lcd display leak supplier

Stockwell Elastomerics is a leading provider of gaskets for touch screens, displays and integrated touch panel assemblies that serve several functions: sealing, load distributing, gap filling, mechanical shock protection and over-press cushioning.

Often a touch screen gasket or display gasket will help spread the compression load of the housing or bezel on the display. Without a gasket, the enclosure that holds the display in place can create pressure points on the display. In some cases, these pressures can cause distortions, false contacts or short circuits.

Similar to load distributing, touch panel gaskets are used to fill gaps between the screen and the display and/or the screen and bezel. The display gasket will take up gaps generated by tolerance stack-ups in the device.

Display gaskets offer some degree of cushioning to protect the display from damage due to mechanical shock. In the event that a device is dropped or banged, the gasket will act as a touchscreen cushion, offering a limited amount of protection.

Touchscreen gaskets also serve as display cushions when a user presses on the display too hard. The gasket deflects, takes up and spreads the load offering some protection from over-press or overloading in a small area.

LCD dust seals and touch screen dust seals are the most basic requirement of display gasketing. These are often static (not portable), indoor applications where the device is not to be exposed to water. Sealing can be achieved by closed cell sponge materials or fine pore open cell materials such as PORON urethane foam.

Outdoor displays such as outdoor information kiosks, ATMs and remote monitoring equipment require more design consideration. To contend with environments such as direct or wind-driven rain, sealing an enclosure, case or housing from ingress requires the proper material as well as proper compression on the gasket. Silicone foam or silicone sponge materials are preferred. Silicone gaskets remain flexible at low temperatures allowing for continued sealing against melting ice and snow as well as protecting against mechanical shock where many other materials will firm up in the cold and transfer energy. Other key features are: closed cell structure, low-stress relaxation, UV and ozone resistance, and general long life.

Light leaking is sometimes a concern with certain LCD or LED display applications. This can be addressed with black gasketing with either a very thin adhesive or a black supported adhesive. A common material configuration for this is soft PORON urethane foam with 3M 9795B adhesive. The 3M 9795B is a film supported double coat adhesive with a black PET support layer that does not pipe light.

Touchscreen gaskets and display gaskets tend to have narrow walls that don’t always lend themselves to easy installation. This can be addressed in a few ways such as fixturing or utilizing the centers as temporary supports. The preferred adhesives for touchscreen gaskets and display gaskets are repositionable adhesives such as Adchem 8311M or 3M 9415 depending on the bond strength required. Stockwell Elastomerics also offers medium and high bond strength adhesives for permanent bonding. View the current listing of pressure sensitive adhesive options.

Broad recommendations such as “closed cell foam” do not take into consideration factors such as stress relaxation, compression set, long term sealing performance, outgassing, plasticizer interaction, cost, and manufacturability. Over-designing the gasket can drive the cost up, whereas under designing could result in damaged devices and leaks when the units are in the field. Stockwell Elastomerics can offer guidance on design and manufacturability of touchscreen gaskets or touch panel gaskets. Key design points include:

It is important to keep in mind the clamping loads. While wider gasket walls generally seal better, the overall surface area is directly related to the loads applied to the LCD and touchscreen. Compression Force Deflection curves of various materials are available to aid designers.

The gasket thickness will depend on the designed gap in the enclosure, the fastening scheme, rigidity of the housing and the level of sealing required. Many touch screen gaskets are thin and soft but as the display gets larger the tolerance stacks typically get larger as well. This may require a thicker gasket depending on the fastener locations.

Some OEMs and contract manufacturers prefer to have the center of the gasket remain in place, held in place with small, breakaway tabs. Leaving the centers intact allows for easier positioning on the display when a fixture is not being used. Low tack, clean peeling adhesive is needed.

LCD screen display with two polarized materials, between them is a crystal crystal solution. In the use of many users will encounter liquid crystal screen leakage problems, most users are no clue to this, do not know how to do Today, Xiao Bian gave you popular LCD screen leakage of the repair problem, the way to teach you how to maintain the LCD screen.

Seal damage: the main will appear in the screen of the four edge position, if the beverage, fruit juice, soft drinks, tea and other acid-base liquid accidentally from the outside into the screen edge of the soak, it will cause damage to the sealant, inside the LCD Leakage. Screen in the production process if the sealant problems, the same will appear such a failure.

Screen surface by external damage: generally concentrated in the middle of the screen position, can see the obvious signs of glass cracks, then hand pressure leakage parts, you can see the movement of liquid crystal trajectory along the direction of movement.

Physical phenomena: Notebook or liquid crystal display surface has a very obvious block of dark spots (in the case of power), or there are light and dark uneven patches (in the case of no power) at the same time there are cracks. Individual LCD screen due to external force is not too large, although the liquid crystal screen caused by leakage, but the surface does not produce cracks, the fault is not easy to find, especially in the case of liquid crystal display power is not bright to pay attention. After the liquid crystal display breaks the leak, the image can still be displayed. At the same time after the liquid crystal screen leakage test machine will not produce a new fault, we do not have to worry.

Causes and repair: liquid crystal display by external force extrusion or impact, resulting in liquid crystal screen rupture and leakage phenomenon. Solution and maintenance costs: This type of failure is a very clear man-made physical damage, because the display accidentally squeeze or child with a finger press, it may be caused by the impact of the transport process. LCD screen damage to the higher maintenance costs for the LCD screen if the LCD screen is generally not damaged, because the cost of replacing the LCD screen is close to the cost of a model with the same type of liquid crystal display.

The highest possible sensitivity.If you want to find leaks faster for your customers, try the Fieldpiece DR82 Infrared Refrigerant Leak Detector. Our newest detector can sniff out leaks at <0.03 oz/yr. That’s 20 times more sensitive than soap bubbles. This exceeds detection standards so you can quickly find and pinpoint leaks. DR82 triggers on all HFC, CFC, HCFC, HFO and blends.

There are very obvious massive black spots on the surface of the long bar LCD screen, or there are uneven patches of light and dark and cracks at the same time. The liquid crystal display is squeezed or impacted by the external force, resulting in the liquid leakage phenomenon caused by the rupture of the liquid crystal screen. The external force is not too large, although the liquid crystal screen leakage, but there is no crack on the surface, this fault phenomenon is not easy to find, especially in the case of LCD power is not bright. After the liquid crystal display ruptures the leak, the image can still be displayed.

Strip liquid crystal screen leakage is physically damaged, and the liquid crystal screen is cut and manufactured as a whole, once the leakage will slowly expand, or even can not display normally, which is irreparable unless the entire screen is replaced. But in terms of the cost of making liquid crystal displays, the screen accounts for 2/3, so it"s not cost-effective to replace the screen, so it"s better to buy a new monitor.

The control and drive circuit in the bar display module is a low-voltage, micro-power CMOS circuit, which is easy to be breakdown by static electricity. Electrostatic breakdown is a kind of irreparable damage, which must be paid attention to and should not be careless. Therefore, the display screen in the operation, assembly and use should be careful, to strictly prevent static electricity.

It is best to add a gasket of about 0.1 mm between the bar display module and the front panel, and the panel should also be flat to avoid distortion after assembly.

A maintenance film is affixed to the surface of the installed bar display screen to prevent defilement of the appearance during assembly, so it should not be removed before the whole machine is assembled, so as not to stain or damage the appearance surface.

The above is how to maintain the whole content of the bar LCD screens, I hope that we can learn the method of maintenance, so as to prolong the life of the LCD screens. If you want to purchase bar lcd screens, please contact us by email to

-To be clear, the researchers didn’t observe any adverse health effects from the accumulation of liquid crystals in the human body; they only found that these crystals do in fact leak from devices, and that they have the potential to be toxic. “We don’t know yet whether this a problem, but we do know that people are being exposed, and these chemicals have the potential to cause adverse effects,” said Giesy.

-If you crack LCD screens and find the liquid crystal leakage, don’t panic. Just remember that the liquid crystal materials might not be more toxic than your detergents for stove or washroom. Just wash your hands with soup throughout. Never try to play with it or even worse to taste it. The liquid of the cracked computer screen will not evaporate, no emissions worries.

-Any electronics has environment impact and can’t be used landfills. If you want to get rid of old LCD monitors or LCD TVs, give them to electronic collection stations. Let’s the professionals to handle them. They will extract some precious metals/parts and make them into something useful or at least not hazard. FYI, liquid crystal materials are retrievable.

I used to work for a laptop manufacturer doing support, and we were instructed that in the event that a customer ever called reporting a leaking LCD we were to IMMEDIATELY tell them to hang up the phone, call emergency services, and get a hazmat team onsite, while we escalated the call to our internal dedicated safety response team. That seems like a pretty harsh response (it"s more severe than what I would have been expected to do for anything short of "My laptop set my house on fire") so I"m inclined to think this stuff isn"t especially safe. It may be true that it"s only a hazard if ingested, though; based on my semi-limited knowledge of the chemistry involved that seems possible. If it were me, though, I"d take the extra cautious route just in case.

(In practice, this basically never happens short of a severe puncture like a blade would cause because of the way these things are manufactured. I"ve actually never personally heard of a situation where an LCD was leaking short of taking a bullet.) EDIT: Let me just make this stronger. This hardly ever happens, ever, anywhere, ever - it"s designed to prevent exactly this sort of problem. Unless you actually witness it in action there is probably no reason to worry about it. See further discussion in comments.

Distributor of LED displays including liquid crystal (LCD) displays and electronic system displays. Available in different types and specifications. Capabilities include inventory management, supply chain management, in-plant warehousing, automated inventory replenishment, barcoding and labeling. LED displays can be used in defense, aerospace, industrial, commercial, healthcare, medical, computer and test equipment industry applications. Lamps and lighting devices are also available. Services include design engineering, quick-turn prototyping, contract and custom manufacturing, box build, in-circuit and functional testing and assembly services. KANBAN and JIT delivery services are available.

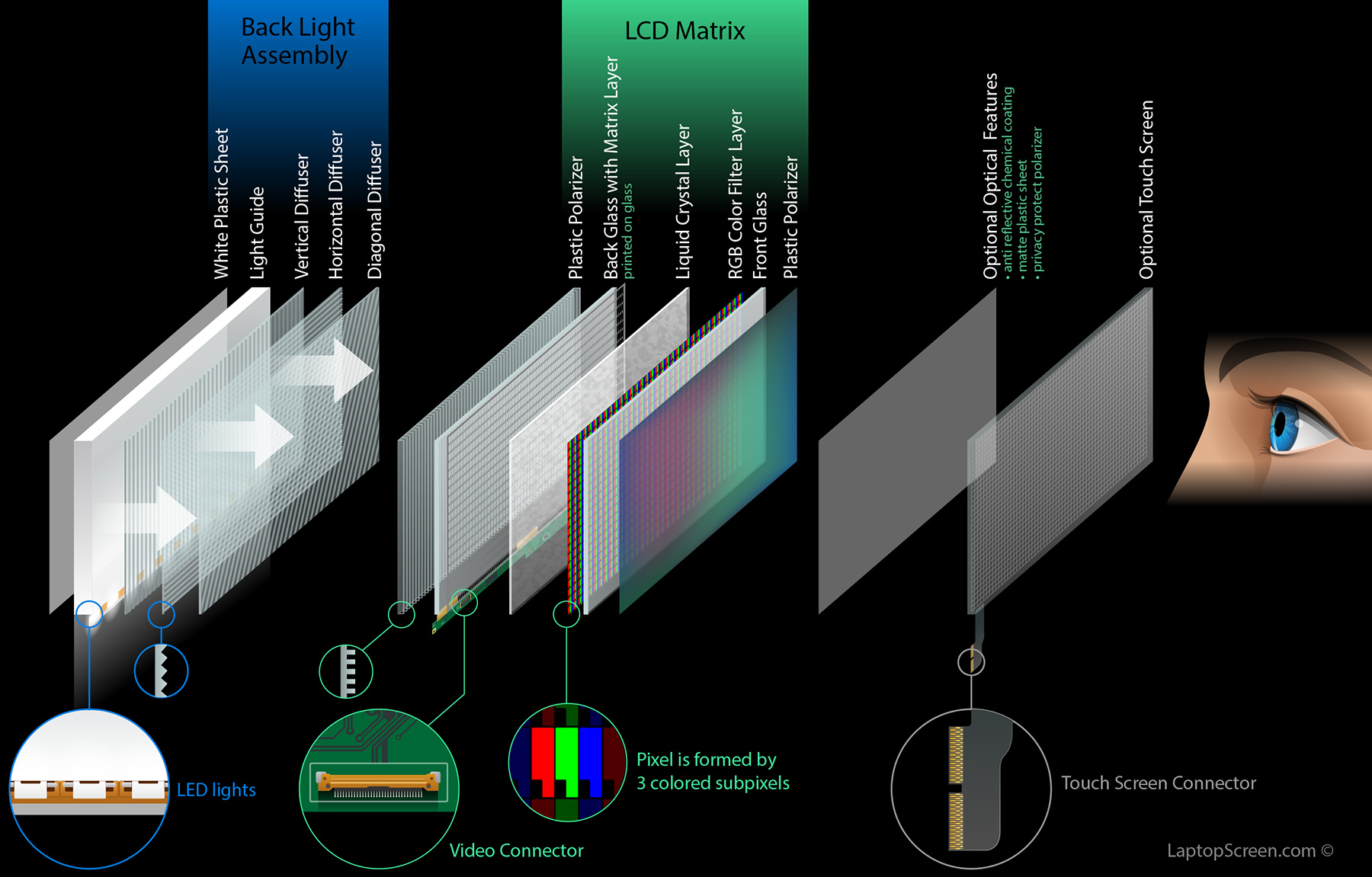

But can one go even further and fix a cracked LCD panel? In a word – no. LCD screen consists of a back-light assembly, LCD matrix and may include additional layers in front to add a glossy effect or to diffuse reflections and can also include a touchscreen layer overtop.

Most modern LCD panels should not “leak” anything, since although liquid crystals are a liquid, they don’t necessarily “flow out” of the monitor and leak everywhere. Very rarely will you see actual liquid come out of a broken LCD screen (it is very viscous). A common chemical to use in LCD screens is MBBA.

The first situation is light leaking from the four corners of the LCD screen, just like in the picture shown above. This kind of issue is caused by an assembly error. The Polaroid film positioned between the touch screen and LCD screen wasn’t placed correctly. However, it can’t be corrected by hand.

LCD display screens make use of Liquid Crystal Display technology. The screen is embedded with liquid crystals, a substance that has properties in between a conventional liquid and a solid crystal. Liquid crystals can flow, but their molecules carry a crystal-like solid orientation.

There are no ways to completely remove this, though it can be reduced in some scenarios. If you have too much backlight bleed, you might be able to RMA your display. Your LED LCD, whether it’s a TV or a monitor, uses a LED backlight to create the image through the liquid crystal display panel.

Liquid crystal monomers widely used in flat-screen TVs, smartphones and computer screens, are highly toxic and deadly. Toxic chemicals that leak from LCDs (Liquid Crystal Displays) are more likely to be spotted in household dust.

Black spots on LCD screens are a result of dirt, or dead or stuck pixels. Black spots on an LCD television can interfere with picture quality and viewing experience, especially if located in the center. In the best case scenario, black spots are caused by dirt, dust, or debris that has collected on the screen surface.

LCD TV repair typically costs $60 to $85 for diagnostics testing, and $200 to $300 to perform repairs. LCD TVs use backlighting, which may fail. Newer LCD TVs use LED strips for backlighting. Older ones might use CCFL.

People typically decide to buy a new device when this happens. Fortunately, with an LCD repair, you can fix the device without needing to replace it.Jan 30, 2018

If you drop your phone and the screen is cracked or shattered, but the display is still lit up, you have probably only damaged the front screen. However, if you see lines, black spots or discolored areas, or the screen won’t light up, your LCD screen is most likely damaged and will need to be repaired.

So: Touchscreen (AKA digitizer) is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device. LCD screen is the panel that is inside the device, which displays the image.

The picture quality of an LED display is far better than an LCD. Due to modular light-emitting diodes, an LED screen produces better control over the contrast, rendering a clear picture. Also, LED provides RGB contrast, which can show truer blacks and truer whites.

When comparing LCD vs LED on the parameter of brightness, an LED TV stands out as a winner. This is because it appoints an individual dimming and backlighting system, which in comparison to LCD, makes your projections more defined, authentic, and closer to reality.

LCD screens also tend to offer better viewing angles and a wider field of view. LED monitors, on the other hand, can be the better option with general eye fatigue related to prolonged use and blue light, as they tend to offer a more robust dimming system.

HUATEC HD-107 Geomembrane leak detection equipment, at the scene of the absorption adopt a generation of user feedback, on the basis of the integration of various conditions around the application experience, further optimization, by testing the large, improve the core component of pressure, make the output voltage of up to 50 kv, according to check the thickness of the geomembrane, conductivity, and soil dry and wet sensitivity can fit match, with better easily detect funnelled position, and continue to alarm prompt.This system equipment still has good portability and operability. After the upgrade, the output is more linear and the detection of leakage point is more efficient. In view of the large battery capacity doubling to 4400AMH, it is more suitable for long-term continuous construction in the field.

The HD-107 equipment is suitable for floor waterproofing, pond waterproofing, pit leakage, river dam waterproofing and other construction waterproofing detection.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey