pic tft lcd interface factory

A TFT LCD display module consists of a TFT LCD panel, one or more COG (chip-on-glass) or COB (chip-on-board) driver ICs, a backlight, and an interface. Several TFT display interface technologies exist today. Picking the right interface depends on specific end-product concerns. There are several types of TFT display interfaces which have been designed in the last number of years for various screen sizes, including LVDS, (Low-Voltage Differential Signaling) parallel, SPI (Serial Peripheral Interface) RGB and so on. Here is an overview of these display interfaces to give you a better idea of the variety of TFT LCD displays that are taking center stage.

SPI LCD Interface: Serial Peripheral Interface allows serial (one bit at a time) exchange of data between two devices. It has an advantage over parallel ones, that of simpler wiring. SPI also can have longer cables, since there is much less interaction or crosstalk in the cable. The downside of SPI is that you can"t read from the TFT LCD display, you can only write on it and it is slow. That"s why you normally see smaller TFT LCD screens use SPI.

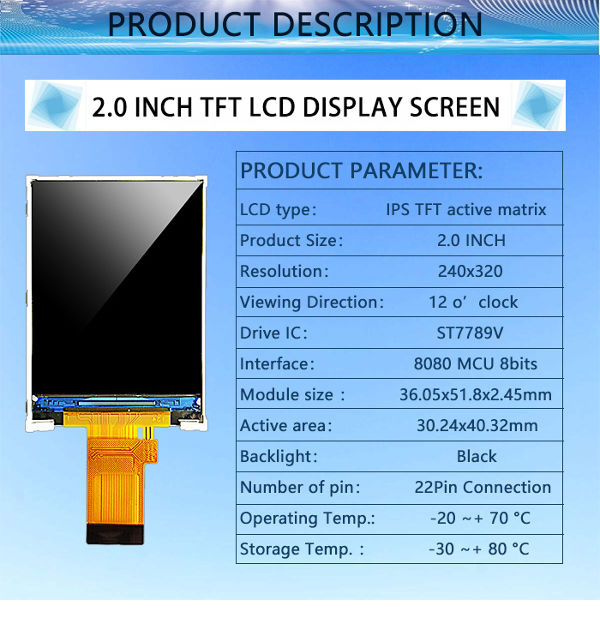

MCU Parallel Interface: Many modern MCUs have built-in LCD controller function. There are two types that are commonly used, 6800 and 8080. Generally, MCU/Parallel interface consist of data signal(4/8/9/16 bits) and control signal. MCU interface is simple, but requires display RAM.

RGB Interface: RGB interface is a special kind of parallel interface. It requires no display RAM. MCU directly updates the TFT screen, sending Red Green & Blue sub-pixel data (16/18/24 bits) and timing signals. RGB interface provides high speed communication to TFT LCD, but it needs more data wires and controlling is more complex.

LVDS Interface: Low-voltage differential signaling is an electrical digital signaling standard. Devices with LVDS interface can communicate at very high speeds over inexpensive twisted-pair copper cables. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from TFT LCD display.

UART/RS232/RS485: These serial interfaces are used in Topway"s Smart TFT LCD display module. Universal Asynchronous Receiver/Transmitter (UART) is a block of circuitry responsible for implementing serial communication. Essentially, the UART acts as an intermediary between parallel and serial interfaces. On one end of UART is a bus of eight-or-so data lines (plus some control pins), on the other is the two serial wires – RX and TX.

HDMI Interface: High Definition Multimedia Interface is a connector and cable definition that supports high-quality and high-bandwidth streams of video and audio between devices.

MIPI DSI: MIPI Display Serial Interface defines a high-speed serial interface bewteen host processor and display module. The interface facilitates a high performance, low power and low EMI way to render brilliant color for the most dempanding image and video scenes.

To choose your product"s TFT LCD interface, besides above technical considerations, target use environment and bandwidth are two main factors as well. You can read more about how to choose LCD interfaces here, or consult with us. Topway has been manufacturing TFT LCD in the past 20s years. Our TFT LCD modules cover full spectrum of interfaces. And we surely can suggest a TFT LCD display that suits your use case.

This guide is about DWIN HMI Touch Screen TFT LCD Display. HMI Means Human-Machine Interface. DWIN is specialized in making HMI Touch screen displays that are compatible with all microcontrollers like Arduino, STM32, PIC, and 8051 families of Microcontrollers.

This is a Getting Started tutorial with 7-inch DWIN HMI TFT LCD Display. We will see the architecture, features, board design, components, and specifications. We will also learn about the TTL & RS232 interfaces. Using the DGUS software you can create UI and with SD Card you can load the firmware on display memory.

You can change the TTL Interface mode or RS232 mode from here. Just solder these two terminals as shown here to enable TTL Interface. By default, the module is in RS232 Interface.

On the LCD board, you can see the flip-open connector. Just flip open the connector and insert the FCC cable. Keep in mind that the blue ends should be on top. Now you can just press the lock so the FCC cable is locked.

One of the method to load the firmware to the T5L DWIN LCD Display is by using the SD Card. An SD Card of up to 16GB can be used to download the firmware files. We can easily insert the Micro SD card into the SD Card slot on the backside.

After copying the file, remove the SD Card from your computer and insert it into the SD Card slot of DWIN LCD Display. Then power the display using the USB Cable. The firmware downloading process will start automatically.

The next part of this tutorial includes creating UI and interfacing DWIN LCD Display with Arduino. For that you can follow the DWIN LCD Arduino Interfacing Guide.

Please see the DT028CTFT for reference designs. The schematics between the A and the C are the same with the exception that the A does not have the IPS interface.

Showcase high quality graphics and images on our 800 x 480 7” TFT display! The DT070CTFT LCD module is an upgraded version to our DT070ATFT module. Compared to the previous model, this new 7 inch display offers improved viewing angle and brighter LEDs. The DT070CTFT also uses the Himax HX8264E + HX8664B display drivers. This LCD display is available with a resistive or capacitive touchscreen panel.

NHD-3.5-320240MF-PIC Eval Board | Evaluation Board with 3.5" Resistive TFT for PIC Starter Kit | Includes TFT NHD-3.5-320240MF-ATXL#-T-1 | Discontinued EOL Product

This NHD-3.5-320240MF-PIC Eval Board (DKSB1014B-ND) evaluation board was developed with Digi-Key to provide the user with a 3.5" resistive touch LCD and hardware interface for select Microchip PIC32 evaluation/starter kits. This PIC32 adapter board combines a combination of existing Microchip demonstration boards, our 3.5" resistive TFT without controller, and a custom interface board. This development tool features 3M bump-on"s for perfect mating to the Microchip evalution boards (SJ5749-0-ND), AVX flat flex ZIF connector (478-5598-1-ND), and Efficient Diodes Inc. white LED step-up backlight driver, (AP5724WG-7DICT-ND). Take the pain out of prototyping your next graphical display embedded application.

TFT LCD Monitors are primarily discussed in our previous blogs. TFT LCDs are an everyday landscape, with TFT LCD being an extensively used display in different ways looking, from medical equipment, automobiles or advertisements, and smartphones.

One of our blogs, TFT LCD MONITOR: WHAT YOUR BUSINESS NEEDS TO KNOW, clearly mentioned how customers value Liquid Crystal Display (LCD) for the clear, high-quality images it produces. However, industry professionals are increasingly incorporating new technology into creating LCD screens. New inventions have recently taken the tech world by storm, replacing outdated LCD versions, such as the TFT LCD Monitor.

The terms reflective, transmissive, and transflective describe how LCD modules illuminate. Compared to emissive display technologies such as OLED displays (organic light-emitting diode) and VFDs (vacuum fluorescent displays), LCDs need an ambient light source like the sun, artificial light, or a merged backlight.

Some displays use ambient lighting instead of backlights. This mode of operation is termed reflective. A mirror is installed behind the liquid crystal layer in this mode, which is either on the LCD cell or the rear polarizer...Read More

Display interfaces are used to exchange information across different components. It operates over three primary functions, i.e., image decompression, image assembly, and communication to and from the display daemon.

LVDS signaling is considered ideal for large displays, e.g., TV, laptops, and other computers. Its capability of transferring large pixels in less time makes it a popular and favorable choice for developing PMOLED, AMOLED, TFT, and different types of displays.

Today, there is a high demand for electronic devices featuring high brightness displays. Liquid Crystal Display Technology (LCD) is one of the most popular display technologies in use today. They are found in various electronic devices right from mobile phones, computer monitors, tablets, touchscreen displays, tablets, television sets, and more. Over the years, there have been variations to these displays. TFT LCDs have gained immense popularity in recent years. These are thin-film-transistor liquid-crystal displays, which utilize thin-film transistors to optimize image qualities. These LCD displays are nowadays available in different configurations. Of these, 10.25 inch TFT LCD displays offered by Microtips USA have gained popularity in recent years due to various reasons...Read More

TFT, which stands for thin film transistor, is an advanced offshoot of the LCD technology. These are active matrix LCDs, which immensely improve the quality of color, contrast, image clarity, and more. This is one reason why TFTs are used in displays of many electronic devices, along with capacitors. The 3.9-inch bar type color TFT LCD display comes with such amazing quality and features in terms of the resolution, size, interface, and so on. This display finds applications in many industrial equipment, marine equipment, point of sale (POS) terminals, automobiles, advertising displays, server systems, and so on. There are many 3.9-inch TFT LCD module manufacturers making this display although features may slightly differ based on the manufacturer...Read More

TFT or thin film transistor is a variant of the LCD technology. TFTs are active matrix LCDs, which help improve contrast, color, and picture quality. Thin film transistors are used along with capacitors to improve image quality in many electronic devices. Owing to their several advantages, these TFT displays are available in various specifications. The 4.3 inch TFT display is one of the most popular among them. The 4.3-inch TFT LCD display module touch screen has a resolution of 480X272 with an RGB interface. This display finds applications in mobile phones, cars, embedded systems, and certain industrial equipment among others. There are many 4.3-inch TFT LCD module manufacturers making this display; however, certain features may slightly differ based on the manufacturer...Read More

Over the years, various display technologies have gained popularity across the world and the liquid –crystal display technology, abbreviated as LCD, stands tall among them. This technology has become a choice for manufacturers of electronic devices such as mobile phones, televisions, computers, and more, owing to several advantages offered by them. However, the advances in this technology have opened new options for device manufacturers. Thin-film-transistor is one of the most popular types of LCDs used by electronics manufacturers all over the world. Today, it is produced in various specifications to meet your application requirements. However, the 12.3 inch TFT LCD display by Microtips Technology has gained the attention of electronic device manufacturers...Read More

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Beijing STONE Technology co., ltd was established in 2010 and devoted itself to manufacturing and developing high-quality intelligent TFT LCD display modules.

Our core TFT LCD display modules integrate a CPU, flash memory, and touch screen in the hardware unit. Paired with an easy-to-use free GUI design software and complete instruction set, customers can avoid time-consuming accessories selection and system integration tasks. These units greatly reduce the workload in HMI development and make the entire process faster and easier.

The modules come with a UART TFT serial interface that can be controlled by any MCU through the simple but powerful instruction set like the 8051 series, AVR series, MSP430 Series, STM32 series, MC9S12, and Arduino series, among others.

Each TFT display LCD module has a wide range of applications, such as automated system control, vending machine functionality, intelligent lockers, electricity equipment (oiling machine, EV charger), elevators, smart home and office, precision instruments, and much more.

To date, we have delivered custom display solutions to over 3000 customers around the world. Our TFT LCD modules have been widely praised for their quality and performance and that is in large part thanks to our partners, including NI, Siemens, ThyssenKrupp, and many others. These long-term cooperative relationships have been mutually beneficial and we hope to continue a long history of success.

Our group has two LCD display factory members with state-of-the-art production facilities, which cover area of 50,000 square meters, and have over 2000 employees. We are specialized in manufacturing all kind of LCD display products including color TFT LCD displays, OLED displays, graphic/character LCD modules, E-Ink displays, TFT driver boards, HDMI displays, and industrial monitors. Our monthly production capacity is over 4 million pieces. Our display products are widely used in automotive, communication, industrial instruments & meters, medical device, GPS navigation, office automation, POS machine, home appliances, instrumentation, consumer electronics, etc. We not only manufacture standard LCD displays, but we also provide custom design solutions to meet our customer’s unique requirements. The customization includes TFT LCD glass size, TFT LCD Interface, FPC adjustment, backlight structure & luminance, IPS all viewing angle, high-resolution, high-brightness, touch panel, optical bonding, etc. We design and produce LCD displays to meet customers" high quality and customization requirements. Our LCD products have been selling to customers in the United States, Germany, Japan, China, and many other countries. For more information, please visit: www.gtdisplays.com.

With mass production, manufacturing refinements, and competition, thin film transistor (TFT) displays have drastically dropped in price while dramatically improving in performance. They are the de facto standard to the point where it is not only expected, it is demanded that any modern user interface be full color, brightly backlit, touch sensitive, and have high video speeds and a good viewing angle.

While simple low-cost 8-bit microcontrollers could easily handle the multiplexed 7- and 14-segment LED and alphanumeric LCD displays, the memory, processor speeds, and peripheral resources needed to drive a TFT are more than most modest microcontrollers can handle. As a result, dedicated controller chips, embedded modules, or faster, denser, and more streamlined processor architectures are needed.

This article looks at the factors that make a good MCU-to-TFT interface. This includes memory depths and architectures, paging, data transfer, signaling levels, interfaces, and on-chip peripherals to look for when selecting a microcontroller for a TFT application. It examines the TFT technology and present day product offerings, which your designs will need to drive. It also looks at some microcontrollers that provide native support for color TFT displays, looking at their techniques, features, trade-offs, and limitations. All displays, microcontrollers, drivers, inverters, and development tools mentioned in this article are available from Digi-Key Corporation.

TFT displays are a type of liquid crystal display in which the transistor controlling the pixel’s crystal is etched into a layer of amorphous silicon deposited on the glass (see Figure 1). As in an IC process, very small transistors are geometrically formed. The small size of the transistor means it will not significantly attenuate the light passing through.

The advantage of TFTs is that they are fast enough for video, provide a large and smooth color palette, and are pixel addressable through an electronic two-dimensional control matrix (see Figure 2). Most low-cost displays use an amorphous silicon crystal layer deposited onto the glass through a plasma-enhanced chemical vapor deposition.

Many versions of TFT technologies have led us to the modern displays. Early complaints like poor viewing angles, poor contrast, and poor backlighting have been addressed. Better light sources, diffusers, and polarizers make many displays very vivid, some even claiming to be daylight readable. Modern day techniques like in-plane switching improve viewing angles by making the crystals move in a parallel direction to the display plane instead of vertically. Better speeds and contrasts of modern display make them high performance for a fairly low cost.

Since TFTs are not emissive devices, they require backlighting. The most commonly deployed backlight technology is cold cathode florescent lighting (CCFL). These devices were designed, chosen, and used because they are very efficient and have very long lives. Typically, a CCFL bulb is rated as having in the ball park of a 50,000 hour ‘half-life. ’ This means that after 50,000 hours, it still works, but with half the intensity when it was new.

Transflective technology is steadily improving and is available in some TFT displays. This is where both a backlight and ambient external light are used to make the display visible. Sunlight may make it viewable, but generally speaking the transflective displays are less transmissive. This means that the backlight will have to be brighter (and require more power) to be on par with a purely transmissive display that requires a backlight all the time.

With TFT and most color display technologies, an individual pixel contains a red, a green, and a blue picture element (pel). The relative intensity of each color will determine the resulting blended color.

Either a gamma correction chip or a lookup table can be inserted into the data stream to do this correction. You should have a consistency of the LCD. Note that many LCD manufacturers do not make their own mother-glass. As such, they are subject to the slight variations from supplier to supplier. Unless you use a supplier that truly manufactures its own glass, this could be an issue later on down the road.

The color depth or color palette is dependent on the bit resolution used for each color. This typically ranges from an 18-bit interface consisting of 6 bits each for red, green and blue, to 24-bit interfaces using 8 bits per color.

Some displays will use dithering and alternating pixel colors to achieve a better blend of intermediate colors. Higher frame rates are also used since the persistence effect of phosphor-based displays does not carry over to LCDs. Determine the quality and smoothness of the display you will use. Not every frame rate control technique yields flicker- and jitter-free performance, especially at some resolutions. If you notice it, so will your customers and end users of your design.

The memory required to map the display image is key. While some micros will contain enough memory to hold a single page of display data (and not much else), you can see that a lot of memory is required for even a modest ¼ VGA display. This is more than what a typical microcontroller can house (see Table 1). As a result, an external bus interface to external RAM (SRAM, DRAM, or SDRAM) will be needed, especially if paging will be used.

A key feature when selecting a microcontroller for TFT interfacing is the DMA support. Multi-channel, flexible DMA will make a world of difference, especially when it comes to moving data between pages, character generator and rendering tables, animations and video. Along these lines, a preprogrammed and autonomous DMA functionality will allow you to refresh a display while the core microcontroller goes to sleep. This is a key power-reducing feature that can make a world of difference when operating from batteries.

Very high volume applications may justify using an OEM only for the glass and implementing your own control electronics from the glass up. This is especially true when designing a very small form factor device where the added flexibility of using your own PCB layout is critical to success. For those designing from the glass up, the primary interface will be drivers for the thin film transistors. The stable common voltage reference to which all pixels are referenced is key. This is called VCOM and several discrete and integrated solutions for generating a VCOM signal are available.

One effective solution is to use the National Semiconductor LMH6640MF/NOPB which is a rail-to-rail (up to 16 volts), voltage feedback, high output (up to 100 ma) amplifier optimized for TFT transistor driving. The fast 170 V/µS slew rate yields a 28 MHz full power bandwidth (at five volts) and its small SOT-23 package can be fit into tight spaces (see Figure 3).

Also , the VCOM function and all its subtleties are often times integrated into more encompassing TFT driver chips like Texas Instruments’ LM8207MT/NOPB which combines an 18 channel gamma corrected driver with VCOM referencing buffer (see Figure 4). Note that the built-in VCOM buffer will allow a buffer tree to be created from a single reference for larger displays.

One approach to driving a TFT display without the need for a higher end processor is to use a discrete TFT controller chip that can be interfaced to a processor of lesser horsepower. An example is the Intersil TW8811-LD2-GR TFT controller chip (see Figure 5).

The on-chip SDRAM interface provides the depth and cost-effective performance needed for displays up to WXGA resolutions, and the –40 to +85 degree temperature range makes this usable for a variety of harsh environment applications.

If a single microcontroller can control the task at hand as well as the embedded display, this is usually the most cost-effective solution. Most people will use a TFT module which already houses the VCOM, gamma correction, and TFT transistor drivers. As a result, the interface to the module is TTL, CMOS, or Low Voltage Differential Signaling (LVDS).

Thankfully, to help make TFT design tasks doable in a reasonable amount of time, the chip makers provide solutions targeted at display designs. Typically, these are higher-end, 32-bit, RISC-type processor architectures with streamlined peripherals and resources that handle both display-oriented and non-display-oriented functions such as communications, sensor interfacing, etc.

For example, the NXP Semiconductor LPC2478FBD208,551 is an ARM7™-based 72 MHz high- end microcontroller with LCD control up to 1024 x 768, 24-bit pixel resolutions. In addition to the very flexible DMA functionality, it incorporates USB, four UARTS, I²S, RTC, SD/MMC memory card, Ethernet, I²C, CAN, and more. It is a “Swiss Army Knife” processor that targets integrated, single processor type designs.

Devices like this need development environments and evaluation units and NXP is right there. The DK-57VTS-LPC2478 is a programmer’s development system that includes a 5.7 inch TFT with touch interface as well (see Figure 6). Note the 2M x 32 SDRAM for page buffering and graphic manipulations. NXP also offers the DK-57TS-LPC2478 which aims at sensor-based applications.

NXP Semiconductors is not alone by any means. Renesas Electronics America also provides processors with built-in support for TFTs. Take for example the DF2378RVFQ34V, an H8-based processor with advanced block transfer functionality built into the DMA. Like the NXP parts, it incorporates a slew of peripherals, Flash, memory interfaces, and I/O.

Not every processor needs to have a dedicated TFT interface to make it a viable candidate. For example, the TI TMS470R1B1MPGEA is a RISC-based 60 MHz ARM7 processor that can easily interface to a slew of TFT modules that are driven via a digital interface. While some modules need constant refreshing, others can be loaded with display data and generate all the timing and display data movement internally unburdening the host CPU. The CPU must be fast enough to keep up with any animations or video if this is the case.

TOKYO, April 10, 2017-Mitsubishi Electric Corporation (TOKYO: 6503) announced today the immediate launch of a new intelligent-GUI (graphical user interface) TFT-LCD module featuring a high-quality graphics board and touch panel. The graphics board, equipped for video camera image processing/display and interchangeable GUI, delivers broad graphical-expression capabilities while reducing needs for GUI-design development resources.

Mitsubishi Electric will exhibit its intelligent-GUI TFT-LCD module during the 20th Embedded Systems Expo (ESEC Spring) at the Tokyo Big Sight exhibition complex from May 10 to 12.

-One-stop solution (graphics board, touch panel and LCD module) is combined with Mitsubishi"s proprietary tool for GUI design, Intelligent GUI Designer

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey