM processors. The drawback of the PIC controllers is using Microchips programming environment, but this is based on preference.

The Intel MCS-51, more commonly known as the 8051 microcontrollers have a CISC architecture and an 8-bit processor. These processors differ in architecture from the previous and are programmed using a combination of C and assembly languages. The program memory is read only and does not have an on-board ISP. A special programming device is needed to rewrite the EEPROM or flash memory. These processors are typically small, low cost and low powered. This can make them favorable for battery powered devices. These processors are commonly used to initialize TFT displays and are combined with a graphics controller to provide the required resources such as RAM and clock frequency.

Development environments and online resources become considerably valuable when creating an application for your display. A brand new or uncommon microcontroller will have very few resources for reference. Even knowledgeable engineers can find frustrations with the manufacturers programming environments. There are many microcontroller choices that will support your display with similar and overlapping features. Choosing a microcontroller with an available FAQ, application notes or is accessible on a familiar programming platform can save a lot of time.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

Designer agrees that prior to using or distributing any applications that include FocusLCDs products, Designer will thoroughly test such applications and the functionality of such FocusLCDs products as used in such applications.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Since the display includes the Ilitek ILI9320 controller, then your interface requirements are much lower, as the microcontroller no longer has to interface directly with the TFT and instead only talks to the controller chip via a simple interface: either SPI, which takes six wires: RS, CS, CLK, MOSI, MISO and RESET. Or you can use an 8080-compatible parallel interface which takes 13 wires: an 8-bit data bus, and RS, CS, WR, RD and RESET. (There are options to use larger data-buses, up to 18 bits, but I don"t recommend that for a low end microcontroller.)

There are two optional interfaces in which the microcontroller generates all of the clock signals (VSYNC, HSYNC and DOTCLK); you don"t want to do that since it would require a high-end controller.

So just about any microcontroller will do, however you need to have enough flash memory to hold whatever static items you want to display; for example if you are going to be displaying text then you will need to allocate arrays to store bitmaps for whatever fonts you will use. Even a small font can take 60KB.

This application note describes the i.MX6 CPU graphical system and the steps to define a new custom TFT (Thin Film Transistor) display panel in Digi Embedded Yocto and discusses the most standard panels available. Some panels may need special consideration.

An LCD panel is a matrix of pixels that are divided into rows and columns. These pixels are individually painted according to different signals and timing parameters, and you can control each pixel"s color individually. The panel is continuously refreshed, typically at around 60 Hz, from the contents of the frame buffer memory. Each memory location on the frame buffer corresponds to a pixel on the LCD panel.

A 1024 x 600 resolution display requires 614400 memory locations, with each location having a number of possible colors. The number of bits needed to describe the available colors is called bits per pixel (bpp). For example, 16 bpp can describe 65536 colors and 24 bits can describe 16777216 colors (known as true color). A panel with 614400 24-bit locations requires a 1800 KB frame buffer.

Every manufacturer provides display timings in a slightly different way and some provide more detail than others. Most LCD panels work with a range of timing parameters.

The ConnectCore 6 system-on-module is designed in different module variants with both the i.MX6 Quad/Dual or i.MX6 DualLite/Solo System-On-Chips. The i.MX6 Quad/Dual has two Image Processing Units (IPU0, IPU1), each containing two Display Interfaces (DI0, DI1) while the i.MX6 DualLite/Solo has just one IPU.

NoteIf you are working on the ConnectCore 6 SBC, the corresponding IOMUX settings for the different interfaces are already configured on DEY. If you are working on a custom carrier board, you must provide the corresponding IOMUX settings on the machine"s device tree.

The i.MX6 Dual/Quad has two IPUs, each containing two DIs. Additionally, the driver allows for an overlay frame buffer per IPU (to be displayed over the frame buffer of DI0). These overlay frame buffers are also represented by nodes /dev/fbN.

Frame buffer devices provide an abstraction for the graphics hardware. You must create a frame buffer entry on your platform"s device tree file and bind it to a graphics driver through the compatible property.

The driver"s binding documentation at Documentation/devicetree/bindings/fb/fsl_ipuv3_fb.txt describes additional properties for the frame buffer. You must complete the node with required and optional properties that match your hardware, for example:

You can create as many frame buffer entries as you have available display interfaces in your platform. For example, the i.MX6 Dual/Quad has two IPUs, each containing two display interfaces, equaling a total of four displays:

NoteYou can configure the LVDS display bridge for different modes (separate 0 mode on the above example). Refer to the driver"s binding documentation at Documentation/devicetree/bindings/fb/fsl_ipuv3_fb.txt and to the i.MX6 CPU reference manual for details about the different supported modes.

LCD displays must be created as nodes in the device tree with a display-timings subnode. Display timings binding documentation at Documentation/devicetree/bindings/video/display-timing.txt explains the required timing properties to describe an LCD.lcdname {

Digi Embedded Yocto for the ConnectCore 6 SBC platform supports the Fusion 10.1" LVDS display out of the box. This section describes how this display was added so that you can use it as reference for similar displays.

With the information on the datasheet you must fill in the display-timings property of your display node in the device tree. This example uses the values on the typical column:

hfront-porch is the horizontal front porch, the number of clock pulses (pixels) between the last valid pixel data in the line and the next HSYNC pulse. According to the LCD data format, this value is zero.

hback-porch is the horizontal back porch, the number of clock pulses (pixels) between HSYNC signal and the first valid pixel data. According to the image above, this value is zero.

hsync-len is the number of clock pulses (pixels) during which the HSYNC signal is active. On the datasheet this corresponds to t6 Horizontal Blanking Time (176).

vfront-porch is the vertical front porch, the number of lines (HSYNC pulses) between the last valid line of the frame and the next VSYNC pulse. According to the LCD data format, this value is zero.

NoteThe recommended timings from the LCD datasheet often do not work perfectly, as each platform introduces noise and delays that affect the display"s signals and timings.

Using the information on the datasheet, you must fill in the display-timings property of your display node in the device tree. This example uses the values on the typical column:

hfront-porch is the horizontal front porch, the number of clock pulses (pixels) between the last valid pixel data in the line and the next HSYNC pulse. The datasheet does not provide this number but it provides the complete Horizontal period (TH) and the Horizontal period (High) (THd) so you can calculate the horizontal front porch as TH - THd = 1680 - 1280 = 4001.

This color chart displays a white one-pixel frame at the edges of the LCD (which allows you to verify correct position and width/height), and gradients of red, green, blue, and white (which allow you to verify correct color depth and format).

We will organize the kinds of display interfaces we offer, and how they differ. You will get to know what kind of external and internal interfaces we have and what are their main applications.

First, let us start with dividing internal and external interfaces in LCD modules. Internal interface of display means it used inside the device. Those are usually the embedded interfaces that are not visible, and we do not have access to them as the users of the device. External interfaces, on the other hand, are connected to the device using a cable. Once we have defined internal and external interfaces, both of these categories come as universal or image transfer interfaces.

A protocol defines the rules of information exchange, where the interface is the medium. The example here could be the language. When I use my voice to communicate with other people, my voice is an interface. Over this interface my voice is being sent to other people’s ears, and the protocol is the language used. Right now, I am using the English protocol. If you understand the protocol, you understand what I am saying. If I switch to a different language, Polish or some other language that you do not understand, you have the same interface, you will still hear me, but because of a different protocol, you do not understand me anymore. In this article we will talk only about interfaces, how to connect devices to each other. We will not focus on protocols.

Let’s try to get the interfaces right. For internal interfaces, interfaces embedded into the device, we have universal interfaces and image transfer interfaces. Universal display interface can send other data, not only an image. Being universal, they are not perfect for image transfer, because in most of the displays used nowadays, the image transfer is one of the most demanding. The bit rate, the data transfer needed for the image transfer is rather high. Higher that many universal interfaces can offer. If we need to send an image every once in a while, then we don’t need very high bandwidth. If we do not need live video stream, then we can use some of the internal universal interfaces such as SPI, I2C or even slow interfaces as RS232 or UART.

The first universal interface will be SPI (Serial Peripheral Interface). This interface is serial, used for communication between a host, in SPI called a Master, and devices called Slaves. One host can communicate with many slaves. To select the Slave, we use the Chip select or SS line and then we use two data lines, Master output or Master input. And of course we have to define the clock, to synchronize the data, because this is a clock synchronized interface.

It can be fast but is not fast enough for live video. The baud rate can be 1 MBd, but it can also be 10 MBd or even 50 MBd on the SPI or QSPI. QSPI is a Quad SPI, a kind of modification of SPI that is faster. But still this interface is very universal, we can use it to connect memory or some input and outputs internally in our device. In the display universe the SPI is used for simple displays, for small size displays, where we can transfer the image relatively fast, because the resolution is low. The maximum size for SPI display interface would be 3.5 inch, 320 by 240 pixel TFT displays. If we have higher resolution, image transfer will be too slow to use SPI even with a high-speed SPI.

Next, we have the I2C interface. This kind of interface is usually slower than SPI. It uses only two lines, so one is a clock for synchronization, and the other one is the data line. This data line is bidirectional. It means that if in SPI we have two data lines, one outgoing and one incoming, then in an I2C interface we have only one data line.

If, for example, the Master is sending some data, the only thing Slaves can do is to receive it. And then we need to wait a little bit for the Master to finish. We can then respond as Slave to Master. In I2C Slave selection works a little bit different than in SPI, where we had a Chip Select line (CS line) or SS line to select from. In I2C we first need to send the logical address to the interface that is being written by Slaves. In general, this procedure is slow and universal interface used also to connect the simple memory and some other I2S that we have around our microcontroller on the PCB. It is very useful, but usually not used for image transfer. This interface is very popular in the display world for touchscreens. Most of the embedded touch screens that we use have I2C interface because the touchscreen does not generate many data. We only have coordinates of the finger or few fingers at most, that need to be sent back to the microcontroller, to the device processor. The slow baud rate is good enough for the touchscreen, but not enough for the image.

The UART is basically the same as RS232, but it is a fully internal interface. It is pretty slow. We have a TX line and a RX line – a Transmit Line and a Receive Line. We do not have a clock here, we only have a clock to synchronize the device internally, but the clock signal is not sent out. So, we need to synchronize the data that is coming through the lines and to do that we need to set the same baud rate on both sides of the communication line. That means that before we use UART we need to agree first what speed we will use.

That is not a case for SPI or I2C, because we have a clock there that gives the speed to every device. Then each device works according to the clock. In UART we do not have a clock. It is rather not used for image transfer. The UART, or SPI, or I2C can be used for low resolution displays. For high resolution displays we need an Intelligent Display, a display that will generate the image internally and through these slow universal interfaces we only send commands, or we send the image once, the image is being stored into the internal memory of the intelligent display, that we will use later sending the commands. You can find Riverdi’s intelligent display line on our website: https://riverdi.com/product-category/intelligent-displays/.

These Riverdi products are very advanced Intelligent Displays, made with Bridgetek controllers. The controllers use SPI and QSPI for communication. That means your software, your system, your microcontroller can be simple. You can use SPI interface to drive them, and you can still have high resolution image, even as high as 1280 by 800 pixels in 10.1-inch LCD displays. So, please remember that if you want to use a slow universal interface and have a high-resolution image, you need to use an Intelligent Display.

There are also the internal image transfer interfaces. The image transfer interface allows continuous high speed image transfer. Internal transfer is high enough to refresh the display many times per second. This is called the refresh rate of a display. When you go to a display, monitor, or TV set specification, you will see refresh rate or maximum refresh rate parameter. If it’s 60 Hertz, that means the display image is refreshed 60 times per second. More advanced displays would have higher values, like 100 Hertz. The refresh rate means we need to send full image 60 times or 100 times in each second. To visualize this amount of data, we need to multiply refresh rate by the resolution of the screen. For example, for a 7-inch Riverdi LVDS display with resolution 1024 by 600 it is roughly 600 thousand pixels.

The most common internal image transfer interface in industrial LCD displays nowadays is LVDS – Low Voltage Differential Signal. A crucial feature of this interface is that it is differential. It means that the signal is immune to interference and we can use a twisted pair of wires to transfer the data. We can send data fast and it will not be corrupt by any noise, interference. This kind of data corruption is quite common in other interfaces.

The next, older image transfer interface is called RGB. Name comes from the colors sent parallelly to the display: red, green and blue. LVDS is a serial interface and the RGB is a parallel interface. The main difference is that RGB is not differential, so it is easier to disturb signal with noise and you configure the speed of this interface too high. Parallel interface means that we send every bit in a separate line. In theory this interface could be fast, but because it is not differential, the transfer speed is limited. Moreover, the RGB display interface will work with rather small screen sizes – usually up to 7-inch or 10-inch.

12 inch screen size is the total maximum for a LCD display with RGB interface, but the resolution will be lower, like 800 by 600. For this display size it is very low resolution. This is the reason why the 7-inch is size above which the LCD displays are being switched from RGB to LVDS interface. Among Riverdi products (if you go to the Riverdi website and to the IPS display tab), there are displays without the controller, and the small displays like 3.5-inch, 4.3-inch and 5-inch are equipped with RGB interface. But when you go to the 7-inch LCD displays tab on Riverdi website, you will find RGB, LVDS and MIPI displays. But when you go to the 10-inch or bigger displays, you will only find the LVDS displays because our 10-inch LCD displays are high resolution 1280 by 800, and it is impossible to build it with the RGB interface.

MIPI – Mobile Industry Processor Interface – is an internally embedded image transfer interface, getting popular these days. This kind of interface is used in mobile applications, tablets or mobile phones, but it is entering as an option in industrial applications. In Riverdi we offer 7-inch MIPI displays, but please be careful with other MIPI displays on the market. Many come from mobile phones or tablet market. Also, the TFT glass availability may not be stable as the mobile market changes really fast, every six months or every year. When you buy a 7-inch Riverdi MIPI interface display you are safe, because it is an industrial display.

This is why we have a limited number of displays with MIPI interface – we want to be sure that what we sale will be available for a long time. Longevity is one of Riverdi’s core values and we do not want to deliver anything that will not be supported for a minimum 3 to 5 years. It is because many of our customers are making industrial, medical or military devices and they need displays to be available long-term.

Next interface is the Vx1. It is similar to LVDS and MIPI, so it’s low voltage differential signal. Vx1 is a very high-speed interface, usually used in large high-resolution screens, like 55-inch 4K TVs or even larger ones. If you buy this kind of a TV set right now, probably the embedded interface inside will be the Vx1.

Key takeaway: Vx1 is a super-fast interface used for high bandwidth image transfer, with high refresh rate and high-resolution displays, used in 4K screens and above.

The last internal image transfer interface is Embedded DisplayPort (eDP). We call it the new LVDS, because many new industrial displays are equipped with the eDP. If you go through industrial manufacturers of TFT LCD displays, you will notice increasing number of models available with the eDP. eDP is also a native interface in new Intel or AMD based processors.

Key Takeaway: With the embedded DisplayPort as a native display interface you can cut down costs, because you do not need anything extra to connect a display to the processor.

Now, with the processors on the market, we need displays with embedded DisplayPort. Many laptops or monitors already use embedded DisplayPort as an internal interface instead of LVDS. LVDS still is the most popular industrial LCD display interface. All the internal image transfer interfaces like MIPI, Vx1 and eDP are variations of LVDS, where the protocols and the signals are a little bit different. For example, for eDP we can have lower noise and reduced power consumption. All of them have advantages over regular LVDS, but they are all LVDS type.

Now, let’s take a closer look at external interfaces. Those are the ones that we usually have direct access to. It can be TV or monitor connected to your computer with the HDMI . It can be a DVI usually used for monitors. Or VGA which is an outdated image interface for monitors. The DisplayPort that is a HDMI successor. Finally, an universal USB-C, the most common interface nowadays used to connect devices.

USB-C transmits up to 100 watt of power, because you can increase voltage and current. In a regular USB it is usually 5 volt and 0.5 or 1.0 amp, so only a couple watts. In USB-C you increase the voltage up to 20 volt and with the 5 amp current, so in total it’s even 100 watt of power. This interface is made not only for data, but for real power transfer. Through USB-C you can charge your phone and your laptop. If you buy a new laptop right now, you may even not get a regular power connector, but only an USB-C. The USB-C is a very smart interface. If you connect the devices, they can negotiate with each other which one has more power. For example, if we connect a charger to a laptop, the charger has more power and will charge the laptop, but if you connect the laptop with the same interface to your mobile phone, then they will discuss the power levels, and of course the laptop will be charging the phone. You can already find monitors on the market that have USB-C instead of HDMI. Those monitors can be powered from your computer and need only one USB cable, both for image transfer and power. For sure the future belongs to USB-C implementations.

Let’s move on to image transfer interfaces. The most common one is HDMI – High-Definition Multimedia Interface. M stands for Multimedia, because it transfers image with sound. If you connect your computer to your TV set with HDMI, you will need one cable for both the video and the audio. There are variations of HDMI connectors:

You have app. 15% of the article left. That content is exclusive for our Riverdi University members only. Please fill out the Riverdi University Membership form below and join our community!

The next one is DVI – Digital Visual Interface. The first DVI was not a multimedia interface, because it did not have audio data transfer. Nowadays, there are some variations that can transfer audio, but it is non-standard. We can assume DVI is rather for image transfer. It is a digital interface, similar in signals to HDMI. The latest variation is DVI-I, where I stands for integrated interface. It can have a digital and analog part for VGA compatibility. In the picture above there is a DVI-D, digital only, where we do not have the pins for analog VGA interface. Analog VGA is sometimes available in your desktop computer, but not in laptops anymore.

The oldest video interface still in use is the VGA – Video Graphic Array interface. It becomes less and less popular. This is an analog interface, not a digital one like all the other abovementioned interfaces. Analog interface means that we do not transmit the bits, but we send the voltages values. The analog signals are not stable, they are quite easy to disturb, so the transfer cannot be very high in speed and volume

The last external interface that we can find in our devices nowadays is a DisplayPort. DisplayPort is similar to HDMI or DVI. It can also transfer image and sound. It is even faster than the HDMI. Usually, the DisplayPort is used for high resolution displays, for new monitors and TVs with 4K or 8K resolution where it is really hard, or nearly impossible, to achieve such resolution using HDMI interface.

Please remember to SUBSCRIBE to our YouTube channel and fill out the MEMBERSHIP FORM, to be informed about our Riverdi University materials and live events!

In the past decade, LCD monitors have replaced CRT screens for all but the most specialist applications. Although liquid crystal displays boast perfect

Maybe you have even seen some displays that were used outdoors and sometimes they become black. We call that the blackening effect. If they become black, that means the crystals become isotropic. You can sometimes see that the part of the display is black or sometimes the whole display becomes black, depending on the temperature. The good thing is that it is not damaging the display, so once the temperature drops it goes back to the nematic phase and the display is working again, but in a high temperature you cannot see anything on the display, it is not working.

On the picture above, we have an example from a data sheet of a display with high temperatures. As we said it’s a liquid crystal from -40 to +110 degrees, and this is the latest technology. But you need to be careful! This is only about the surface of a display, the TFT glass itself. If we have the sunlight going to the display it can increase the temperature of the whole display as a module.

For the whole display module, the operating temperature range can be as low as 0 to +50 degrees or -20 to 70 degrees. We can have two operating temperatures, that means if we use the display outdoors, we are safe from the sunlight, the surface of the display can go very high, but we need to control the ambient temperature inside the display housing to not go too high. +50 or +70 will be maximum, usually we need fans to remove the heat from inside. Typically, in our case we have a computer inside and we have more devices that cannot work at high temperatures like +100 degrees, so we control the temperature anyway. So, the temperature cannot be too high inside and for sure cannot be that high as a liquid crystal itself can withstand, which is +110 degrees.

And that will be all in this article about contrast, brightness, and temperatures. Just one more thing: if you are planning on buying a laptop today, you can find brightness in the specification. Look at this number because this will determine how good your laptop will be outdoors. There are laptops on the market today that will have 1000 candelas or even more. If you are looking for a new device my recommendation also goes for mobile phones. Low brightness mobile phones can have 300, maybe 500 candelas, but nowadays the standard will be around 1000 candelas, but there are phones on the market that already have 1500 or even 1800 candelas. That means if you are in the sunlight you will still be able to see the image clearly. Of course, the battery will be drained faster, but sometimes it is not so important, maybe you just want to check something quickly, to read something and you want to have a clear image just be aware that this number is pretty important when you buy new devices!

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

ASI-T-1302A10SPN/A is a 1.3 inch all-view TFT display with a resolution of 240 x 240, SPI interface, and a high brightness of 1000 Nits, ideal for outdoor viewing.

ASI-T-1402A8SCN/A is a 1.4 inch TFT with a resolution of 240 x 240, IPS all-view, CPU and SPI interface, and a high brightness of 800 Nits, ideal for sunlight viewing.

ASI-T-17711A1SPN/D is a 1.77 inch transflective TFT with a resolution of 160 x 128, SPI interface and with a brightness of 110 Nits; viewable in direct sunlight.

ASI-T-20043A5PMN/AY is a 2.0 inch TFT with a resolution of 480 x 360, 3W SPI+16 bit RGB or MIPI interface, IPS all view, with a high brightness of 500 Nits.

ASI-T-240DA8BN/D is a 2.4 inch high brightness TFT with a resolution of 240 X 320, CPU 16-bit interface and with a brightness of 800 Nits; viewable in direct sunlight.

ASI-T-240DA10SMN/AQ is a 2.4 inch high brightness TFT with a resolution of 240 x 320, SPI & MCU interface, IPS all-angle view and with a brightness of 1000 Nits; viewable in direct sunlight. It also features an extra wide operating temperatures of -30 to +80C; perfect for extreme environmental applications.

ASI-T-240DAKBN/D is a 2.4 inch high brightness TFT with a resolution of 240 x 320, MCU interface and with a brightness of 1000 Nits; viewable in direct sunlight.

ASI-T-283DAKCRN/A is a 2.83 inch high brightness TFT with a resolution of 240 x 320, CPU, RGB, SPI interface and with a brightness of 1000 Nits; viewable in direct sunlight

ASI-T-3501RA1EN/A is a 3.5 inch TFT with a resolution of 480 x 640, 18 bit RGB, All View interface and with a brightness of 120 Nits; viewable in direct sunlight

ASI-T-3501RA1EN/D is a 3.5 inch TFT with a resolution of 480 x 640, 18-bit DBI Type B, All View interface and with a brightness of 120 Nits; viewable in direct sunlight

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

A controller board is a piece in an electrical circuit that interfaces with a peripheral object by connecting the computer to it. The connection may be with other computer parts, such as the memory controller, or with an external device, like a mouse, that acts as a peripheral controller for an operation of the original device.

The LCD controller board is often called the Analog/Digital (A/D) board. As a type of hardware processor, it allows for various video source inputs to be connected, selected, and displayed on the LCD screen. It does this by converting the different video input signals into a format manageable by the LCD panel.

In conjunction with the LCD controller, the LCD driver is a form of software that is the interface of and dependent on the controller piece. Combined, the two form an LCD controller driver board. As the controller connects the computer to the operating system (OS), the driver facilitates that communication. Though there is typically just one display controller per LCD, there can be added drivers to extend the reach of the drive to further segments of the LCD.

To generalize the process, the LCD controller/driver adjusts the input signal, scaling resolution if needed, and then outputs the signal for the LCD monitor to use. Some of these output interfaces are low-voltage differential signaling (LVDS), SPI, I2C, and Parallel.

In most LCD controller/driver boards, there are two other input/output systems. Both these systems, however, are two-way pathways. One involves controlling and monitoring options, such as controls for brightness, image, and color using the on-screen display (OSD) control panel. The other is for communication via connections like Ethernet, Bluetooth, or IP.

With modern developments, touch screen devices have become much more prominent, and so the touchscreen controller has as well. There are two types of touchscreens: the resistive one that measures pressure and the capacitive one that reads touch. In both of these, there are sensors that detect the touch signal which then transmit the signal data to the controller. The controller then processes the command for the OS.

To delve deeper into the details, consider the previously mentioned input signals. There are a variety of signals that LCD technology processes, such as VGA, HDMI, DVI, and DisplayPort. These computer display standards vary in format and characteristics like aspect ratio, display size, display resolution, color depth, and refresh rate. One of the biggest differences between these standards is their usage of analog signals or digital signals.

In an analog signal, the signal is continuous, but in digital, they are discrete values, typically of 0 and 1. Digital signals have become the most used, as they can more easily carry information and have better quality maintenance; if the analog signal is used and unnecessary information is present, it is impossible to remove it due to the continuous nature of the analog signal. In order to make that switch to digital signals, converters are used to replacethe real numbers of the analog sequence with a set of discrete values.

The VGA, short for video graphic array, standard is one of the most popular analog-based technologies. In recent years, however, the VGA interface has been overshadowed by interfaces like high definition multimedia interfaces, better known as HDMI, which has become a de facto standard for digital signal transmissions.

The HDMI is a combination of digital audio and digital video transmission. There are many HDMI connectors, such as the standard, dual-link, and micro. These connectors are what the input signal travels through to reach the LCD controller and to direct what to display.

The DVI (Digital Visual Interface) offers both analog signals, digital signals, or a combination of the two. Like the HDMI, it has various connector types for different signal types.

The VGA to HDMI adapter, however, must overcome greater differences, as they are not naturally as compatible as each were with DVI. Not only are there differences in the analog/digital signals, but also the VGA only uses video interface, whereas the HDMI uses both audio and video. A cable and an adapter are needed to connect the two devices.

And last from the list of examples of input signals is the DisplayPort. It is similar to HDMI in its purpose to replace outdated VGA and DVI as well as its transmission of audio and video through its interface. The DisplayPort does not have as much variation in cables and connectors as the HDMI, with only one cable and two types of connectors. From the DisplayPort, there is a growing technology called the embedded DisplayPort interface, or eDP interface. LCD manufacturers have begun to gravitate towards this interface due to its fewer connections, smaller size, and ability to quickly transmit high quality displays.

Bringing the subject back to LCD controllers, with the various types of computer display standards, the video signal inputs can be a challenge to accommodate and translate for the LCD panel, but with the help of adapters and the growth of these standard types, displays continue to become faster and develop with greater resolutions.

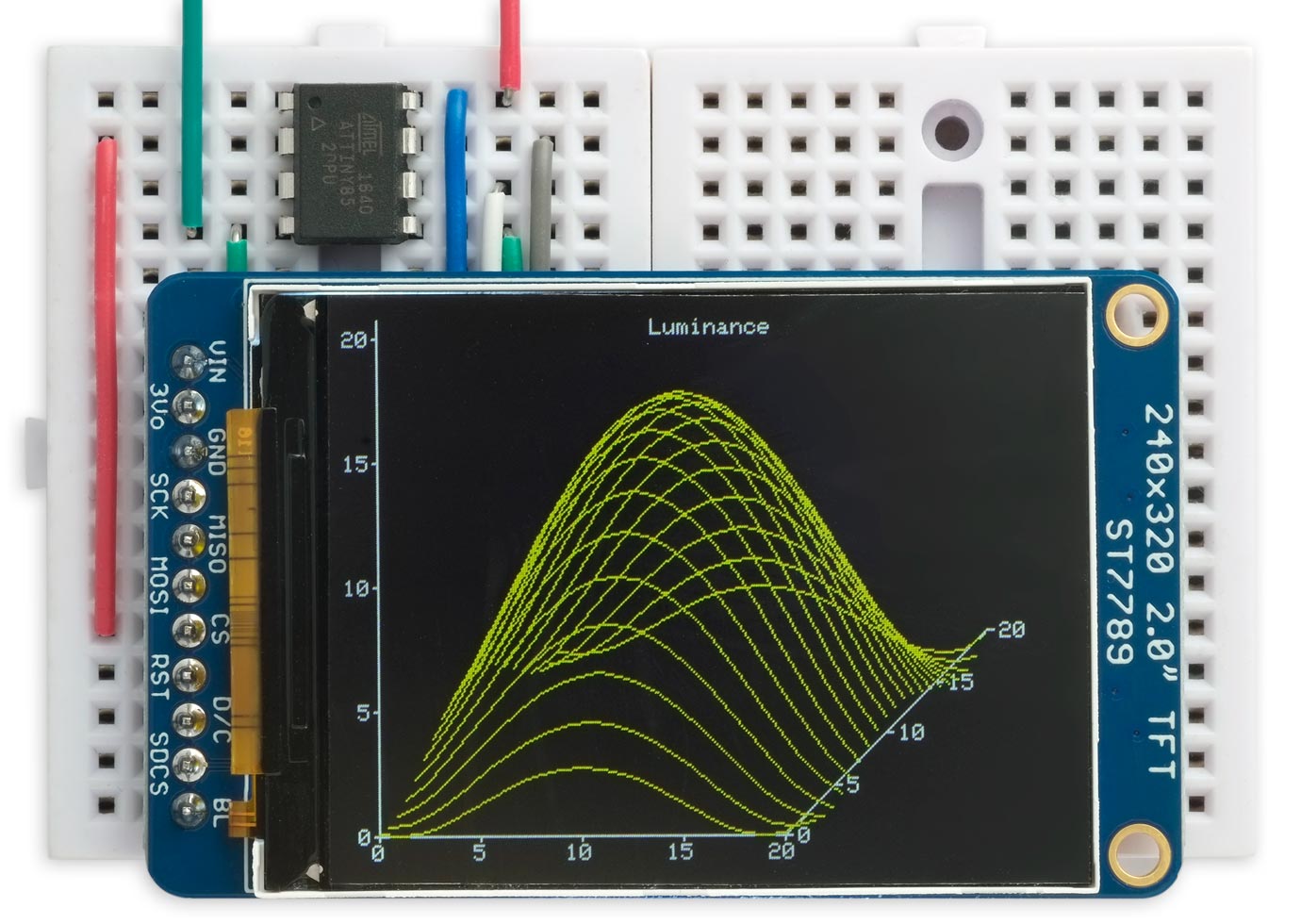

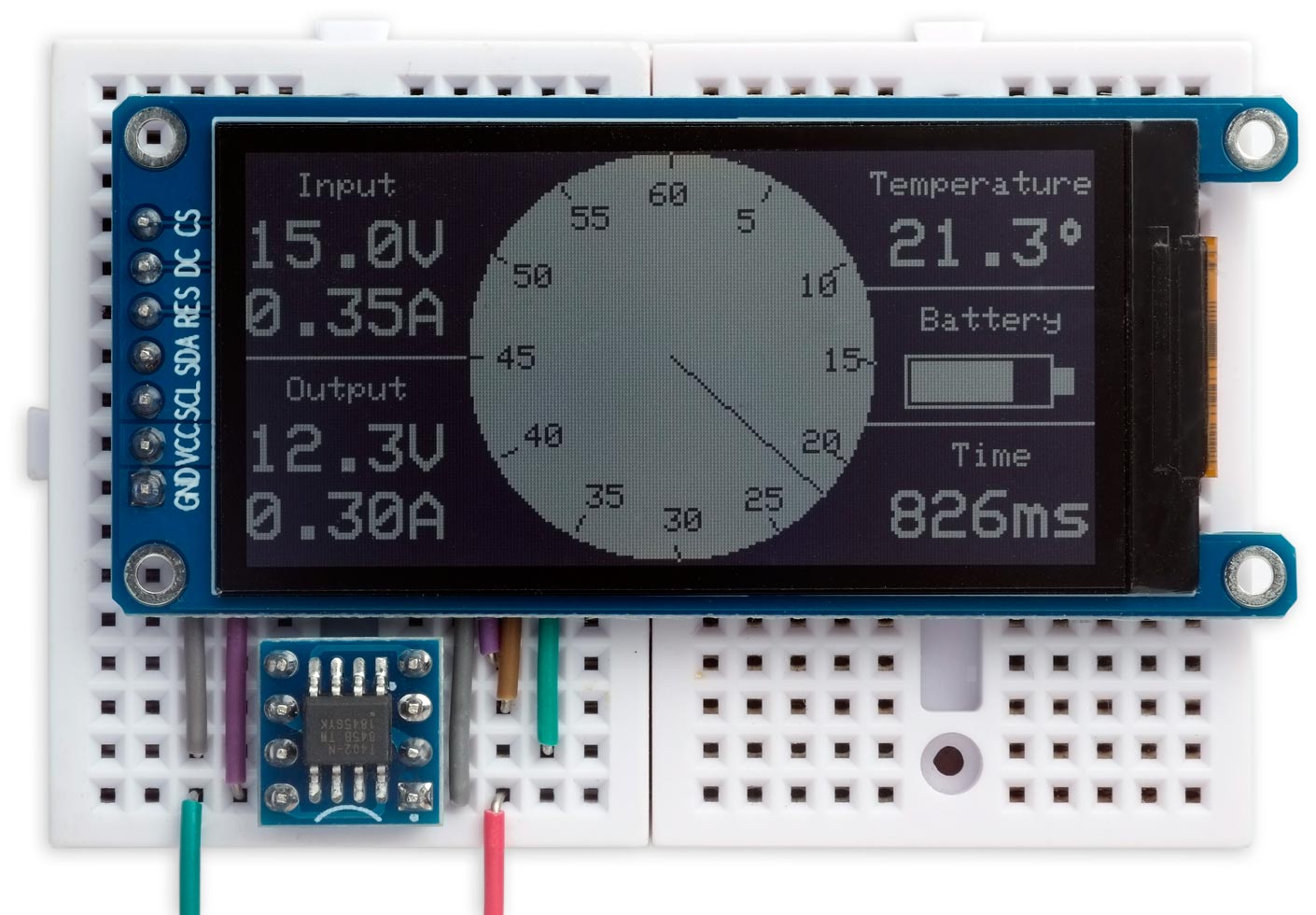

This is a small graphics library, specifically aimed at ATtiny microcontrollers, for the variety of small colour TFT displays available at low cost from suppliers like Adafruit, AliExpress, or Banggood:

It"s an updated version of my Tiny TFT Graphics Library. This latest version of the library supports both the classic ATtiny processors, such as the ATtiny85, and the new 0-series, 1-series, and 2-series ATtiny processors, such as the ATtiny402. Like the original library it allows you to plot points, draw lines, draw filled rectangles, and plot characters and text with an optional scale factor, in 16-bit colour.

This version adds the ability to plot outline rectanges, and outline and filled circles. I"ve included demo curve-plotting and histogram-plotting programs that adjust to fit any display.

This library supports TFT displays that use an SPI interface and require four pins to drive the display. This leaves one pin free on an 8-pin chip such as the ATtiny85 or ATtiny402. If you need more pins choose a larger chip, such as the ATtiny84 or ATtiny404.

Unlike my Compact TFT Graphics Library which uses standard Arduino SPI calls, this library uses direct I/O pin manipulations. This means that you can use any assignment of pins to the four I/O lines needed by the display, and makes it about twice as fast as one using SPI calls. I"ve also added support for some additional displays, so it now supports 16 different TFT displays.

On the classic ATtiny processors, such as the ATtiny85, the library uses the feature that you can toggle one or more bits in a port by writing to the PINB register; for example, to enable or disable the chip-select signal:

So provided you set all the pins to their disabled state at startup, the display routines can simply toggle the appropriate pins to enable or disable them.

The differences between each family of processors are handl

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey