pic tft lcd interface in stock

This is SainSmart 7 inch TFT LCD module with the TFT LCD shield kit For arduino enthusiasts. It includes one pcs of 7 inch TFT LCD display and a TFT LCD shield for Arduino Due.We will provided you the whole document including the example project of Arduino Due with the kit. We will supply you the technical support after your purchase.

It is 100% compatible with the normal MCU like ARM AVR PIC and 8051, especially on Arduino family such as Arduino Due and Arduino MEGA2560(R3).The module uses the LCD controller Chip SSD1963 with 5 inch LCD including the touchscreen.

LCD-specificed intialization code is provided, so that you can save time to optimize power control register and gamma curves for best display performance. We have test the provided code, it gives the best display performanace

This is SainSmart TFT LCD Extend shield for Arduino Due .Using this shield can help you out of the bothers to use other cables. You just need to plug the module to Arduino Due through this shield.

The shield defines that all the the data transmit ports are PC1-PC8 and PC12-PC19,the controll pins are PD0-PD3.The perfect design could realize that the data transmits in high speed. The SPI interface is designed in the ISP header of arduino due so that the SPI transfer with DMA could be achieved in high speed with no drag.

This shiled is just for Arduno Due. If you need the LCD Extend shield for Arduino MEGA2560(R3), you need a similar shield which is also provided from our webstore.

This shiled is just for 7 inch TFT LCD.If you need the LCD Extend shield for 3.2"" or 5"", you need a similar shield which is also provided from our store.

This is Sainsmart 5 inch TFT LCD module with the TFT LCD shield kit for arduino enthusiasts.It includes one piece of 5 inch TFT LCD display and a TFT LCD shield for Arduino MEGA2560 (R3).We will provided you the whole document including the example project of arduino due with the kit. We will supply you the technical support after your purchase.

LCD-specified initialization code is provided, so that you can save time to optimize power control register and gamma curves for best display performance. We have test the provided code, it gives the best display performanace

It is 100% compatible with the normal MCU like ARM AVR PIC and 8051,especially on arduino family such as arduino due and arduino mega2560(R3).The module uses the LCD controller Chip SSD1963 with 5 inch LCD including the touchscreen.

The shield defines that all the the data transmit ports are PC1-PC8 and PC12-PC19,the controll pins are PD0-PD3.The perfect design could realize that the data transmits in high speed.The SPI interface is designed in the ISP header of arduino due so that the SPI transfer with DMA could be achieved in high speed with no drag.

In chapter 7, we made use of the segmented LCD display on the Wonder Gecko Starter Kit through the use of a pre-built LCD library and driver when designing the user interface for the sprinkler timer. That made things easy for us, and we didn’t really need to dwell on how the driver worked. In this chapter, we will dig into some of those details so that we can connect the EFM32 to any kind of display we choose.

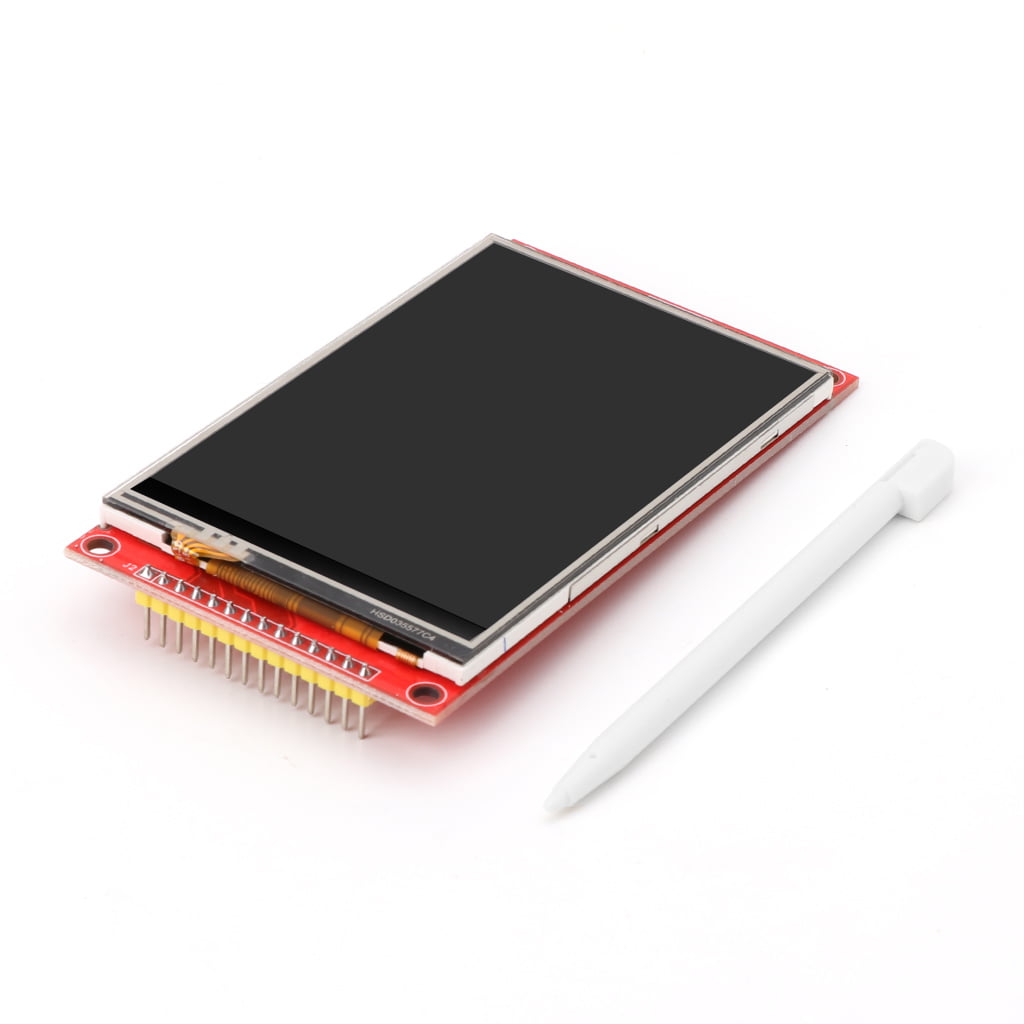

The display we will be using for this chapter is the Adafruit 2.8” 240x320 TFT LCD Capacitive Touch screen, shown below. We will interface with it over SPI for transferring image data and I2C for reading the touch interface. We will learn how to interface with it with our own drivers and build our own simple graphics libraries, as well.

Segmented Display: We have already worked with the segmented LCD display in chapter 7, also known as a character display. In such a display, there are a fixed matrix of LCD segments that are preconfigured in hardware to convey specific information. They are not flexible enough to display an image, but they don’t require many pins on the MCU and are easier to program. For example, the number “9” can be formed on such a display with as few as 6 signals.

Note that a new “Memory LCD” described in Silicon Labs application note AN0048 couples a memory device within each pixel so that constant refreshing is not necessary, reducing power consumption as well.

Graphical display screens have many different technologies, from passive-matrix Liquid Crystal Display (LCD) or active-matrix Thin Film Transistor (TFT) LCD, Light Emitting Diode (LED), or Organic LED (OLED). Display technology is not the focus of this chapter. No matter which technology you choose, you will still need to understand the topics of this chapter in order to display your images.

The LCD pixel matrix is the heart of the display. This part is responsible for displaying the image and, in the case of LCD displays, it will either allow or prevent light from a backlight to pass through. In the case of LED displays, the pixel matrix produces the light and forms the image in one step. No matter the process, the pixel matrix is comprised of an array of pixels in height and width of a certain color depth that make up the display. For the display used in this chapter, the color depth is 18 bits, consisting of 6 bits each for the red/blue/green components of a pixel. That means that the information required to paint the screen one time is 240 bits wide x 320 bits tall x 18 bits of color = 172,800 bytes. That’s a lot of data, and it is more data than we can hold in the RAM of the Wonder Gecko MCU. Therefore, it will require some intelligent code to drive the display or an external memory buffer to store the image data.

The backlight is necessary for TFT LCD displays to allow the display to be seen. Without a backlight, a color TFT LCD will show no image. A monochrome LCD is a little different, since the segments can be seen if they are in the “on” state. The brightness of an LCD screen is sometimes controlled by applying a Pulse Width Modulated (PWM) signal to a pin (or pins) that controls the LED backlight. This is exactly what we have already done in the last chapter to dim an LED.

A frame buffer is a block of RAM that holds all of the color information for every pixel (172 kB for this display) that is used to paint a single image (or “frame”) to the display. This buffer is required to exist somewhere in the system because it is used by the display driver chip to refresh the LCD image many times per second.

A touch interface is an optional component and will often have its own control chip or control signals that are separate from the display driver chip.

A resistive touch screen is pressure sensitive. It requires that your finger (or stylus) makes contact with the screen and causes a tiny grid of precisely controlled resistance wires to touch each other, and then measures the resistance to calculate the position. The resistive touch screen requires four signals to interface the MCU, two of which must be fed into an Analog to Digital Comparator (ADC) in order to read the touches. The Wonder Gecko has several ADC inputs that can be used for this purpose. Resistive touch screens may require calibration by the user to perform accurately.

A capacitive touch screen requires no physical contact between the user and the sensor. Therefore, the sensor can be placed beneath hardened glass or plastic. A valid touch is formed by the change in capacitance measured on the sensor. A human finger can change the capacitance of this sensor, whereas a plastic stylus will not produce a change in capacitance. The capacitive touch screen used in this chapter uses a controller that communicates via the I2C interface.

In the RGB interface mode, the MCU acts as the image driver. This means that it must constantly drive data to the display, refreshing all 320 x 240 pixels many times per second. You can imagine the amount of work that would require of your MCU. If the frame buffer is too big to fit in the MCU RAM, an external memory chip must be used. The frame buffer can be attached to the MCU via serial interfaces such as I2C or SPI for static images such as device menus, but must utilize a parallel interface in order to keep up with the demands of full motion video. The External Bus Interface (EBI) can be used with external memory for maximum speed and ease of use, as long as your particular model of EFM32 supports it. EBI extends the RAM of your EFM32 and allows you to address external memory as if it resides within the RAM address space of the EFM32 itself.

These driver chips usually offer both parallel and serial interfaces to receive image data from the MCU. Parallel interfaces are required if the display will be used for full-motion video and require 8 or more data interface pins. Serial interfaces can be used for static images like device menus and only require 3 or 4 interface data pins.

There are displays available on the market (such as the EVE series from FTDI) which go well beyond a display driver chip. They contain the ability to create graphical shapes such as lines, rectangles, and circles, as well as device controls such as windows, sliders, and buttons. These displays can even offer an integrated touch controller and audio capabilities. The displays communicate over I2C or SPI, and the data that is sent is similar to a software Application Programming Interface (API). The specs of such displays define the commands that the controller chip accepts, and the application software simply communicates each graphic primitive one-by-one to the display to paint the appropriate picture on the screen. These types of displays can be easier to program, but are not the focus of this chapter.

Depending on the graphics library complexity, it may even create a full windowing capability with sliders or popups and add all of the comforts of a modern computer interface to your embedded application, all within the limited RAM available in an MCU. Silicon Labs provides the Segger emWin graphics library as part of the Simplicity Studio installation. We will introduce the emWin library at the end of this chapter.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

3.5inch RPi LCD (A) and 3.5inch RPi LCD (B) are hardware compatible with each other (uses different driver), and can be mutually substituted in most cases. (A) for low cost ver. while (B) for IPS ver. with better displaying.

Why the LCD doesn"t work with my Raspbian?To use the LCD with the Raspberry Pi official image, driver (SPI touch interface only) should be installed first. Please refer to the user manual.

However, for the first testing, you may want to use our image directly (if provided).Why the LCD still doesn"t work with the Waveshare provided image?Make sure the hardware connection is correct and connects fine.

Since the first-generation Raspberry Pi released, Waveshare has been working on designing, developing, and producing various fantastic touch LCDs for the Pi. Unfortunately, there are quite a few pirated/knock-off products in the market. They"re usually some poor copies of our early hardware revisions, and comes with none support service.

This is a 2.2” TFT LCD Display Module with an input voltage of 3.3V~5.5V, which is used to display colorful patterns and characters. The fastest screen refresh speed is about 256ms. The module is able to display multiple patterns in a cycle and realize dynamic display effect. At present, there are 19 common defined colors in the library, and users can also customize16-bit color codes. If we take the central point of the display as the origin of coordinates, the maximum absolute value of the positive and negative axis will be 64.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey