lcd display leak quotation

Just recently I"ve noticed a very sticky liquid leaking out of one corner of the screen. There are now bright and dark patches on the screen near where it"s leaking. As well as round the screen the sticky stuff gets onto the base of the laptop where I rest my hands to type. lt"s really hard to clean off and I"m worried it may be toxic.

There has been no physical damage to the laptop at all - it just started leaking. Is this a common fault or is it a sign of a defect in the design and manufacture?

You probably have a leak or fracture in the liquid crystal layer of your monitor causing it to loose fine control of the light blocking ability of the liquid crystals.

Your display has many layers. One of those layers is a liquid crystal layer that can be controlled in order to block or allow light to pass through to the actual coloured pixel layer. If you can see some kind of image then the light emitting layer is okay as is the actual pixel colours. As you have some image it is quite likely that there is some crystals moving to allow a tiny amount of light through, but not enough to make a reliable image.

The MIB2 unit has been having issues like ghost touches and non-responsiveness for a few months now. Since it was liveable I did not bother to get it checked before. But now, I can see visible signs of the LCD screen showing leakage. I have no plans to buy a new unit as it is very expensive at 45 or 50k as quoted by VW ASC. The other option is to just replace the LCD screen and possibly the associated board but I have no idea where to source this from.

The unit on my car is made by Technisat and I have attached an image which shows the leakage on the left top corner and the weird pattern at the bottom of the screen. I have also spent additional money on getting the unit equipped with Android Auto and Apple CarPlay, hence, the added hesitation in replacing this unit.

Here"s what BHPian RajaTaurus had to say about the matter:Here is me, 40k and 5 years Jetta TSI CL. I am the one whose screen is paralysed 1 inch on left, right and top. And as you said, LCD is leaking (!) through the gap in the bottom. Also Technisat Poland unit. My VW service people gave up on it. No repair and no replacement. I am living with it. As I haven"t done any upgrade to it, I don"t plan to do anything with it. Functionally all works fine. Importantly park pilot is ok. Right knob has some menu functions that helps.

The good news: a broken screen doesn’t mean your phone is kaput. In fact, if only the glass is broken, the fix is quick and inexpensive. The bad news: if the LCD screen is broken, you’re looking at a pricier repair.

If you’ve looked into replacement parts, you’ve likely come across two very different options: a glass screen, and an LCD screen. While the first option is cheap, the second is definitely not. Here’s the difference:

1. The glass screen is the exterior layer on your phone’s display. While it is specially engineered for durability, it’s still just glass (between layers of plastic film), which is why it’s not very pricey to replace.

If you encounter any of these problems, you’re dealing with a broken LCD screen. If the glass is shattered, but the display is clear and touch capability is working, that’s a good sign. The problem is probably just the glass screen.

Whether you’re dealing with cracked glass or a broken LCD screen, you can find a quick, reliable repair service at FastPhoneRepair.com. Our qualified technicians will get your iPhone repaired and up and running again in record time and at reasonable rates.

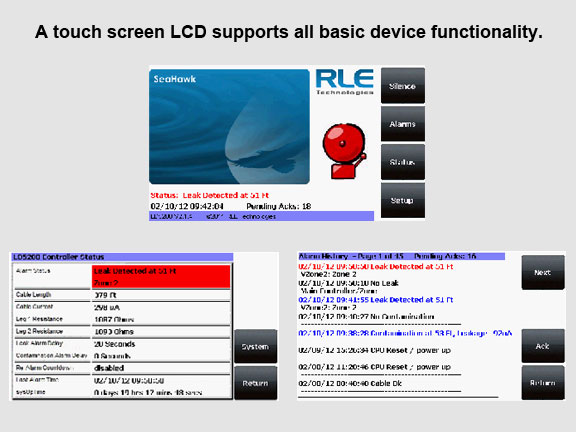

Protecting a facility from damaging leaks is an important part of any disaster mitigation plan. The LD5200 pairs superior leak detection technology with an easy-to-use interface. This integration helps users quickly and efficiently establish a distance-read leak detection system that monitors up to 10,000 feet of sensing cable and reliably protects valuable assets.

The LD5200 was designed with the end user in mind. All basic device functionality is available from the LCD touch screen – configure, monitor, locate, and acknowledge leaks from the front panel of the LD5200. The LD5200 can be used as a stand-alone device without sacrificing any leak detection or alarm notification functionality.

Once the LD5200 is connected to a network, a robust web interface expands the capabilities of the unit. Use the web interface’s interactive facility mapping tool to create an interactive overlay that displays on top of an uploaded floor map image. When a leak is detected, the LD5200 displays its location on the map, making leak location quick and easy.

While the LD5200 can function as a stand-alone device, it also has powerful integration capabilities. Multiple communications ports allow the LD5200 to act as an aggregate device for a wide variety of related secondary devices. The highly scalable LD5200 can provide leak detection and notification for an entire building through one IP address. It can also seamlessly integrate into a BMS or NMS. The LD5200 is ideal for applications that require a stand-alone system that can also be integrated into a larger centralized monitoring system.

TPI 721 Combustible Gas Leak Detector with Bargraph LCD DisplayWarning: To reduce the risk of ignition of a flammable atmosphere, batteries must only be changed in an area known to be nonflammable.

The Combustible GAS detector is a leak locating tool and is not intended for use as a confined-space, personal safety tool. It will not specifically identify a gas or a CFC, and it does not tell you the precise level of a combustible gas or CFC that may be present.High concentrations of combustible gas/CFC can cause explosions, fires, asphyxia, and other hazards that could cause serious personal injury or death. Be informed on the characteristics and hazards of the gas/CFC you are working with, and use proper precautions to avoid hazardous atmospheres.

OverviewThe TPI 721 offers 10ppm sensitivity to detect combustible gasses. Easily operated with one hand, leaks are pinpointed using the audio and visual indicators. An adjustable "tic" rate helps eliminate background gas concentration in contaminated environments.

The Combustible GAS detector is a leak locating tool and is not intended for use as a confined-space, personal safety tool. It will not specifically identify a gas or a CFC, and it does not tell you the precise level of a combustible gas or CFC that may be present.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure, and is therefore not covered under the standard warranty of the LCD-Monitor. Such damage is most often the result of a drop or an impact to the LCD screen or any other part of the product which may render the device.

Non-functional :Such type of damage are only covered under an Accidental Damage service offering which is in addition to the basic warranty of the computer. Accidental Damage is not to be confused with an occasional no display or stuck pixel.

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

If you find somewhere in the system with oil traces, probably that is the leakage point. This inspection method can’t position precisely because the leakage point is usually very tiny and many parts of the refrigeration system are barely visible. Unless it’s a big leakage point due to sudden break and the leaking liquid is colored.

Fill the cooling system with 10-20kg / cM2 pressure nitrogen, and then smear various parts of the system with soapy water. The Bubbling is the leakage point. This is the most common approach for repair workers. But due to human’s limited arms and visual acuity, you cannot very easily find the leakage points.

Fill the system with 10-20kg / cm2 pressure nitrogen, and soap it in the water. The bubbling is the point of leakage. One obvious drawback of this method is that the water for leak detection can easily enter the system. This will lead to corrosion of the materials in the system. At the same time, the high-pressure gas may cause more damage to the system. And the labor intensity during the leak detection is also great.

It applies the principle that fluorescent leak detector will emit a bright yellow-green under the UV / blue light leak detector. It could be used as detection for fluid leakage in various types of systems. What you need to do is just to add the fluorescent agent to the system according to a certain proportion. And after the system operates for 20 minutes, wear special glasses and shine the outside of the system with the leakage light detector. The leakage points will be yellow fluorescent.

By using the pressure difference between interior and exterior of the system, the sensor will enlarge this difference and express the test results in methods like digital, voice or electronic signal. This test way is also only “qualitative” to know whether the system leaks and cannot accurately find the leakage points.

By holding lighted-up halogen lamp close to the system, the flame color will turn into purple-blue when there is a leak. This method is dangerous not only with the flame but also the combination of flame and refrigerant will produce harmful gases, in addition, it is not easy to accurately locate the leak. So this method is almost out of use now.

This method has rapidly occupied the market thanks to its reliable and accurate functioning. By moving the probe against the possible leakage places, the device will give an alert when there is a leakage. The electronic leak detector is the most simple, quick and scientific leak detection method.

Stockwell Elastomerics is a leading provider of gaskets for touch screens, displays and integrated touch panel assemblies that serve several functions: sealing, load distributing, gap filling, mechanical shock protection and over-press cushioning.

Often a touch screen gasket or display gasket will help spread the compression load of the housing or bezel on the display. Without a gasket, the enclosure that holds the display in place can create pressure points on the display. In some cases, these pressures can cause distortions, false contacts or short circuits.

Similar to load distributing, touch panel gaskets are used to fill gaps between the screen and the display and/or the screen and bezel. The display gasket will take up gaps generated by tolerance stack-ups in the device.

Display gaskets offer some degree of cushioning to protect the display from damage due to mechanical shock. In the event that a device is dropped or banged, the gasket will act as a touchscreen cushion, offering a limited amount of protection.

Touchscreen gaskets also serve as display cushions when a user presses on the display too hard. The gasket deflects, takes up and spreads the load offering some protection from over-press or overloading in a small area.

LCD dust seals and touch screen dust seals are the most basic requirement of display gasketing. These are often static (not portable), indoor applications where the device is not to be exposed to water. Sealing can be achieved by closed cell sponge materials or fine pore open cell materials such as PORON urethane foam.

Outdoor displays such as outdoor information kiosks, ATMs and remote monitoring equipment require more design consideration. To contend with environments such as direct or wind-driven rain, sealing an enclosure, case or housing from ingress requires the proper material as well as proper compression on the gasket. Silicone foam or silicone sponge materials are preferred. Silicone gaskets remain flexible at low temperatures allowing for continued sealing against melting ice and snow as well as protecting against mechanical shock where many other materials will firm up in the cold and transfer energy. Other key features are: closed cell structure, low-stress relaxation, UV and ozone resistance, and general long life.

Light leaking is sometimes a concern with certain LCD or LED display applications. This can be addressed with black gasketing with either a very thin adhesive or a black supported adhesive. A common material configuration for this is soft PORON urethane foam with 3M 9795B adhesive. The 3M 9795B is a film supported double coat adhesive with a black PET support layer that does not pipe light.

Touchscreen gaskets and display gaskets tend to have narrow walls that don’t always lend themselves to easy installation. This can be addressed in a few ways such as fixturing or utilizing the centers as temporary supports. The preferred adhesives for touchscreen gaskets and display gaskets are repositionable adhesives such as Adchem 8311M or 3M 9415 depending on the bond strength required. Stockwell Elastomerics also offers medium and high bond strength adhesives for permanent bonding. View the current listing of pressure sensitive adhesive options.

Broad recommendations such as “closed cell foam” do not take into consideration factors such as stress relaxation, compression set, long term sealing performance, outgassing, plasticizer interaction, cost, and manufacturability. Over-designing the gasket can drive the cost up, whereas under designing could result in damaged devices and leaks when the units are in the field. Stockwell Elastomerics can offer guidance on design and manufacturability of touchscreen gaskets or touch panel gaskets. Key design points include:

It is important to keep in mind the clamping loads. While wider gasket walls generally seal better, the overall surface area is directly related to the loads applied to the LCD and touchscreen. Compression Force Deflection curves of various materials are available to aid designers.

The gasket thickness will depend on the designed gap in the enclosure, the fastening scheme, rigidity of the housing and the level of sealing required. Many touch screen gaskets are thin and soft but as the display gets larger the tolerance stacks typically get larger as well. This may require a thicker gasket depending on the fastener locations.

Some OEMs and contract manufacturers prefer to have the center of the gasket remain in place, held in place with small, breakaway tabs. Leaving the centers intact allows for easier positioning on the display when a fixture is not being used. Low tack, clean peeling adhesive is needed.

The 55800 leak detector employs a new metal oxide gas sensor for the detection of chlorofluorocarbon gasses and blends. This tin oxide sensor is characterized by high sensitivity and a fast response, upon detecting the presence of extremely small levels of chlorofluorocarbon gases.

“Super Sensitive Function”allows the unit further sensitizing beyond the standard settings for locating small leaks with gases such as R1234yf and R407C

INT: This indication appears whenever the microprocessor detects conditions that are not suitable for reliable leak detection. Excessive wind blowing, blocked probe (no airflow), burned-out fan, or a missing or defective sensor that needs to be replaced

Verify or calibrate a Sentinel instrument’s pressure display with this easy-to-use portable digital vacuum/pressure gauge. With the appropriate fitting, the gauge easily connects to the test port of Sentinel instruments. Featuring a standard 4-1/2 digit LCD display with 1/2" character size, you can view results in one of nine selectable engineering units. This gauge has an accuracy of 0.13% full scale.

We offer our combination vacuum/pressure leak test gauges in two ranges: vacuum to 60 PSIG, and vacuum to 300 PSIG. All models include a padded carrying case, an adapter fitting for easy attachment to the test line, and an NIST*-traceable calibration certificate.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey