tft lcd manufacturing process made in china

![]()

In this article, we are looking at the benefits of looking for Chinese TFT LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with STONE Tech.

There is no doubt that China has taken the mass manufacturing business by storm. There are few products that we can encounter in our lives that don’t have the words ‘Made in China’ scribbled underneath. There is a glut of products that are mass-manufactured by the Chinese and then shipped out internationally to be sold.

Handbags, wallets, phone cases, and other similar items have become the favorites of wholesalers and bulk buyers. These products are directly sold to end consumers. However, the fascinating thing about the Chinese production and manufacturing business is that it does not only cover the end-consumer products. Rather, you can also acquire raw and basic materials needed for the further manufacturing of goods and products. One such product is LCD displays.

LCD displays have become something of a necessity in today’s world of tech advancement. Many things in our daily life have been automated, and are operated using an interactive user interface. For these kinds of machines and gadgets, LCD displays are typically necessary.

In this article, we are looking at the benefits of looking for Chinese LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with Stoneitech.com.

STONE Tech is an LCD manufacturer located in Beijing, China. It was founded back in 2010, and it has been developing TFT LCD display modules ever since. These modules can be used for a variety of different machines including electric equipment, precision instruments, and civil electronics etcetera.

This is probably the biggest advantage that you can get when working with manufacturers from China. It can even be assumed that this is probably the biggest reason why the Asian country is at the forefront of the mass manufacturing business.

The same applies to LCD displays. When you save up on costs when buying LCD displays, you can set a lower price for the whole machine or gadget that you are producing.

When it comes to LCD modules, the orders are not received by the hundreds or thousands as is the case with other smaller products such as handbags and wallets etcetera. One module can cost around $250, and it is for this reason that the dynamics are a little different with this business. That is why STONE offers single pieces for sale as well as multiple pieces. This encourages smaller businesses to make their purchases since they can easily purchase as many modules as they like. As long as you meet the limit stated by the supplier, you are good to go.

In the case of LCD modules, this benefit relates to a reselling business. For example, if you are planning on buying some modules to use in your machines etcetera, then there is not a very suitable opportunity for you to expand. If you want to start a business in another country, you will have to open a manufacturing unit there so that your products can be produced and then get sold. Or, you will have to transport your final products to the other country in order to run your business.

However, if you are buying the LCD modules to resale at a profit, you can use the Chinese markets to grow your business. You can buy the modules at a reduced price and then sell them at a profit in a different area or city where the people will be willing to pay more.

Now that we have seen the benefits of choosing Chinese manufacturers for LCD modules, let us narrow it down a bit and look at why you should choose STONE specifically.

One of the main things that you have to look at in any supplier is the level of reliability and trust. This is usually determined by the level of experience and the time that the supplier has spent in the market. STONE was founded in 2010 and has been producing LCD modules for the past 10 years.

If you are looking to buy LCD modules in bulk, look no further than the Middle Kingdom. China has become the hub of mass manufacturing and is the favorite spot for wholesalers and business owners.

In case you need some convincing about buying from the Chinese, we have compiled a list of benefits that you can enjoy when looking for TFT LCD manufacturers in China.

![]()

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

The famous china LCD display manufacturers. It is the world’s leading semiconductor display technology, products, and services provider. Products are widely used in mobile phones, tablets, laptops, monitors, televisions, cars, digital information displays, and other display fields.

Focus on the development and production of china HMI (Intelligent TFT LCD Module) LCD display manufacturers, production, and sales of LCD display modules for 16 years. The company master TFT LCD technology and software system. The main products are industrial electronic series, advanced series, and civil and commercial series. Application scenarios include automation systems, medical beauty equipment, vending machines, smart lockers, energy, and power equipment (refueling machines, charging piles), elevators, smart homes, and offices, measuring instruments, public transportation, etc.

Mainly committed to the r&d, production, and sales of TFT-LCD/stn-LCD /OLED display modules, it is a modern high-tech enterprise that provides a full range of product LCD module technology and manufacturing support services for TCL group member enterprises and international electronic enterprises.

Set an LCD display module (LCM), capacitive touch screen (CTP), fully integrated touch display module (TDM), LCD thin technology development, production, and service in one national high-tech company.

Domestic size of the top four small and medium-sized flat panel display manufacturers. The products cover medium and small-size TFT-LCD display modules and high-precision miniature cameras, which have been widely used in the fields of smartphones, medical treatment, and industrial display.

The LCD business division is specialized in the r&d, production, and sales of the LCD display (LCD) and LCD module (LCM) series of products. It has ten semi-automatic COG production lines, 1.5KK of monthly COG products, covering COG, TAB, COB, and other LCD module products, TFT, CSTN, and other color LCD display products, and OLED display products. touch screen manufacturers.

Byd IT products and business mainly include the establishment of rechargeable batteries, plastic parts, metal parts, hardware, and electronic products, mobile phone keys, microelectronics, LCD display module, optoelectronic products, flexible circuit board, chargers, connectors, uninterruptible power supply, dc power supply, solar energy products, mobile phone decoration, mobile phones ODM, mobile phone test, assembly operations, laptop, ODM, manufacturing, testing and assembly operations, etc.

Star source products cover backlight, LCD, optical diaphragm, etc., widely used in LCD modules, photo frames, tablets, portable, instruments, and meters.

The company has long invested in the research and development of the TFT-lcm LCD module, focusing on consumer products and industrial control products. Currently, 3.5-11.6 inch modules are available, among which 4.0, 4.3, 5, 6, and 10.1-inch products have reached the leading level in the industry. Products are mainly used in vehicles, mobile TV, PMP, DVD, EPC, security, and industrial control products.

Professional development, design, production, and sales of LCD display module (LCM), products cover COB, TAB, COG, and other LCD module products, TFT, CSTN, and other color LCD display products, as well as OLED display products. Products are widely used in mobile phones, communications, digital products, household appliances, industrial control, instrumentation, vehicle display, color screen display, and other fields.

Mainly engaged in research and development, manufacturing, and sales of the LCD display and LCD display module. Products are widely used in all kinds of electronic products and equipment HMI interface, such as medical equipment, instruments and meters, audio, household appliances, telephone and clocks, game machines, and other different types and use.

Focusing on the LCD module industry, is a collection of research and development, manufacturing, sales as one of the high-tech enterprises. TFT module size from 1.44 to 7 inches, product specifications cover QVGA, WVGA, qHD, HD, etc., the market prospects are broad.

The display manufacturers company mainly researches and develops the LCD display, charger, battery, and other products of mobile communication mobile phone, telephone, MP3, and other high-tech products.

The company integrates research and development, design, production, sales, and service into one, and provides comprehensive touch and display integrated solutions for the complete machine touch screen manufacturer of smartphones, specializing in the development and manufacture of Sensor sensors, capacitive touch screens (GFF/OGS/GG), small and medium-sized LCD (TN/HTN/STN/CSTN/TFT) and corresponding modules and glass cover plate products. The company’s products are widely used in communication terminals (smartphone, tablet computer, etc.), household appliances, car electronics, digital products, and other industries, exported to Europe and America, Japan and South Korea, Singapore, and other countries.

Mainly produces medium and small-size LCD display module (LCM), multi-point capacitive touch screen (CTP), and other high-tech products. At present, more than 1000 models of 1.2-12.1 inch products have been developed. Products are widely used in mobile phones, GPS, mobile TV, tablet computers, digital photo frames, e-books, and other consumer electronics.

It is a professional development and production of small and medium-sized flat panel display upstream materials manufacturers. The company’s main products include LCD display panels, color filter, ITO conductive glass (CF), TFT LCD panel, and capacitive touch screen with multi-touch control functions (sensor and the final module), can provide complete medium and small size flat-panel display device using the solution of raw materials, product specifications varieties complete, widely used in 10.4 inches below the smartphone, tablet, PMP, digital camera, digital camera, GPS and other products of the display panel.

Now it is divided into mobile phone business division: the main products are (2.8-6) inch and the LCD screen and capacitive screen all fit together.MID tablet computer and ultrabook computer division: the main production product size is (7-15) inch capacitive touch screen.

It set TP lamination, assembly lamination r & d, production, sales as one of the production and processing enterprises. Its products are dedicated to mobile phones, tablets, industrial control equipment, and other fields.

Committed to 3.5~4.3 inches, 5 inches, 5.88 inches, 6.2 inches, 7.0 inches, 8.0 inches, 9.7 inches, 10.1 inches, 12.1 inches medium size FOG, backlight process production, products should be widely used in high-end communication phones, tablets, notebook computers, car TV, navigator, and other display products. automotive LCD display touch screen manufacturers.

The company has an injection molding business division, SMT business division, FPC business division, backlight business division, irrigation crystal business division, TFT module business division, SIN module business division, products involving touch screen, LCD display module, backlight, black and white screen, flexible circuit board.

Engaged in the laptop, tablet, smartphone, computer high-performance board card, LCD module, and other electronic products research and development, production, and sales of high-tech private enterprises.

Is a professional engaged in LCD display module, electronic components, production, design, research and development, sales as one of the high-tech enterprises. Products are widely used in mobile phones, game consoles, PDA, portable DVDs, video phones, intercom doorbells, car video, industrial control medical, and other fields.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Generally, LCDs are filled with a liquid crystal layer with a thickness of about 3~4um between the upper and lower transparent electrodes, and the electric field of the liquid crystal interlayer is controlled by the method of filling the pixel electrode voltage, and then the intensity of the transmitted light is adjusted to produce a full brightness. Gray level between and full darkness. At present, LCD is mainly composed of three parts: color filter (CF), TFT array (TFT Array) substrate and backlight module (Backlight) as shown in Figure 1 (a). Each Pixel of TFT-LCD has a set of TFTs to control its voltage value, and to make the light generated by the backlight module and transmitted through the LC have different colors, red, blue, and green (R/B/G) are needed. Three colors of color resist are formed on the CF glass, and the gray scales are used to produce a full-color effect; after the TFT array and the CF substrate are respectively completed, then the CF upper plate and the TFT lower plate are filled with LC and bonded together. Finally, attach the polarizer. This process is called the "LCD process"; and the final "LCM process" is the connection between the driver IC and the control circuit board (PCBA) and the glass substrate (JI Process). Assemble with the backlight module (MA Process), and finally the lighting detection of the module... and so on as shown in Figure 1 (b).

AU Optronics (hereinafter referred to as AU Optronics) has developed a process above the 8.5 generation factory to produce large-size LCD TV panels (see Figure 2). In December 2008, AUO successfully lighted the first 46-inch LCD TV panel produced in the G8.5 plant in China. The process technology once again led the whole Taiwan, marking a new page in the milestone of the new generation of TFT-LCD plant. Also established a new model of TFT-LCD green plant. The size of the G8.5 glass substrate is equivalent to the size of a pool table, but the thickness of the glass is less than 1mm. Therefore, the new-generation plant requires higher process technology; as the technology of large-size panels gradually matures, AUO will still Continue to focus on the development of new-generation plants, and continue to advance with the goal of increasing production capacity, improving process quality, and targeting customer service.

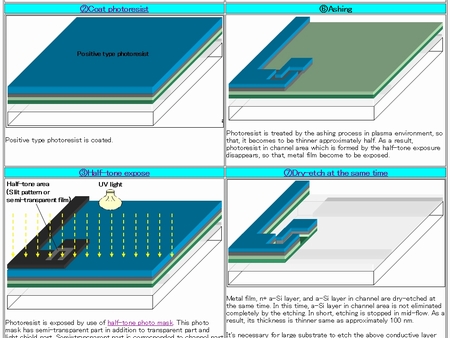

The development direction of next-generation process technology is nothing more than simplifying the process and selecting optimized raw materials and components to increase process yield and productivity, and reduce production costs. The capital investment of the front-end TFT Array and CF process equipment accounts for more than 60% of the total TFT-LCD expenditure. Therefore, the front-end process research and development first focuses on simplifying the process and improving the utilization of raw materials: for example, the four-pass mask technology that simplifies the mask process ( See Figure 3 (a)) and the pattern forming method without exposure and etching. In addition, the use of thinned glass substrates not only reduces the consumption of glass raw materials, but also has the advantages of lighter weight and thinner products; at the same time, it can achieve the goals of energy saving and waste reduction such as reducing packaging materials and improving transportation efficiency. As for LCM, with the rapid development of gate drive circuit substrate technology (Gate on Array, GOA) and HSD (Half source driving) technology in Figure 3 (b), it has not only simplified the material dependence of traditional panels on a large number of driver ICs. , Also contributes to the increase of LCM production capacity. In terms of module backlights, replacing traditional cold cathode tubes with light-emitting diodes (Light Emitting Diode, LED) not only avoids the harm of mercury (Hg) vapor in the tubes to the environment; the better luminous efficiency of LEDs also makes the products more efficient Energy saving.

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for Advantages Of Tft Display, Liquid Crystal Module, Round Lcd, Rugged Military Lcd Display,Stone Tft Display. Our products are new and old customers consistent recognition and trust. We welcome new and old customers to contact us for future business relations, common development. Let"s speeding in the dark! The product will supply to all over the world, such as Europe, America, Australia,Croatia, San Francisco,Berlin, Frankfurt.The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer"s trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

In ruling NY N320557 (August 4, 2021), Customs and Border Protection (CBP) discussed the country of origin of five Thin Film Transistor – Liquid Crystal Display (TFT-LCD) modules. All five modules are virtually identical in composition, as they are all composed of a TFT-LCD cell, polarizers, a backlight, a driver and control printed circuit board (PCB), and a flexible PCB for connection. TFT display technology allows for the construction of high-resolution LCD displays, and the modules – once completed – can be incorporated into a variety of consumers display applications.

The manufacturing process for the five modules is also identical. The process begins in Japan where the TFT-LCD cell is manufactured. The TFT is created by depositing transistors onto a substrate through chemical vapor deposition, while the color filter is manufactured by building a color matrix on a glass substrate. The creation process of the cells is then completed when a layer of liquid crystal is deposited between the color filter and TFT as the two part are bonded together, creating a sheet of TFT-LCD cells. As next steps, the sheet of cells is delivered to China to be cut into individual cells. The cut-up cells are then bonded to the printed circuit board assembly (PCBA) – which contains the driver and control circuity – before the polarizers, backlight, and flexible connection PCBA are attached.

CBP also established that “substantial transformation” takes place when a particular product “emerges from a process with a new name, character or use different from that possessed by the article prior to processing.” The agency explained that the completed TFT-LCD cell is what imparts the essential function of the module and that the manufacturing process in Japan is what renders the end-use of the product. Despite the assembly that took place in China, the process did not substantially transform the cell into a new and different article. As such, CBP determined that the country of origin of the five modules is Japan.

RE:Country of origin; Thin Film Transistor (TFT); Liquid Crystal Display (LCD); TFT/LCD module; PCB; flat panel display computer monitor; marking; outermost container; ultimate purchaser; substantial transformation; Hitachi; Japan; China; HRL 560427; 19 CFR 134.1(a); 134.32(d).

This is in reply to your letter, dated April 8, 2002. In that letter, you requested a ruling on the country of origin marking requirements for TFT- LCD modules assembled in China of Japanese components and imported into the United States to be used to make notebook computer monitors and flat panel desktop computer monitors. Our response follows.

Hitachi will produce finished thin film transistor (TFT)/liquid crystal display (LCD) modules that will be imported into the United States. The two products at issue are: 1) TFT/LCD modules for use with notebook computers; and 2) a Super IPS (In Plane Switching) TFT-LCD module to make flat panel desktop computer monitors.

The Back Light Unit is assembled in China. The process includes first adding a reflection sheet to a plastic mold case, the latter sometimes also made in China. Then, the Cold Fluorescent Lamp (CFL) unit, which is made by assembling bushing rubber, the CFL, CFL connector and CFL cable, is affixed to the reflection sheet with a doubled sided adhesive tape. A light guide is also attached to the CFL unit. Then, a diffuser sheet is attached to the top of the light guide. A lens film is then affixed on the diffuser sheet. Another lens film is attached and lastly, a diffuser sheet is placed on top of the lens film.

You state that although the Japanese-origin TFT-LCD Cell is the primary component, the Japanese components are substantially transformed in China when they are assembled into a TFT-LCD module in China. You contend that the components, which include the PCB, Back Light Unit (with CFL), tape, frame, cables, and the TFT-LCD Cell, when assembled result in a different commercial article, that is, a completed TFT-LCD module ready for use to manufacture notebook computer monitors or flat panel desktop computer monitors.

A representative of your company stated by telephone on April 24, 2002, that after importation of the finished TFT-LCD modules into the U.S., your company stores them in a warehouse as part of your company’s inventory. When a customer orders the modules, they are shipped to the customer. Your representative stated that because the imported articles are highly sensitive and fragile, your company does not normally repackage the imported articles. Your company’s customers then incorporate the TFT-LCD modules into a monitor when manufacturing their final computer product. In other words, the modules are not ready to be used as monitors when imported into the U.S. because they lack components such as the frame, power supply, driver, et cetera and must be further processed in the United States.

What are the country of origin marking requirements for finished TFT-LCD modules assembled in China from Japanese components and imported into the United States to be used for manufacturing notebook computer monitors and flat panel desktop computer monitors?

Section 134.35(a), Customs Regulations (19 C.F.R. § 134.35(a)), provides that the manufacturer or processor in the U.S. who converts or combines the imported article into a different article having a new name, character or use will be considered the ultimate purchaser of the imported article within the contemplation of 19 U.S.C. § 1304(a), and the article shall be excepted from marking. The outermost containers of the imported articles shall be marked in accord with this part.

Also, 19 C.F.R. § 134.1(d)(1) states that if an imported article will be used in manufacture, the manufacturer may be the “ultimate purchaser” if he subjects the imported article to a process which results in a substantial transformation of the article, even though the process may not result in a new or different article. See also 19 C.F.R. § 134.32(d), which provides for exceptions to marking of imported articles for which the marking of the containers will reasonably indicate the origin of the articles.

Based on the facts provided, it is our opinion that the assembly of various components used in producing the TFT/LCD module in China, including the Back Light Unit which is made in China from approximately 12 components, effects a substantial transformation of the individual components. The individual components, most of which are made in Japan, lose their identity and become integral part of the new article – TFT/LCD module. The assembly operations are also not minimal or simple. Thus, the TFT/LCD module as imported into the United States qualifies as a product of China and therefore should be marked as such.

In HRL 560427, the LCD module was made in Japan and imported into the U.S. The LCD module was then combined with nine other U.S. components to manufacture the final Flat Panel TFT/LCD monitor for personal computers. Customs ruled that the Japanese-origin LCD module was substantially transformed in the U.S. when incorporated into the monitor in the U.S. Similarly, in the instant case, the TFT/LCD module made in China will be incorporated in the United States into flat panel desktop computer monitors and notebook computer monitors manufactured by your customers.

In the instant case, unlike the case in 560247, the importer is not the manufacturer or the processor. However, subject to the terms of 19 C.F.R. § 134.35(a) and 19 C.F.R. § 134.1(d)(1), your company’s customers, who use the imported TFT/LCD modules to produce the flat panel desktop computer monitors and notebook computer monitors in the United States would be considered the ultimate purchasers. Therefore, as in HRL 560247, the imported article in the instant case qualifies for the marking exception provided in 19 C.F.R. § 134.35(a) and 19 C.F.R. § 134.32(d). Consequently, the country of origin marking requirements may be met in the instant case by having the imported articles’ containers (i.e. boxes or other containers that hold the modules) marked with the country of origin, assuming that those containers also reach your customers.

For the foregoing reasons and based on the facts provided, the TFT/LCD modules are products of China and therefore should be so marked. However, because the TFT/LCD modules will be used by your customers to manufacture flat panel desktop computer monitors and notebook computer monitors in the United States, your customers are the ultimate purchasers. Therefore, the marking requirements may be met by marking the containers of the imported articles with their country of origin, assuming that your customers receive the articles in those containers.

The present invention relates to a method of manufacturing a TFT array panel for a LCD. More particularly, the selective deposition and photo-resist lift-off techniques are used to implement the method of manufacturing a TFT-LCD array panel. By using the method for manufacturing a TFT-LCD array panel according to present invention, it can reduce and shorten the manufacturing process.

Liquid crystal displays have the advantages of small volume, light weight, low power consumption, low radiation, excellent image quality, broad applications, and are widely applied in the consumer electronic products or computer products, such as medium to small portable TVs, mobile phones, camcorders, notebook computers, desktop computers and projection TVs, etc. However, the mass cost causing from manufacturing LCDs is a key for the development in the LCD field. In order to overcome the cost problem, most companies and producers focus on the issue of reducing manufacturing cost. The biggest portion of the total cost in a LCD is on the manufacturing process of the TFT-LCD array panel. According to above description, the present invention is to provide a method for simplifying the TFT-LCD array panel manufacturing process. Further, it can achieve the cost reduction thereto shorten the manufacturing process.

According to the conventional method for manufacturing a TFT-LCD array panel, the layout of the panel circuit has to be implemented through at least four masking processes. However, the more masking processes, the more manufacturing costs. In other words, it means the more exposing lithography and etching processes need to be processed. The steps can cause serious effect on the reliability of the components. Therefore, the present invention is to provide a method for manufacturing a TFT-LCD array panel. More particularly, the method uses a selective deposition process to implement. The metal wire can be formed by using the selective deposition process. The process with circuit layout can alternate the conventional technique which of using more masking process to form the metal wire with multi-layer. It, therefore, can simplify and shorten the manufacturing process.

Besides, the metal deposition and photo-resist lift-off steps are further used in the consequent process of the transmission line. By using the present invention, it provides a method of manufacturing a TFT-LCD array panel. Further, it can avoid the damage risk in the operational channel while performing an etching process.

It is an object of the present invention to provide a method for manufacturing a TFT-LCD array panel. More particularly, a selective deposition method is used herein. It can reduce the numbers of masking processes thereto implement the growth of the low resistance metal wire.

It is another object of the present invention to provide a method of manufacturing a TFT-LCD array panel. More particularly, a lift-off technique is used in the method, and also applied in the manufacture of any metal conducting layer. The present invention can be illustrated as shown in the growth of the second metal wire. This can, therefore, reduce the cost of etching process. Furthermore, it can avoid the damage risk in the operational channel while performing etching process.

More, one of the main objects of the present invention is to provide the circuit of a TFT-LCD array panel. More particularly, the conducting metal layer is formed by using a low-resistance metal. It can improve the RC delay effect while happening in a big area panel.

The present invention is to provide a method for manufacturing a TFT-LCD array panel. Please referring to FIG. 1 a, it is one of the preferred embodiments of the present invention showing a metal conducting wiring layout. In the first masking process, a transparent conducting electrode material is formed on the substrate 10, and the gate electrode 21, a transparent conducting electrode 23, and a storage capacitor electrode 22 are defined. Then, the graph of the transparent conducting electrode and the layouts of the gate electrode and the storage capacitor electrode are independent. According to the character of connection between the gate electrode and the storage capacitor electrode, the selective deposition method is used to deposit a low-resistance metal or a multi-layer metal wiring layer with metal diffusion passivation. The deposited metal material herein is composed of the low resistance metal, such as Al, Cu, Ag, Mo, Cr, Ti, W, or other alloy materials. The selective deposition method uses the selective conducting current to deposit the low-resistance metal on the right position of the gate electrode, the storage capacitor electrode. Therefore, it does not require extra masking process to define the first metal wire. The transparent conducting electrode layer can be made of ITO or IZO.

Accordingly, please referring to FIG. 1 b, a dielectric layer, an A-Si layer and a poly-Si layer are deposited as shown in the figure. Further, a dielectric layer 30, and an A-Si layer 40 and a poly-Si layer 50 are deposited in order, and are covered on the substrate 10, the gate electrode 21, the storage capacitor electrode 22 and the transparent conducting layer 23. Then, performing the second masking process. Please referring to FIG. 1 c, it is one of the preferred embodiments according to the present invention showing the contact window in the masking process. Firstly, photo-resists 501, and 502 are used to shield the outside of the transparent conducting electrode 23. Then, the contact window 24 is defined in the masking process. Please referring to FIG. 1 d, it is one of the preferred embodiments according to the present invention showing the contact window formed in the etching process. Then, the photo-resists 501, 502 are removed. More, the deposition method forming an A-Si layer, a transparent conducting electrode, or a gate electrode can use PVD, low pressure CVD, or plasma enhanced CVD to implement.

Further, the source electrode and the drain electrode are defined. Please referring to FIG. 1 e, it is one of the preferred embodiments according to the present invention showing the source electrode and drain electrode. The photo-resists 511, 231 are used to define the source electrode and the drain electrode in the third masking process. Then, performing metal layer deposits with a low-resistance metal or a diffusion material, but not removes the photo-resists 511, 231. Please referring to FIG. 1 f, it is an example of the present invention showing the metal deposition process, herein said metal is Cu. Cu is deposited on the photo-resists 61, 62 and on the place 60 without photo-resist covering.

Further, it presents a photo-resist lift-off process. Please referring to FIG. 1 g, it is one of the preferred embodiments according to the present invention showing a photo-resist lift-off process for implementing the deposition of the second metal wiring. Then, it uses the poly-Si layer 50 with etching technique to block the channel of the source and drain electrodes thereto the operational channel 411. Please referring to FIG. 1 h, it is one of the preferred embodiments showing the operational channel according to the present invention. The second metal wire can be made of the low-resistance metal materials, such as Al, Cu, Ag, Mo, Cr, Ti, W, or the induced material such as diffusion, and adhesion with multi-layer structure of the metal material.

Finally, the fourth masking process is discussed herein. The passivation layer 70 of the deposition component can be made of SiO2or silicon nitride. Please referring to FIG. 1 i, the passivation layer is shown herein. In the final masking process, the liquid crystal contact window 24 is formed to implement the TFT-LCD array panel according to the present invention as shown in FIG. 1 j.

For further description, the present invention is to provide a method of manufacturing a TFT-LCD array panel. The method can be applied in the pixel electrode circuit of a TFT-LCD array panel. Please referring to FIG. 2, it presents the circuit layout of the pixel electrode. It comprises a transparent conducting electrode 23, a gate electrode 21, and a storage capacitor electrode 22. Also, they are formed on the substrate 10 in the first masking process. Then, using the selective sputtering method deposits the first metal wires 211, 221. Further, the contact window of the transparent conducting electrode is implemented in the in the second masking process. More, the depositions of the second metal wires 63 64, 65 are implemented in the third masking process. Finally, the deposition of the passivation layer 70 is implemented for forming a pixel electrode.

Furthermore, the present invention relates to a method of manufacturing a TFT-LCD array panel. The transparent conducting metal layer is defined in the first masking process. More, the low-resistance gate electrode, the metal wiring layout of the storage capacitor electrode is implemented by the selective deposition method.

Further, the present invention provides a method of manufacturing a TFT-LCD array panel, wherein the metal wire of the second layer is as a hard mask to process in the operational channel, and does not require extra masking process to implement.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and OLED display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

Technology trends in backplane technology are driving higher gas demand in display manufacturing. Specific gas requirements of process blocks are discussed, and various supply modes are reviewed.

Since its initial communalization in the 1990s, active matrix thin-film-transistor (TFT) displays have become an essential and indispensable part of modern living. They are much more than just televisions and smartphones; they are the primary communication and information portals for our day-to- day life: watches (wearables), appliances, advertising, signage, automobiles and more.

There are many similarities in the display TFT manufacturing and semiconductor device manufacturing such as the process steps (deposition, etch, cleaning, and doping), the type of gases used in these steps, and the fact that both display and semiconductor manufacturing both heavily use gases.

However, there are technology drivers and manufacturing challenges that differentiate the two. For semiconductor device manufacturing, there are technology limitations in making the device increasingly smaller. For display manufacturing, the challenge is primarily maintaining the uniformity of glass as consumers drive the demand for larger and thinner displays.

As the display mother glass area gets bigger and bigger,so does the equipment used in the display manufacturing process and the volume of gases required. In addition, the consumer’s desire for a better viewing experience such as more vivid color, higher resolution, and lower power consumption has also driven display manufacturers to develop and commercialize active matrix organic light emitting displays (AMOLED).

In general, there are two types of displays in the market today: active matrix liquid crystal display (AMLCD) and AMOLED. In its simplicity, the fundamental components required to make up the display are the same for AMLCD and AMOLED. There are four layers of a display device (FIGURE 1): a light source, switches that are the thin-film-transistor and where the gases are mainly used, a shutter to control the color selection, and the RGB (red, green, blue) color filter.

Technology trends TFT-LCD (thin-film-transistor liquid-crystal display) is the baseline technology. MO / White OLED (organic light emitting diode) is used for larger screens. LTPS / AMOLED is used for small / medium screens. The challenges for OLED are the effect of < 1 micron particles on yield, much higher cost compared to a-Si due to increased mask steps, and moisture impact to yield for the OLED step.

The challenge to MO is the oxidation after IGZO metalization / moisture prevention after OLED step, which decreases yield. A large volume of N2O (nitrous oxide) is required for manufacturing, which means a shift in the traditional supply mode might need to be considered.

Although AMLCD displays are still dominant in the market today, AMOLED displays are growing quickly. Currently about 25% of smartphones are made with AMOLED displays and this is expected to grow to ~40% by 2021. OLED televisions are also growing rapidly, enjoying double digit growth rate year over year. Based on IHS data, the revenue for display panels with AMOLED technol- ogies is expected to have a CAGR of 18.9% in the next five years while the AMLCD display revenue will have a -2.8% CAGR for the same period with the total display panel revenue CAGR of 2.5%. With the rapid growth of AMOLED display panels, the panel makers have accel- erated their investment in the equipment to produce AMOLED panels.

There are three types of thin-film-transistor devices for display: amorphous silicon (a-Si), low temperature polysilicon (LTPS), and metal oxide (MO), also known as transparent amorphous oxide semiconductor (TAOS). AMLCD panels typically use a-Si for lower-resolution displays and TVs while high-resolution displays use LTPS transistors, but this use is mainly limited to small and medium displays due to its higher costs and scalability limitations. AMOLED panels use LTPS and MO transistors where MO devices are typically used for TV and large displays (FIGURE 3).

This shift in technology also requires a change in the gases used in production of AMOLED panels as compared with the AMLCD panels. As shown in FIGURE 4, display manufacturing today uses a wide variety of gases.

These gases can be categorized into two types: Electronic Specialty gases (ESGs) and Electronic Bulk gases (EBGs) (FIGURE 5). Electronic Specialty gases such as silane, nitrogen trifluoride, fluorine (on-site generation), sulfur hexafluoride, ammonia, and phosphine mixtures make up 52% of the gases used in the manufacture of the displays while the Electronic Bulk gases–nitrogen, hydrogen, helium, oxygen, carbon dioxide, and argon – make up the remaining 48% of the gases used in the display manufacturing.

The key ga susage driver in the manufacturing of displays is PECVD (plasma-enhanced chemical vapor deposition), which accounts for 75% of the ESG spending, while dry etch is driving helium usage. LTPS and MO transistor production is driving nitrous oxide usage. The ESG usage for MO transistor production differs from what is shown in FIGURE 4: nitrous oxide makes up 63% of gas spend, nitrogen trifluoride 26%, silane 7%, and sulfur hexafluoride and ammonia together around 4%. Laser gases are used not only for lithography, but also for excimer laser annealing application in LTPS.

Silane: SiH4 is one of the most critical molecules in display manufacturing. It is used in conjunction with ammonia (NH3) to create the silicon nitride layer for a-Si transistor, with nitrogen (N2) to form the pre excimer laser anneal a-Si for the LTPS transistor, or with nitrous oxide (N2O) to form the silicon oxide layer of MO transistor.

Helium: H2 is used for cooling the glass during and after processing. Manufacturers are looking at ways to decrease the usage of helium because of cost and availability issues due it being a non-renewable gas.

The consumer demand for displays that offer increas- ingly vivid color, higher resolution, and lower power consumption will challenge display makers to step up the technologies they employ and to develop newer displays such as flexible and transparent displays. The transistors to support these new displays will either be LTPS and / or MO, which means the gases currently being used in these processes will continue to grow. Considering the current a-Si display production, the gas consumption per area of the glass will increase by 25% for LTPS and ~ 50% for MO productions.

To facilitate these increasing demands, display manufacturers must partner with gas suppliers to identify which can meet their technology needs, globally source electronic materials to provide customers with stable and cost- effective gas solutions, develop local sources of electronic materials, improve productivity, reduce carbon footprint, and increase energy efficiency through on-site gas plants. This is particularly true for the burgeoning China display manufacturing market, which will benefit from investing in on-site bulk gas plants and collaboration with global materials suppliers with local production facilities for high-purity gas and chemical manufacturing.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey