tft lcd manufacturing process brands

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

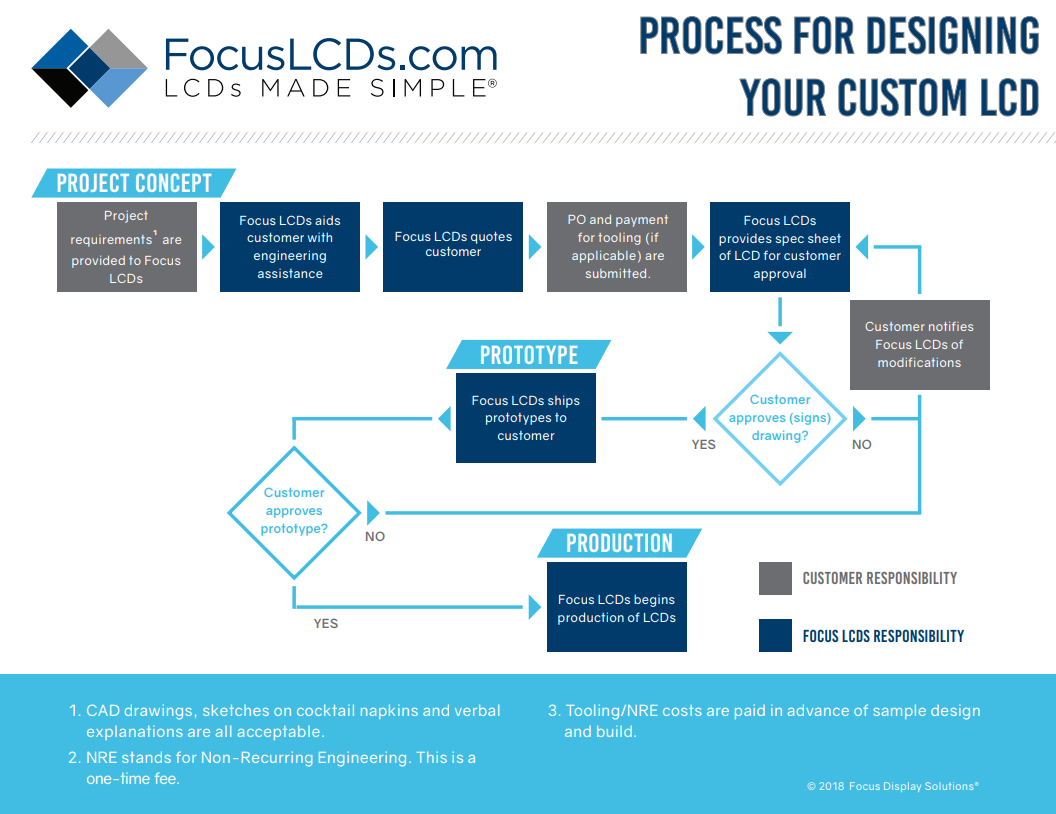

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

Smart IoT Systems Business includes Intelligent Manufacturing Services, IoT Solution, and Digital Art IoT Platform. BOE provides integrated IoT solutions in smart retail, smart finance, digital art, business office, smart home, smart transportation, smart education, smart energy, and other fields. In the field of digital art, BOE has launched its digital art IoT solution – BOE iGallery, realizing the perfect combination of technology and art. For smart retail, BOE provides IoT solutions in price management, shelf management, and customer behavior analysis to achieve seamless online and offline convergence.

BOE has manufacturing bases located in Beijing, Hefei, Chengdu, Chongqing, Fuzhou, Mianyang, Wuhan, Kunming, Suzhou, Ordos, Gu’an, etc. BOE boasts a global marketing and R&D centers in 19 countries and regions like the United States, Germany, the United Kingdom, France, Switzerland, Japan, South Korea, Singapore, India, Russia, Brazil, and Dubai, with its service networks covering the world’s major areas such as Europe, America, Asia, and Africa.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

The global display market reached a value of US$ 151.5 Billion in 2021. As per the analysis by IMARC Group, the top manufacturers in the display industry are focused on manufacturing advanced display variants in different sizes that are equipped with speakers, built-in cameras, and video calling features. They are also making heavy investments in the advancement of display technologies, such as liquid crystal display (LCD), cathode ray tube (CRT), light-emitting diode (LED), organic LED (OLED), gas plasma, quantum dot, and e-paper. Along with this, the development of smart displays integrated with innovative technologies, such as the Internet of Things (IoT) and artificial intelligence (AI) that assist in real-time monitoring and provide remote access, is offering lucrative opportunities to key players. Furthermore, the leading manufacturers are entering into partnerships and collaborations and focusing on research and development (R&D) activities to launch technologically advanced displays. Apart from this, the introduction of interactive and flexible displays that offer enhanced brightness, flexibility, and low power consumption is creating a positive market outlook. Looking forward, the market value is expected to reach US$ 197.3 Billion by 2027, growing at a CAGR of 4.10% during the forecast period (2022-2027).

AU Optronics Corp. is a leading provider of optoelectronic solutions that offer a wide range of display applications and smart solutions integrating software and hardware. The company was formed by the merger of Acer Display Technology, Inc. and Unipac Optoelectronics Corporation. It is committed to developing innovative display technologies for its premium and value-added display product applications. Over the years, it has earned worldwide recognition for its smart diversified solutions with its strong R&D capacity, manufacturing expertise, and comprehensive product portfolio. Currently, it has operations in numerous countries across the globe, including Taiwan, Mainland China, Japan, Singapore, South Korea, the US, and Europe.

BOE Technology Group Co. Ltd. is a leading semiconductor display company that offers ultra-high-definition, flexible, and micro-display solutions. It also provides smart products and professional services for information interaction and human health. The company operates through five segments, including semiconductor display, sensor and solution, MLED, smart system innovation, and smart medicine and engineering. It has several manufacturing bases in Beijing, Hefei, Chengdu, Chongqing, Fuzhou, Mianyang, Wuhan, Kunming, Suzhou, Ordos, and Gu"an. Its subsidiaries are located in 19 countries and regions, including the USA, Germany, UK, France, Switzerland, Japan, Korea, Singapore, India, Russia, Brazil, and UAE.

Corning Incorporated is one of the leading innovators in materials science worldwide that specializes in glass, ceramics, and concrete manufacturing. The company’s industry-leading products include damage-resistant cover glass for mobile devices; precision glass for advanced displays; optical fiber, wireless technologies, and connectivity solutions for state-of-the-art communications networks; trusted products to accelerate drug discovery and delivery; and clean-air technologies for cars and trucks. It operates through five segments, including display technologies, optical communications, environmental technologies, specialty materials, and life sciences.

DuPont de Nemours Inc. is a global innovation and technology leader, serving the semiconductor, display, circuit board, digital and flexographic printing, healthcare, aerospace, industrial, and transportation industries. The company is a leading supplier of innovative display materials and processes that enable enhancements to advanced flat-panel display (FPD), liquid crystal display (LCD), and organic light-emitting diode (OLED) display technologies. It operates several manufacturing facilities and offices in around 40 countries across the globe, including the United States, China, Taiwan, Singapore, Indonesia, India, Japan, Mexico, Australia, Canada, Korea, France, Germany, United Kingdom, Italy, Spain, Philippines, Thailand, Vietnam, Belgium, and Brazil.

E Ink Holdings Inc. is the originator, pioneer, and leader in ePaper technology. It delivers its advanced display products to the leading brands and manufacturers across the globe, allowing them to install extremely durable, low-power displays in previously impossible or unimaginable applications and environments. It also develops, manufactures, and markets thin-film transistor liquid crystal displays (TFT-LCDs). At present, the company has operations in Taiwan, China, North America, Japan, and Korea.

Innolux Corporation is a global leader in display technology engaged in producing and supplying TFT-LCD, liquid crystal panel modules, and touch modules. It provides advanced display integration solutions with innovative and differentiated technologies, such as 8K4K ultra-high-resolution, active-matrix AM miniLED, AM microLED, LTPS, and touch solutions. The company also covers a range of display application products, including TV panels, desktop monitors and notebook computer panels, small and medium-sized panels, medical panels, and automotive panels.

Leyard Optoelectronic Co., Ltd. is a global leader in audio-visual technology. It operates through four segments, including intelligent display, international business, nightscape lighting, cultural tourism, and VR entertainment. In addition, the company offers a variety of display products, such as small pitch LED, conventional LED, LCD products, creative LED, LED leasing, LED modular, and conference and commercial display products.

Qisda Corporation is an ODM/OEM leader engaged in manufacturing electronic products for consumer, commercial, medical, and industrial applications. It has a diverse product portfolio, consisting of LCD monitors, digital signage and professional displays, projectors, scanners, multifunctional printers, 3G/4G smartphones, medical gateways, medical imaging and telecare, automobile infotainment devices, e-reader, and tablets. Moreover, the company owns and operates manufacturing facilities in China, Mexico, and Taiwan.

Sharp Corporation is a Japanese multinational corporation primarily engaged in the manufacturing and sales of electric and electronic application equipment, electronic components, and telecommunications equipment. The company operates through three segments, including smart life, 8K ecosystem, and ICT. It has a diverse product portfolio, consisting of display modules, LCD TVs, semiconductor lasers, sensor modules, audio equipment, in-vehicle cameras, multi-function printers, information displays, and business projectors.

Sony Corporation is a Japanese multinational conglomerate corporation that manufactures electronic products, semiconductor solutions, and imaging and sensing solutions. It also offers a wide range of professional displays, including LCD, HDR, LED, and OLED display technologies, ideal for digital signage, screen mirroring, and various professional solutions. The company currently has operations across several countries and regions worldwide, including Japan, the United States, Europe, China, India, Australia, Indonesia, Malaysia, New Zealand, Philippines, Singapore, Thailand, and Vietnam.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Transform your design into an innovative product with our electronics manufacturing services. Scale your product with the help of a reliable manufacturing partner.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Asahi Glass, Co., Ltd. (Headquarters: Tokyo; President: Shinya Ishizu) decided to increase its manufacturing capacity of glass substrates used for TFT-LCD (Thin Film Transistor Liquid Crystal Display). With this increase the company will install new furnace of glass substrate at its Kansai factory and augment its glass panel polishing line in Taiwan. Engineering will commence from August of this year and is expected to be completed in October, 2003. Total funds to be injected into the project are estimated at 17 billion yen. The total production capacity as a result of this increase is estimated to be 10 million square meters annually, using four furnaces of glass substrates.

The demand for TFT-LCD displays is predicted to increase at a rate of 30% annually through the year 2005, since a steady increase is predicted not only for their use in notebook PCs, but even more so for their use in PC monitors. Their use in TVs is also expected to sky rocket. In addition, TFT-LCD substrate panel manufacturers announce they plan to use the large substrates to reduce their cost, and that in the future the "5th Generation Size" of glass substrates with a surface are exceeding one square meter, will be the industry mainstay.

Unlike many competitors, Asahi Glass incorporates floating method in manufacturing process of the glass substrates, which is suited to the mass production of large size. The company decided to increase the manufacturing capacity of its TFT-LCD glass substrates because it felt that the increasing demand for TFT-LCD displays and calls for larger glass substrates for TFT-LCD displays presented a great opportunity to further expand this business area and become the global leader in the impending. Details of the future capacity increase are as follows:

We will install the fourth furnace of TFT-LCD glass substrate at the Kansai Factory (Amagasaki City, Hyogo Prefecture). The new furnace will enable highly efficient multi-line production of ultra-large-sized substrates, primarily ultra-large glass substrates larger than one square meter, making possible the manufacture of glass substrates of approximately four meters in width. The manufacturing capacity of this furnace is four million square meters annually, nearly twice that of our existing furnaces, and requires a capital investment of roughly 12 billion yen.

We will augment the TFT-LCD glass panel polishing line, which is targeted for the fifth generation size glass substrate, at Asahi Glass Fine Techno Taiwan Co., Ltd. (a fully owned subsidiary of Asahi Glass, Co., Ltd., located in Douliu City, Taiwan), which has been operating a polishing line since 2001. Capital investment for the new line is roughly five billion yen. Although Asahi Glass Fine Techno in Japan (a fully owned subsidiary of Asahi Glass, Co., Ltd., located in Yonezawa City, Yamagata Prefecture) also conducts polishing of TFT-LCD glass substrates, the line addition will be made in Taiwan, since future production volumes of TFT-LCD substrates will greatly increase there and since it is expected that Taiwanese TFT-LCD panel manufacturers will employ the 5th generation size of glass substrate before manufacturers in Japan do.

We will fully leverage the features of the float method, which is especially suited for larger glass substrates, to address increasing demand and proceed with the expansion of the TFT-LCD glass substrate business.

We are the only glass manufacturer in the world employing the float method in the manufacturing process of TFT-LCD glass substrates. Produced using this method and brought to market in 1998, our "AN100" product exhibits the following major features:

The "AN100" comes fully equipped with the qualities sought after in the future TFT-LCD industry"s 5th generation line of large glass substrate (one square meter or larger), and is very highly regarded by our customers.

Our "AN100" is an environmental friendly product. In fact, it is the only non-alkaline glass substrate used in TFT-LCD displays that does not use the harmful substances known as Arsenious Acid (As2O3) and Antimony (Sb2O3) in the manufacturing process.

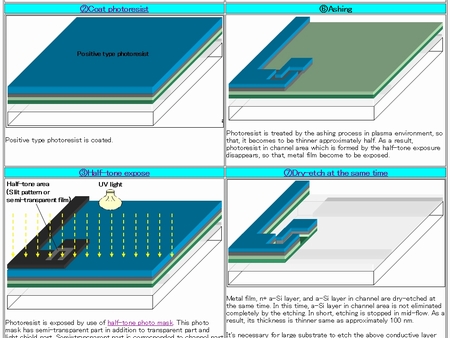

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

In the LC filling process, if the quantity of LC injected is not enough, the spare space will form bubbles. And loose LC containing sealant will result in LC leakage.

For the first two situations, that’s because the circuit on the TFT and CF controlling that defective pixel point is shorted or broken. While the third situation is caused by damaged color pixel.

The production of the circuit and color pixel is under micro scale, and the technology is similar to semiconductor technology. Hundreds of thousands micro materials will be printed during the production process, you can understand some of the materials not being printed correctly, which result in the point defect.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

To avoid this problem, we have to pay attention to the gap distance parameter in sealing process. By the way, newton’s rings has became a method to exam the glass sealing process in reverse .

The black matrix on CF glass or a additional shield bar is used to avoid this problem. So if this problem occurs, we have to check the CF deposition process.

... Specification TOPWAY HMT035ATA-1C is a Smart TFT Display Module with 32bit MCU on board. Its graphics engine provides numbers of outstanding features. It supports TOPWAY TML 3.0 for preload and pre-design ...

TOPWAY Smart LCDs embed a display engine and a versatile range of TFT display module sizes and Touch-Panels to support a wide range of industrial and instrumentation ...

TOPWAY HMT101ATA-C is a Smart TFT display module with 32bit MCU on board. Its graphics engine provides numbers of outstanding features. It supports TOPWAY TML for preload and pre-design display ...

... the range of the alphanumeric panel-mount displays, microSYST has included a new type of panel-mount display with touch function to its portfolio. The "mitex TFT" is a HMI panel with ...

Industrial and medical applications place high demands on TFT displays. Tianma has launched the professional P-Series with diagonals from 3.5 to 27 inches especially for these applications. All P-Series ...

Technology trends in backplane technology are driving higher gas demand in display manufacturing. Specific gas requirements of process blocks are discussed, and various supply modes are reviewed.

Since its initial communalization in the 1990s, active matrix thin-film-transistor (TFT) displays have become an essential and indispensable part of modern living. They are much more than just televisions and smartphones; they are the primary communication and information portals for our day-to- day life: watches (wearables), appliances, advertising, signage, automobiles and more.

There are many similarities in the display TFT manufacturing and semiconductor device manufacturing such as the process steps (deposition, etch, cleaning, and doping), the type of gases used in these steps, and the fact that both display and semiconductor manufacturing both heavily use gases.

However, there are technology drivers and manufacturing challenges that differentiate the two. For semiconductor device manufacturing, there are technology limitations in making the device increasingly smaller. For display manufacturing, the challenge is primarily maintaining the uniformity of glass as consumers drive the demand for larger and thinner displays.

As the display mother glass area gets bigger and bigger,so does the equipment used in the display manufacturing process and the volume of gases required. In addition, the consumer’s desire for a better viewing experience such as more vivid color, higher resolution, and lower power consumption has also driven display manufacturers to develop and commercialize active matrix organic light emitting displays (AMOLED).

In general, there are two types of displays in the market today: active matrix liquid crystal display (AMLCD) and AMOLED. In its simplicity, the fundamental components required to make up the display are the same for AMLCD and AMOLED. There are four layers of a display device (FIGURE 1): a light source, switches that are the thin-film-transistor and where the gases are mainly used, a shutter to control the color selection, and the RGB (red, green, blue) color filter.

Technology trends TFT-LCD (thin-film-transistor liquid-crystal display) is the baseline technology. MO / White OLED (organic light emitting diode) is used for larger screens. LTPS / AMOLED is used for small / medium screens. The challenges for OLED are the effect of < 1 micron particles on yield, much higher cost compared to a-Si due to increased mask steps, and moisture impact to yield for the OLED step.

The challenge to MO is the oxidation after IGZO metalization / moisture prevention after OLED step, which decreases yield. A large volume of N2O (nitrous oxide) is required for manufacturing, which means a shift in the traditional supply mode might need to be considered.

Although AMLCD displays are still dominant in the market today, AMOLED displays are growing quickly. Currently about 25% of smartphones are made with AMOLED displays and this is expected to grow to ~40% by 2021. OLED televisions are also growing rapidly, enjoying double digit growth rate year over year. Based on IHS data, the revenue for display panels with AMOLED technol- ogies is expected to have a CAGR of 18.9% in the next five years while the AMLCD display revenue will have a -2.8% CAGR for the same period with the total display panel revenue CAGR of 2.5%. With the rapid growth of AMOLED display panels, the panel makers have accel- erated their investment in the equipment to produce AMOLED panels.

There are three types of thin-film-transistor devices for display: amorphous silicon (a-Si), low temperature polysilicon (LTPS), and metal oxide (MO), also known as transparent amorphous oxide semiconductor (TAOS). AMLCD panels typically use a-Si for lower-resolution displays and TVs while high-resolution displays use LTPS transistors, but this use is mainly limited to small and medium displays due to its higher costs and scalability limitations. AMOLED panels use LTPS and MO transistors where MO devices are typically used for TV and large displays (FIGURE 3).

This shift in technology also requires a change in the gases used in production of AMOLED panels as compared with the AMLCD panels. As shown in FIGURE 4, display manufacturing today uses a wide variety of gases.

These gases can be categorized into two types: Electronic Specialty gases (ESGs) and Electronic Bulk gases (EBGs) (FIGURE 5). Electronic Specialty gases such as silane, nitrogen trifluoride, fluorine (on-site generation), sulfur hexafluoride, ammonia, and phosphine mixtures make up 52% of the gases used in the manufacture of the displays while the Electronic Bulk gases–nitrogen, hydrogen, helium, oxygen, carbon dioxide, and argon – make up the remaining 48% of the gases used in the display manufacturing.

The key ga susage driver in the manufacturing of displays is PECVD (plasma-enhanced chemical vapor deposition), which accounts for 75% of the ESG spending, while dry etch is driving helium usage. LTPS and MO transistor production is driving nitrous oxide usage. The ESG usage for MO transistor production differs from what is shown in FIGURE 4: nitrous oxide makes up 63% of gas spend, nitrogen trifluoride 26%, silane 7%, and sulfur hexafluoride and ammonia together around 4%. Laser gases are used not only for lithography, but also for excimer laser annealing application in LTPS.

Silane: SiH4 is one of the most critical molecules in display manufacturing. It is used in conjunction with ammonia (NH3) to create the silicon nitride layer for a-Si transistor, with nitrogen (N2) to form the pre excimer laser anneal a-Si for the LTPS transistor, or with nitrous oxide (N2O) to form the silicon oxide layer of MO transistor.

Helium: H2 is used for cooling the glass during and after processing. Manufacturers are looking at ways to decrease the usage of helium because of cost and availability issues due it being a non-renewable gas.

The consumer demand for displays that offer increas- ingly vivid color, higher resolution, and lower power consumption will challenge display makers to step up the technologies they employ and to develop newer displays such as flexible and transparent displays. The transistors to support these new displays will either be LTPS and / or MO, which means the gases currently being used in these processes will continue to grow. Considering the current a-Si display production, the gas consumption per area of the glass will increase by 25% for LTPS and ~ 50% for MO productions.

To facilitate these increasing demands, display manufacturers must partner with gas suppliers to identify which can meet their technology needs, globally source electronic materials to provide customers with stable and cost- effective gas solutions, develop local sources of electronic materials, improve productivity, reduce carbon footprint, and increase energy efficiency through on-site gas plants. This is particularly true for the burgeoning China display manufacturing market, which will benefit from investing in on-site bulk gas plants and collaboration with global materials suppliers with local production facilities for high-purity gas and chemical manufacturing.

TFT displays are now used in a wide range of products, including TVs, computers, appliances, medical equipment, instruments, mobile, and other gadgets. The utilization of LCDs in all market segments was significantly enhanced by incorporating thin film transistors into LCD architecture.

The liquid crystal display (LCD) uses TFT (thin-film transistor) technology and contains a transistor for each pixel (that is, for each of the tiny elements that control the illumination of your display). Since each pixel has a transistor, the current that initiates pixel lighting may be reduced and turned on and off more quickly. The active matrix display technology is another name for TFT (and contrasts with the "passive matrix," which does not have a transistor at each pixel).

The materials required to make a TFT display include ITO glass, liquid crystal, polarizer, sealing glue, and intermediate powder. These components themselves are simple enough, but the manufacturing process can often involve heavy investment in tooling, sourcing, and research. Each step of the process requires a unique line and space in the factory, along with dedicated design, engineering, and manufacturing staffing.

A custom sized TFT display will likely need to be designed such that each component fits into an appropriately sized housing that the project will require; this will often require experimentation and creative resources.

Regarding engineering support, the bespoke panels will need to be designed to function reliably and with the performance required for the use. This process will also require sourcing the tooling or suppliers for individual parts in order to manufacture the custom display. Finally, manufacturing the custom display will require a dedicated assembly line with the training to create the bespoke display configuration. Depending on the use case, this may require custom or unique processes that will require an investment in training and quality assurance. The quality assurance process for devices that are not mass-produced can be difficult and time-consuming. Because there are usually tight deadlines to follow and a limited number of samples, it can be difficult to reliably assess samples and understand the breadth of limitations surrounding a design.

Therefore, it may not make sense for a small project scope if you need a small number of TFTs with custom sizes. While the overall cost may be lower due to unit price reductions as the number of displays purchased leads to a decreased cost per unit, this price reduction will not be feasible with a smaller purchase size of custom-size displays. Additionally, when considering the tooling cost, this is not able to be spread over a smaller number of custom displays purchased, leading to limited cost savings on small purchase orders. Custom can be cheaper if your project falls within mid-range volumes, but this is not the case for small projects.

Consequently, due to design, sourcing of materials, manufacturing considerations, and cost and time of quality assessment, it can be impractical to order a custom TFT configuration for smaller projects. Fortunately, FocusLCDs offers a wide variety of mass-produced screen sizes that allows you to benefit from economies of scale and may even be a perfect fit for your specific project.

A type of flat panel display known as an LCD (Liquid Crystal Display) operates primarily on liquid crystals. Portable electronic games, viewfinders for digital cameras and camcorders, video projection systems, electronic billboards, computer displays, and flat-panel televisions are all typical applications for LCDs. #Top 10 LCD Manufacturers in the World.

The demand for electronic components is rising quickly as a result of the evolutionary changes in consumer electronics over the past few years. LCD display modules utilize the liquid crystals" ability to manipulate light as an electrically modulated optical device or flat-panel display.

The need for LCD display modules is rising as more electronic products, including instrument panels, computer monitors, LCD televisions, indoor and outdoor signs, and aviation cockpit displays, are produced. Manufacturers of LCD display modules are concentrating on creating cutting-edge goods to draw in more consumers and boost income from the sale of displays.

There have also been significant structural changes in the display sector worldwide. China, Japan, and South Korea are now the key LCD industrial hubs. The expansion of continental display manufacturers" manufacturing capacity will soon make mainland China the world"s largest LCD-producing region. Additionally, local Chinese firms like BOE have recently surpassed LCD producers from Korea and Japan. China LCD businesses supplied 97.01 million square meters of TFT LCD in the first three quarters of 2020. Furthermore, China"s LCD display makers anticipate quickly capturing 70% of worldwide exports of LCD panels.

Thus, considering the global LCD market, due to rising demand for touch-enabled displays, and low power consumption electronics, the LCD panel industry is one of the fastest-growing sectors in the economy. As a result, producers of LCD display modules are developing new products with characteristics such as backdrop display colors, character sizes, number of rows, and others, which are causing the LCD display module"s integration to rise. With this analysis and introduction, let us now get into our topic which is “Top 10 LCD Manufacturers in the World”,and if you are also one of those who are searching about this topic, you are at the right spot.

The top producers of TFT-LCD display worldwide are Innolux, formerly known as Chimei Innolux, and they were founded in 2003. Innovative and creative technology is used in Innolux"s sophisticated display integration solutions, which provide a comprehensive spectrum of small, medium, and large LCD panels and touch-control displays.

Innolux is a TFT-LCD provider to information technology companies and consumer digital product producers worldwide, offering a comprehensive variety of TFT-LCD panel modules and touch panels, including TV panels, desktop monitors, laptop computer panels, and AV & mobile panels.

11 manufacturing lines are currently in use at BOE. A Gen 5 TFT LCD line and a Gen 8.5 TFT LCD line are two examples of this in Beijing. There are more production lines in Ordos, Chongqing, Hefei, Chengdu, and Hefei. The Gen 10.5 TFT LCD plant in Hefei, which has the highest generation in the world, began pilot production in October and will go into mass production in January 2018.

Beijing, Chongqing, Chengdu, Hefei, Ordos, Gu"an, Suzhou, and Xiamen are all home to BOE manufacturing facilities. Additionally, BOE has a sizable global network for marketing, sales, and service that spans the world"s major continents, including Europe, America, and Asia.

Founded in 1996, AUO employs 38,000 people worldwide spanning Asia, the United States, and Europe. Their display innovations continuously revolutionize human-technology interaction by drawing on their decades of industry leadership. Commercial and industrial-grade panels are used in the design and manufacturing process by AUO, which also has a wealth of display expertise. These factors enable AUO to produce highly dependable products of the highest quality with long life cycle support to ensure stable operation in challenging environments.

The sector"s first and largest 65-inch AQUOS LCD color TV was successfully created by Sharp Corporation at the time. The size of LCD TV screens was formerly thought to be limited to 45", yet size has been rising considerably, indicating that LCD technology will continue to advance.

With its development and ownership of cutting-edge technologies in the SLT-LCD, LTPS TFT-LCD, AMOLED, etc., Tianma has distinct advantages in both world-class technology and manufacturing capabilities.

Ampire is a Taiwan-based maker of LCD modules with more than 15 years of expertise. Ampire offers a variety of high-quality products (TFT, CSTN, FSTN, STN, TN) with various technologies (COG, TAB & COB), as well as bespoke designs where appropriate, to fulfill varied applications.

Ampire provides premium LCD mother glass along with other common display panels. However, Ampire Display"s primary area of expertise is the creation of customized TFT display modules.

Japanese company Ortus Technology (ORTUSTECH) produces tiny and medium-sized TFT displays of excellent quality that are intended for use in outdoor applications. With more than 30 years of expertise in industrial displays, ORTUSTECH is a market innovator in the LCD space. The unique Blanview technology from ORTUSTECH effectively combines the benefits of transmissive and transflective displays. Its major strengths include optimal readability and color accuracy in practically all viewing angles and lighting circumstances, even when exposed to direct sunlight. The technology is ideal for all mobile applications and battery-powered devices because Planview screens also consume up to 60% less power than traditional transmissive displays. The display produces less heat when operating due to decreased power consumption. This is a tremendous benefit, particularly when exposed to intense sunshine.

They offer a variety of goods and concentrate on the vertical integration of industrial resources with our G5.3 TFT-LCD production in Tainan and the Nanjing LCM/Touch factories, developing innovative products for upcoming uses and business models.

Back-end liquid crystal panel (LCM) processes and touch products are the primary businesses of HannStar Display (Nanjing) Corporation. Through ongoing improvements, equipment upgrades, as well as the vertical resources integration of HannStar"s LCD production process, they provide clients with high-quality display products.

The aforementioned businesses are among the global providers of LCD Display modules. In order to compete in the worldwide market, LCD display makers are developing new features and enhanced functionality for the screens.

Yeebo Group was established in 1988, and principally has been engaging in developing, manufacturing and marketing of high quality Monochrome LCD and LCD Modules. Yeebo’s products have a strong global presence in key electronic market sectors including Automotive indumenta, Telecommunications, Medical equipment and Electronic consumable products such as Audio, White products, Watches and Electronic notebooks.

Yeebo Group is a publicly held company listed on the Stock Exchange of Hong Kong. With headquarter located in Hong Kong, our manufacturing activities operate with one each LCD manufacturing plant and LCM assembly plant in Jiangmen, Guangdong. Our LCD foundry and LCM assembly facilities are equipped with multiple, highly automated production lines which have latest state-of-the-art equipment to produce ITO coated glass. Lately the group successfully developed OLED, together with Tsinghua University and has invested in Kunshan Visionox Technology Company Ltd. who specialized at OLED manufacturing.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey